Reconceptualising stakeholders for the management of distributed value creation networks through open design-led businesses

Abstract

Openly shared design knowledge and open-to-participate design processes present potential for democratising innovation through diffuse value creation networks that can diverge into different directions and design outcomes. This potential mostly concretises through the distributed production paradigm that localises production, closes material loops and empowers communities to meet their specific needs. This paper argues that there is a need for formalising truly alternative ways of doing open design-led businesses that can establish distributed value creation networks. In an attempt to enable and facilitate envisioning such alternatives, this paper presents a novel conceptualisation of stakeholders and framing of their ever-shifting roles and responsibilities in complex value creation networks suggested by distributed production through a systematic literature review of 131 journal articles at the intersection of open design, distributed production and business models. The analysis revealed two main categories of stakeholders namely value-creation-for-self and value-creation-for-others, with a total of six sub-categories presenting varying capacities to participate in networked value creation processes. The article concludes with a discussion on how this conceptualisation can enable envisioning novel, open design-led business models in terms of collaborative value creation, managing distributed value networks and a layered approach to design and value offerings.

Introduction

Openly shared design knowledge and open-to-participate design processes present potential for democratising innovation through diffuse value creation networks that can diverge into different directions and design outcomes. Many researchers give credit to open design for transitioning towards sustainable futures through facilitating socially, environmentally, and economically beneficial practices by empowering individuals to influence what is produced (e.g., Manzini, 2015), enabling new types of enterprise (Gasparotto, 2017), new ways of manufacturing (e.g. Raasch & Herstatt, 2011) and circular economy practices (e.g. Hobson, 2020). These mostly concretise through the distributed production paradigm that localises production, closes material loops and empowers communities to meet their own local needs, as well as the needs of citizens in the future through open, adaptable solutions and knowledge sharing (Kostakis et al., 2015). These opportunities presented in literature often embody varying sustainable future visions in terms of de-centralised governance and deploy varying assumptions about the roles of consumers/users/citizens, prosumers, makers, producers, and policymakers (Bauwens et al., 2020). However, the literature also warns about open design being absorbed into business-as-usual practices and becoming incapable to contribute to any transition towards a sustainable future unless alternative modes of production and consumption materialise (Thackara, 2011). Thus, the need for formalising truly alternative ways of doing open design-led businesses that can establish distributed value creation networks becomes prominent; however, this article argues that widely deployed separation between businesses and consumers in business model development hinders envisioning such alternative ways of doing business managed by the openness of design processes and outcomes.

In an attempt to enable and facilitate envisioning such alternatives, this paper presents a novel conceptualisation of stakeholders and framing of their ever-shifting roles and responsibilities in complex value creation networks suggested by distributed production, through a systematic review of the literature at the intersection of open design, distributed production and business models. The paper is structured as (1) the background of this study, (2) the systematic literature review methodology adopted, (3) the types of stakeholders that emerged from the analysis of selected literature and their varying roles in open design and distributed production, and (4) a discussion about how this novel conceptualisation of stakeholders can enable devising truly alternative ways of doing business.

Background

Open design – process and outcomes

Open design is informed by various bodies of research and practice with varying foci, including the open-source software movement, DIY maker culture, hacker culture and new understandings of the roles and responsibilities of, and the relationships between, designers and users (Bakırlıoğlu & Kohtala, 2019). These can be broadly categorised into two strands, namely (1) openly shared, publicly available design knowledge and data, and (2) open-ended, open-to-participate design processes (Marttila & Botero, 2013). The former involves free sharing and adopting of design data, stemming from the DIY movement that emerged back in the 1970s (e.g., Hennessey & Papanek, 1973) which evolved with Web 2.0 technologies and user-generated content. This strand is also closely related to commons-based peer production that involves the open-source production of software and tangible products (Benkler, 2006; Hess & Ostrom, 2011). The latter involves people's participation in open-ended design activities to design and produce, similar to how participatory design practice is becoming more and more open-ended (Marttila & Botero, 2013). The open-ended design process was also depicted by Jones in 1983, inspired by the then evolving software technologies and development processes – especially how they are made, changed, iterated and updated. This led to his very early conceptualisation of a continuous designing and redesigning process that responds to different contexts, needs and preferences, and that diverges in multiple directions through collaboration (Jones, 1983), very similar to how the open design process is conceptualised to diverge and fork (Tooze et al., 2014), especially through the modularisation of design outcomes (Raasch et al., 2009). This diverging process presents potential for the democratisation of design if the design outcomes are ‘pre-hacked’ (Richardson, 2015), and openness is embedded into the design process (Menichinelli, 2015). This paper argues that such potential can flourish within an accompanying production paradigm, such as distributed production, and through alternative ways of doing business.

