Design and Optimization of Fresnel Lens for High Concentration Photovoltaic System

Abstract

A practical optimization design is proposed, in which the solar direct light spectrum and multijunction cell response range are taken into account in combination, particularly for the Fresnel concentrators with a high concentration and a small aspect ratio. In addition, the change of refractive index due to temperature variation in outdoor operation conditions is also considered in the design stage. The calculation results show that this novel Fresnel lens achieves an enhancement of energy efficiency of about 10% compared with conventional Fresnel lens for a given solar spectrum, solar cell response, and corrected sunshine hours of different ambient temperature intervals.

1. Introduction

Because of the expensive cost and quality degradation, high reflectivity mirrors are not recommended for a concentration photovoltaic system (CPVs) [1], and optical refractive polymer components such as Fresnel lenses are most frequently used for commercial CPVs, which possess advantages of compactness, simplicity in manufacture, and relative cheapness [2–4]. However, the Fresnel lenses also have several inherent disadvantages.

The first is the dispersion of the solar spectrum, which leads to an essential decrease of the energy efficiency of the solar cells, especially for the Fresnel lens having a high concentration and a small aspect ratio (i.e., the ratio of focal length to the aperture of lens). The previous Fresnel lens design is mainly based on the concept that all the grooves are with the same design wavelength λ, which is popularly chosen to be either 0.54μm [5] or the center wavelength of the solar spectrum limit [6], respectively, for the consideration of the relative peak irradiance of solar radiation and the balance of dispersion effect. Then each groove profile is obtained at this wavelength by means of simple trigonometry. These investigations were mostly devoted to analyzing the effect of dispersion of solar spectrum of the solar cell after designing, rather than to considering the solar direct light spectrum in the design stage of Fresnel lens [6–10]. Although Watson and Jayroe Jr. [11] presented a method for the design of Fresnel lens with consideration of solar spectrum, the multijunction cell response and the influence of ambient temperature variation were not considered in design process.

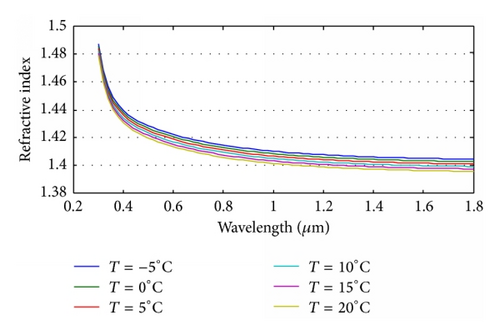

The second is the variation of outdoor temperature conditions during operation, which directly affects the spectral decomposing of the Fresnel lens. Usually Fresnel lens concentrator modules are characterized under standard testing conditions by subjecting them to an irradiation of 1000 W/m2 with an AM1.5D spectrum and a temperature of 20°C [12]. Nevertheless, the modules would not perform in accordance under actual conditions. Their efficiency is strongly affected by the environmental fluctuations. The previous studies paid more attention to the analysis of optical performances of CPVs affected by the variation of temperatures outdoors [13, 14]. The temperature dependence of refractive index caused thermal effects which had rarely been taken into account in the design stage of Fresnel lens.

With this background, in this paper, a more realistic optimization method is proposed to design a high concentration Fresnel lens with a small aspect ratio. Each groove is assumed with a specific design main wavelength related to the solar spectrum and the solar cell response. Then golden section search method is used to search the optimal design main wavelength to obtain the maximal energy efficiency of the solar cell. In addition, the influence of the change of refractive index caused by ambient temperature variation is also considered in the design process.

