Flow and Heat Transfer of Cu-Water Nanofluid between a Stretching Sheet and a Porous Surface in a Rotating System

Abstract

The aim of the present paper is to study the flow of nanofluid and heat transfer characteristics between two horizontal plates in a rotating system. The lower plate is a stretching sheet and the upper one is a solid porous plate. Copper (Cu) as nanoparticle and water as its base fluid have been considered. The governing partial differential equations with the corresponding boundary conditions are reduced to a set of ordinary differential equations with the appropriate boundary conditions using similarity transformation, which is then solved analytically using the homotopy analysis method (HAM). Comparison between HAM and numerical solutions results showed an excellent agreement. The results for the flow and heat transfer characteristics are obtained for various values of the nanoparticle volume fraction, suction/injection parameter, rotation parameter, and Reynolds number. It is shown that the inclusion of a nanoparticle into the base fluid of this problem is capable of causing change in the flow pattern. It is found that for both suction and injection, the heat transfer rate at the surface increases with increasing the nanoparticle volume fraction, Reynolds number, and injection/suction parameter and it decreases with power of rotation parameter.

1. Introduction

The fluid dynamics due to a stretching sheet are important from theoretical as well as practical point of view because of their various applications to polymer technology and metallurgy. During many mechanical forming processes, such as extrusion, melt-spinning, cooling of a large metallic plate in a bath, manufacture of plastic and rubber sheets, glass blowing, continuous casting, and spinning of fibers, the extruded material issues through a die. Provoked by the process of polymer extrusion in which extradite emerges from a narrow slit, Crane [1] first analyzed the two-dimensional fluid flow over a linearly stretching surface. Later, this problem has been extensively studied in various directions, for example, for non-Newtonian fluids, porous space, and magneto-hydrodynamics [2–5]. It is worth mentioning that, in recent years, interests in flow and heat transfer through porous media have grown considerably, due largely to the demands of such diverse areas such as geophysics, chemical and petroleum industries, building construction, and nuclear reactors [6, 7]. There are very few studies in which authors have considered the channel flow. Borkakoti and Bharali [8] studied the two-dimensional channel flows with heat transfer analysis of a hydromagnetic fluid where the lower plate was a stretching sheet. The flow between two rotating disks has many important technical applications such as in lubrication. Keeping this fact in mind Vajravelu and Kumar [9] studied the effects of rotation on the two-dimensional channel flows. They solved the governing equations analytically and numerically. Fluid heating and cooling are important in many industries fields such as manufacturing and transportation. Effective cooling techniques are absolutely needed for cooling any sort of high-energy device. Common heat transfer fluids such as water, ethylene glycol, and engine oil have limited heat transfer capabilities due to their low heat transfer properties. In contrast, metals thermal conductivities are up to three times higher than the fluids, so it is naturally desirable to combine the two substances to produce a heat transfer medium that behaves like a fluid but has the thermal conductivity of a metal.

Recently, due to the rising demands of modern technology, including chemical production, power station, and microelectronics, there is a need to develop new types of fluids that will be more effective in terms of heat exchange performance. Nanofluids are produced by dispersing the nanometer-scale solid particles into base liquids with low thermal conductivity such as water, ethylene glycol, oils, etc. The term “nanofluid” was first coined by Choi [10] to describe this new class of fluids. The characteristic feature of nanofluids is thermal conductivity enhancement, a phenomenon observed by Masuda et al. [11]. Nanofluids are envisioned to describe fluids in which nanometer-sized particles (usually less than 100 nm in size) are suspended in convectional heat transfer basic fluids. Numerous methods have been taken to improve the thermal conductivity of these fluids by suspending nano/microsized particles in liquids. There have been published several numerical studies on the modeling of natural convection heat transfer in nanofluids recently such as [12–14]. Most scientific problems and phenomena are inherently in form of nonlinearity. Except a limited number of these problems, most of them do not have exact solution. Therefore, these nonlinear equations should be solved using the other methods. Liao [15, 16] proposed a new asymptotic technique for nonlinear ordinary differential equations (ODEs) and partial differential equations (PDEs), named the homotopy analysis method (HAM). Based on the homotopy in topology, the homotopy analysis method contains obvious merits over perturbation techniques: its validity does not depend on small/larger parameters. Thus, the HAM method can be applied to analyze more of the nonlinear problems in science and engineering. Another advantage of the homotopy analysis method is that it provides larger freedom to select initial approximations, auxiliary linear operators, and some other auxiliary parameters. This method does not need small parameters such as the Adomian decomposition method [17] and homotopy perturbation method [18] so it can overcome the restrictions and limitations of perturbation methods. These Analytical methods have already been successfully applied to solve some engineering problems [19–22].

