Analysis of Free Edge Stresses in Composite Laminates Using Higher Order Theories

Abstract

This paper presents the determination of the interlaminar stresses close to the free edges of general cross-ply composite laminates based on higher order equivalent single-layer theory (HESL). The laminates with finite dimensions were subjected to a bending moment, an axial force, and/or a torque for investigation. Full three-dimensional stresses in the interior and the boundary-layer regions were determined. The computed results were compared with those obtained from Reddy’s layerwise theory. It was found that HESL theory predicts precisely the interlaminar stresses near the free edges of laminates. Besides, high efficiency in terms of computational time is obtainable when HESL theory is used as compared with layerwise theory. Finally, various numerical results were presented for the cross-ply laminates. Also design guidelines were proposed to minimize the edge-effect problems in composite laminates.

1. Introduction

Laminated composite materials are being used in several industries due to their high strength-to-weight ratio and stiffness-to-weight ratio. However, they are susceptible to different types of damage such as delamination which occurs due to high stress concentration near the edge of composite laminates. These stresses are induced by mismatch in elastic properties between adjacent plies of composite laminates [1]. It has been shown that the state of stresses in the edge zone of the laminate is three-dimensional (3D) in nature. Many attempts have been made to compute these stresses next to laminate’s free edges [1–12]. However, because of intrinsic complexities involved in the problem, no exact solution is known for elasticity equations. Therefore, many approximate methods used to determine the interlaminar stresses are recorded in the survey paper by Kant and Swaminathan [3]. Based on a laminated model containing anisotropic layers, the first approximate solution of interlaminar shear stresses was presented by Puppo and Evensen [4]. Other approximate analytical methods used to examine the problem are the employment of the higher order plate theory proposed by Pagano [2], the perturbation technique by Hsu and Herakovich [5], the boundary-layer theory by Tang and Levy [6], and the approximate elasticity solutions by Pipes and Pagano [7]. An approximate theory is also utilized by Pagano [8, 9] based on assumed in-plane stresses and the use of Reissner’s variational principle. The principle of minimum complementary energy and the force balance method are used by Kassapoglou and Lagace [10] to study the symmetric laminates under uniaxial loading. A variational method involving Lekhnitskii’s stress function is utilized by Yin [11, 12] to determine the interlaminar stresses in a multilayer strip of a laminate subjected to combinations of mechanical loads. Lin et al. [13] improved the technique developed by Kassapoglou and Lagace [10] for symmetric laminates under uniaxial tension to evaluate the interlaminar stress distribution near the straight free edges of symmetric and unsymmetric laminates under different types of loading conditions. The first numerical method to solve the 2D governing elasticity equations is given by Pipes and Pagano [1]. They utilized a finite-difference technique to establish the interlaminar stresses in a long symmetric laminate under uniform axial strain. A layer reduction technique and a layerwise theory (LWT) are employed by Lee and Chen [14] in the analysis of a reduced laminate. They neglected the through-thickness stretching and solved a simply supported plate subjected to bidirectional sinusoidal distributed loading. A displacement-based variable kinematic global-local finite element method is offered by Robbins and Reddy [15]. Their displacement field hierarchy contains both a conventional plate expansion (2D) and a full layerwise (3D) expansion. Neves et al. [16, 17] developed a higher order theory that considers deformations in the thickness direction under Carrera’s unified formulation to predict the buckling behaviour of laminated plates and modeling functionally graded plates accounting for extensibility in the thickness direction. The obtained governing equations and boundary conditions are then interpolated by collocation with radial basis functions. Mantari et al. [18] developed a new shear deformation theory for sandwich and composite plates. The presented theory is relatively close to 3D elasticity bending solutions. The theory accounts for adequate distribution of the transverse shear strains through the plate thickness and tangential stress-free boundary conditions on the plate boundary surface; thus, a shear correction factor is not required. A new model is proposed by Rahmani et al. [19] based on the high-order sandwich panel theory to study the effect of external loads on the free vibration of circular cylindrical composite sandwich shells with transversely compliant core, including also the calculation of the buckling loads. Thai et al. [20] present a novel finite element formulation for static, free vibration and buckling analyses of laminated composite plates. The higher order shear deformation plate theory (HSDT) is introduced in the present method to remove the shear correction factors and improve the accuracy of transverse shear stresses. A new improved high-order theory is presented by Kheirikhah et al. [21] for biaxial buckling analysis of sandwich plates with soft orthotropic core. Third-order plate theory is used for face sheets, quadratic and cubic functions which are assumed for transverse and in-plane displacements of the core, respectively.

