Effect of Crack Healing of SiC according to Times of SiO2 Colloid Coating

Abstract

Crack healing behavior of SiC ceramics with large crack width has been studied as a function of coating and heat treatment. The SiO2 colloid coating was carried out on two types: hydrostatic pressure coating and roll coating. The crack healing was one hour at 1173 K in air. The crack part formed SiO2 oxides until the critical times by a hydrostatic pressure method. The crack does not anymore heal if it exceeds the critical times. The crack part and the base part have many O components and Si components regardless of the times of coating and heat treatment. The combined hydrostatic and rolling coating method did not have nearly an effect on crack-healing for large crack width over 1.4 μm. The study for more effective healing of a large crack width must be carried out in the future.

1. Introduction

Due to a combination of unique properties, silicon carbide (SiC) ceramics find extensive application in several fields of engineering as materials for advanced energy systems, such as high-performance combustion systems, fuel-flexible gasification systems, fuel cell/turbine hybrid systems, nuclear fusion reactors, and high temperature gas-cooled fission reactors [1–4]. The SiC/SiC composite material is especially under study as the first wall material of the blanket because of its excellent heat resistance and low activation property [5–9]. Many studies are being conducted in order to solve the brittle nature of ceramics [10–14]. (a) Non-destructive inspection with very high ability, (b) Increase fracture toughness by fiber-reinforcement and decrease the sensitivity to crack, (c) Introduce self-crack-healing ability. It has also been reported that the cracks formed by machining were healed completely [15, 16]. In particular, some results suggest that the cracks in silicon carbide, once healed, surprisingly become even stronger than the original silicon carbide. They conclude from the crack length that it was an important factor of crack healing by oxidation in silicon carbide [17]. Furthermore, there has been no clear explanation about the effect of SiO2 colloid coating for crack.

In this paper, the SiC ceramic with sintering additive Y2O3 and Al2O3 was prepared. We observed the effect of coating method and coating times in relation to crack healing in SiC ceramic and examined the effect of the crack width for crack healing.

2. Materials and Test Methods

Commercially available SiC (Ultrafine grade, Ibiden Co., Japan), Al2O3 (AKP-700, Sumitomo Chemical Co. Ltd., Japan), and Y2O3 (CI Chemical Co., Japan) were used as the starting materials. The mean particle sizes of the SiC, Al2O3, and Y2O3 powders were 0.27 μm, 0.1 μm, and 33 μm, respectively.

The SiC ceramic was prepared using a mixture of 90 wt.% SiC powder and sintering additives (Al2O3 + Y2O3 = 10 wt.%). Individual batch was milled in isopropanol for 24 hours using SiC ball (φ5). The mixture was placed in a 363 K furnace to extract solvent and to make a dry powder mixture. The dry powder was then passed through a 106 μm sieve. The mixtures were subsequently hot-pressed in N2 gas for one hour via hot pressing conducted under 35 MPa at 2053 K.

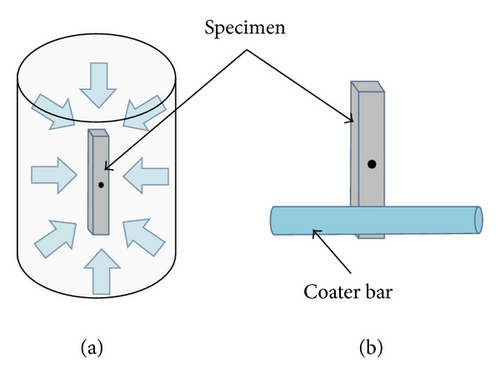

For crack healing test, the crack was made in the center of the polished face of the specimen by a Vickers indentation at a load of 24.5 N to 196 N in air. This loading introduced a semicircular crack(2c) of 100 μm to 1000 μm in diameter. The crack healing by SiO2 nanocolloid coating has a large effect on fracture strength. The colloid coating was carried out at two types of method, hydrostatic pressure coating and roll coating like Figure 1. Hydrostatic pressure coating (a) put the specimen in a solution of a sealed container and was maintained for 10 min at a pressure of 58.8 MPa. The roll coating (b) coated the solution on the surface through a rolling process using a coater bar. The crack healing was one hour at 1173 K in air. Cooling was spontaneous in the furnace. In order to analyze the effect of coating and heat treatment, coating and heat treatment was carried out up to three times. To investigate the crack-healed surface and the component analysis of crack healing substances, SEM (scanning electron microscope), SPM (scanning probe microscope), and EDX (energy dispersive X-ray) analyses were used, respectively.

3. Test Results and Discussion

3.1. The Effect of Hydrostatic Pressure Coating

All surface crack of SiC ceramic could heal in case of that is smaller than the crack width of 1.4 μm and the crack length of 450 μm [17]. In order to investigate the healing effect for larger crack width, this study applied hydrostatic pressure method as a way to penetrate the SiO2 nanocolloid. The cracks are healed by being filled with amorphous silica that is produced by the oxidation of silicon carbide [15, 18].

