Survey of BGFA Criteria for the Cu-Based Bulk Amorphous Alloys

Abstract

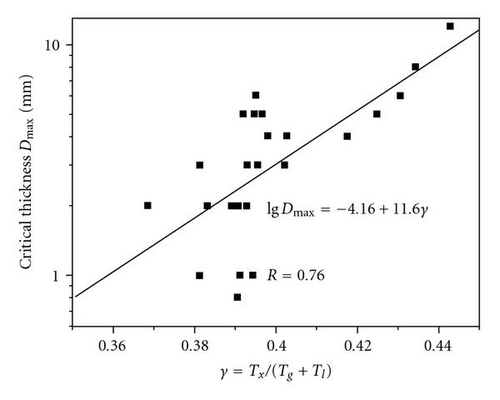

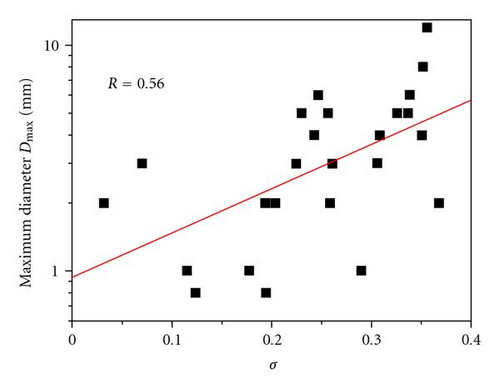

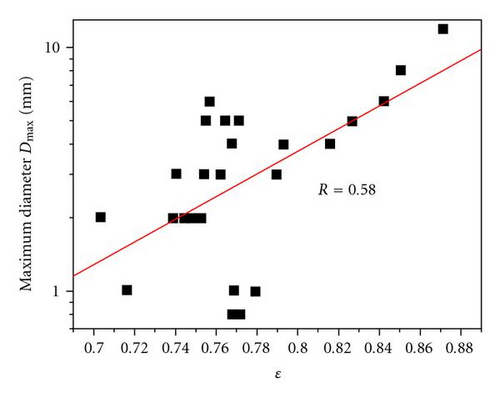

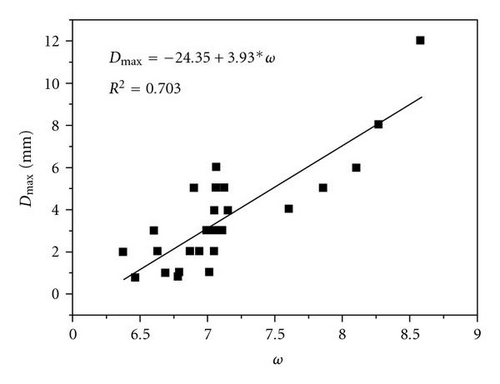

To verify the effect of composition on the bulk glass forming ability (BGFA) of Cu-based alloys, properties have been collected from the literature (~100 papers, more than 200 alloys). Surveying the BGFA criteria published so far, it has been found that the atomic mismatch condition of Egami-Waseda is fulfilled for all the Cu-based BGFAs, the λ value being above 0,3. The Zhang Bangwei criterion could be applied for the binary Cu-based alloys. The Miracle and Senkov criteria do not necessarily apply for Cu based bulk amorphous alloys. The critical thickness versus γ = Tx/(Tg + Tl) plot of Lu and Liu extrapolates to γ = 0.36, somewhat higher than the 0.33 value found in other BGFA alloys. The Park and Kim parameter correlates rather poorly with the critical thickness for Cu based alloys. The Cheney and Vecchino parameter is a good indicator to find the best glass former if it is possible to calculate the exact liquids projection. In 2009 Xiu-lin and Pan defined a new parameter which correlates a bit better with the critical thickness. Based on this survey it is still very difficult to find one parameter in order to characterize the real GFA without an unrealized mechanism of crystallization.

1. Introduction

In the field of metallic materials development the most important aims are to improve the strength, hardness, and the wear resistance without the important decreasing of the plasticity. The copper-based bulk metallic glasses (BMGs) occupy a special place in the family of BMGs owing to their relatively low priced. The serial industrial applications were blocked in the recent past by the small thickness of formed metallic glasses; the maximum size of Cu-based metallic glasses is still restricted to a few mm (12 mm has been reported [1]), at the time being. In order to develop new bulk metallic glasses with larger size there is imperative need for the quantification of GFA.

The BGFA criteria would tell both the type and atomic percentage of the glass forming elements. Inoue defined three empirical rules for the bulk amorphous alloys systems [2]. More and more researchers define further GFA criteria since the first metallic glass was published. There is not a standard definition of GFA up to now; some researcher characterizes the GFA with the critical cooling rate; however the exact measuring of critical cooling rate is very difficult. From the engineering aspect, the critical thickness would be a good choice of the measuring the GFA, nevertheless the critical thickness strongly depends on processing parameters and the impurities. We have selected seven BGFA criteria from the literature, and we have applied them for Cu-based BMGs published so far in the literature (more than 200 alloys). In this work the seven GFA parameters are presented in chronological order.

