Modeling of Partially Hydrolyzed Polyacrylamide-Hexamine-Hydroquinone Gel System Used for Profile Modification Jobs in the Oil Field

Abstract

The cross-linked polymer gel systems are being used increasingly to redirect or modify reservoir fluid movement in the vicinity of injection wells for the purpose of permeability/profile modification job in the oil field due to their high temperature stability and capability to provide rigid gel having high mechanical strength. In this study, a partially hydrolyzed polyacrylamide-hexamine-hydroquinonegel is used for the development of polymer gel system. The experimental investigation demonstrates that the gelation time varies with polymer and crosslinker concentration and the temperature. The mathematical model is developed with the help of gelation kinetics of polymer gel and using Arrhenius equation, which relates the gelation time with polymer, crosslinker concentrations, and temperature. The developed model is solved with the help of multivariate regression method. It is observed in this study that the theoretical values of gelation time have good agreement with the experimental values.

1. Introduction

The reservoir heterogeneity, permeability variations, and presence of fractures and fracture network in the reservoir are the main hurdles of the water flooding operations used to enhance the oil recovery from matured oil fields. Normally during water flooding, water sweeps through more permeable sections of the reservoir leaving back oil in low permeability channels leading to low oil recovery and early water breakthrough. This excessive water production from the producers leads to rise in handling and disposal costs and reduces the economic life of the well. The polymer gels block or reduce the permeability in high permeability channels and divert the injected water through the low permeability sections, which were not flooded or swept earlier, leading to improvement in oil recovery. This technique is known as profile modification or permeability modification technique and the proper application of this technique is essential for the success of water flooding projects in the oil fields [1–3].

Basically two types of polymers have been used for profile modification jobs. These are polyacrylamides with different degrees of hydrolysis and polysaccharide such as xanthan biopolymer. These are cross linked with inorganic and organic crosslinkers to produce a three-dimensional polymer structure of the gel [4–7]. The inorganic gel system based on the crosslinking of the carboxylate groups on the partially hydrolyzed polyacrylamide chain (PHPA) with a trivalent cation like Cr (III). This crosslinking is believed to rely on coordination covalent bonding. It should be mentioned that Cr (III) based polymer gel system were reported to be stable at temperatures up to 300°F [8–10]. The organically crosslinked gels developed using phenol and formaldehyde crosslinkers are thermally stable under harsh environmental conditions. But, these crosslinkers are not environment friendly. To overcome the toxicity issues associated with formaldehyde and phenol, the formaldehyde can be replaced with less toxic derivatives like hexamethylenetetramine, glyoxal, paraformaldehyde, acetaldehyde, propionaldehyde, butyraldehyde and so forth and phenol can be replaced with hydroquinone, resorcinol, pyrogallol, phenyl salicylate and so forth [11–13]. Other system is based on PEI crosslinker and a copolymer of acrylamide and t-butyl acrylate (PA-t-BA). PA-t-BA is a relatively low molecular-weight polymer is expected to provide rigid ringing gels. Polyethyleneimine (PEI) cross-linking a copolymer of acrylamide and tert-butylacrylate (PAtBA) as water shutoff gels has been widely used in recent years [14].

The gelation mechanism of organic crosslinkers is done by covalent bonding, which is much more stable than the ionic bonds. Organic crosslinkers were introduced to obtained gels that can remain stable over a wide temperature range. For high temperature (>90°C) reservoirs, acrylamide-based copolymers with organic crosslinking agents, such as phenol-formaldehyde and its derivatives, can be used to form a gel with thermal stability, and the gelation time is adjustable [15, 16].

The different methods are presented in the literature for the determination of the physical and chemical properties of polymer gel system such as bottle testing method, sealed tube method, dynamic shear method (rheometer), and static shear method (viscometer). Out of these methods, the bottle testing method is most suitable, faster, and inexpensive method to study the gelation kinetics [17].