Distributed production – potential and barriers

The existing mode of production and consumption demonstrates the centralisation of different stages of the product life cycle at different geographical locations, such as raw material extraction in South America or production and assembly in the Far East, resulting in value accumulation in the Global North. This places transportation in between each step of the value creation process and ends up with large CO2 emissions throughout the production and consumption process (Diez, 2011). Furthermore, such accumulation of value in certain geographical regions further entrenches inequality in terms of accessibility to resources and the wellbeing of people. Localisation of design and production through integrating global, regional and local scales for environmental sustainability has long been discussed in the literature and conceptualised to empower local skills and improve the wellbeing of individuals (e.g., Dogan & Walker, 2008). The literature on distributed economies emphasises such integrated scales of design and production through improved fabrication and ICT technologies and proposes a radical shift towards more equal distribution of value, the democratisation of innovation and demand-driven production.

Srai et al. (2016) present re-distributed manufacturing enabled through digital fabrication and IoT technologies as an opportunity to bring production much closer to end-users through smaller and even micro-scale manufacturing units that are flexible and adaptable. This can result in the active participation of end-users and other stakeholders in design, development and production, enabling the personalisation of products, and democratisation of design (Ul Haq & Franceschini, 2020). Such processes can be supported by artificial intelligence for decision-making and enable individual, local and regional stakeholders to devise their production and diffuse supply chains more responsive to environmental issues and social inequalities (Fox, 2017). Outsourcing certain tasks to automated systems or supporting software can facilitate the involvement of larger audiences in design and production by enabling the personalisation of shared designs for non-CAD-literate people (Nilsiam & Pearce, 2017). While such developments in digital fabrication technologies are influential in conceptualising distributed production, there are also certain limitations of these technologies. For example, additive manufacturing technologies are not developed to a point where they can assure no production defects affecting functionality, durability or aesthetic quality (Baumers et al., 2017). Similarly, pre- and post-processing technologies are not as adaptive as additive manufacturing (Despeisse et al., 2017). Considering these, Rayna & Striukova (2021) propose a hybridisation of production methodologies and value chains, where standardised, mass-produced parts, such as Arduino circuit boards, are combined with 3D printed components to exploit the potential opportunities enabled by local manufacturing. However, there seems to be a lack of standards or ‘plug-and-play’ solutions for mass-produced components that would accommodate such flexibility (Chaudhuri et al., 2019).

Openness – an ideal or a competitive business component

The open design approach has created much enthusiasm at the beginning of new millennia through the opportunities conceptualised around it, and after twenty years, it is also possible to observe the consolidation of certain open design practices (Gasparotto, 2020). Such open practices are discussed as open-source technologies, open governance, open innovation, open business model through value share, open access and open production (Seo-Zindy & Heeks, 2017). These practices, however, are interrelated and should be formalised in tandem. Throughout the literature, ‘openness’ in design and how it contributes to value creation seem to be divided into two points of view. On the one hand, there are communities of like-minded people advocating for openness as an ideological stance for the democratisation of knowledge and resources; on the other hand, there are companies that utilise openness as a competitive business component (Ferdinand & Meyer, 2017). While such separation between different perspectives on openness is conceptually possible, it should also be noted that these do not necessarily result in strictly separated communities. It is important to understand the similarities and differences between these perspectives nonetheless, to be able to comprehend what drives different kinds of stakeholders into adopting open practices.