It was found from the literature that no work has been found to study interlaminar stresses by higher order equivalent single-layer theory (HESL). Here, HESL theory is used to analytically study the interlaminar stresses in both finite and long cross-ply laminates subjected to a bending moment, an axial force, and/or a torque. Then HESL results are compared with those calculated from LWT. The presented works (HESL) are either accurate enough (and general) or computationally efficient.

2. Higher Order Equivalent Single-Layer Theory (HESL)

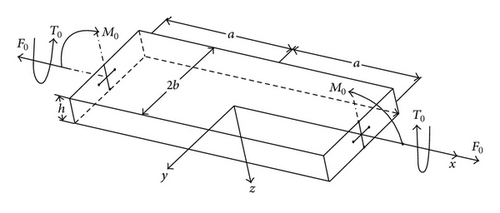

General cross-ply laminates are subjected to the bending moment, the axial force, and/or the torque in order to accurately determine the interlaminar stresses. The geometry of the laminate is illustrated in Figure 1. The formulation is limited to linear elastic material behavior, small strain, and displacements. The coordinate system (x, y, z) is located at the middle plane of the laminate. Thickness, width, and length of the laminate are h, 2b, and 2a, respectively.

2.1. Displacement Field and Strains

3. Layerwise Theory

3.1. Displacement Field and Strains

3.2. Equilibrium Equations

3.3. Displacement Equations of Equilibrium

For completeness, the details of the steps involved in the analytical solutions are displayed in Appendix C.

4. Results

4.1. Numerical Results and Discussion

To verify the accuracy and efficiency of the present method, several numerical examples are presented for general cross-ply laminates subjected to the bending moment, axial force, and/or torque. The analyses were performed for 4-layer and 6-layer laminates made of graphite/epoxy. The used mechanical and physical properties of the layers are presented in Table 1 [24].

| Engineering properties | E1 (GPa) | E2 = E3 (GPa) | G12 = G13 (GPa) | G23 (GPa) | υ12=υ13 | υ23 |

|---|---|---|---|---|---|---|

| Graphite/epoxy | 132 | 10.8 | 5.65 | 3.38 | 0.24 | 0.59 |

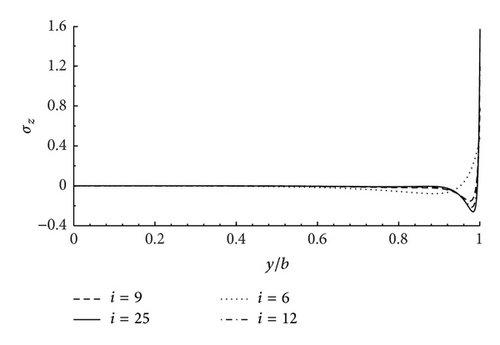

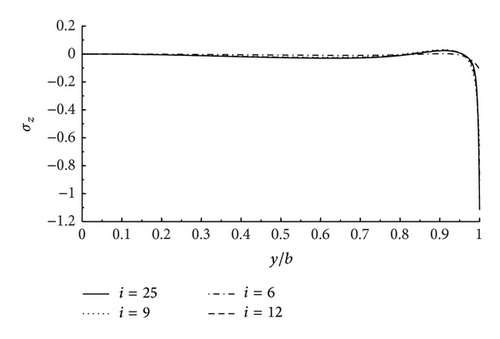

To study the convergence of the stresses near free edges, two symmetric laminates and subjected to the bending moment, the axial force, and the torque are considered. On account of the nature of the cross-ply laminates, both σxy and σxz are zero here as expected. Figures 2 and 3 demonstrate the convergence of the solution for σz versus y at the z = h/4 for the and laminates. It is seen that, for both and , σz is seen to rise or fall suddenly near the free edge, while being zero in the inner region of the laminate also the peak stress steadily increases as the number of terms (i) taken is increased. This is often attributed to a possible singularity at the 0°/90° interfaces.

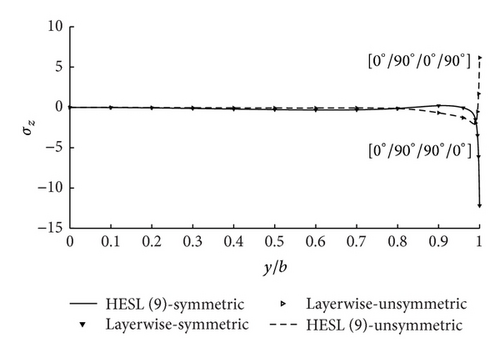

Numerical results are obtained from equilibrium equations. The present results are directly compared with those obtained from LWT. Figure 4 shows the σz distribution at the 0°/90° interfaces of [0°/90°/90°/0°] and [0°/90°/0°/90°] laminates under the bending moment and the axial force. An excellent agreement is found between the present solutions and those of LWT.

