Deformation Properties and Fatigue of Bituminous Mixtures

Abstract

Deformation properties and fatigue performance are important characteristics of asphalt bound materials which are used for construction of pavement layers. Viscoelastic asphalt mixtures are better characterized via dynamic tests. This type of tests allows us to collate materials with regard to axle vibrations which lie usually in the range of 6 Hz–25 Hz for standard conditions. Asphalt modified for heat sensitivity in the range from −20°C to +60°C has significant impact on the overall characteristics of the mixture. Deformation properties are used as inputs for empirical mixture design, and fatigue performance of asphalt mixtures reflects the parameters of functional tests. Master curves convey properties of asphalt mixtures for various conditions and allow us to evaluate them without the need of time expensive testing.

1. Asphalt Binders and Asphalt Mixtures

Deformation properties, resistance to deformation, and fatigue performance of asphalt mixtures have a significant influence on operational performance of asphalt pavements. Within the pavement construction, the asphalt serves as a binder for mineral aggregate of surfacing layer. Asphalt is a bituminous material obtained as a residue of vacuum distillation process during the refining of crude oil [1]. Mechanical properties of asphalt mixture are mostly affected by the properties of applied asphalt binder. In regard to mixing process, asphalt binder must be fluid enough at high temperatures—about 160°C—to create homogenous coating of the aggregate. Local climate plays a role as the binder has to maintain prescribed stiffness at the highest summer temperature to resist rutting deformation, yet it has to remain flexible enough at low temperatures during the winter season [2].

The assessment of deformation properties is performed by means of dynamic impact test and fatigue life of particular asphalt mixture. Evaluation of fatigue life is based on resistance decrease or deformation increase in different binders and mixtures. Concurrently, the evaluation itself is performed in accordance with standard for measurement of complex modulus [3] and fatigue [4] of asphalt reinforced materials, that is, mixtures; these regulations represent realistic traffic-car axle during normal operation at the frequency from 6 to 25 Hz.

1.1. Asphalt Binder Laboratory Tests

2. Performed Testing

The comparison of rheological parameters η*, G′, and G′′ was performed for selected unmodified and polymer modified asphalt binders at the temperatures of 46°C–60°C (80°C). Rheological properties were determined and compared for unmodified bituminous binders B 50/70 and B 70/100 (Q8). Basic properties of tested materials are in Table 1. The composition of aggregate is equal for both mixtures, it is shown in Table 2.

| Type of binder | Unmodified binders | |

|---|---|---|

| B 50/70 | B 70/100 (Q8) | |

| Softening point (°C); STN EN 1427 | 46–54 | 43–51 |

| Penetration at 25°C (0,1 mm); STN EN 1426 | 50–70 | 70–100 |

| Mixture | Mixture 1 (A1) % | Mixture 2 (A2) % |

|---|---|---|

| B 70/100 (Q8) | PmB 70/100-83 | |

| Filer | 7,1% | |

| 0/2 mm | 29,3% | |

| 2/4 mm | 15,6% | |

| 4/8 mm | 22,6% | |

| 8/11 mm | 19,8% | |

| Binder | 5,6% | |

| Sum | 100,00% | |

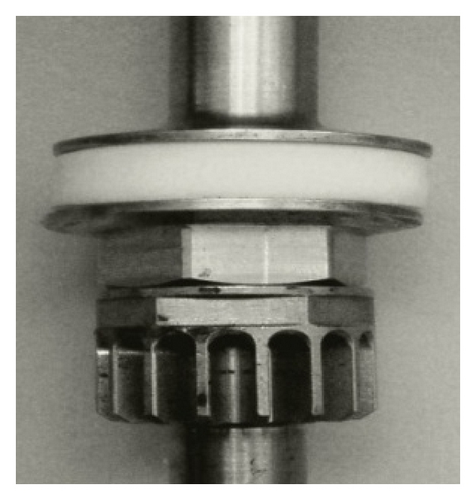

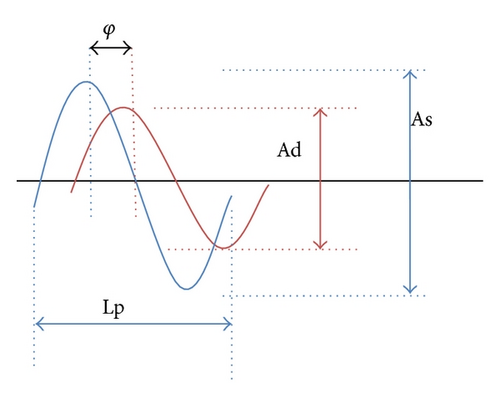

Measurements were performed on the oscillatory Physica Rheometer MCR301 with convection heating device CTD 450. The applied method was the frequency sweep test (FS). FS method uses parallel plate system—PP system: lower plate is stationary; upper plate performs oscillatory motion and thus creates a shear in the sample. The distance between the plates—shearing interval—is well defined (Figure 1).