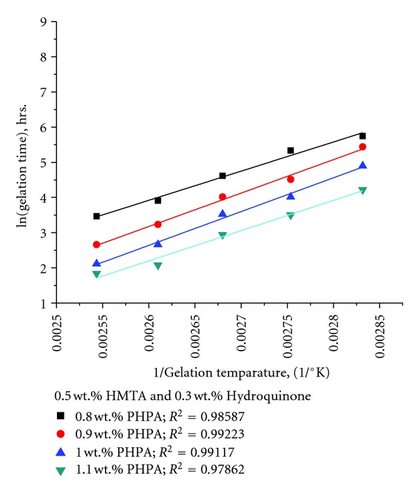

Several models have been reported in the literature to relate the gelation time with temperature. Jordan found that the gelation time of a specified system decreases as the temperature is increased. Plots of the logarithm of gelation time versus the reciprocal of the absolute reaction temperature were found to be linear for the systems studied. This correlation showed that the system apparently followed the Hurd and Letteron model which assumed rate dependence on only one species. Hurd and Letteron studied the effect of temperature on the formation of silicic acid gels and found empirically that plot of the logarithm of the gelation time versus the reciprocal of the absolute temperature linear. They developed an equation, similar to the Arrhenius equation, which relates gelation time and the temperature and support the linear relationship [15]. But very few or rare models relate the gelation time with polymer and crosslinker concentration and temperature in case of polymer gel system used in the oil fields. For the successful design of the profile modification job the mathematical model equation consists of polymer and crosslinkers concentration as well as temperature is essential.

The present paper involves bulk gelation studies of the polymer gelant prepared from partially hydrolyzed polyacrylamide (PHPA) and hexamine (HMTA)/hydroquinone (HQ). The gelation time determined from the bulk gelation studies at different temperatures is useful because its knowledge at reservoir temperature is required to find out the depth up to which the gel can be placed in the petroleum reservoir rock. The gelation time and gel strength mainly depend on polymer and crosslinker concentrations and reservoir temperature were also reported in this paper. On the basis of the kinetics of polymer gel system, the mathematical model for the gelation behavior is also proposed which relates the gelation time with polymer-crosslinkers concentrations and temperature. The theoretical values of gelation time obtained from the proposed model matches with the experimental data.

2. Gelation Mechanism

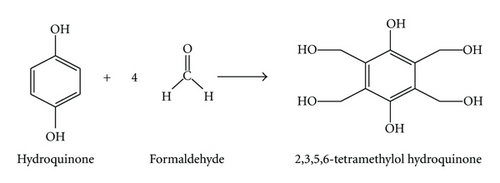

The hexamine on hydrolysis yields formaldehyde which then combines with hydroquinone and form 2,3,5,6-tetramethylol hydroquinone. Further, partially hydrolyzed polyacrylamide reacts with 2,3,5,6-tetramethylol hydroquinone and forms three dimensional networks of polymer gel, the different steps of which are as follows.

Step II. Formaldehyde produced in Step I then react with hydroquinone to form a condensed structure known as 2,3,5,6-tetramethylolhydroquinone (see Scheme 1).

Step III. The condensed molecule formed in Step II then reacts with PHPA to form the 3-dimensional gel structure which helps in profile modification jobs (see Scheme 2).

3. Development of Mathematical Model

The rate of gelation process for partially hydrolyzed polyacrylamide-hexamine-hydroquinone system may be present as follows.

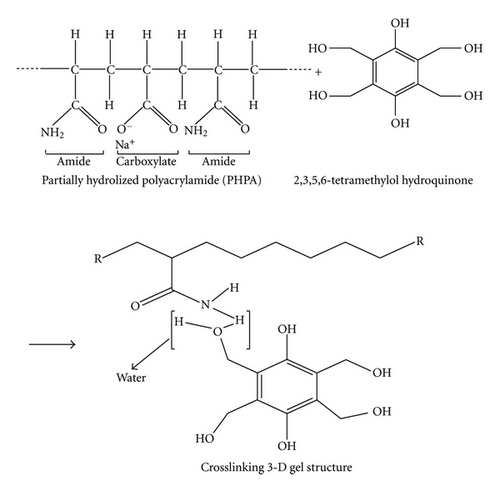

4. Solution Procedure of the Developed Model

The mathematical model for gelation time consists of four variable parameters (CA, CB, CC, and T) and five constants (a0, a1, a2, a3, and a4). For the determination of these constants, five simultaneous equations are generated by multiplying the variables in both side of the model equation and utilizing the experimental data, the flow diagram for solution of proposed model is shown in Figure 1. Further, these equations are solved by multivariate regression method and values of the constants a0, a1, a2, a3, and a4 are determined. After putting these values in the model equation, the gelation time are calculated by varying the different parameters (CA, CB, CC, and T). Finally, these calculated values are compared with the actual values obtained from the laboratory work.