The objective of the present paper is to study the nanofluid flow and heat transfer due to a stretching cylinder with uniform suction/injection. The nanofluid model proposed by Tiwari and Das [23] is used. Copper (Cu) as nanoparticle and water as its base fluid have been considered. The reduced ordinary differential equations are solved analytically using the homotopy analysis method (HAM). The effects of the parameters governing the problem are studied and discussed.

2. Flow Analysis

2.1. Governing Equations

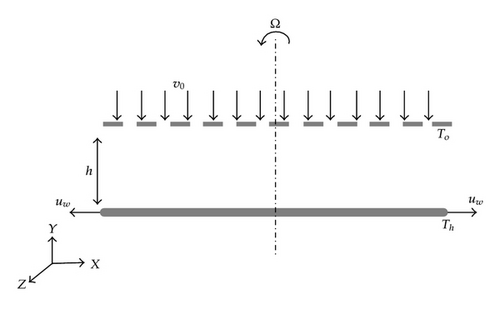

Consider the steady flow of a nanofluid between two horizontal parallel plates when the fluid and the plates rotate together around the axis, which is normal to the plates with a constant angular velocity of Ω.

A Cartesian coordinate system (x, y, z) is considered as follows: the x-axis is along the plate, the y-axis is perpendicular to it, and the z-axis is normal to the x-y plane (see Figure 1). The origin is located at the lower plate, and the plates are located at y = 0 and y = h. The lower plate is being stretched by two equal opposite forces so that the position of the point (0,0, 0) remains unchanged. The upper plate is subjected to a constant wall suction with velocity of v0 (<0) or a constant wall injection with velocity of v0 (>0), respectively. The lower and upper plates are maintained at constant hot (Th) and cold (T0) temperature, respectively.

- (i)

incompressible,

- (ii)

no-chemical reaction,

- (iii)

negligible viscous dissipation,

- (iv)

negligible radiative heat transfer,

- (v)

nano-solid-particles and the base fluid are in thermal equilibrium and no slip occurs between them.

The thermophysical properties of the nanofluid are given in Table 1 [25].