2. BGFA Criteria

2.1. Egami-Waseda Criterion Structural Factor

| Alloy | λ0 | Alloy | λ0 |

|---|---|---|---|

| Cu-Zr-Ti | 0,352 | Cu-Zr-Al | 0,485 |

| Cu-Zr-Ti-Ni | 0,278 | Cu-Hf | 0,509 |

| Cu-Zr-Ti-Hf | 0,451 | Cu-Hf-Ti | 0,400 |

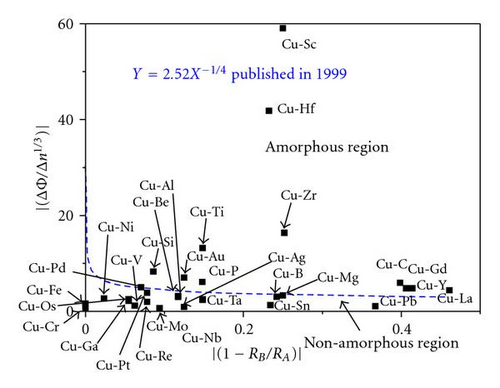

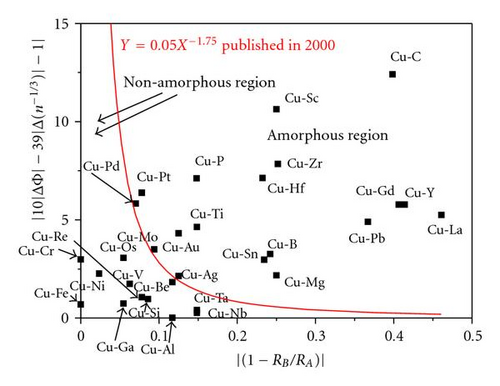

2.2. Bangwei Criterion Based on Miedema’s Model

2.3. Senkov-Miracle Criterion Structural Factor

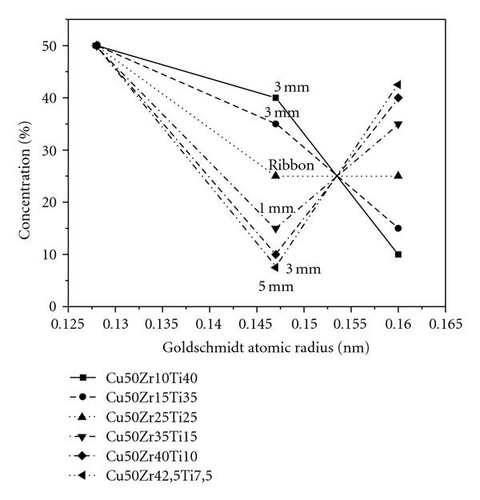

In 2001 Senkov and Miracle examined different bulk amorphous alloys based on Mg, Cu, Zr, Al, Ni, Fe, and Pd. They represented the concentration of elements versus the atomic size, obtaining different distributions for bulk amorphous alloys. They concluded that a concave upward plot generally characterizes the good glass forming ability [11]. Unfortunately, critical cooling rates and critical thicknesses are given only in limited number of publications [6, 8]. In Figure 2 numbers note the maximum thickness of the amorphous alloys. It can be seen that the very similar plots have different maximum thickness (Figure 2(a)). For the same maximal thickness (e.g., 3 mm) the curve plotted in Figure 2(b) could show concave upward shape or concave downward shape tendency. Based on these findings we can assert that the Senkov and Miracle criterion does not apply to Cu-based bulk amorphous alloys.

2.4. Lu and Liu Criterion Based on the Measured Thermal Parameters

2.5. Park and Kim Criterion Structural Factor

2.6. Cheney and Vecchino Parameter Based on Phase Diagram

2.7. Xiu-lin and Pan Criterion Based on Thermodynamic Approach

3. Conclusions

- (1)

The critical cooling rate is less studied in the literature although it is an important aspect during the solidification. The authors of the present work believe that the method applies for crystalline alloys, estimating the cooling rate from the secondary dendrite arm distances [14–16].

- (2)

The critical thickness was given only in some cases, often without mentioning the measuring error.

- (3)

The characteristic temperatures (Tg, Tx, and Tl) measured by DSC and DTA depend on the heating rates. One may use only those temperatures which were measured with the same heating rate. Especially, the liquidus temperature is affected by a great error.

- (4)

The composition of ingots has not been analysed in general; there are different data relative to the same nominal composition. For example Tg changes from 700 K [17] to 724 K [9] at 40 K/min heating rate and the liquid temperature changes from 1152 K [17] to 1175 K [9] at 10 K/min heating rate in the case of Cu60Zr30Ti10 alloy.

- (5)

The BGFA parameters do not take the undercooling of the crystallize phases into consideration. Every phase has a different undercooling and a critical cooling rate.

As a summary of this survey we can state that in order to characterize the real GFA we have to establish a real GFA criterion based on the mechanism of crystallisation which is not one single indicator but some associated indicators.

To our knowledge with numerical simulation methods it has not been possible to give a reliable forecast for the mechanism of nucleus formation with the ab inito method.

Researchers have to do numerous experiments to finding out the best BMG composition.