2. Optimization Design Method

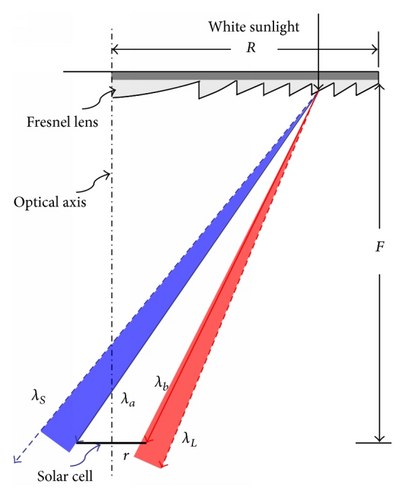

For simplicity (in both designing and manufacturing), we restrict ourselves to the case as follows. The Fresnel lens array is replicated in one piece into a silicone rubber on glass; the exit surface of each groove is curvilinear and the depth of each groove is identical. As shown in Figure 1, the exit surface profile of each groove can be easily determined as a portion of a hyperbola in the condition that the parallel sunlight beam with a design wavelength λ is focused on the center of solar cell [15].

Considering the excellent performance of the solar cell at high concentration sunlight, one of the purposes of our work is to design a nonimaging Fresnel lens used in CPVs with a high concentration factor and an aspect ratio of a relatively small value.

For the most efficient design of Fresnel lens for CPVs, the lens should focus maximum amount of energy in a small spot size [1]. For this, an appropriate design method of the Fresnel lens which guarantees the CPVs with maximal energy collection efficiency is needed. In the next section we will describe the realistic optimization design method in detail, with the consideration of the solar spectrum, the multijunction cell response, and the variation of the ambient temperatures.

2.1. Consideration of the Solar Spectrum

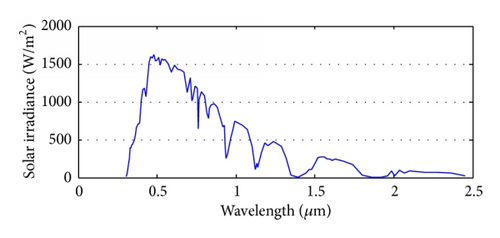

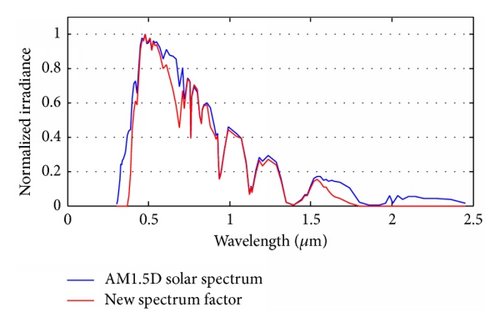

For Fresnel lens concentrators, the solar radiation spectrum mostly used in the analysis is in the range of AM1.5D (at sea level) [16]. As can be seen in Figure 2, it has a quite wide wavelength range of 300–2500 nm. Considering the multijunction solar cell response, we are only interested in wavelength range of 350–1750 nm [17]. However, this spectrum range is still too wide for the Fresnel lens with serious dispersion effect. If we force all the wavelengths of sunlight to be collected by solar cell for a given relatively small aspect ratio, such as that often used in commercial CPVs of 1.2, the dimension of solar cell would be rather larger, corresponding to a small concentration factor of 175X (spectrum of 350–1750 nm). In other words, in order to achieve a high concentration, the dimension of solar cell should not be too large, and all the sunlight would be not captured by the relatively small solar cell (as shown in Figure 3).

Figure 3 illustrates schematically how the sunlight beam passes through an arbitrary groove of Fresnel lens and is intercepted by a small solar cell. It is noted that the dimensions of the solar cell and spectrum are locally exaggerated for the interpreting conveniently. The sunlight is dispersed at the focal plane of the Fresnel lens due to the wavelength dependence of refractive index of lens material n = n(λ) and then is intercepted by the relatively small solar cell. The blue and red zones denote the loss of shorter and longer wavelength beam, respectively. Thus, the solar radiation spectrum interval effective for the solar cell changes from the entire spectrum (λS, λL) to the intercepted spectrum (λa, λb).

