Controlled Roof Collapse during Secondary Mining in Coal Mines

Abstract

The problem considered is an investigation of the possible collapse of the roof between the pillar next to be mined in secondary coal mining and the first line of pillar remnants called snooks. The roof rock between the pillar, which is the working face, and the snook is modelled as an Euler-Bernoulli beam acted on at each end by a horizontal force and by its weight per unit length. The beam is clamped at the pillar and simply supported (hinged) at the snook. The dimensionless differential equation for the beam and the boundary conditions depend on one dimensionless number B. We consider the range of values of B before the displacement and curvature first become singular at B = B1. The model predicts that for all practical purposes, the beam will break at the clamped end at the pillar. The failure of the beam for values of B greater than B1 is investigated computationally.

1. Introduction

We consider the challenge posed by coal mine pillar extraction [1, 2]. Secondary mining involves revisiting a mine and extracting coal from the pillars. The mining of these pillars commences from the area furthest away from the point of entry of the mine. This exercise involves cutting the existing pillars into smaller pillars called snooks. As each section is mined, the roof must collapse in a controlled manner in order to pose no safety risk to those miners operating underground. We analyse the behaviour of the roof of the mine between the pillar next to be mined and the first line of snooks. This is the work area and must be safe for the miners.

2. Model

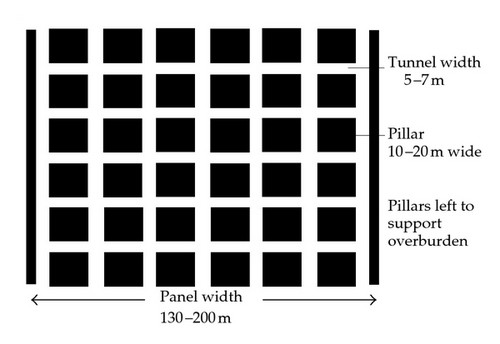

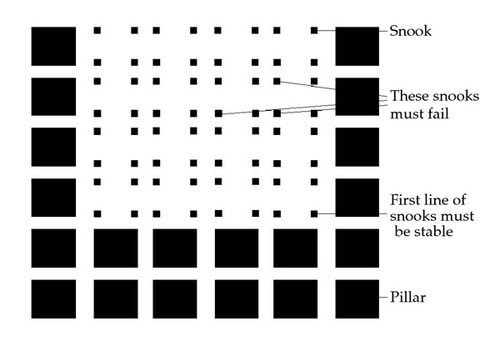

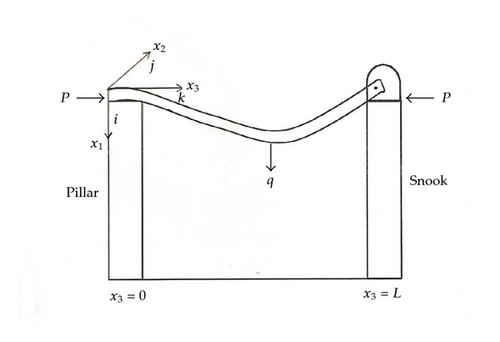

In Figure 1, a mining panel in shown prior to pillar extraction. The tunnels are excavated in coal which are approximately 5 m to 7 m wide. They are excavated in a fixed pattern crossing at right angles creating a checker board layout. The coal between the tunnels forms the pillars which support the overburden rock. The width of the pillars is approximately 10 m to 20 m wide and is a function of the depth of the mine. The height of the tunnels ranges from 3 m to 4 m. Secondary mining is carried out in two stages. In the initial stage, approximately 5 to 10 pillars are removed and the roof is left to collapse. This stage is modelled in [2]. Following this, adjacent pillars are mined and smaller sections are left to collapse. The purpose of this paper is to model the second stage in the extraction process. Figure 2 shows the snooks after pillar extraction. The pillars are cut to leave four snooks, approximately 2 m, one at each corner. The snooks have to be small enough to fail when the miners are a safe distance (about the width of a pillar) from the working face but they have to be large enough to be stable right next to the unmined pillars.