| ρ (kg/m3) | Cp (j/kgk) | k (W/m·k) | β × 105 (K−1) | |

|---|---|---|---|---|

| Pure water | 997.1 | 4179 | 0.613 | 21 |

| Copper (Cu) | 8933 | 385 | 401 | 1.67 |

2.2. Heat Transfer Analysis

3. The HAM Solution of the Problem

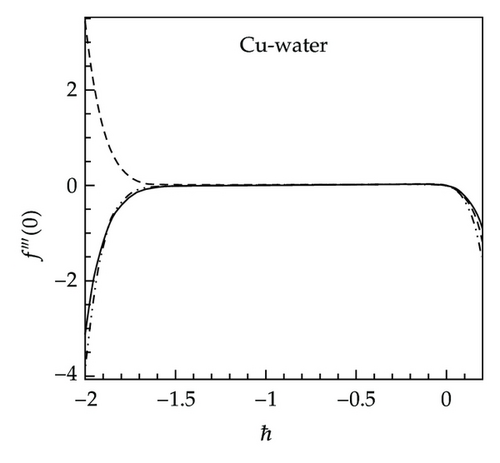

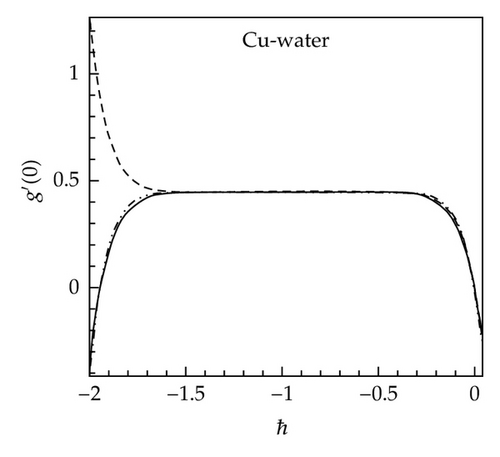

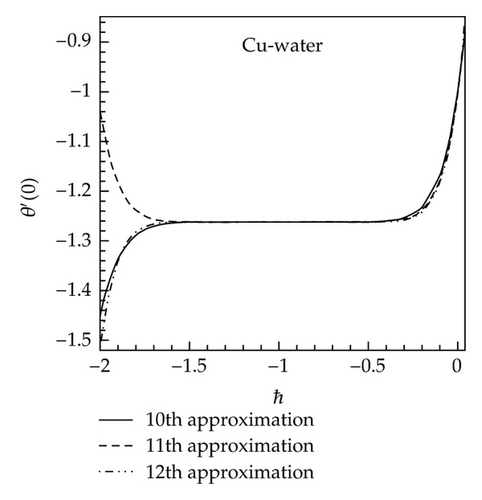

4. Convergence of the HAM Solution

As pointed out by Liao [28], the convergence and the rate of approximation for the HAM solution strongly depend on the values of auxiliary parameter ℏ. This region of ℏ can be found by plotting f′′′(0), g′(0), and θ′(0) for ℏ (ℏ-curve) and choosing ℏ, where f′′′(0), g′(0), and θ′(0) are constant. It is worthwhile to be mentioned that for different values of flow parameters (ϕ, Kr, R, λ) a new h-curve should be plotted as using a unique ℏ-curve for all cases may lead to a considerable error. Therefore, in this study, we have obtained admissible values of ℏ for all cases but only depicted the ℏ-curves of f′′′(0), g′(0), and θ′(0) for one case in Figure 2 for brevity.