FS test is performed at a constant temperature. This measurement method enables simultaneous monitoring of rheological parameters G′, G′′, and η* in the selected interval of angular frequencies [6]. Each test sample was placed between the two parallel plates with a diameter of 25 mm (PP25 system), with 1 mm distance from each other—shearing interval = 1 mm.

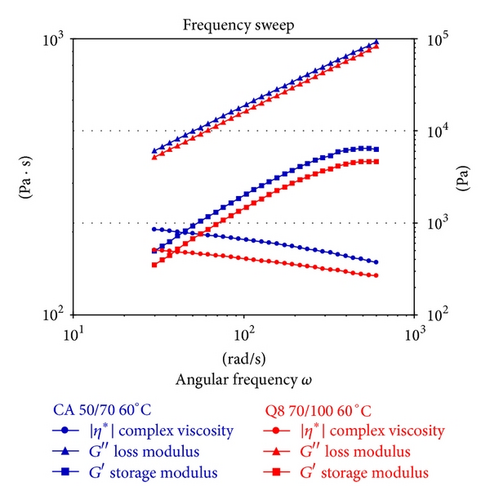

The trend of monitored rheological parameters G′, G′′, and η* in dependence on angular frequency is linear except for storage modulus G′ at angular frequencies 400–600 s−1 at 60°C (Figure 2). Except for the above mentioned case, the G′ and G′′ curves are nearly parallel. Ratio between viscous and elastic properties remains the same; this means that degradation which would be shown by changes in molecular weight—networking or macromolecular chains breaking—is not probable [6].

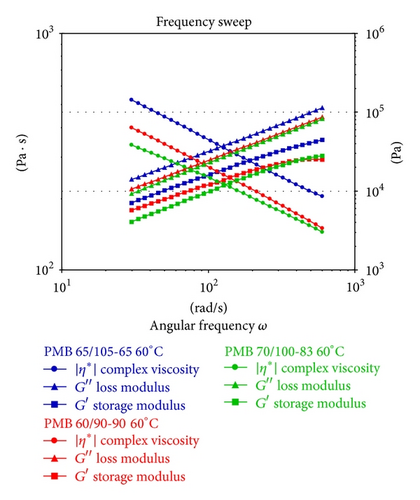

In addition, the modified binders were also tested. The chart curves expressing storage modulus G′ are losing their linearity at angular frequencies of 400–600 s−1. The sharp decrease of G′ denotes higher ratio between loss modulus G′′ and storage modulus G′, that is, damping factor. This points to degradation related to the loss of elasticity.

- (i)

polymer-modified binder achieves the highest values of evaluated rheological parameters G′, G′′, and η* in the considered interval of angular frequencies at the temperature of 60°C. The lowest values of rheological parameters were measured for unmodified binder Q8 70/100;

- (ii)

modified binders show more significant reduction in complex viscosity with the increase of angular frequency in comparison to unmodified binders;

- (iii)

according to the obtained results, from the set of tested binders, the modified binders are most suitable for heavy duty pavements in climate with strong temperature fluctuations.

In order to obtain required properties, asphalt binders are not used exclusively in the form of pure asphalt, that is, unmodified asphalt binders; instead, they can be modified by synthetic polymers. Polymer modified bitumen (PMB) has higher softening point and lower breaking point than unmodified ones. Therefore, it is recommended for construction of heavy duty pavements in climates with large temperature fluctuations [3–5].

2.1. Laboratory Tests of Asphalt Mixtures

An accurate assessment of the fatigue life of asphalt mixtures depends on the criteria used in the fatigue analysis [9].

Fatigue is reduction of strength of a material under repeated loading when compared to the strength under a single load [10]. The value ε6 = 1 · 106 cycles (in m/m) is the strain corresponding to 106 cycles [10].

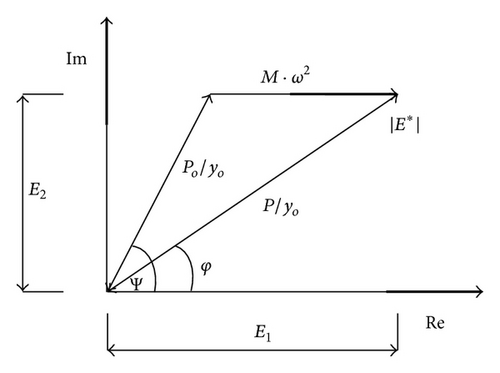

The tests of the complex modulus and fatigue performance were carried out in the laboratory of the Department of Construction Management of the University of Zilina (Figure 6). The equipment works with constant deviation. It is possible to change the frequency from 0.1 to 30 Hz and temperature for the tests from −20°C to +30°C.