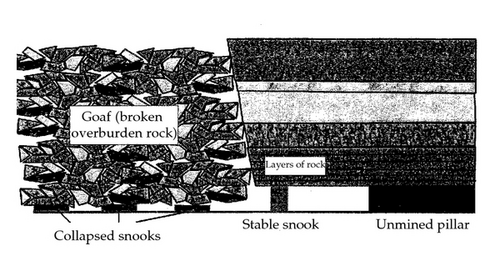

The roof consists of horizontal layers of rock of approximate thickness 0.5 m to 20 m, as shown in Figure 3. The Euler-Bernoulli beam equation can be used to describe the horizontal layers of rock in the roof. The use of the Euler-Bernoulli beam equation assumes that the roof is thin compared with its horizontal extent and that only the horizontal direction is important. The horizontal extent of the beam is the distance from the next pillar to be mined to the first line of snooks which is the width of the tunnel and is approximately 6 m. The ratio of the thickness of the beam to its length ranges from about 0.1 to about 3 and thus for the theory to apply the thickness of the beam should not exceed 2 m. The width of the mining panel ranges from about 130 m to 200 m. If we take the width of the mining panel as the width of the beam then the ratio of the length of the beam to its width varies from about 0.05 to 0.03. Dependence of the variables in the direction of the width of the beam can therefore be neglected. The use of the Euler-Bernoulli beam is therefore justified for a beam of thickness less than about 2 m.

In this paper we will investigate if roof collapse can occur between the next pillar to be mined and the first line of snooks when these snooks are stable and do not fail. In order to achieve this, we consider the roof of the mine to be clamped at a pillar while at the adjacent snook, the roof is simply supported or hinged. We consider the roof to be simply supported at the snook since as secondary mining takes place, disturbances in the rock mass and also the roof collapse due to the failure of the neighbouring snooks could change the roof structure in the region where the snooks support the beam [3]. We model this by assuming that at the snook the beam is no longer clamped and use instead that the beam is simply supported or hinged at the snook. We also consider the behaviour of this small section of the roof when a disturbance, such as a seismic event, causes a sudden increase in the horizontal force acting at each end of the section of the roof.

Previous work on roof failure due to the failure of snooks is reviewed in [5]. Useful texts are [6–9].

3. Derivation of the Differential Equation

The combined beam and strut is shown in Figure 4. We will use the notation and conventions of Segal and Handelman [10]. The coordinate axes are defined in terms of the undeformed beam. The x1- and x2-axes are along the axes of principle moments of inertia of the cross-section of the beam with the x1-axis vertically downwards. The x3-axis is horizontal and passes through the centroid of each cross-section. The origin of the coordinate system is at the centroid of the cross-section of the left end of the beam. Unit vectors, i, j, and k are directed along each coordinate axis. For simplicity, we denote x3 by x.

4. Mathematical Solution

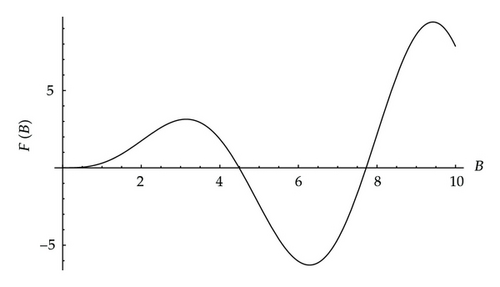

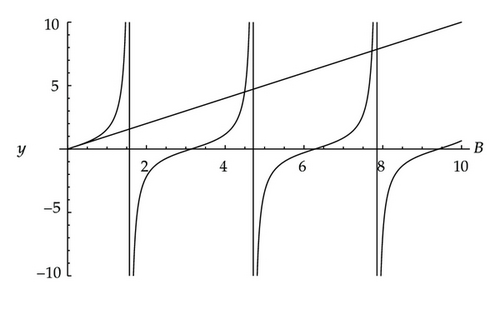

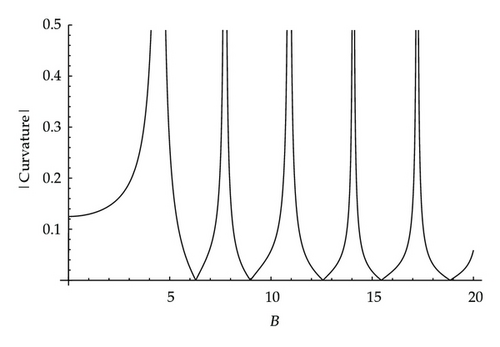

At these values of B, the displacement becomes infinite. Since B = 4.4934 is the first nonzero value of B for which the displacement becomes singular, our primary concern is in the interval 0 < B < 4.4934. In the next section, we discuss the solution (4.3) for the displacement and calculate the curvature of the beam which determines the location at which the beam will break.