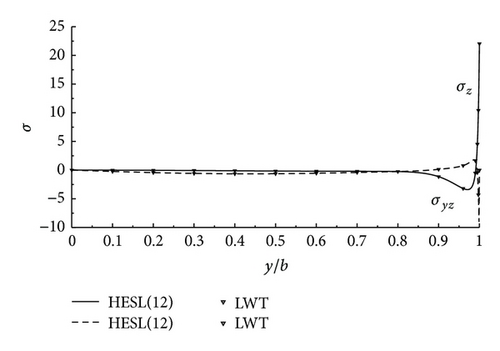

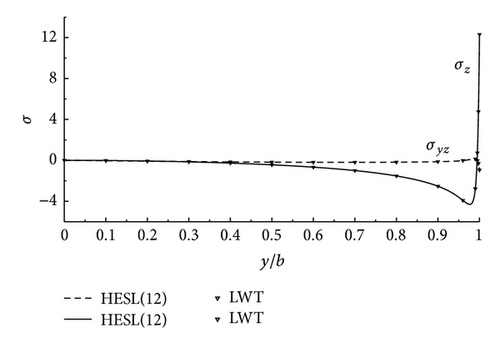

Figures 5 and 6 show the σz and σyz distribution at the 0°/90° interfaces of [0°/90°/90°/90°/90°/0°] and [0°/0°/0°/90°] laminates under the bending moment and the torque. Good accordance is seen between the results of the two theories. It is noted that the accuracy of HESL theory can be improved by taking more terms. Also the layerwise theory needs to take many terms to approach accurately the results of the present theory and these terms cause that LWT is more complex and computationally more time consuming than the HESL theory, so, it is better that HESL theory is used to compute the local phenomena such as free-edge-effect problems and the distribution of interlaminar stresses more precisely and less computationally than the layerwise theory in laminate composites.

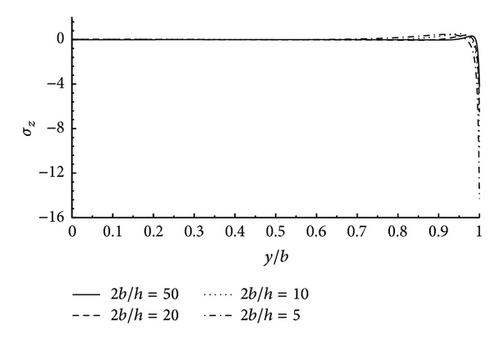

The effect of the laminate width-to-thickness ratio on the interlaminar stresses for the [90°/0°/90°/0°/90°/0°] laminate under the bending moment is investigated in Figure 7. By decreasing the width-to-thickness ratio, the boundary-layer region is expanded towards the internal region of the laminate with its width being almost equal to the thickness of the laminate. It is seen that the magnitude of the interlaminar stress at the free edge does not change while the width-to-thickness ratio of the laminate changes. On the other hand, this is evident that the highly localized nature of interlaminar stresses occurs near and exactly at the free edges of the laminate.