5. Results and Discussions

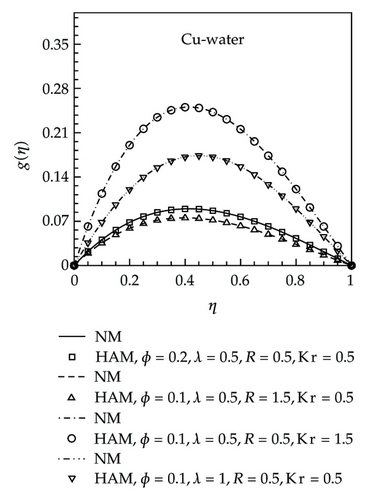

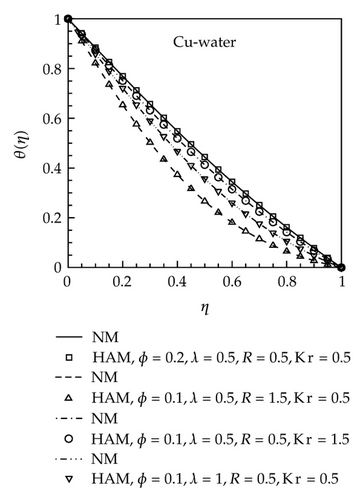

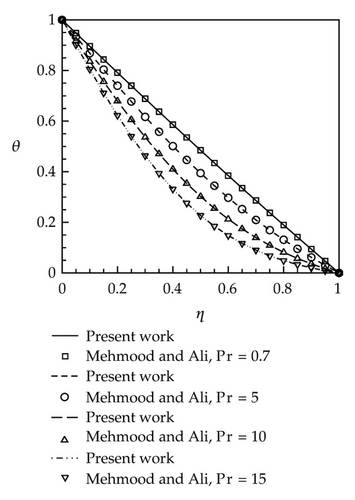

The governing equations and their boundary conditions are transformed to ordinary differential equations that are solved analytically using the homotopy analysis method (HAM) and the results compared with numerical method (fourth-order Runge-Kutta) [29]. The results obtained by the homotopy analysis method were well matched with the results carried out by the numerical solution obtained by the four-order Runge-kutta method as shown in Figure 3. In order to test the accuracy of the present results, we have compared the results for the temperature profiles θ(η) with those reported by Mehmood and Ali [24] when ϕ = 0 (regular or Newtonian fluid) and different values of the Prandtl number.

After this validity, results are given for the velocity, temperature distribution, wall shear stress, and Nusselt number for different nondimensional numbers.