For a beam with both ends clamped [2], the displacement becomes singular for B = 2nπ where n = 1,2, 3, …. Comparing the first points at which the displacement becomes singular in the two models, we note that 4.4934 < 2π = 6.2832. Small displacements and small derivatives are used in the derivation of the Euler-Bernoulli beam equation. The theory therefore breaks down in the neighbourhood of the points x = Bn where the curvature has singular behaviour. A full nonlinear theory would need to be used in these regions. However, the beam will break when its tensile strength is exceeded which could be well before the singularities in the curvature are reached.

5. Analysis of the Results

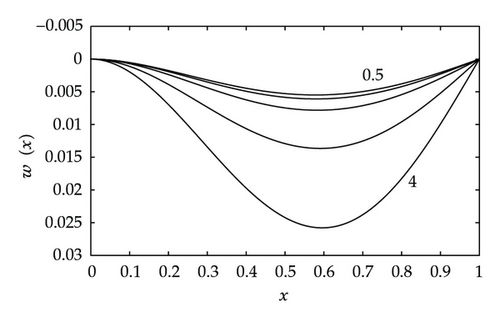

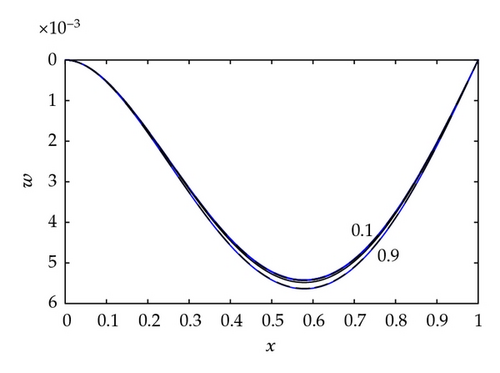

Graphs of the displacement w(x) for values of the beam number, B, in the range 0 < B < 4.4934 are shown in Figure 7. The displacement has two stationary points which are located at x = 0 and at an interior point.

The displacement is nonzero when B = 0 because of the weight per unit length, q, acting on the beam. Graphs of the displacement w(x) for small values of B are presented in Figure 8. From the graphs, we can see that (5.1) is a good approximation for the displacement for B ≤ 0.9.

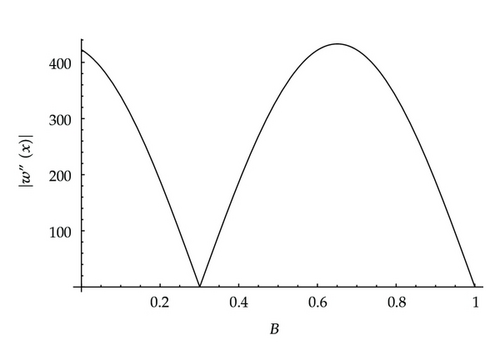

Graphs of the magnitude of the curvature for a range of values B < B1 are given in Figure 9.

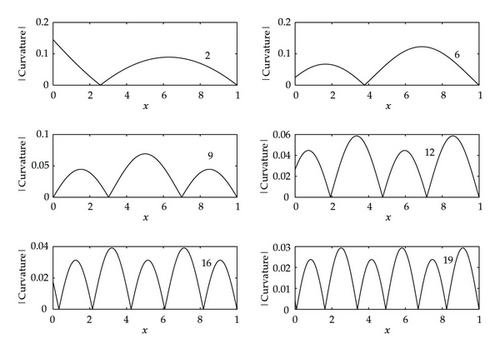

The curvature vanishes at x = 1 because the end x = 1 is simply supported. Denote by x1 the position of the local maximum of the magnitude of the curvature when 0 < x < 1. Since the sign of the curvature at x = 0 is opposite to that at x = x1, the curvature must vanish at a point, say x2, where 0 < x2 < x1. We can deduce from Figure 9 that x2 does not change significantly as B is increased. For the range of values used in Figure 9, the magnitude of the curvature at x = 0 is greater than at x = x1. We will investigate later as to whether this is always the case.