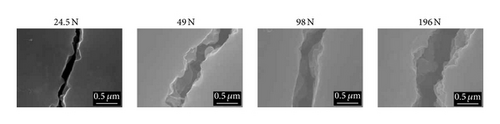

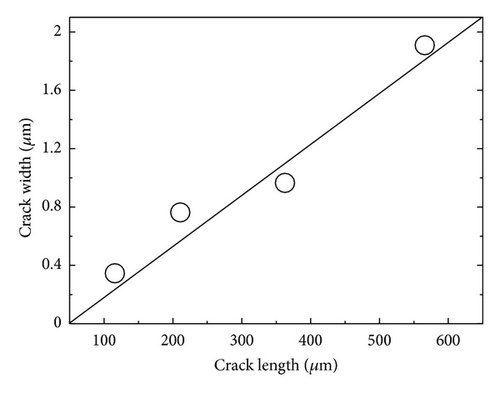

Figure 2 shows the relationship between crack and Vickers load. Figure 2(a) shows the relations of crack width and Vickers load. Figure 2(b) shows relations of crack length and crack width. The crack width gradually became wider according to the increase of crack length; that is, the Vickers indentation load increased. As the Vickers indentation load increased, crack length and crack width also increased linearly.

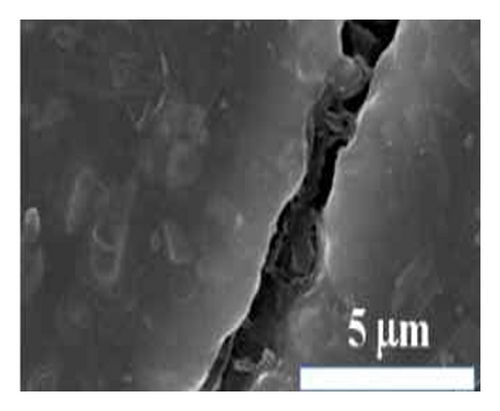

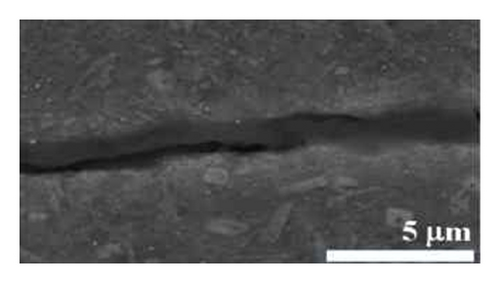

Figure 3 is surface crack before and after heat treatment. This infiltrated the SiO2 nanocolloid at crack by hydrostatic pressure method. Figure 3(a) shows the crack width of about 2 μm. Figure 3(b) shows the crack shape of crack healing with the hydrostatic pressure coating of one time. Figure 3(b) was difficult to expect the crack healing with coating of one time. Though the crack part was made of cross link, the crack did not heal completely. Therefore, in order to infiltrate in the crack part with SiO2 nanocolloid, the coating and heat treatment was repeated. Figure 3(c) was carried out the coating of two times by the hydrostatic pressure method. The crack healing was not perfect, but Figure 3(c) became more healing than Figure 3(b). Figure 3(d) with the same process of three times did not increase more the amount of SiO2 oxides. The surface condition is fairly rough. Therefore, if the coating is repeated until the critical times by hydrostatic pressure, SiO2 oxide can be formed densely. However, if it exceeds the critical times, it was judged that crack does not anymore heal.

3.2. The Effect of Combined Hydrostatic Pressure Coating and Roll Coating

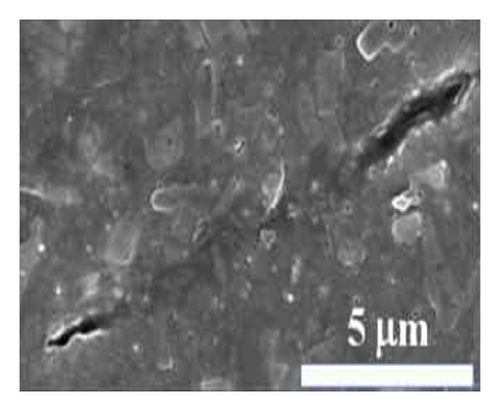

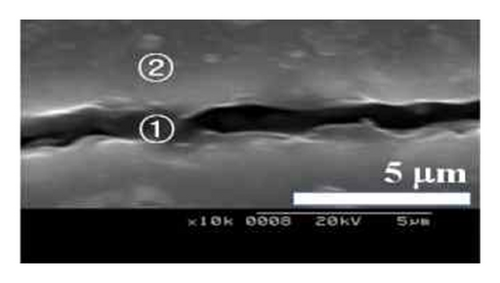

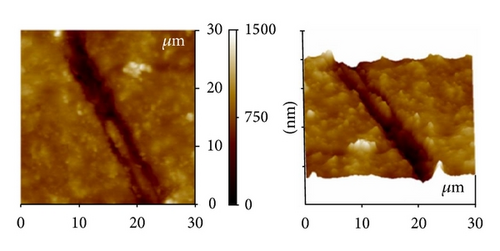

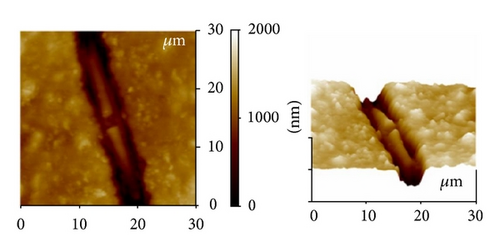

Figure 4 was coating by the combination of hydrostatic pressure method and rolling method, the crack width is about 1.8 μm. In Figure 4(a), though the reduction of the crack width by SiO2 oxides was significantly not observed, the crack inside formed the cross link and the width was reduced. Figure 4(b) still has a crack, but crack have been more healing than that of one time. But Figures 4(b) and 4(c) did not show much difference.

