Vibration of an Offshore Structure Having the Form of a Hollow Column Partially Filled with Multiple Fluids and Immersed in Water

Abstract

This paper employs the numerical assembly method (NAM) to determine the exact frequency-response amplitudes of an offshore structure such as piles or towers having the form of a hollow column filled with multiple fluids, immersed in water, carrying an eccentric tip mass supported by a translational spring and/or a rotational spring, and subjected to a harmonic force. The hollow column is modeled as a Bernoulli-Euler cantilever beam fixed at the bottom. For the case of zero harmonic force, the simultaneous equations of the vibration system reduce to an eigenvalue problem so that the natural frequencies and mode shapes of the beam can also be obtained. The effect of height of filled fluids on the characteristics of free vibration is also presented.

1. Introduction

In offshore engineering, structures such as towers or piles immersed in water can be predicted with rational accuracy from a fixedly supported beam with a tip mass. Many important papers [1–5] have been published in the field. Those researches was assumed that the beam was solid or empty hollow. Chan and Zhang [6] presented the natural frequency of a cantilever tube filled with only one liquid by using the continuity and equilibrium conditions at the liquid level position. Amabili [7] studied the free vibration of circular cylindrical shells and tubes completely filled with one dense fluid and partially immersed in one different fluid. Wu at el. [8–10] used three different methods to present the natural frequencies and mode shapes of an immersed solid beam carrying an eccentric tip mass with rotary inertia. Lin [11–13] presented the exact natural frequencies and mode shape of a beam carrying multiple concentrated elements.

From the foregoing literature review one finds that the literature regarding determination of the natural frequencies and mode shapes of a hollow beam (partially or completely) filled with fluids of different densities and (partially or completely) immersed in different fluids is little. In this paper an accurate method is presented to determine the natural frequencies and mode shapes of an immersed hollow beam filled with fluids of different densities and carrying an eccentric tip mass supported by a rotational spring and a translational spring. The vibration characteristics of the beam system subjected to a harmonic force are also presented.

In the exploratory offshore drilling operations, the long slender vertical cylindrical pipe placed between the sea surface and the ocean floor for conveying various fluids is called “riser.” In the existing literature concerning the analyses of marine risers [14], the fluids in the “riser” are assumed to be uniform with constant mass density for simplicity. In practice, the last assumption may be different from the actual situations to some degree, because the riser pipe may be filled with several fluids with different mass densities simultaneously, such as water, gas, oil, or clay. For this reason, this paper tries to present a technique to study the dynamic behaviors of a pipe filled with multiple fluids and immersed in water. Because the presented mathematical model is closer to the marine risers, it is believed that more satisfactory results will be obtained.

In order to confirm the reliability of the presented approach, the numerical example illustrated in this paper is also conducted by using the FEM and good agreement is achieved. One of the predominant merits for the presented approach is that its numerical results belong to the “exact solutions” and may be the benchmark for evaluating the accuracy of the other approximate methods (such as FEM).