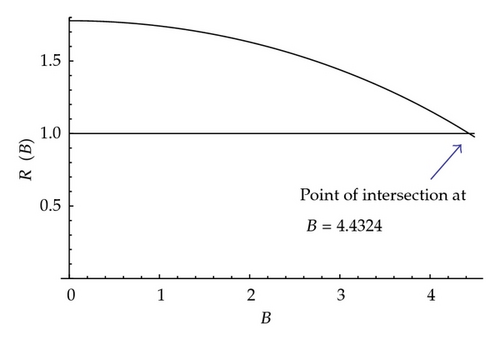

For the range of values of B considered in Figure 9, R(B) > 1. However, as B approaches the first singular value B = B1 = 4.4934, the ratio R approaches and may exceed unity. This is illustrated in Figure 10 where B = 4.4930. We now investigate analytically the ratio R(B) for 0 ≤ B ≤ B1.

The graph of R(B) against B for 0 ≤ B < B1 is presented in Figure 11. The analytical results for B → 0 and B → B1 agree with the graph. In comparison when the two ends of the beam are clamped, R(B) > 1 for 0 ≤ B < B1 and R(B1) = 1, where B1 = 2π.

6. Numerical Estimates

As the beam becomes more fractured with time the Young’s modulus E will decrease and Lc will decrease.

Table 1 summarizes numerical estimates for Lc for a beam with one end clamped and the other simply supported. In a coal mine the distance between the pillars ranges from 5 m and 7 m. When the bending moment or curvature exceeds the tensile strength of the beam the roof will collapse. This may occur for beam lengths L less than Lc since Lc provides only an upper limit on the length of the beam for collapse.

| h(m) | H = 120 m Lc(m) |

H = 500 m Lc(m) |

|---|---|---|

| 0.1 | 9.26 | 4.54 |

| 0.2 | 18.53 | 9.08 |

| 0.3 | 27.80 | 13.62 |

| 0.4 | 37.06 | 18.16 |

| 0.5 | 46.33 | 22.7 |

| 0.6 | 55.60 | 27.23 |

| 0.7 | 64.86 | 31.77 |

| 0.8 | 74.12 | 36.31 |

| 0.9 | 83.39 | 40.85 |

| 1 | 92.65 | 45.39 |

If Lc is reduced below about 6 m due to an increase in P then a roof collapse may occur.

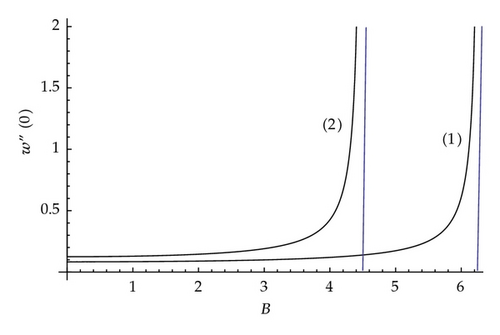

In Figure 12 the graphs of and are plotted against B. We see that when the end x = 1 is simply supported the curvature at x = 0 is greater for a given value of B than when it is clamped. The tensile strength of the beam will be exceeded at the end x = 0 for lower values of B when the end x = 1 is simply supported than when it is clamped. The simply supported boundary condition has the effect of increasing the bending moment at the end x = 0 and causing the beam to break at x = 0 for lower values of B.

7. Values of the Beam Number B Greater Than B1

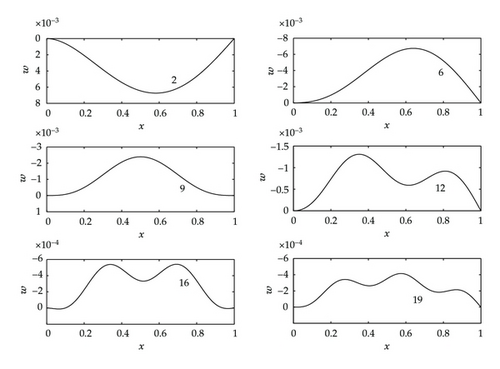

Consider first the displacement. The displacement for values of B in the first interval, I1, was considered in Figure 7. In Figure 14 graphs of the displacement for representative values of B in the intervals, I1 to I6, are presented. We see that as B increases through the intervals the number of turning points increases and that the displacement can take negative values beyond interval I1. The amplitude of the displacement will depend on how close B is to the singular end points of the interval.