5. Experimental Work

5.1. Material Used

The materials used for this work are partially hydrolyzed polyacrylamide, hexamine, hydroquinone, sodium chloride, hydrochloric acid, and sodium hydroxide. Partially hydrolyzed polyacrylamide is procured from Oil and Natural Gas Corporation Limited, Mumbai, India. Hexamine is purchased from Otto Kemi Mumbai, India and hydroquinone is procured from Ranbaxy Fine Chemicals Ltd., New Delhi, India. Hydrochloric acid is purchased from Central Drug house (P) Ltd. New Delhi, India. Sodium chloride is purchased from Nice Chemical Pvt. Ltd. Cochin, India and sodium hydroxide is purchased from S. D. Fine-Chem Ltd. Mumbai, India.

5.2. Experimental Procedure

Initially stock solution of partially hydrolyzed polyacrylamide was prepared in brine solution and kept for aging at ambient temperature for 24 hrs and further fresh solution of hexamine and hydroquinone were also prepared in brine. The appropriate solution of partially hydrolyzed polyacrylamide, hexamine, hydroquinone, and brine were thoroughly mixed at room temperature by magnetic stirrer. The pH of the gelant solution was measured by Century CP-901 digital pH meter and the pH of the gelant solution was adjusted by using 1 N sodium hydroxide and 1 N hydrochloric acid. Finally, the gelant solution was transferred into small glass bottle and kept at the desire temperature in the hot air oven (temperature ranges from 80°C to 120°C). Due to the increased temperature and the crosslinking reaction, gel formation takes place. The quality of gel was visually inspected at regular intervals and gelation time was noted. Here, the time for the formation of stiff/rigid gel was only considered.

6. Results and Discussions

The gelation behavior of the polymer gel system largely depends on the polymer-crosslinker concentrations and the temperature. The effects of these parameters on gelation time are described below.

6.1. Effect of Temperature on Gelation Time

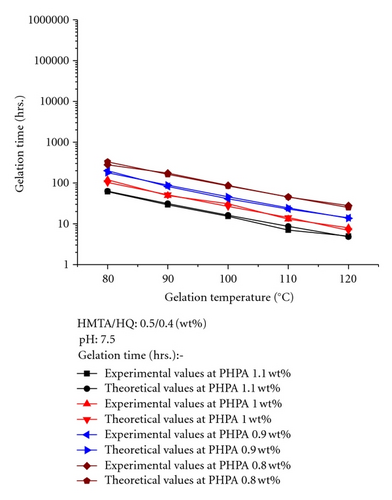

Different gelling solutions were prepared with different concentrations of polymer and crosslinking agent at pH 7.5 and kept for gelation at different temperature. The reaction rate between amide group and methylol group was accelerated by increasing temperature and the gelation time decreased. Increasing the gelation temperature results in a decrease in gelation time since at higher temperature gels are formed in lesser time due to rapid crosslinking as is depicted in Figures 2 and 3 and Tables 1, 2, 3, 4, and 5. A possible explanation for rapid cross-linking is either due to an increase in molecular mobility or formation of new cross-linking sites as a result of gelation reaction. It is a known fact that degree of hydrolysis of the polymer increases at elevated temperatures which in turn increases the number of cross-linking sites that is found increasing the reaction rate and decreasing the gelation time.

| Sl. No. | Polymer | Crosslinkers | Experimental values of gelation time (hrs.) |