As an ideal, openness advocates for limitation-free access to data, knowledge and resources for design and production/fabrication, and involves various drivers, like altruism (Troxler & Wolf, 2017), hedonism (Fox, 2017; Halassi et al., 2019; Wolf & Troxler, 2016), democratisation (e.g., Arndt et al., 2021; Beltagui et al., 2021; Mortara & Parisot, 2018), sustainability (e.g. Bonvoisin, 2017a; Hobson, 2020), degrowth (e.g. Hankammer & Kleer, 2018), and empowerment (de Rosnay & Musiani, 2016; Nascimento & Pólvora, 2018; You et al., 2020). These drivers are also aspirations towards an environmentally, socially, and economically sustainable and just future. Such ideals are, however, hard to enact upon in the existing contexts – or the attempts at them might remain short of what is being idealised. For example, Hankammer & Kleer (2018) identify the lack of and the need for formalising organisational models that do not aim at maximising profits in the degrowth literature, in addition to alternative forms of collaboration between consumers and organisations. Unterfrauner et al. (2019) identify the novel practices emerging from the maker movement in terms of value creation innovation and value proposition, which might define new strands for the economical sustainability of such practices in the existing environment unfit for them to flourish. These involve opportunities stemming from new capabilities through digital fabrication technologies and material innovation, new forms of collaborations and partnerships, and novel types of supply chains (e.g., through distributed production), resulting in on-demand production, localisation, reduction of transportation costs, etc. Friesike et al. (2019) point out the potential for empowerment through open design communities, not only for learning and skills building but also through designing things beyond one's capabilities. Schmidt (2019) points to the social innovation potential through people getting involved in creativity labs.

These are in tension with the real-life implications of such practices, as openness of design data can be sacrificed for economical sustainability (e.g., Balka et al., 2010) or for compliance with safety regulations in certain sectors like healthcare (e.g., Carpentier, 2021). Furthermore, such communities are a form of social curation with various implicit and explicit selection mechanisms (Schmidt, 2019), which may result in exclusionary practices, albeit unintended.

On the other hand, openness can become a strong competitive tool in value creation with open product development processes, platformisation, open innovation and similar approaches. This relates to collaborating with stakeholders through openly shared knowledge and expertise, usually taking on predefined roles and responsibilities with clear, pre-determined frames. The level of openness of designs, governance, accessibility, and production varies greatly according to the economic concerns of the collaborating parties and the hierarchical relationships amongst them. For example, Coelho et al. (2018) identify the possibility to earn money as the most prominent motivation of the participants of crowdsourcing design platforms, if their designs are selected for production by the community. There are also various ethical concerns in crowdsourcing, such as unpaid ‘voluntary’ labour the community members put in and the exploitation of participants' knowledge and expertise without proper compensation (Standing & Standing, 2018). In the platformisation approach, the main offering is an open-source platform with design solutions open to adaptations for both commercial and non-commercial purposes, and the platform owner offers certain services around their platform. Such platforms can create the infrastructure to drive technological innovation and entrepreneurship (Cota et al., 2020). There is also evidence that open hardware can be utilised as a knowledge transfer strategy that is low-cost and practical, that enables the development of an institution-led (and secured) open-source hardware community and that does not erode commercial value (Kauttu, 2018). The latter might be especially true for high-tech innovations that require not only the knowledge and expertise to develop but also large investments and physical infrastructure to set up – since such innovations cannot be realised apart from a handful of market actors anyway. For low-tech open designs that can be produced increasingly more easily with the dissemination of digital fabrication equipment, there remains the risk of licensing infringement. In such cases, open designs can be supported by expert design and production services as sources of income and economic sustainability. For example, the Open Desk company that openly shares its office furniture designs complements their business with interior design services and acts as an intermediary between the end-users and producers around them, effectively becoming a platform (Gasparotto, 2017).

In both strands, whether openness is deployed as an ideal or as a tool for competitive advantage, it is important to recognise the opportunities it enables in terms of accessibility to design knowledge and distributed forms of collaboration in design, development, and production. Such opportunities can concretise with novel business models within distributed value creation networks, in which value can be not only economic but also social, cultural, and environmental. Developing business models as networked activities require conceptualising stakeholders through such a lens and accounting for their varying capacities to partake in these networks.