2. Theoretical Model

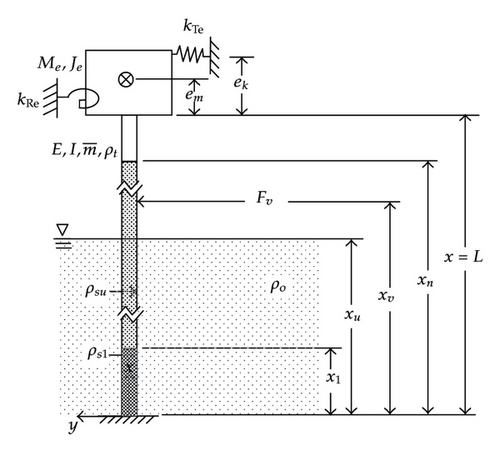

Figure 1 shows the sketch of a immersed hollow beam filled with fluids of different densities and carrying an eccentric tip mass with rotary inertia, rotational spring, and translational spring supports. The points corresponding to the locations of fluid interfaces and/or applied concentrated forces are referred to as “stations.” The positions of stations are defined by xn(n = 1, …, n) and the subscript of xn refer to the numbering of the stations. Symbol “⊗” denotes the center of mass of the tip mass. E is Young’s modulus of the beam, I is moment of inertia of the cross-sectional area of the beam, do and ds are outer and inner diameters of the hollow beam, respectively, is mass per unit length of the beam, ρt, ρo, and ρs are the density of the stainless steel beam, density of the outer fluid (water) of the hollow beam, and density of the filled fluids of the hollow beam, respectively. Me is the tip mass, Je is its moment of inertia, kTe is the translational spring constant of supporting tip mass, kRe is the rotational spring constant of supporting tip mass, em is the distance between the upper end of beam and center of gravity of the tip mass, and ek is the distance between the upper end of beam and the translational spring support.

2.1. Equation of Motion and Displacement Function

2.2. Coefficient Matrix [Bu] for an Intermediate Fluid Interface

In the above equations (2.25) and (2.26), the symbols, [] and {}, denote the rectangular matrix and column vector, respectively. The coefficient matrix [Bu] is placed in (A.1) of Appendix A.

2.3. Coefficient Matrix [Bv] for an Intermediate Applied Force

And the coefficient matrix [Bv] is placed in (B.1) of Appendix B.

2.4. Coefficient Matrices [B0] and [BN] for the Two Ends of the Entire Beam

And the coefficient matrix [BN] is placed in (C.1) of Appendix C.

2.5. Determination of Natural Frequencies and Mode Shapes of the Beam

In this paper, the incremental search method is used to find the natural frequencies of the vibrating system, ωv (v = 1,2, …). With respect to each natural frequency ωv, one may obtain the corresponding integration constants from (2.56). The substitution of the last integration constants into the displacement functions of the associated beam segments will determine the corresponding mode shape of the entire beam, Y(v)(ξ).

2.6. Determination of Forced Vibration Response of the Beam

3. Numerical Results and Discussions

Before the vibration analysis of an immersed hollow beam filled with fluids of different densities, subjected to a force, and carrying an eccentric tip mass supported by a translational and a rotational spring is performed, the reliability of the theory and the computer program developed for this paper are confirmed by comparing the present results with those obtained from the existing literature.

3.1. Reliability of the Developed Computer Program

The first example studied is a fixedly supported immersed beam carrying tip mass with rotary inertia and eccentricity e = 0.5 m and two intermediate lumped masses kg located at x2 = 13 m and x3 = 14 m, respectively, for the case of draft ratio and water density ρ = 1000 Kg/m3. The dimensions of the solid beam are as follows: Young’s modulus = 2.068 × 1011N/m2, diameter d= 0.3 m, mass density ρ = 7850 Kg/m3, and total length L = 15 m. The lowest four natural frequencies of the immersed beam are shown in Table 1. From Table 1, one sees that the results of this paper are in good agreement with those of [9].

| Methods | Parameters | Natural frequencies (rad/sec) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ω1 | ω2 | ω3 | ω4 | |||||||

| Present | 13 | 14 | 0.1 | 0.1 | 0.1 | 0.1 | 2.5978 | 10.0440 | 42.3158 | 109.7077 |

| [9] | 13 | 14 | 0.1 | 0.1 | 0.1 | 0.1 | 2.5978 | 10.0441 | 42.3158 | 109.7078 |

3.2. Natural Frequencies and Mode Shapes of the Immersed Hollow Beam Filled with Two Kinds of Fluids Carrying an Eccentric Tip Mass with Rotary Inertia, Translational and Rotational Spring Supports