Bending tests are used to ascertain the complex modulus and fatigue resistance of asphalt pavement surfacing materials. The two-point bending test on trapezoidal sample is arguably the most repeatable and reproducible bending test method detailed in the relevant EN 12697 directives [8, 10]. The samples were carefully stored on a flat surface protected from the sun at a temperature of <30°C to prevent distortion. The samples were measured with an accuracy of 0.1 mm.

In this test, the bottom of the sample is fixed and the free top is moved sinusoidally with constant displacement amplitude. The trapezoidal samples are tested simultaneously; they are subjected to constant strain amplitude at a selected frequency and temperature until the stiffness modulus decreases. Fatigue life of a sample is the number of cycles Ni,j,k corresponding to the conventional failure criterion at the set of test conditions k-temperature, frequency, and loading mode, for example, constant deflection level, or constant force level, and or any other constant loading condition. It is a number of load applications, Nf/50, during which the complex modulus decreases to half of its initial value [10].

3. Tested Mix Designs and Measurements Results

Complex modulus and fatigue performance were tested for two mix designs. The aggregate content and ratios stay the same for both mixtures. However, the 1st mixture (A1) contains generic asphalt binder B 70/100 (Q8) compared to the 2nd mixture (A2) which contains polymer modified bitumen PmB 70/100-83. Both mixtures can be applied for the AC 11 pavement layer. In general, pavement performance properties are affected by the bitumen binder properties; it is known that the conventional bitumen has a limited range of rheological properties and durability that are not sufficient enough to resist pavement distresses [11]. Therefore, the testing was aimed to show us the magnitude of impacts on mixture properties attained through binder modification.

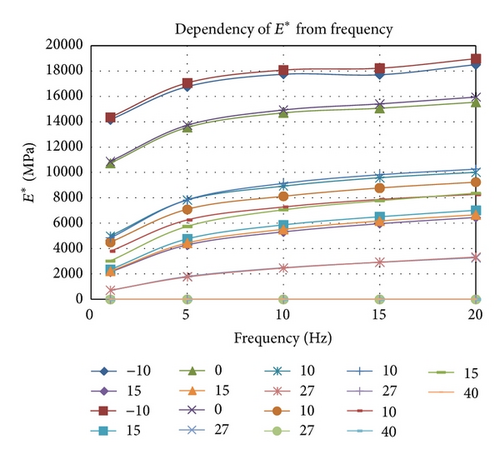

3.1. Results: Complex Modulus

-

= 8364,7 MPa,

-

= 5938,0 MPa.

| Temperature (°C) | Complex modulus E* (MPa) | ||||

|---|---|---|---|---|---|

| Frequency (Hz) | |||||

| 1 | 5 | 10 | 15 | 20 | |

| −10 | 14158 | 16769 | 17744 | 17700 | 18503 |

| −10 | 14351 | 17063 | 18073 | 18219 | 18970 |

| 0 | 10727 | 13551 | 14698 | 15062 | 15538 |

| 0 | 10874 | 13723 | 14927 | 15407 | 15943 |

| 10 | 4991 | 7827 | 8923 | 9586 | 10009 |

| 10 | 4494 | 7098 | 8122 | 8778 | 9233 |

| 10 | 4832 | 7844 | 9138 | 9818 | 10260 |

| 10 | 3786 | 6256 | 7276 | 7873 | 8272 |

| 15 | 3021 | 5749 | 7055 | 7773 | 8366 |

| 15 | 2151 | 4284 | 5315 | 5958 | 6451 |

| 15 | 2339 | 4759 | 5867 | 6506 | 7014 |

| 15 | 2216 | 4436 | 5515 | 6173 | 6660 |

| 27 | 695 | 1798 | 2487 | 2915 | 3275 |

| 27 | 713 | 1755 | 2460 | 2922 | 3327 |

-

= 5844 MPa,

-

= 4032 MPa.

In addition, deformation properties were verified for a third mix design A3rec, which is prepared from mixture A2 with 40% of the aggregate made of asphalt recycled material—recycle aggregate. For the A3rec mix design, less favourable deformational properties were ascertained. These were probably the consequence of brittleness of old asphalt in the new mixture and altered grain distribution curve as a result of added recycled material.

Complex modulus was measured by ε < 50 · 10−6 (microstrains). The reason to introduce this mix design to the test was that as natural aggregate sources are becoming depleted due to high demand in road construction and as the amount of disposed waste material keeps increasing, researchers are exploring the use of alternative materials which could preserve natural sources and save the environment [12].