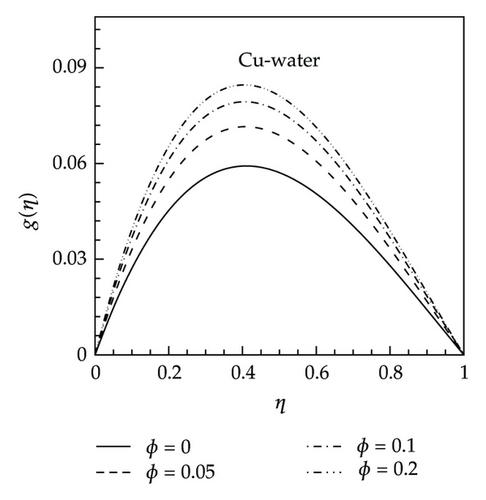

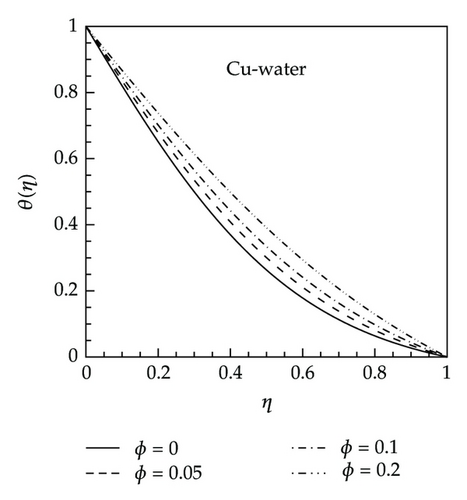

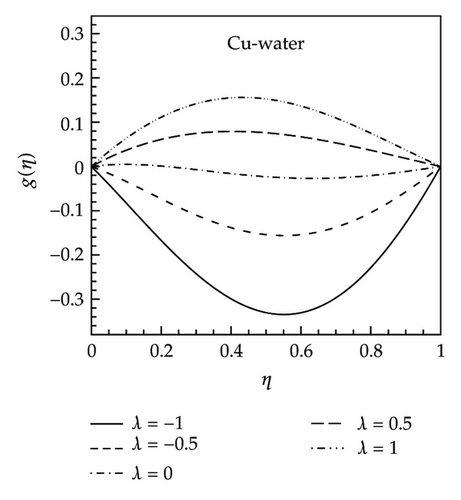

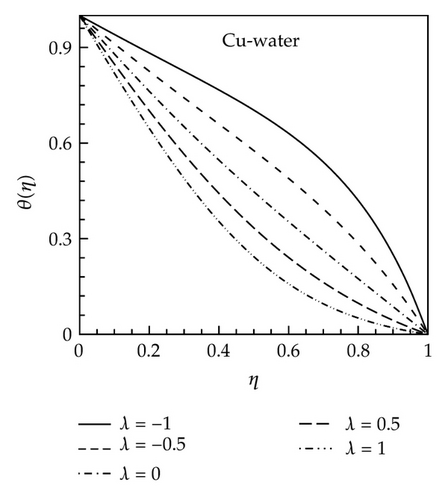

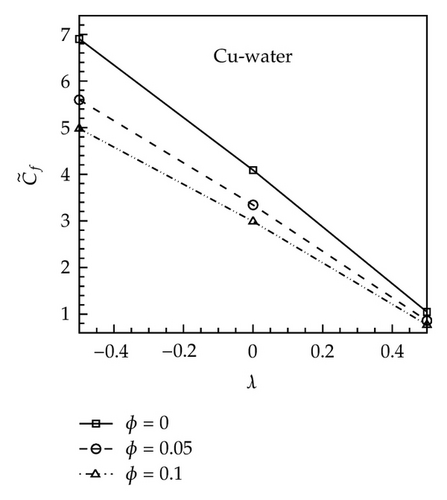

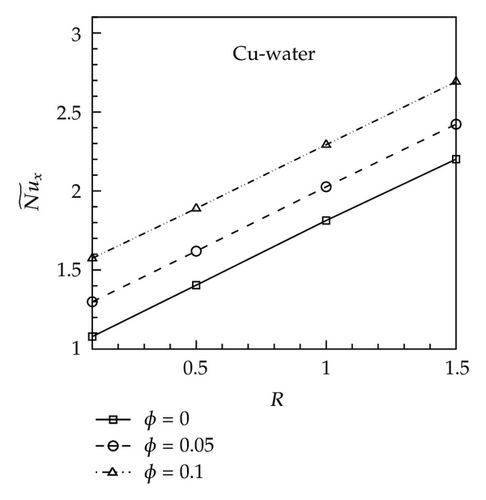

Figure 4 shows the effect of nanoparticle volume fraction (ϕ) on (a) velocity profile and (b) temperature distribution when Kr = 0.5, R = 1, λ = 0.5, and Pr = 6.2. Effects of suction/injection parameter (λ) on (a) velocity profile, (b) Temperature distribution, (c) skin friction coefficient, and (d) Nusselt number when Kr = 0.5, R = 1, ϕ = 0.1, and Pr = 6.2 are shown in Figure 5. It has been found that when the volume fraction of the nanoparticle increases from 0 to 0.2, the thickness of the momentum boundary and thermal boundary layer increases (Figure 4). Figures 5(a) and 5(b) show that all boundary layer thicknesses decrease as λ increases from negative (injection) to positive (suction) values. We know that the effect of suction is to bring the fluid closer to the surface and, therefore, to reduce the thermal boundary layer thickness, while for injection opposite trend is observed. As suction/injection parameter (λ) increases, the magnetic skin friction coefficient decreases and Nusselt number increases (Figures 5(c) and 5(d)). The sensitivity of thermal boundary layer thickness to volume fraction of nanoparticles is related to the increased thermal conductivity of the nanofluid. In fact, higher values of thermal conductivity are accompanied by higher values of thermal diffusivity. The high value of thermal diffusivity causes a drop in the temperature gradients and accordingly increases the boundary thickness as demonstrated in Figure 4(b). This increase in thermal boundary layer thickness reduces the Nusselt number; however, according to (2.26), the Nusselt number is a multiplication of temperature gradient and the thermal conductivity ratio (conductivity of the of the nanofluid to the conductivity of the base fluid). Since the reduction in temperature gradient due to the presence of nanoparticles is much smaller than thermal conductivity ratio, an enhancement in Nusselt takes place by increasing the volume fraction of nanoparticles as it can be seen in Figures 5(c) and 5(d). Also Figure 5(c) indicates that increasing nanoparticle volume fraction leads to decrease in magnitude of the skin friction coefficient.

