Fuzzy Optimization Modeling Approach for QFD-Based New Product Design

Abstract

Quality function deployment (QFD) is a planning and problem-solving tool for translating customer requirements (CRs) into the engineering characteristics (ECs) of a product. Owing to the typical vagueness of functional relationships in a new product, product planning is becoming more difficult under uncertainties. To tackle the vagueness or imprecision in QFD, numerous scholars have applied the fuzzy set theory to QFD and proposed various fuzzy QFD models. In this study, a fuzzy linear programming model is developed to determine the optimal level of ECs, where the objective function is the overall customer satisfaction and the cost constraint is fuzzified. Finally, we use a software product design as a numerical example, which demonstrates that the proposed methodology can help the QFD team realize the overall customer satisfaction of new products catching up with or exceeding the competitors in the target market.

1. Introduction

Being able to perform new product development in a short lead time and at a low cost is the key to improve competitiveness for enterprises in the global market. To successfully fulfill it, the key is to apply customer-driven design and manufacturing approach in enterprises. Customer requirements (CRs) play a vital role in the design of products and services. Originated in Japan in the late 1960s [1], quality function deployment (QFD) is a planning and problem-solving tool for translating CRs into the engineering characteristics (ECs) of a new product. QFD is a structured approach to defining customer requirements and translating them into specific plans to develop products or services to meet those CRs. QFD has been widely known to be one of the most useful tools in customer-driven products or services development [1–4]. As far as product planning and development decisions are concerned extensively, the application of QFD has been applied in many areas [1–3]. QFD can help the design team systematically determine ECs for developing a new product with maximum customer satisfaction. The core concept of QFD is to translate CRs to ECs and subsequently into part characteristics, process parameters, and production requirements. Accordingly, the QFD process includes four sets of matrices called houses of quality (HOQ) to relate CRs to product planning, parts deployment, process planning, and manufacturing operations [1].

The determination of the ECs’ target levels has attracted increasingly more and more researchers’ attention recently. The process of setting the target levels of ECs is accomplished in a subjective adc manner or in a heuristic way. Due to many tradeoffs that may exist among implicit or plicit relationships between CRs and ECs and among ECs, these relationships cannot be identified using engineering knowledge. Moreover, such relationships are generally vague in practice [5]. To solve a search engine quality improvement problem, Sener and Karsak [5] put forward a fuzzy regression model to identify the functional relationships between CRs and ECs and among ECs and developed a mathematical programming model to determine target levels of ECs using the functional relationships obtained by fuzzy regression. However, their method has not considered the cost may be fuzzy.

Due to cost and other resource constraints, tradeoffs among ECs are always needed. Many optimization methods have been applied into the QFD process to maximize customer satisfaction. In practical problem, optimal results are sometimes difficult to achieve by using existing optimization methods. In this study, to determine the optimal level of ECs, a fuzzy linear programming model is developed, where the objective function is the overall customer satisfaction and cost constraint is fuzzified. Results indicate that the proposed approach is better than that based on the method of Sener and Karsak [5].

The rest of this paper is organized as follows. Section 2 reviews some related works about fuzzy QFD. In Section 3, an intelligent optimization model with fuzzy cost constraint is formulated to attain the maximum overall customer satisfaction. In Section 4, we use a software product design to illustrate the proposed methodology. Finally, the conclusions in this work are summarized in Section 5.

2. Literature Review

In order to determine the optimal level of ECs, the QFD team should develop the optimization model by taking the final importance of ECs and various constraints (cost, development time, technical feasibility, etc.) into account. One of the most commonly used optimization methodologies is linear programming. But the linear programming itself also has some shortcomings. For instance, some researches assumed that ECs are continuous variables, but the values of ECs are often discrete. On the other hand, some researches often assumed that the relationship between the customer satisfaction and ECs is linear. However, these relationships are often nonlinear in practice.