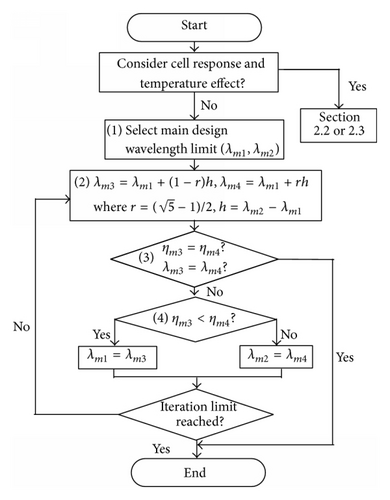

The objective of optimization design is to find the optimal main wavelength of design, corresponding to the maximal energy efficiency, which can be potentially realized via an iterative search, such as the well-known golden section search method. The flow chart of the basic procedure is shown in Figure 4 and the major steps of the algorithm are listed as follows. At first we determine whether we take into account the solar cell response and temperature effects. If yes, see Sections 2.2 or 2.3; otherwise, the following steps begin. (1) Select the main design wavelength limit (λm1, λm2). (2) Calculate the golden section points of λm3 and λm4. (3) Determine whether the utilized energy efficiency ηm3 equals ηm4 and whether λm3 equals λm4. If the condition is satisfied, the iteration finishes. (4) Compare the solar cell efficiency ηm3 with ηm4. If ηm3 is smaller than ηm4, make λm1 = λm3. Otherwise, λm2 = λm4. Then, judge whether the iteration limit reaches, if it reaches, the iteration finishes. If not, come back to step (2) and continue iteration. In general, the optical performance of the Fresnel lens is automatically improved by the iteration, and the iteration converges to a good solution at final.

2.2. Consideration of the Solar Cell Response

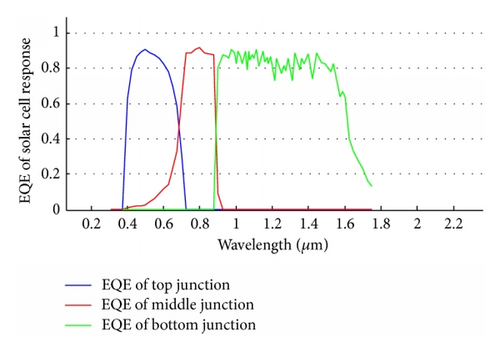

III–V based multijunction cells can operate easily at very high concentration levels and so they are excellent for high concentration system. For example, metamorphic monolithic dual-junction cells of GaInp/GaInAs achieved an efficiency of 30% at 1000 suns. A monolithic triple-junction cell of GaInP/GaInAs/Ge achieved efficiency of 39% at a concentration of 236 suns [18]. Multijunction solar cells consist of a monolithic stack of semiconductor structures of different materials. Each material has a different band-gap, and the junction is with a certain conversion range of the solar spectrum [19, 20] (Figure 5). Therefore, the combination of solar direct light spectrum and cell response range should be taken into account in the design stage of Fresnel lens.

The characteristic of the normalized irradiance distribution of the spectrum factor that describes the compound relationship of the solar spectrum and the solar cell response will be specified as the design spectrum. In further design, the spectrum factor will substitute the solar spectrum in the optimization process mentioned above.

2.3. Consideration of the Outdoor Ambient Temperature

With the same optimization method as the optimization of solar spectrum mentioned above, as well as (6) and (7), the optimal design main wavelength for each groove and total maximal energy efficiency could be finally calculated under the consideration of ambient varying temperatures in one day.