Systematic Literature Review

Systematic literature reviews aim to aggregate all sources on a defined topic of interest and synthesize them (Pattinson et al., 2016; Pittaway et al., 2004). As part of the DF-MOD project, a systematic literature review was deployed at the intersection of open design, distributed production, and business models, in order to synthesize the state-of-the-art in novel open design-led business models that can enable the distributed fabrication and value creation networks and to reveal opportunities for and barriers against their creation and implementation. The researcher initially identified various keywords related to open design (e.g., open-source design, open hardware, distributed production, collaborative production, peer production, fabrication lab, makerspace, etc.) and in a series of tries, formed a search string to identify the peer-reviewed literature that clearly mentions business models and open design or relevant terms. The search string aimed to cover the fields of title, abstract, and keywords of peer-reviewed articles to provide a satisfactory snapshot of the existing literature, as of September 2021, that clearly contains ‘business model’ and ‘open design’ or other terms presented. This search string was run in three academic databases (i.e., Web of Science, Scopus, and EBSCO Academic Search Elite). The author removed duplicates, manuscripts in languages other than English, and manuscripts other than journal articles - since other formats tend to present preliminary work (e.g., conference proceedings), extended manuscripts based on earlier works published as journal articles (e.g., books, book chapters), expert opinions not necessarily grounded in research work (e.g., periodicals), or review of others' work (e.g., book reviews). The author carried out an initial review of abstracts and also removed the articles that mention open design and other relevant concepts (1) in passing, but the paper is not directly related to them, (2) to support their arguments about another approach (e.g., sharing economy, helix models of innovation, etc.), (3) to identify different approaches in digital products and services (e.g., open-source software, open education, etc.), rather than physical products and services, or (4) refer to other meanings of openness (e.g., open-ended or unsolved processes, modular structures, open knowledge, etc.) not in the scope of this review. As a result, a final list of 131 articles was identified that provides a snapshot of the reviewed literature. The second stage started with the inductive coding of sources by the researcher without any previous categories in mind. This initial coding of 15 papers revealed various thematic areas of analysis, including value creation processes; drivers/themes; business model elements/components; collaboration, people's involvement, and governance; intellectual property mechanisms; alternative, sustainable production & consumption; economic sustainability of open design business models; and life cycle stages addressed. The remainder of the articles were analysed according to these thematic areas. The outcomes of this process provide empirical data and expert insights into a wide range of opportunities, limitations, and barriers at micro, meso and macro scales. This analysis revealed a conceptual divide between two types of stakeholders in terms of value creation purposes in distributed production settings, as presented below. The authors believe such conceptualisation of stakeholders can empower open design practitioners and other stakeholders to develop novel, innovative business models.

Types of stakeholders in distributed value creation networks

The traditional separation among users, designers and producers has long been challenged by various approaches such as participatory design (Björgvinsson et al., 2010) and codesign (Fuad-Luke, 2013), and the lines among stakeholders are getting increasingly blurry in the past couple of decades, espousing hybrid roles and novel forms of collaboration (Stappers et al., 2011). Open design is an approach suggesting different forms of collaboration and co-creation among these stakeholders with varying degrees of skills, capabilities, and resources, through transparency and accessibility of design knowledge to formulate more accessible, participatory, expansive and diverging processes (Bakırlıoğlu & Doğan, 2020). However, there is a need to formalise these stakeholders in a manner that would enable conceptualising novel, collaborative and open value creation processes. This section presents such definitions of stakeholders, their skills and capabilities, and their engagement with open (design) knowledge in a meaningful way.

Through a literature review about users' active design engagement in various literature bodies, Kohtala et al. (2020) distilled various forms of engagement to propose a scale of active user participation from use-as-is to active use, user design and user innovation. For this study, however, there is a need to categorise different stakeholders not only in terms of the practices they enact but also the roles they embody in distributed production settings. The reviewed literature revealed various conceptualisations of stakeholders in open, collaborative design and production processes depending on the framing of the studies and focussed sectors. For example, Fox & Stephen (2014) distinguish DIY innovation and prosumption and further identify DIY entrepreneurship that facilitates prosumption. The authors identify the opportunities for DIY entrepreneurship, especially where traditional manufactured goods don't reach, and DIY-ers can take on the production of such goods through the knowledge and resources provided by DIY entrepreneurs (Fox & Stephen, 2014). In their study on social product development (SPD) companies, Coelho et al. (2018) differentiate the community members as designers and non-designers, and the SPD company acts as the governance structure and facilitator for these community members and takes on the production and distribution of produced goods. Similarly, Fiaidhi and Mohammed (2018) also differentiate Industry 4.0, local entrepreneurs and individual makers.