Table 1 shows the surface elemental analysis of crack healing part of Figure 3. In Figure 4, ① and ② indicate the crack part and the base part, respectively. The crack part and the base part have many O components and Si components regardless of the times of coating and heat treatment, respectively. And the amount of O increased and the amount of Si decreased according to the increase of the number of times. This is the cause that the crack and base parts have defective by formation of the oxides due to excessive heat treatment. Therefore, if the crack width is the wider, the crack healing also has hardly an effect by repeated coating and heat treatment in a variety of ways.

| Condition | Element | ||||

|---|---|---|---|---|---|

| O (wt.%) | Al (wt.%) | Si (wt.%) | Y (wt.%) | ||

| (a) One time | ① | 24.91 | 2.32 | 72.54 | 0.24 |

| ② | 13.67 | 3.31 | 82.79 | 0.23 | |

| (b) Two times | ① | 57.02 | 0.33 | 41.53 | 1.11 |

| ② | 34.92 | 2.72 | 59.66 | 2.69 | |

| (c) Three times | ① | 56.54 | 0.40 | 42.02 | 1.04 |

| ② | 34.60 | 2.24 | 60.25 | 2.91 | |

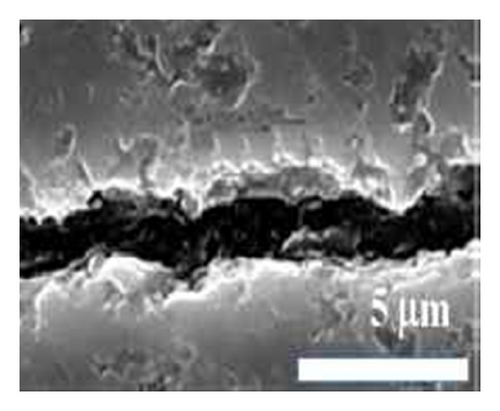

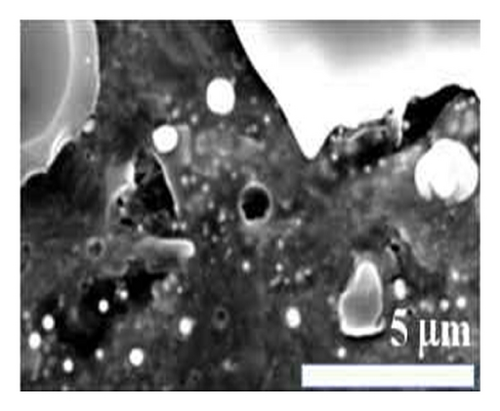

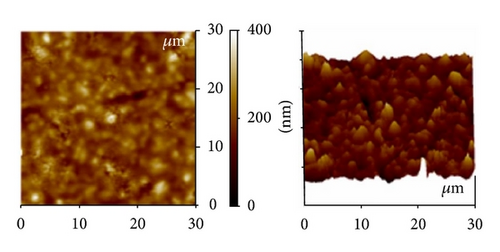

The formation of the SiO2 oxides at crack part was observed by SPM. Figure 5 shows 1.0, 1.08, and 4.05 μm of crack widths, respectively. Figure 5(a) has been completely crack healed for one time. However, Figures 5(b) and 5(c) can see that SiO2 oxides were also locally formed at crack part for three times. It can be seen that this has not been made completely crack healed compared to Figure 5(a). Therefore, it was determined that the hydrostatic and rolling coating does not have a large effect on crack healing for SiC ceramics with large crack width. For the more effective healing of a large crack width, the study on width and depth of crack and coating method of SiO2 nanocolloid solution must be carried out in the future.

4. Conclusions

The crack healing behaviors of SiC ceramic were investigated the effect according to the coating method, the times of coating, and heat treatment for the crack width. If the coating is repeated until the critical times by hydrostatic pressure method, crack part formed SiO2 oxides. However, if it exceeds the critical times, the crack does not anymore heal. The crack part and the base part have many O components and Si components regardless of the times of coating and heat treatment, respectively. And the amount of O increased and the amount of Si decreased according to increase of the times. The combined hydrostatic and rolling coating method does not have a large effect on crack healing for SiC ceramics with large crack width over 1.4 μm. The study for the more effective healing of a large crack width must be carried out in the future.

Acknowledgment

This work was supported by a Research Grant from Pukyong National University (2013 year: C-D-2013-0508).