3. Example and Discussion

A simple high concentration circular Fresnel lens is designed and simulated to validate this novel design method. The specifications of the design parameters are as follows. The diameter and the focal length of Fresnel lens are, respectively, 270 mm and 320 mm, the diameter of solar cell is 7.78 mm, and the solar half angle is 0.27° [24, 25]. The geometrical concentration is 1200X and the aspect ratio is 1.2. For this study we choose polymeric plastic silicone as the base material of Fresnel lens. This is a very good option with high transmission factor, susceptible of molding manufacture and low cost. Its temperature coefficient is k = −3.4e − 4°C−1. The depth of each groove has an identical value of 0.5 mm, which can be freely adjusted under manufacturing condition. The characteristic of multijunction cell response is shown in Figure 5. The geographical location of CPVs installed practically is selected at west of China, Qinghai-Tibet Plateau. It is a good location for constructing the solar power plant due to its greatly abundant solar resource with the annual radiation reaching the ground mostly more than 6700 MJm−2 year−1 (the data stems from China Meteorological Administration). More importantly, building power plant at this place will solve the problem of power shortage there and improve the living standard and the life quality of the western people.

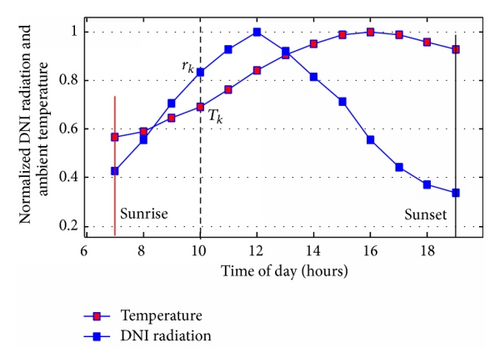

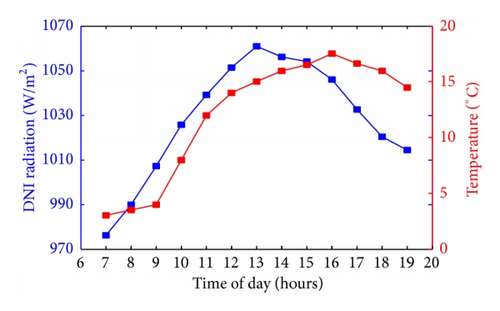

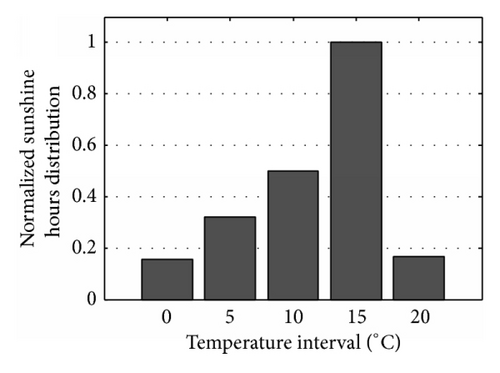

Figure 9 shows the variation of solar DNI radiation as the ambient temperature in mid-June of Waliguan in Qinghai, which lies more than 3800 meters and has less cloud in sky. After sunrise solar DNI radiation reaches the ground, and the ambient temperature gradually increases. The solar DNI radiation reaches its maximum around noon time, but the maximum of temperature occurs at 4 p.m. The difference between the diurnal highest and lowest temperature is up to 15°C (Figure 9(a)). The maximal daily sunshine hours corrected by DNI radiation occur at temperature of 10°C–15°C, which is considerably deviated from the conventional designing and testing standard temperature of 20°C for Fresnel lens (Figure 9(b)). It is clear that the change of the ambient temperature may badly impact the efficiency utilized by the solar cell.