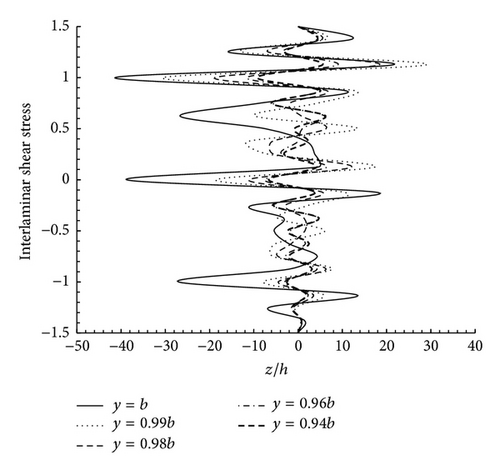

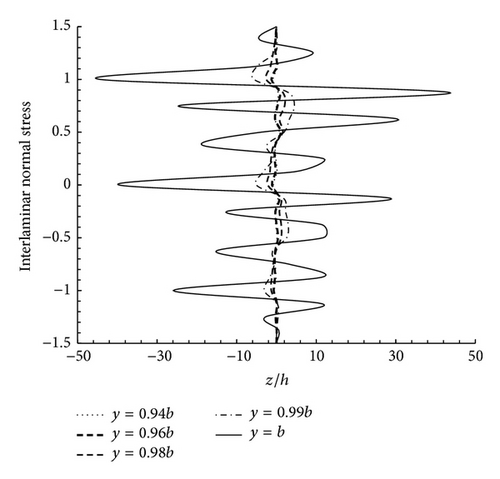

The variation of interlaminar shear stress σyz through the thickness and near the free edge of the [90°/0°/90°/0°] laminate under the bending moment and the torque is revealed in Figure 8. It is observed that the maximum negative and the maximum positive values of σyz occur within the bottom 90° layer and the top 0° layer at the 90°/0° interfaces of the laminate, respectively. The variations of interlaminar normal stress σz through the thickness of the unsymmetrical cross-ply laminate [90°/0°/90°/0°] under the bending moment and the axial force are portrayed in Figure 9. The maximum negative and the maximum positive values of σz occur within the bottom 90° layer and the top 0° layer both near the 90°/0° interfaces at the free edge (i.e., y = b), respectively. From Figure 9, it is seen that σz decreases away from the free edge as the inner region of the laminate is approached.

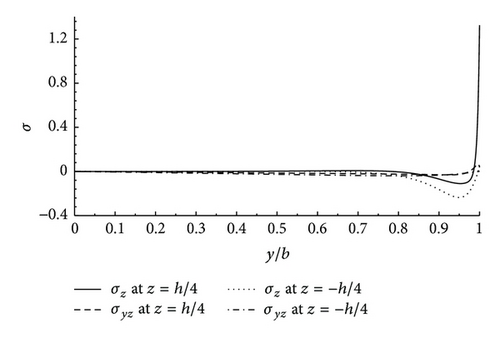

The distributions of the interlaminar stresses σz and σyz along the upper and lower interfaces of the unsymmetrical cross-ply [90°/90°/0°/90°] laminate subjected to the bending moment, the axial force, and the torque are demonstrated in Figure 10. It is observed that the interlaminar stresses demonstrate high stress gradient near the free edge. Both stresses are seen to grow suddenly near the free edge, while being zero in the interior region of the laminate. It is also observed that the interlaminar shear stress σyz rises toward the free edge and decreases (or increases) rather abruptly to zero at the free edge.

4.2. Preliminary Design Guidelines

- (1)

The laminates stacking sequence (LSS) should be symmetric about the midplane to avoid extension-bending coupling. If this is not possible due to other requirements, locate the asymmetry or imbalance as near to the laminate midplane as possible. Avoid symmetric LSS that create high interlaminar tension stresses (s) at free edges.

- (2)

Avoid grouping of 90° plies and separate 90° plies by a 0° ply to minimize interlaminar shear and normal stress. Minimize groupings of plies with the same orientations to create a more homogeneous laminate and to minimize interlaminar stress. If plies must be grouped, avoid grouping more than four plies of the same orientation. Minimizing grouping helps to increase strength and minimize interlaminar shear and normal stresses and therefore minimize the tendency to delaminate.

- (3)

Shield primary load carrying plies by positioning them inside of laminate to increase tensile strength and buckling resistance.

- (4)

An LSS should have at least both distinct ply angles (e.g., 0°, 90°) with a minimum of 10% of the plies oriented at each angle. Ply angles should be selected such that fibers are oriented with principal load axes.

- (5)

Locating 90° ply toward the exterior surfaces improves the buckling allowable in many cases.

5. Conclusions

In this research, analytical solutions were established within HESL theory for the edge-effect problem of general cross-ply composite laminates with finite dimensions under the bending moment, the axial force, and/or the torque. The edges of the laminates at y = ±b were assumed to have traction-free boundary conditions. The accuracy and effectiveness of HESL theory in describing the localized three-dimensional effects were demonstrated by comparing the results of HESL theory with those calculated from the layerwise theory. Good agreement was observed between the results of HESL and LWT theories. Furthermore, the analysis using HESL was found to be more cost effective and accurate, so HESL was employed to assess the local phenomena instead of LWT theory. Here, several numerical results were shown for the different loading problems. The design guidelines were developed to provide cross-ply laminate stacking sequences with minimized the free edges effects.

Conflict of Interests

The authors declare that there is no conflict of interests regarding the publication of this paper.

Appendices

A.

B.

C.

C.1. Analytical Solutions

The solution procedure for (C.16b) with the boundary conditions in (C.20b) and (C.17) and with the boundary conditions in (C.19) is similar to the one discussed in (C.16b), and therefore, for the sake of brevity, it will not be taken up here. The boundary conditions in (C.15) will identically be satisfied.