Theoretical values of gelation time (hrs.) |

Temperature (°C) |

|

|---|---|---|---|---|---|---|

PHPA (wt%) |

HMTA (wt%) |

HQ (wt%) |

||||

| 1 | 0.8 | 0.5 | 0.4 | 280 | 328.8475 | 80 |

| 2 | 0.9 | 0.5 | 0.4 | 200 | 178.3855 | |

| 3 | 1.0 | 0.5 | 0.4 | 120 | 103.3145 | |

| 4 | 1.1 | 0.5 | 0.4 | 61 | 62.9199 | |

| 5 | 0.8 | 0.5 | 0.4 | 174.3 | 163.9435 | 90 |

| 6 | 0.9 | 0.5 | 0.4 | 82.3 | 88.9322 | |

| 7 | 1.0 | 0.5 | 0.4 | 49 | 51.4565 | |

| 8 | 1.1 | 0.5 | 0.4 | 29.3 | 31.3681 | |

| 9 | 0.8 | 0.5 | 0.4 | 87 | 84.8392 | 100 |

| 10 | 0.9 | 0.5 | 0.4 | 41 | 46.0215 | |

| 11 | 1.0 | 0.5 | 0.4 | 31 | 26.6282 | |

| 12 | 1.1 | 0.5 | 0.4 | 15.3 | 16.2326 | |

| 13 | 0.8 | 0.5 | 0.4 | 45.3 | 45.4394 | 110 |

| 14 | 0.9 | 0.5 | 0.4 | 23 | 24.6489 | |

| 15 | 1.0 | 0.5 | 0.4 | 13 | 14.2619 | |

| 16 | 1.1 | 0.5 | 0.4 | 7 | 8.6941 | |

| 17 | 0.8 | 0.5 | 0.4 | 28 | 25.1225 | 120 |

| 18 | 0.9 | 0.5 | 0.4 | 14 | 13.6278 | |

| 19 | 1.0 | 0.5 | 0.4 | 8 | 6.8917 | |

| 20 | 1.1 | 0.5 | 0.4 | 5 | 4.80681 | |

| Sl. No. | Polymer | Crosslinkers | Experimental values of gelation time (hrs.) |

Theoretical values of gelation time (hrs.) |

Temperature (°C) |

|

|---|---|---|---|---|---|---|

PHPA (wt%) |

HMTA (wt%) |

HQ (wt%) |

||||

| 1 | 0.8 | 0.5 | 0.3 | 312 | 376.7173 | 80 |

| 2 | 0.9 | 0.5 | 0.3 | 230 | 204.3528 | |

| 3 | 1.0 | 0.5 | 0.3 | 134 | 118.2393 | |

| 4 | 1.1 | 0.5 | 0.3 | 68 | 72.0791 | |

| 5 | 0.8 | 0.5 | 0.3 | 207 | 187.8085 | 90 |

| 6 | 0.9 | 0.5 | 0.3 | 91 | 101.8779 | |

| 7 | 1.0 | 0.5 | 0.3 | 55.3 | 58.9469 | |

| 8 | 1.1 | 0.5 | 0.3 | 33.3 | 35.9343 | |

| 9 | 0.8 | 0.5 | 0.3 | 101 | 97.1891 | 100 |

| 10 | 0.9 | 0.5 | 0.3 | 55.3 | 52.7208 | |

| 11 | 1.0 | 0.5 | 0.3 | 34 | 30.5045 | |

| 12 | 1.1 | 0.5 | 0.3 | 19 | 18.5956 | |

| 13 | 0.8 | 0.5 | 0.3 | 50 | 52.0539 | 110 |

| 14 | 0.9 | 0.5 | 0.3 | 25.3 | 28.237 | |

| 15 | 1.0 | 0.5 | 0.3 | 14.3 | 16.338 | |

| 16 | 1.1 | 0.5 | 0.3 | 8 | 9.9597 | |

| 17 | 0.8 | 0.5 | 0.3 | 32 | 28.7795 | 120 |

| 18 | 0.9 | 0.5 | 0.3 | 14.3 | 15.6116 | |

| 19 | 1.0 | 0.5 | 0.3 | 8.3 | 9.0329 | |

| 20 | 1.1 | 0.5 | 0.3 | 6.3 | 5.5065 | |

| Sl. No. | Polymer | Crosslinkers | Experimental values of gelation time (hrs.) |