Zhou [6] proposed a mixed-integer linear programming model that uses a fuzzy ranking procedure to optimize the improvement of target values. Wang [7] considered QFD planning as a multicriteria decision problem (MCDM) and proposed an entropy method and a fuzzy outranking approach to prioritize ECs in QFD. Kim et al. [8] investigated a fuzzy multicriteria modeling approach to QFD planning in which fuzzy linear regression with symmetric triangular fuzzy numbers is used to estimate the functional relationships between CRs and ECs as well as among ECs, and Chen et al. [9] extended it asymmetrically. Taking into account the financial factors in the product design process, Tang et al. [10] dealt with a fuzzy formulation combined with a genetic-based interactive approach to QFD planning. Bai and Kwong [11] proposed an inexact genetic algorithm approach to setting the target values for ECs. Karask [12] investigated a fuzzy multiple objective programming approach to determine the level of fulfillment of ECs. Two fuzzy expected value models were developed to determine target values of ECs for different practical design scenarios [13]. Lai et al. [14] proposed a dynamic programming approach for the optimization problem in QFD. Y. Chen and L. Chen [15] developed a nonlinear programming based possibilistic regression approach, by which more diverse spread coefficients can be obtained than from a linear programming approach. Piedras et al. [16] proposed a mathematical programming technique to optimize the product development process based on concurrent engineering approach.

By integrating the least-squares regression into fuzzy linear regression, Fung et al. [17] developed a pair of hybrid linear programming models with asymmetric triangular fuzzy coefficients to estimate the functional relationships for product planning under uncertainties and extended asymmetric triangular fuzzy coefficients to asymmetric trapezoidal fuzzy coefficients in order to develop another pair of hybrid linear programming models with asymmetric trapezoidal fuzzy coefficients. The method of imprecision was employed to perform multiple-attribute synthesis to generate a family of synthesis strategies by varying the value of s, which indicates the different compensation levels among ECs [18]. Delice and Güngör [19] investigated an approach to QFD processes to obtain the optimal solution from a limited number of design requirements alternatives with discrete value. The problem of lack of solutions in integer and linear programming in the QFD optimization is overcome by using their model. Wang [20] integrated fuzzy QFD (FQFD) and MCDM methods for optimized modular design. Liu [21] utilized FQFD and the prototype product selection model to propose a product design and a selection approach that can substantially benefit developers in new product programming. Sener and Karsak [22] investigated an approach for determining target levels of ECs by integrating fuzzy linear regression and fuzzy multiple objective programming. There are two types of uncertainties in input in the QFD process: human perception and customer heterogeneity. To tackle the two types of uncertainties simultaneously, Kwong et al. [23] integrated FWA method with a consensus ordinal ranking technique.

3. Methodology

According to conventional approach, all the coefficients of LP must be crisp. However, the data in practical problem may only be vague, so they are possible to be characterized with fuzzy numbers. That LP, in which coefficients are fuzzy number, is called fuzzy linear programming problem. In this study, we consider a linear programming problem in which the objective function and the constraint are fuzzified.

We also fuzzify the objective function as follows.

4. Empirical Analysis

4.1. Problem Description

In QFD, target values of ECs identify the definitive and quantitative technical specifications to satisfy CRs. In reality, a design team needs to design a product by incorporating the ECs that are identified in the HOQ into the product. Thus, the main objective of product planning using QFD is to determine the target values of ECs for a new or improved product to maximize the overall customer satisfaction given limited organizational resources. Next, we will illustrate the proposed methodology by using a design of search engine given in [24].

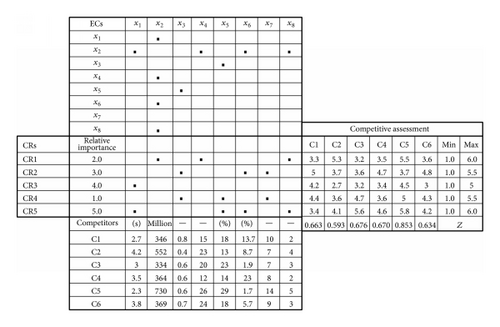

Design of search engine is going to be used as an example to explain the process of target setting in software quality function deployment. The CRs and ECs related to the search engine are obtained through requirement analysis. The house of quality (HOQ), shown in Figure 1, is developed using the customer ratings and technical evaluations of the products of the competitors [24].

Software developers need to keep in mind not only CRs but also the competition this product has to face. Initially, the customer focus group acquires the CRs to develop the product. They are listed as rows in the HOQ on the left-hand side of the house. The five CRs obtained through requirement analysis are scalability (y1), reliability (y2), speed (y3), accuracy (y4), and being easy to use (y5). Once CRs are identified, the ECs are tabulated in the house of quality in order to satisfy CRs. The QFD team will identify the strength of the relationship between CRs and ECs. These relationships are indicated in the interrelationship matrix between the CRs and ECs. The eight ECs determined in order to satisfy CRs are response time (x1), database size (x2), precision (x3), number of languages (x4), unique hits (x5), dead links (x6), update time (x7), and number of formats (x8). The QFD team identified the relationships between the CRs and ECs. The interrelationships among the ECs are indicated in the roof of the HOQ. The engineering data set for customer and technical analysis are collected from the company (C6) and its five competitors: C1, C2, C3, C4, and C5 [24].