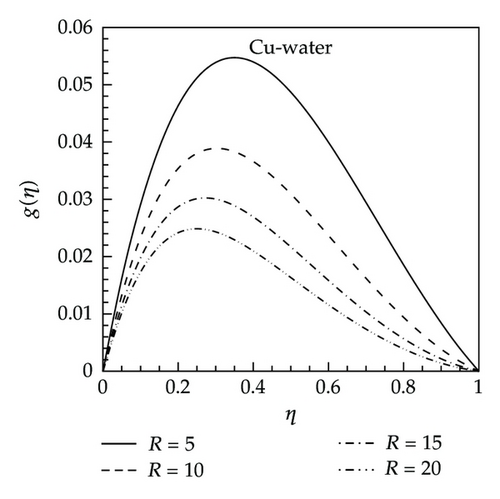

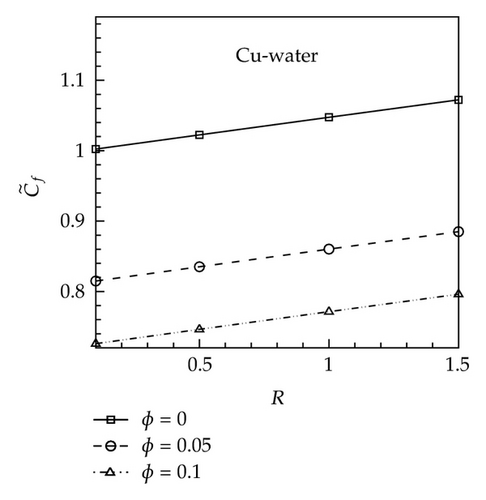

Figure 6 displays the effects of Reynolds number (R) on (a) velocity profile, (b) temperature distribution, (c) skin friction coefficient, and (d) Nusselt number when Kr = 0.5, λ = 0.5, ϕ = 0.1, and Pr = 6.2. It is worth to mention that the Reynolds number indicates the relative significance of the inertia effect compared to the viscous effect. Thus, both velocity and temperature profiles decrease as Re increase and in turn increasing Reynolds number leads to increase in the magnitude of the skin friction coefficient and Nusselt number (Figure 6).