The reviewed literature also identifies the roles of manufacturer/producer stakeholders and their changing supply chain management strategies in the face of emerging and increasingly more capable digital fabrication tools. About the latter, the reviewed literature presented an enhanced focus on 3D printing and there were articles discussing the potential for decentralised nodes of manufacturing firms (e.g., Verboeket et al., 2021; Verboeket & Krikke, 2019), dynamic and adaptable production nodes and business-to-business collaborations at regional scale for cloud manufacturing (e.g., Fisher et al., 2018; Wu et al., 2013) and manufacturing-as-a-service (e.g., Chaudhuri et al., 2021; Gong et al., 2021; Purvis et al., 2020). There were also studies on the roles of local producer SMEs, maker entrepreneurs, crafts producers and other small-scale producer stakeholders (e.g., Campos & Cipolla, 2021; England, 2020; González-Varona et al., 2020; Moreno et al., 2019). With varying capabilities, resources and levels of market reach, these stakeholders can form diffuse networks of production that are dynamic and responsive to the needs and preferences of different localities and individuals.

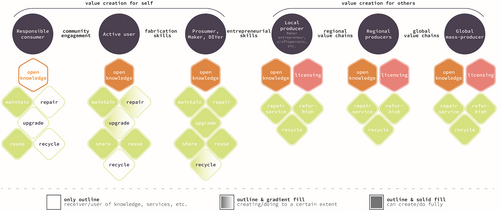

Considering these, Figure 1 identifies the types of stakeholders informed by the reviewed literature. While there are many ways of conceptualising stakeholders, certain divisions were observed in the literature in terms of developing new open design-led business models. The main categorisation is value creation for self and value creation for others.

Value creation for self

The initial set represents stakeholders that participate in a potential distributed production system with the purpose of creating and recapturing value for themselves or their communities. The set includes responsible users/consumers, active users and prosumers/makers/DIY-ers.

Responsible users/consumers acquire products designed and produced by local, regional and/or global, mass-producers to use them as-is – without any involvement in their design or production. These stakeholders do not partake in the production of open design knowledge. They can maintain or get maintenance services for their products. Similarly, they can choose to reuse certain products initially used by others or initiate the reuse of their products through e.g., second-hand markets, sharing services, leasing services, etc. For the remainder of the circular economy strategies (i.e., repair, upgrading and recycling) they are only initiators sending their end-of-life products to other relevant stakeholders.

Active users acquire products designed and produced by local, regional and/or global producers, and adapt them to their own needs and preferences through add-ons/interventions. The interventions can be made either during the design and production stages through pre-defined intervention areas (i.e., mass-customization), or post-purchase via adding parts and features. Former can be achieved through production nodes closer to end-user and additive manufacturing supported by IoT technologies facilitating mass-customization with the flexibility of digital fabrication technologies (e.g., Helms et al., 2008; Hora et al., 2016; Ul Haq & Franceschini, 2020). It can also be achieved through community engagement – online or offline – through actively participating in the design and production processes. Post-purchase alterations can happen through simpler DIY tinkering, fabricating add-ons, etc. These stakeholders both utilize openly shared design knowledge and partake in the production of new open design knowledge. They can carry out self-repair or self-upgrading practices to a certain extent and actively share resources (e.g., equipment, space, etc.) to carry them out.

Prosumers/makers/DIY-ers are the stakeholders that carry out the fabrication and assembly of parts and components to create objects unique to their needs, preferences and wants. They can radically alter component designs, bring them together in different ways, and reutilize these components for self-repair and self-upgrading practices. They also actively share knowledge and resources among themselves and with other stakeholders. They acquire certain parts and components – produced at local, regional or mass/global scale – for these purposes, and additionally design and fabricate their own parts and components.

This set of stakeholders creates value for themselves individually, or for their community, in the forms of knowledge, resources and collaboration. Their skills and capabilities vary greatly in terms of community engagement and fabrication skills, affecting their participation to design, production and post-use processes. However, the researcher also noticed an overlooked aspect of these stakeholders in the literature. These roles are interchangeable in the face of complex material realities; one stakeholder can design and fabricate a unique object for their personal use as part of one distributed production system, but s/he also simply consumes a mass-produced product as part of another distributed production system. While community engagement and fabrication skills are influential in this, it is also important to note other limitations people have. Some products are too complex and expensive to individually produce, and some are too simple to spend time and effort on. As such, the distributed production systems should be designed with this in mind, both accommodating responsible users by offering value recapture services and enabling makers/prosumers/DIY-ers to fabricate their personal objects. Providing all these options must be part of the business models of stakeholders that create value for others, and openness is a crucial part of such endeavour as a design management strategy.