Theoretical values of gelation time (hrs.) |

Temperature (°C) |

|

|---|---|---|---|---|---|---|

PHPA (wt%) |

HMTA (wt%) |

HQ (wt%) |

||||

| 1 | 0.8 | 0.4 | 0.4 | 331 | 411.5734 | 80 |

| 2 | 0.9 | 0.4 | 0.4 | 243 | 223.2606 | |

| 3 | 1.0 | 0.4 | 0.4 | 140 | 129.1795 | |

| 4 | 1.1 | 0.4 | 0.4 | 77 | 78.7483 | |

| 5 | 0.8 | 0.4 | 0.4 | 226 | 205.1856 | 90 |

| 6 | 0.9 | 0.4 | 0.4 | 105 | 111.3043 | |

| 7 | 1.0 | 0.4 | 0.4 | 71 | 64.4011 | |

| 8 | 1.1 | 0.4 | 0.4 | 37.3 | 39.2591 | |

| 9 | 0.8 | 0.4 | 0.4 | 115 | 106.1816 | 100 |

| 10 | 0.9 | 0.4 | 0.4 | 61 | 57.5989 | |

| 11 | 1.0 | 0.4 | 0.4 | 37 | 33.3269 | |

| 12 | 1.1 | 0.4 | 0.4 | 23 | 20.3162 | |

| 13 | 0.8 | 0.4 | 0.4 | 56 | 56.8703 | 110 |

| 14 | 0.9 | 0.4 | 0.4 | 30 | 30.8496 | |

| 15 | 1.0 | 0.4 | 0.4 | 17 | 17.8497 | |

| 16 | 1.1 | 0.4 | 0.4 | 10 | 10.8812 | |

| 17 | 0.8 | 0.4 | 0.4 | 36 | 31.4424 | 120 |

| 18 | 0.9 | 0.4 | 0.4 | 17 | 17.0561 | |

| 19 | 1.0 | 0.4 | 0.4 | 9 | 9.8687 | |

| 20 | 1.1 | 0.4 | 0.4 | 7 | 6.016 | |

| Sl. No. | Polymer | Crosslinkers | Experimental values of gelation time (hrs.) |

Theoretical values of gelation time (hrs.) |

Temperature (°C) |

|

|---|---|---|---|---|---|---|

PHPA (wt%) |

HMTA (wt%) |

HQ (wt%) |

||||

| 1 | 0.8 | 0.4 | 0.3 | 370 | 471.4855 | 80 |

| 2 | 0.9 | 0.4 | 0.3 | 286 | 255.7604 | |

| 3 | 1.0 | 0.4 | 0.3 | 168 | 147.9839 | |

| 4 | 1.1 | 0.4 | 0.3 | 84 | 90.2116 | |

| 5 | 0.8 | 0.4 | 0.3 | 266 | 235.0542 | 90 |

| 6 | 0.9 | 0.4 | 0.3 | 135.3 | 127.5067 | |

| 7 | 1.0 | 0.4 | 0.3 | 78 | 73.7758 | |

| 8 | 1.1 | 0.4 | 0.3 | 42.3 | 44.974 | |

| 9 | 0.8 | 0.4 | 0.3 | 133 | 121.6383 | 100 |

| 10 | 0.9 | 0.4 | 0.3 | 71 | 65.9835 | |

| 11 | 1.0 | 0.4 | 0.3 | 42 | 38.1783 | |

| 12 | 1.1 | 0.4 | 0.3 | 27 | 23.2736 | |

| 13 | 0.8 | 0.4 | 0.3 | 60 | 65.1488 | 110 |

| 14 | 0.9 | 0.4 | 0.3 | 35 | 35.3404 | |

| 15 | 1.0 | 0.4 | 0.3 | 20.3 | 20.4481 | |

| 16 | 1.1 | 0.4 | 0.3 | 12 | 12.4652 | |

| 17 | 0.8 | 0.4 | 0.3 | 39 | 36.0194 | 120 |

| 18 | 0.9 | 0.4 | 0.3 | 19 | 19.539 | |

| 19 | 1.0 | 0.4 | 0.3 | 10 | 11.3053 | |

| 20 | 1.1 | 0.4 | 0.3 | 8 | 6.8917 | |

| Sl. No. | Polymer | Crosslinkers | Experimental values of gelation time (hrs.) |