The objective of the problem is to determine the new target values of ECs of the search engine to exceed the competitors.

4.2. Estimation of the Development Cost

| CF | c1 | c2 | c3 | c4 | c5 | c6 | c7 | c8 | B | b |

|---|---|---|---|---|---|---|---|---|---|---|

| 50 | 18 | 4 | 8 | 4 | 12 | 16 | 8 | 5 | 75 | 5 |

4.3. Development of the Programming Model

4.4. Results and Discussion

The current customer satisfaction S0 and the expected maximum customer satisfaction S0 + s are 0.634 and 0.853, respectively, so s = 0.853−0.634 = 0.219.

The results from the programming models (19) and (20) solved by Matlab software are shown in Table 2. To compare with the method proposed by Sener and Karsak in [5], their results are shown in Table 3.

| z | y1 | y2 | y3 | y4 | y5 | x1 | x2 | x3 | x4 | x5 | x6 | x7 | x8 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.743 | 3.378 | 4.332 | 3.324 | 4.96 | 4.89 | 0.712 | 0.365 | 0.823 | 0.65 | 0.802 | 0.5 | 1 | 0.44 |

| z | y1 | y2 | y3 | y4 | y5 | x1 | x2 | x3 | x4 | x5 | x6 | x7 | x8 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.691 | 3.41 | 4.488 | 3.396 | 5.04 | 4.74 | 0.732 | 0.451 | 0.875 | 0.637 | 0.81 | 0.479 | 1 | 0.48 |

Comparing the results shown in Table 2 with those shown in Table 3, the overall customer satisfaction is increased from 0.691 to 0.734, which means that the overall customer satisfaction of our product ranks the second only smaller than C5. The goal that the overall customer satisfaction is improved is achieved, because the QFD team decreased the levels of customer requirements y1 and y2 to compensate the customer requirements y3, y4, andy5. For instance, the level of y5 for our product is increased from 4.2 to 4.89, and the level of x6 relative to y5 is increased from 0.298 to 0.5. On the other hand, ECs x1 and x6 all belong to S-type, and the level of x1 is decreased, whereas the level of x6 is increased, which indicates that EC x1 compensates EC x6; however, the overall customer satisfaction is still improved. Similarly, ECs x4 and x8 all belong to S-type, the level of x4 is increased, and the level of x8 is decreased, which indicates that EC x8 compensates EC x4. The EC values are determined to achieve such a value tradeoff in the efficient way.

5. Conclusion

Sener and Karsak [22] utilized fuzzy regression to estimate the parameters of functional relationships between CRs and ECs and among ECs. Furthermore, they also considered that the determination of the optimal levels of ECs was related to many objectives such as maximizing the overall customer satisfaction, minimizing technical difficulty, and maximizing extendibility of ECs. So they proposed fuzzy multiple objective programming to determine the target levels of ECs.

Unlike Sener and Karsak [22], we establish a fuzzy linear programming model with fuzzy cost constraint to determine the target levels of ECs in QFD, in which the objective function is fuzzified by considering the overall customer satisfaction compared with competitors and the budget is telescopic.

In the proposed approach, the selection of the value of the telescopic indicator of the budget is problem dependent, and the QFD team must subjectively choose the appropriate value to align with the product development strategy of the company based on their experience and engineering knowledge.

In the context of a customer-driven product or service design process, a timely update of CRs information can provide the company with a better ground to formulate strategies to meet the future CRs. Therefore, in order to adapt to such rapidly changing environment, future research may consider the dynamic information of CRs to set the target levels of ECs.

Conflict of Interests

The authors declare that there is no conflict of interests regarding the publication of this paper.

Acknowledgments

The authors would like to sincerely thank the editor and the anonymous referees for their valuable comments on an earlier version of this paper. The work described in this paper was supported by a Grant from the National Nature Science Foundation of Chinese (Project no. NSFC71272177) and the funds of the “Innovation Program of Shanghai Municipal Education Commission, China (Project no. 12ZS101).”