Value creation for others

The second set of stakeholders create products and services for others' use and involve business models for creating social and environmental value, as well as monetary value for their economic sustainability. These stakeholders can collaborate in the design and production of components and products through e.g., open innovation, manufacturing-as-a-service, supply chain innovation, etc., while also enabling the levels of engagement outlined in the previous section. The literature reveals that all these stakeholders deploy various licensing strategies to manage open knowledge. The set includes local producers, regional producers and global mass producers.

Local producers (e.g., maker entrepreneurs, craftspersons) produce components and products for selling at the local scale. These stakeholders produce certain components through digital fabrication equipment and/or crafts, and bring them together with regionally and globally produced components to create value. They can produce on-demand and adapt the designs of their components and products according to the needs and preferences of their local customers. The direct involvement of active users and prosumers/makers/DIY-ers in the design and production of components and products is facilitated through open knowledge, which in turn can initiate an innovative, iterative open design process. The accessibility of these producers – in terms of proximity – highly improves the realisation of post-use services offered by them; whether they repair, refurbish and recycle components and products or act as intermediaries between customers and regional and global producers.

Regional producers are larger nodes in the distributed production ecosystem that develop products with their batch-produced components and globally mass-produced components. Their product offerings can be adapted according to the region/market they are serving and can be iterated accordingly. The components and products are adaptive to regional needs and preferences and produced from regionally available material resources. The openness of their designs enables local producers to develop and iterate new product offerings, and they utilise the openness of mass-produced components to outsource the production of more complex components that might require higher accuracy and safety regulations.

Global mass producers are the largest nodes with the least range of component and product offerings that are either too simple and widely used so that it is economically sustainable to produce them only en masse, or too complex and require precise production and flawless repetition. Mass production can be regarded as a physical copy-paste function for open designs that enable regional and local producers to build their own product offerings on top of, as well as active users and prosumers/makers/DIY-ers to undertake value creation for themselves. This is against the current market segmentation practice of global producers, which forcibly categorises varying individual, local and regional needs and preferences into tidy segments. The openness of these mass-produced designs is crucial not only for enabling alternative business models to emerge at local and regional scales, but also to ensure standardisation of post-use practices at all scales through interoperability. For simpler components and products, the design strategy might be to simplify design features and offer a basis for new iterations, while the design and development of more complex components and products would require inclusive open innovation practices with local and regional producers as well as prosumers/makers/DIY-ers.

This separation between stakeholders that create value for themselves and stakeholders that create value for others is crucial in conceptualising novel open design-led business models. Such a separation enables clear conceptualisation of what kinds of value are offered and what kinds of value are self-created, as well as how they are enacted at different scales (from individual to local, regional and global). It also frames when business models are required and how the roles of stakeholders can shift in distributed production ecosystems – not only among stakeholders that create value for themselves but also between them and the stakeholders that create value for others. In the following section, the potential implications of such separation will be discussed in terms of managing open design in distributed value network settings.

Discussion

This paper presents a systematic literature review on open design, distributed production and alternative business models, which attempts to reconceptualise stakeholders in potential distributed production settings that democratise the design and production processes and empower circular economy practices (e.g., repair, reuse, remanufacture) at varying levels. The authors acknowledge that the stakeholders identified here are not static. Their roles can change in any direction in time, in different distributed production settings, and according to many factors affecting stakeholders' capabilities. For example, an individual can be categorised as a prosumer/maker when they design and fabricate an object for their personal use; yet this does not mean that they undertake such processes for all the objects they use in their lives – instead, they might be a responsible consumer or an active user in different settings. Similarly, value-creation-for-self stakeholders can become entrepreneurs and producers through e.g., lead-user innovation (von Hippel, 2006). Recognising the limitations of such categorisations, the authors argue that both the main categories of value-creation-for-self and value-creation-for-others and the sub-categories of (1) responsible consumers, active users, and prosumers/makers/DIY-ers, and (2) local, regional, and global producers can enable design researchers to identify drivers for adopting openness for distributed value creation processes.