Theoretical values of gelation time (hrs.) |

Temperature (°C) |

|

|---|---|---|---|---|---|---|

PHPA (wt%) |

HMTA (wt%) |

HQ (wt%) |

||||

| 1 | 0.8 | 0.3 | 0.3 | 451 | 629.6609 | 80 |

| 2 | 0.9 | 0.3 | 0.3 | 362 | 341.5637 | |

| 3 | 1.0 | 0.3 | 0.3 | 216 | 197.63 | |

| 4 | 1.1 | 0.3 | 0.3 | 111 | 120.476 | |

| 5 | 0.8 | 0.3 | 0.3 | 311 | 313.9109 | 90 |

| 6 | 0.9 | 0.3 | 0.3 | 158 | 170.283 | |

| 7 | 1.0 | 0.3 | 0.3 | 102 | 98.5264 | |

| 8 | 1.1 | 0.3 | 0.3 | 55.3 | 60.0621 | |

| 9 | 0.8 | 0.3 | 0.3 | 170 | 162.4459 | 100 |

| 10 | 0.9 | 0.3 | 0.3 | 82 | 88.1198 | |

| 11 | 1.0 | 0.3 | 0.3 | 58 | 50.9864 | |

| 12 | 1.1 | 0.3 | 0.3 | 30 | 31.0815 | |

| 13 | 0.8 | 0.3 | 0.3 | 86 | 87.0051 | 110 |

| 14 | 0.9 | 0.3 | 0.3 | 66 | 57.1604 | |

| 15 | 1.0 | 0.3 | 0.3 | 24.3 | 27.308 | |

| 16 | 1.1 | 0.3 | 0.3 | 15 | 16.6471 | |

| 17 | 0.8 | 0.3 | 0.3 | 45 | 48.1034 | 120 |

| 18 | 0.9 | 0.3 | 0.3 | 23 | 26.094 | |

| 19 | 1.0 | 0.3 | 0.3 | 14 | 15.098 | |

| 20 | 1.1 | 0.3 | 0.3 | 10 | 9.2038 | |

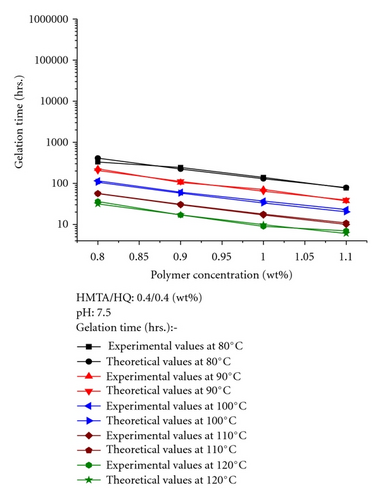

6.2. Effect of Polymer Concentration on Gelation Time

The polymer concentration has a significant effect on the physical properties of gel. The polymer concentration increases and gelation time decreases were shown in Figure 4. The polymer concentration ranges from 0.8 to 1.1 wt% and constant concentration of crosslinker (0.5 to 0.3 wt% HMTA and 0.4 to 0.3 wt% HQ) at pH 7.5 are depicted in Tables 1 to 5. As the polymer concentration increases, it means more crosslinking sites are available for the fast crosslinking reaction takes place. Thus, the gel formation reaction increases, which leads to the decreases of gelation time. This trend is expected to be the same at all gelation temperatures under study. Thus, the required time to obtain a non-flowing polymer gel with a tolerable strength decreased when the polymer concentration was increased.

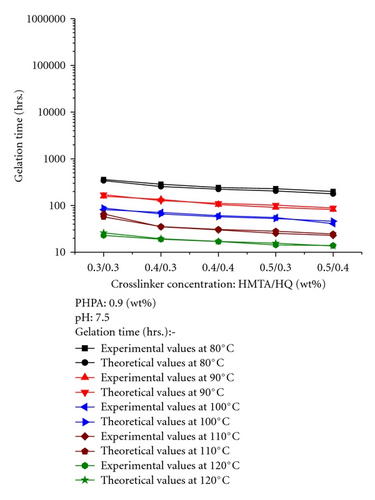

6.3. Effect of Cross-Linker Concentration on Gelation Time

Hexamine and hydroquinone crosslinkers are a multifunctional group which can build a complex network with amide groups of partially hydrolyzed polyacrylamide and form a 3-dimentional gel network structure. Crosslinker concentration has a significant effect on the gel strength. The crosslinker concentration increases and gelation time decreases were shown in Figure 5. The several samples were prepared to investigate the effect of crosslinker concentration on the network strength. Bottle testing results shown in Tables 1 to 5 indicate that when the concentration of both crosslinker was decreased the gelation rate and gel quality is also decreased. In other words, when crosslinking agent concentration was increased, the stage of polymer gel changed from a state of flowing gel to one of deformable non-flowing gel, because crosslinking sites are increased for the formation of gel in lesser time intervals.