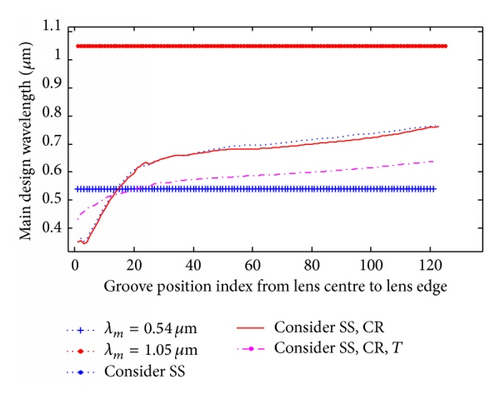

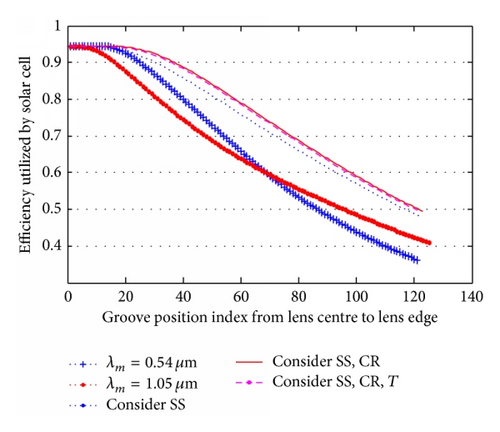

According to the optimization method described above, the optimal design main wavelength and maximal energy efficiency of solar cell for each groove are finally obtained (Figures 10 and 11).

As shown in Figure 10, the design main wavelength is different for each groove, so that the energy collected by solar cell or the collection efficiency of each groove is bigger than that with the conventional design (Figure 11). It is more distinct particularly for the marginal grooves of the Fresnel lens. This could be attributed to the fact that the closer to the edge of Fresnel lens the grooves are, the more serious the dispersion of spectrum is.

As shown in Table 1, for the conventional designs with main wavelength of λm = 0.54 μm and λm = 1.05 μm, they both have energy efficiency more than 92%. Due to the effect of dispersion of solar spectrum, the energy efficiency reduces to less than 65%. Moreover, due to the effect of the ambient temperature, it further reduces to about 62% further. But the novel design with the consideration of the solar spectrum can obtain energy efficiency about 73%, which is, respectively, 9.1% and 9.7% higher than the conventional design with a constant design main wavelength of λm = 0.54 μm and λm = 1.05 μm, respectively. Once the multijunction cell response and the temperature effects are also in consideration in design, the total efficiency would further increase more than 1.5%.

| Design method | Efficiency | Effect of temperature | |

|---|---|---|---|

| Conventional method | |||

| λm = 0.54 μm | SWSd | 92.4% | 62.5% (↓) |

| MWSe | 64.73% (↓) | ||

| λm = 1.05 μm | SWS | 92.7% | 62.14% (↓) |

| MWS | 64.08% (↓) | ||

| New method | |||

| Consider SSa | 73.84% (↑) | — | |

| Consider SS, CRb | 75.76% (↑) | — | |

| Consider SS, CR, Tc | 75.32% | — | |

- aSolar spectrum; bcell response; ctemperature; dsingle wavelength; emultiple wavelengths.

4. Conclusions

A novel optimization design of Fresnel lens used in CPVs was proposed in this paper, in which the solar direct light spectrum, the cell response range, and the change of refractive index resulting from ambient temperature are all taken into account. We assume that each groove of the Fresnel lens has a different design main wavelength and use the golden section method to search the optimal design main wavelength. In this way the intercepted wavelength interval corresponds to the maximal energy efficiency utilized by the solar cell. It is indicated in a comparison of the novel with the conventional design of the Fresnel lens that an increase of energy efficiency more than 9% can be achieved. These will be helpful to substantially improve the performance of CPVs and reduce its related cost in mass installation. The concentration module based on this novel Fresnel lens is a promising option for the development of a cost-effective photovoltaic solar energy generation.

Conflict of Interests

The authors declare that there is no conflict of interests regarding the publication of this paper.

Acknowledgments

The authors sincerely thank Professor Wang ZhaoQi for his help with English language. And the authors gratefully acknowledge the financial support from National Basic Research Program of China under Grant no. 2013AA03A116 and Projects of Science and Technology Development Plan of Jilin Province under Grant no. 20130206018GX.