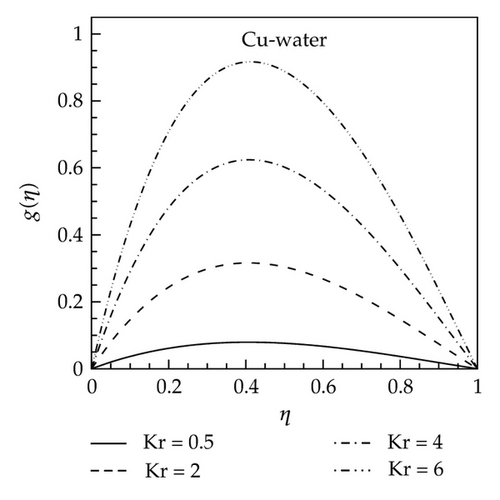

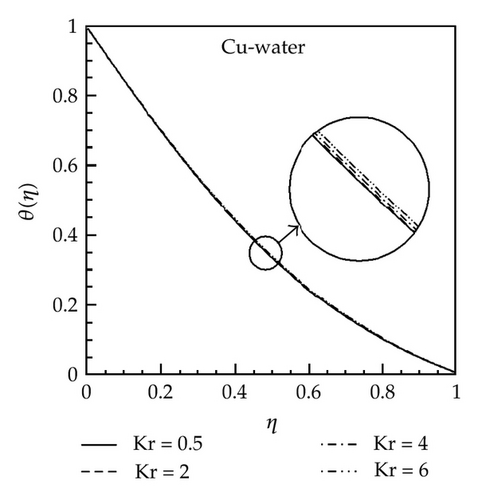

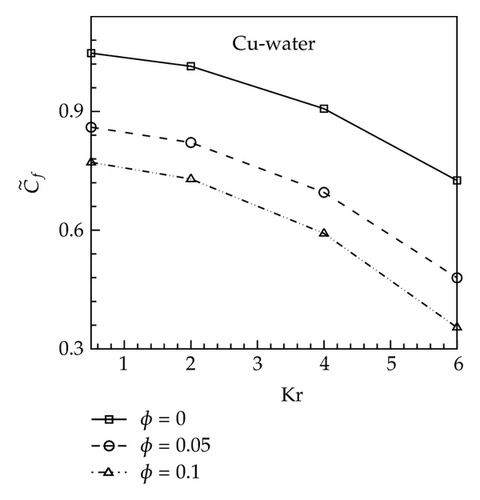

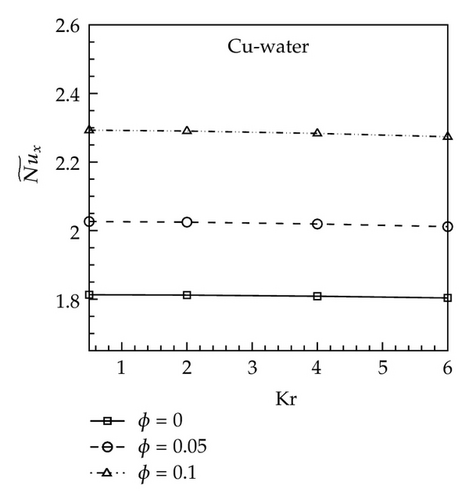

Figure 7 shows the effects of rotation parameter (Kr) on (a) velocity profile, (b) temperature distribution (c) skin friction coefficient, and (d) Nusselt number when R = 1, λ = 0.5, ϕ = 0.1, and Pr = 6.2. Increasing rotation parameter leads to Coriolis force increase that causes both velocity and temperature profiles to increase. Also increasing rotation parameter leads to decreasing the magnitude of the skin friction coefficient and Nusselt number.

6. Conclusions

- (a)

The magnitude of the skin friction coefficient increases as the rotation parameter increases, but it decreases as each of nanoparticle volume fraction, Reynolds number, and injection/suction parameter increases.

- (b)

Nusselt number has direct relationship with nanoparticle volume fraction, Reynolds number, and injection/suction parameter, while it has reverse relationship with power of rotation parameter.

Nomenclature

-

- A1, A2, A3:

-

- Dimensionless constants

-

- Cp:

-

- Specific heat at constant pressure

-

- :

-

- Skin friction coefficients

-

- f(η), g(η):

-

- Similarity functions

-

- L1, L2, L3:

-

- Auxiliary linear operators

-

- ℏ:

-

- Nonzero auxiliary parameter

-

- h:

-

- Distance between the plates

-

- k:

-

- Thermal conductivity

-

- Kr:

-

- Rotation parameter

-

- N1, N2, N3:

-

- Nonlinear operators

-

- Nu:

-

- Nusselt number

-

- p*:

-

- Modified fluid pressure

-

- Pr:

-

- Prandtl number

-

- qw:

-

- Heat flux at the lower plate

-

- R:

-

- Reynolds number

-

- u, v, w:

-

- Velocity components along x, y, and z axes, respectively

-

- uw(x):

-

- Velocity of the stretching surface

-

- v0:

-

- Suction/injection velocity.

Greek Symbols

-

- α:

-

- Thermal diffusivity

-

- η:

-

- Dimensionless variable

-

- θ:

-

- Dimensionless temperature

-

- ρ:

-

- Density

-

- ϕ:

-

- Nanoparticle volume fraction

-

- λ:

-

- Dimensionless suction/injection parameter

-

- μ:

-

- Dynamic viscosity

-

- υ:

-

- Kinematic viscosity

-

- σ:

-

- Electrical conductivity

-

- τw:

-

- Skin friction or shear stress along the stretching surface

-

- Ω:

-

- Constant rotation velocity.

Subscripts

-

- ∞:

-

- Condition at infinity

-

- nf:

-

- Nanofluid

-

- f:

-

- Base fluid

-

- s:

-

- Nano-solid-particles.