This conceptualisation suggests various dimensions for business model development in terms of collaborative value creation, managing distributed value networks and a layered approach to design and value offerings. In terms of collaborative value creation, rather than design and production/fabrication processes of single stakeholders, this conceptualisation suggests a series of stakeholders building value on top of others' value creation processes, allowing forking and diverging in open-ended design and production processes. The collaborative process implied here can be defined as collaboration by iteration, where one stakeholder creates value at the part or component level and other stakeholders in the value network add value to it according to their needs and preferences, whether for their personal use or economic activity.

The suggested collaborative process indicates numerous potential stakeholders in diffuse value creation networks. It may not be feasible to attempt to manage distributed value creation networks within the boundaries of a singular business model. The openness of design knowledge (both the processes and the outcomes) can act as the necessary management tool, being transparent, accessible, and responsive to the stakeholders' needs and preferences. In turn, such networks can expand not only geographically but also in terms of depth and variety of design outcomes in an economically viable way. This train of thought suggests that a business is simply a node in a distributed value creation network. Hence, as opposed to modelling a set of value creation components cleanly framed within a singular business, there arises a need for conceptualising open design-led businesses as networks of stakeholders introduced in this paper.

In such distributed value networks containing all value-creation-for-self and value-creation-for-others stakeholders introduced in this paper, it becomes necessary to recognise their varying capacities to participate in networked value creation processes. Business models readily involve more than tangible and intangible products and differentiate themselves through value offering services for their defined customer range. In a distributed network of value creation, however, the value offerings may require to be layered to accommodate all variance of capacities of responsible consumers, active users and prosumers/makers/DIY-ers. When the design of parts, components, products and services, as well as the design process, are open, such layering of value offerings can also become possible.

Conclusion

This paper introduces a novel conceptualisation of stakeholders in distributed value creation networks, revealed through a systematic review of the literature at the intersection of open design, distributed production, and business models. The authors argue the need for such conceptualisation to enable envisioning truly alternative open design-led business models. Through the analysis of 131 papers identified, the authors identified two main stakeholder categories, i.e., value-creation-for-self and value-creation-for-others, and framed their ever-shifting roles and responsibilities in complex value creation networks suggested by distributed production. The authors also identify and discuss three distinct dimensions for developing open design-led business models revealed through this conceptualisation, namely collaborative value creation, managing distributed value networks, and a layered approach to design and value offerings. While these dimensions are useful in re-imagining open design processes and design outcomes, they still need to be further explored through exploratory and empirical research to reveal their implications for open design-led business models and distributed value creation networks.

Acknowledgements

The study presented in this paper received funding from and Technological Research Council of Turkey (TÜBİTAK) and European Commission's Horizon 2020 Marie Skłodowska-Curie Actions H2020-MSCA-COFUND (Project No: 801509) through the 2236 Co-Funded Brain Circulation Scheme2 (CoCirculation2) (Project No: 120C213). The TÜBİTAK and European Commission support for the production of this publication does not constitute endorsement of the contents which reflects the views only of the authors, and TÜBİTAK or the Commission cannot be held responsible for any use which may be made of the information contained therein.

Biographies

Yekta Bakırlıoğlu is an Assistant Professor at the Department of Industrial Design, Middle East Technical University, Turkey, and a TUBITAK CoCirculation2 (MSCA-CoFund) Fellow with his project titled Distributed Fabrication through Mass-produced Open Designs (DF-MOD). He is also a researcher at the Department of Media and Visual Arts, Koç University, as part of the Pop-Machina H2020 R&I project. He was a postdoctoral researcher at the University of Limerick, Ireland, as part of the Circular Design (L4IDS) Erasmus+ KA project. He received his PhD from METU Industrial Design in 2017, and he was a visiting researcher at NODUS Sustainable Design Research Group, Aalto ARTS, Finland, in 2016. His research interests include open design, distributed value creation networks, design and design-led businesses for sustainability.

Gülay Hasdoğan is a Professor and the Head of the Department of Industrial Design, METU. She is a founding member of the Industrial Designers Society of Turkey (ETMK), and she served as the President between 1996-98. In 2008 and 2010, as an Executive Committee Member of Design Turkey Industrial Design Awards, she coordinated the development of the award scheme and the evaluation process. She received her BSc in Industrial Design (1985) and MSc in Building Science (1988) from METU, and her PhD from Central Saint Martin’s College of Art and Design (1993). She teaches research methods and graduation projects. She has publications about the institutionalization of industrial design, design education and user models in the design process.