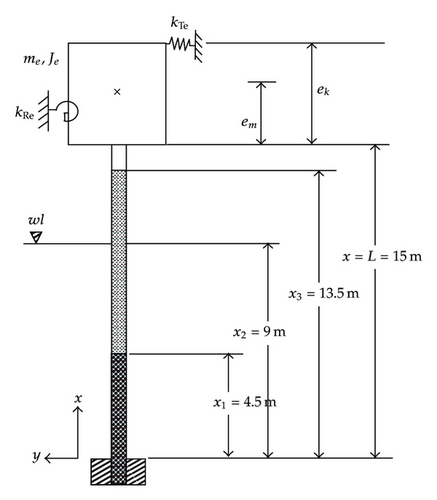

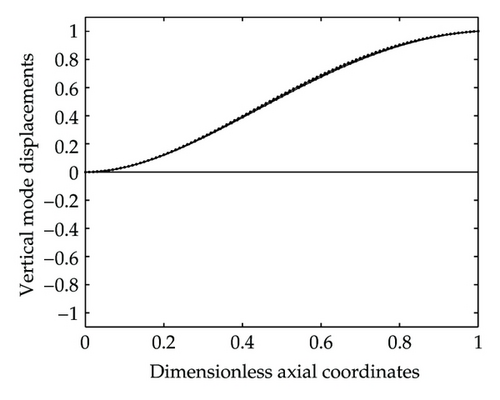

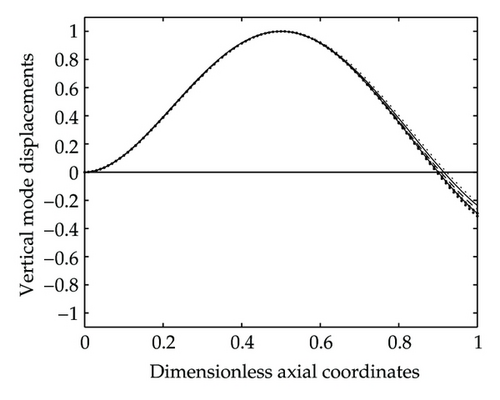

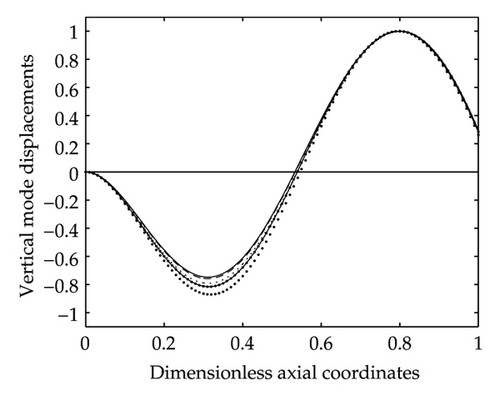

The second example studied is a immersed hollow beam filled with two kinds of fluids and carrying an eccentric tip mass with rotary inertia, translational and rotational spring supports (cf. Figure 2). The parameters of the steel hollow beam are as follows: total length L = 15 m, outer diameter do = 0.6 m, inner diameter m, Young’s modulus E = 2.068×1011 N/m2, density ρt = 7850 kg/m3, density of the inner upper fluids ρs2 = 1000 kg/m3, and density of the inner lower fluid ρs1 = 1400 kg/m3. The nondimensional parameters of the eccentric tip mass are as follows: mass ; rotary inertia of the tip mass ; constants of the rotational spring support ; constants of the translational spring support ; distance between the fixed point of the tip mass and its center of gravity ; distance between the fixed point of the tip mass and the translational spring support ; the nondimensional height of the beam immersed in water ; height of filled lower fluid ; height of filled with upper fluid , respectively. The lowest four natural frequencies and non-dimensional parameters for the hollow beam are shown in Table 2. In order to confirm the reliability of the presented results, the current example is also conducted by using the FEM with the lowest four natural frequencies shown in Table 2. From the table one sees that the lowest four natural frequencies of the hollow beam obtained from FEM are very close to those obtained from the presented approach; furthermore, they decrease with increasing the height of filled upper fluid due to its added mass. Corresponding to the four natural frequencies listed in Table 2, the lowest four mode shapes of the hollow beam are shown in Figures 3(a)–3(c), respectively, where (a), (b), and (c) refer to the 1st,2nd, and 3rd mode shapes of the hollow beam. Besides, the curves − − − −, — — — —, – – – –, …………, and −·−·− denote the mode shapes of the hollow beam filled with the upper fluid height , respectively.