Consider next the magnitude of the curvature. In Figure 9 graphs of the magnitude of the curvature were plotted against x for values of B in the first interval I1. In Figure 15, graphs of the magnitude of the curvature are plotted for the same representative values used to plot the displacement in Figure 14. For the values of B and n considered, the number of local maxima of the magnitude of the curvature in the nth interval In is n. The greatest local maximum is not at the end x = 0 but at interior points. There may be several points for which the magnitude of the curvature has the maximum value. If the bending moment exceeds the tensile strength the beam will break at these interior points. The magnitude of the curvature depends on how close B is to the singular endpoints of the interval. Since B is proportional to the length of the beam L we see from Figure 13 that if the value of B is in the range outside of B1 then a longer beam could be less susceptible to failure than a shorter beam. This could be associated with the beam taking on a higher mode of bending. We see from Figure 14 that the displacement can be negative. For this to be possible in practice the beam would have to be detached sufficiently from the layers above.

8. Conclusions

We investigated the possible roof collapse between the next pillar to be mined and the first line of snooks by modelling the roof as an Euler-Bernoulli beam. The beam was simply supported (hinged) at the snook and clamped at the pillar which was the working face. The model contained one dimensionless number—the beam number B.

Numerical estimates obtained for the critical length Lc are comparable to the expected distance between pillars which in a coal mine is 5–7 m thus making the model credible. The model also predicts that the roof may collapse at the clamped end at the pillar for 0 < B < 4.4324. For the range 4.4324 < B < B1 = 4.4934, the model predicts that the roof may collapse at an interior point closer to the snook than to the pillar where the magnitude of the curvature attains its maximum value. However, this range contributes only 1.36 percent of the range [0, B1] and since it is likely that the threshold of the stress would have been exceeded for values of the beam number below B = 4.4324, for all practical purposes, the beam will break at the clamped end if the threshold of its stress is exceeded. It will therefore break at the pillar which is the working face. However, the model showed that it is not necessary for the beam to break at the clamped end. The beam may break at interior points. In I1, the interior point is unique for a given value of B. Other boundary conditions would need to be considered and analyzed in order to determine whether the beam can collapse at an interior point for practical values of B.

From Figure 12 we deduced that a beam which is simply supported (hinged) at the snook produces a larger bending moment at the pillar (where it is clamped) than a beam which is clamped at the snook. The beam will break at a lower value of the beam number when it is hinged at the snook.

The displacement and curvature become infinite at the zeros of F(B) defined by (4.4) which divides the value of B into intervals. We considered mainly the first interval 0 ≤ B ≤ B1. However, as the snooks fail B can increase discontinuously by finite amounts and may take values in the higher intervals. A preliminary computational investigation was undertaken of the displacement and curvature for values of B in these intervals. It was found that the displacement can take negative values. In the nth interval the magnitude of the curvature had n local maxima. The maximum value of the magnitude of the curvature did not in general occur at the pillar but occurred instead at interior points. If the tensile strength of the beam is exceeded the beam could break at several interior points.

In practice, roof bolts are installed [12].

Acknowledgments

The problem of pillar extraction in coal mines was submitted to the Mathematics in Industry Study Group 2011 (MISG) at the University of the Witwatersrand, Johannesburg. The author thanks the referees for their valuable comments which improved this paper greatly. The author thanks Matthew Woolway, University of the Witwatersrand, Johannesburg, for assisting in creating the diagrams. The author would like to express gratitude and appreciation to Professor Nielen van der Merwe and Dr. Halil Yilmaz of the School of Mining Engineering, University of the Witwatersrand, for submitting the problem. The author would particularly like to acknowledge that she has profited greatly from the discussions held with Professor Nielen van der Merwe. The author would like to acknowledge Professor Colin Please of the University of Southhampton, England, who formulated the model for pillar extraction and roof collapse at the MISG. The author thanks Professor David Mason for his valuable comments, advice, and encouragement while she was writing this paper.