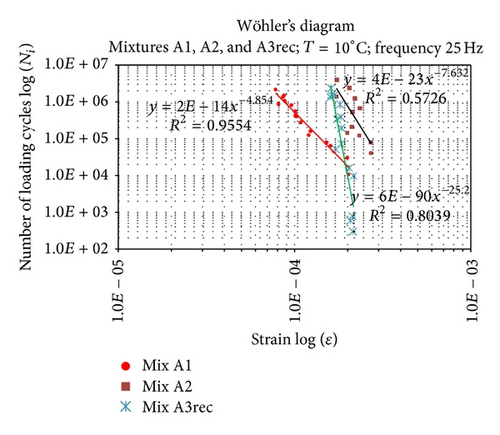

3.2. Results: Fatigue Performance

- (a)

ε6,

- (b)

Δε6,

- (c)

slope l/b,

- (d)

estimated residual standard deviation sN,

- (e)

correlation coefficient r2.

- (i)

the estimation of the strain at 106 cycles (10),

- (ii)

the estimation of the residual standard deviation sN (11),

- (iii)

the quality index Δε6 (12),

()()()

| Mix. | Temp. (°C) |

Freq. (Hz) |

ε6·106 (microstrain) | Ni (cycles) | b (—) | r2 (—) | sN | Δε6 | Category |

|---|---|---|---|---|---|---|---|---|---|

| A1 | +10 | 25 | 87,44 | 10908–2156738 | −0,2060 | 0,9554 | 0,1437 | 4,61E − 10 | ε6-80 |

| A2 | +10 | 25 | 193,10 | 40500–2382028 | −0,1310 | 0,5726 | 0,4481 | 4,41E − 09 | ε6-190 |

| A3rec | + 10 | 25 | 166,38 | 300–2369414 | −0,0397 | 0,8039 | 0,6119 | 1,24E − 09 | ε6-60 |

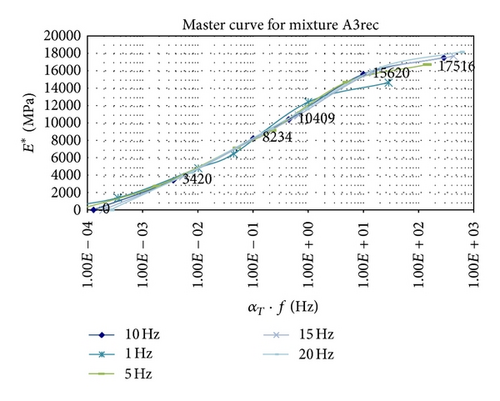

4. Evaluation: Master Curves

The advantage of master curves is that they allow the evaluation of properties of asphalt mixtures for different temperatures and frequencies with lower number of tests—recomputed values that express deformation properties of asphalt mixtures. The master curves convey the changes of complex modulus induced by temperatures affecting the pavement during its life span.

Figure 9 shows the master curves for mixture A3rec. We can observe the changes of complex modulus at different temperatures and the frequencies of excitation force—continuous lines. Discrete values in Figure 9 show the change in complex modulus at a constant temperature but at various frequencies of the excitation force.

5. Conclusions

According to the performed measurements, we ascertained that the mixture A1 with unmodified binder has superior deformation properties (E*), while the modified binder mixture A2 has superior fatigue life parameter (ε6). Asphalt, from the viewpoint of fatigue parameters, has a paramount influence on asphalt mixtures used for construction of pavement surface layers. Deformation characteristics and fatigue of asphalt binder influence normatively prescribed characteristics of pavement layers. Evaluated asphalts have varying complex modulus values in dependence on temperature. In spite of the fact that modified asphalt has higher values of shear modulus, the deformation properties are inferior, whereas fatigue life is superior. This knowledge was confirmed by measurements of other mixtures. The empirical mixture design methods usually use deformation properties; fatigue life characteristics are pivotal for functional testing. All three mixtures are satisfactory from the viewpoint of physicomechanical properties. Design of asphalt bound materials for pavement layers is empirical and utilizes deformation properties like complex modulus. However, for functional tests, fatigue life characteristic (ε6) is more important. For different values of deformation properties and fatigue life, it is pivotal that the designed mixture is evaluated for required bearing capacity and resiliency against climate conditions.

Measurements show that superior modified asphalt mixture is defined by auspicious fatigue parameters. Deformation properties and fatigue life were validated also on mixture A3rec. The recycled aggregate was a milled-out pavement surfacing material. The A3rec mixture has lower fatigue life parameter, the angle of regression line is more acute, and the value of proportional deformation for one million cycles (ε6) is lower. Despite this, the mixture is applicable for pavement construction layers and can be utilized for subbase layers.

Acknowledgments

The research was supported partially by Scientific Grant Agency of Ministry of Education, Science and Sport of Slovak Republic and Slovak Academy of Science Grant VEGA no. 1/0485/12.