| Dimensionless parameters | Methods | Natural frequencies (rad/sec) (dimensionless frequency parameters (Ω)) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ω1 (Ω1) | ω2 (Ω2) | ω3 (Ω3) | ω4 (Ω4) | |||||||

| 0.3 | 0.4 | 1 | 0.01 | 30 | 10 | Present | 24.6479 (2.8932) | 71.9802 (4.9442) | 159.2279 (7.3536) | 268.8851 (9.5559) |

| 0.3 | 0.5 | 1 | 0.01 | 30 | 10 | Present | 24.5520 | 69.9351 | 158.3664 | 267.6327 |

| FEM | 24.5521 | 69.9352 | 158.3665 | 267.6331 | ||||||

| 0.3 | 0.6 | 1 | 0.01 | 30 | 10 | Present | 24.3869 | 68.0844 | 158.2174 | 261.6957 |

| FEM | 24.3869 | 68.0844 | 158.2176 | 261.6961 | ||||||

| 0.3 | 0.7 | 1 | 0.01 | 30 | 10 | Present | 24.1460 | 66.9012 | 156.6135 | 256.6476 |

| FEM | 24.1460 | 66.9013 | 156.6136 | 256.6480 | ||||||

| 0.3 | 0.8 | 1 | 0.01 | 30 | 10 | Present | 23.8382 | 66.4282 | 153.3229 | 255.8103 |

| FEM | 23.8383 | 66.4283 | 153.3231 | 255.8107 | ||||||

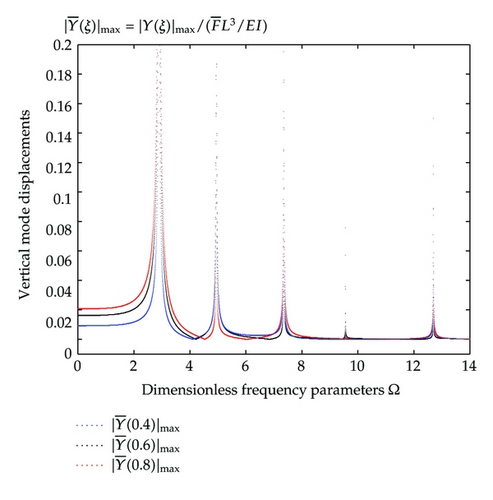

3.3. Forced Vibration Responses of the Hollow Beam Filled with Two kinds of Fluids, Immersed in Water and Carrying an Eccentric Tip Mass

The beam system of the present example is the same as the last one but the beam subjected to a harmonic force is located at ξ = 0.8. For each value of Ω (from 0 to 13.0 with interval ΔΩ = 0.001), one may obtain the integration constants from (2.58). Then we compute the vibration amplitudes when it is placed in different locations on the beam. Figure 4 shows the relationship between the dimensionless frequency parameters (Ω) and the dimensionless response amplitudes for the points located at ξ = 0.4, 0.6, and 0.8, where the horizontal axis is the dimensionless frequency parameter (Ω) and the vertical axis is the dimensionless vibration amplitude (). The blue, black, and red curves are for points located at locations ξ = 0.4, 0.6, and 0.8, respectively. The vibration amplitudes for the point located at either ξ = 0.4, 0.6 or 0.8 have peaks when the dimensionless frequency parameter Ω≈ 2.9, 4.9, 7.4, 9.6, and 12.7. This is because when the dimensionless frequency parameter Ω is near any of the natural frequencies of the beam, as shown in the parenthesis of line 1 of Table 2, resonance appears.

4. Conclusion

The results presented in this work have found that one can obtain the lowest several “exact” natural frequencies and corresponding mode shapes of an immersed hollow beam partially filled with two kinds of fluids and carrying an eccentric tip mass with rotary inertia, rotational and translation spring supports. For the beam subjected to a harmonic force, one can determine the frequency-response curve for any point of the beam using this method. Because a peak will appear in each curve when the exciting frequency of the harmonic force is near any of natural frequencies of the beam, one can determine natural frequencies of the beam based on the peaks of any frequency-response curve.