7. Model Discussion

Equation (12) shows the relation of gelation time with polymer concentration, cross linker concentrations and temperature. Here, CA, CB, and CC are polymers, HMTA and hydroquinone concentrations, respectively, in gm/litre and temperature, are taken in degree kelvin. This equation indicates that the gelation time is inversely proportional to the concentrations of polymer and crosslinking agent, which reflects that the increasing the concentration of polymer and crosslinking agent decreases the gelation time. The proposed model for the study of the gelation behavior of partially hydrolyzed polyacrylamide-hexamine-hydroquinone polymer gel system is shown in (15)-(16). The values of the constants/coefficients a0, a1, a2, a3, and a4 are determined by multivariate regression method.

7.1. Comparison between Developed Model and Civan et al. [18]

The developed model in the present study relates stoichiometric relation between reactants involved in the gelation reaction as well as Arrhenius equation. In this case, gelation time is dependent on polymer and crosslinker concentration as well as temperature. However, model proposed by Civan et al. is simply Arrhenius type equation which is dependent on temperature only. Figure 3 shows the theoretical values of gelation time for different concentration of polymers. It was found that there are several variations in the values of slopes and intercepts as well as R2 and may have different activation energy for different concentrations of polymers. The comparison of theoretical gelation time calculated using Civan et al. model and our developed model at the concentration (0.8% polymer) are approximately the same which is shown in Table 6 and have good agreement with that particular experimental data. But, the developed model presents the same values of coefficients and activation energy for whole experimental study and all data are fitted in that mathematical equation. Hence, it may be more realistic in nature.

Temperature (°C) |

Experimental gelation time (hrs.) |

Theoretical gelation time (hrs.) by Arrhenius type equation {Civan et al. [18]} ln (t) = 8288.47281/T (°K) − 17.63044 (0.8 wt% PHPA, 0.5 wt% HMTA and 0.3 wt% hydroquinone) |

Theoretical gelation time (hrs.) by Developed Model (0.8 wt% PHPA, 0.5 wt% HMTA and 0.3 wt% hydroquinone) |

|---|---|---|---|

| 80 | 312 | 343.66928 | 376.66426 |

| 90 | 207 | 180.07746 | 187.78207 |

| 100 | 101 | 97.68365 | 97.17542 |

| 110 | 50 | 54.70794 | 52.04664 |

| 120 | 32 | 31.55635 | 28.77554 |

8. Conclusion

- (1)

The gelation time of partially hydrolyzed polyacrylamide-hexamine-hydroquinone gel system decreases with increasing the cross linker concentration and temperature.

- (2)

On the basis of kinetics of gelation behavior the mathematical model for the partially hydrolyzed polyacrylamide-hexamine-hydroquinone gel system is the following:

() - (3)

The values of constants a0, a1, a2, a3, and a4 for this study are found to be 1.77831, −5.19301, −1.00564, −0.47246, and 8926.87612, respectively.

- (4)

The final mathematical model for the present study is as follows:

() - (5)

A values show good agreement between experimental and theoretical values of gelation time. This study reveals that the developed model may be used for the study of gelation behavior of partially hydrolyzed polyacrylamide-hexamine-hydroquinone gel system for its application in profile modification jobs.

Nomenclature

-

- CA:

-

- Concentration of partially hydrolyzed polyacrylamide (PHPA) (gm/liter)

-

- CB:

-

- Concentration of hexamine (HMTA) (gm/liter)

-

- CC:

-

- Concentration of hydroquinone (gm/liter)

-

- t:

-

- Gelation time (second)

-

- T:

-

- Temperature ( °K)

-

- k, k′, k′′:

-

- Reaction rate/proportionality constants

-

- CAo:

-

- Initial concentrations of polymer

-

- CBo:

-

- Initial concentrations of hexamine

-

- CCo:

-

- Initial concentrations of hydroquinone

-

- Ea:

-

- Activation energy

-

- R:

-

- Gas constant

-

- a0, a1, a2, a3 and a4:

-

- Constants

-

- a, b and c:

-

- Reaction order with respect to A, B, and C

-

- α, β and γ:

-

- Reactant of species A, B and C present in the reaction respectively.

Acknowledgment

The authors are very thankful to Council of Scientific and Industrial Research (CSIR), New Delhi, India for financial assistance to carry out the research work.