Axial displacement in four implant-abutment connections- In vitro two- and three-dimensional analyses

15630 POSTER DISPLAY BASIC RESEARCH

Background

The trial adaptation of an implant prosthesis in an abutment with axial displacement may greatly affect occlusal contact with the adjacent teeth, and abutment screw loosening may occur. Axial displacement with multiple causes leads to an unfit implant prosthesis and exerts an adverse effect on oral function. Because of this problem, the axial displacement is measured using a micrometer. A more precise and accurate measurement method than the aforementioned techniques is lacking.

Aim/Hypothesis

The purpose of this study was to measure the difference in axial displacement between hand tightening (10 Ncm) and screw tightening at the recommended torque (30 Ncm) according to the type of implant-abutment connection. No difference exists in axial displacement among the four types of the abutment.

Materials and Methods

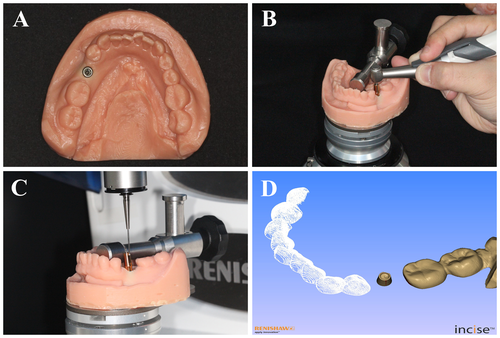

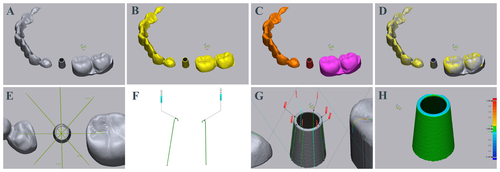

Twenty models of missing mandibular left second premolars were 3D printed and implant fixtures were placed at the same position, using a surgical guide. External and Internal Fixtures (MegaGen) were used. Three implant-abutment internal connection (INT) types and one external connection (EXT) type were prepared. Two of the INT types used titanium (MegaGen)(internal stock, IS) and zirconia (Osstem)(internal zirconia, IZ), and the other was a customized abutment (internal customized, IC), fabricated using a computer numerical controlled milling machine. The EXT type used titanium (MegaGen)(external stock, ES). Screws were tightened at 10 Ncm, representing hand tightening, and then at the recommended torque (30 Ncm) 10 min later (Fig. 1). Abutments and adjacent teeth were then scanned with a contact 3D scanner for 2D and 3D analyses conducted using 3D inspection software (Fig. 1, 2). To determine the difference, a one-way analysis of variance and Tukey HSD test were conducted (α + = .05).

Results

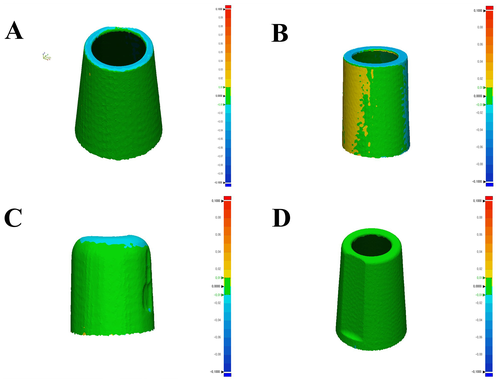

The results of 2D and 3D analyses of the four types of abutment revealed significant differences according to the type of implant-abutment connection (P < .001) (Table 1). In addition, the vertical displacement value (2D) of the abutment was larger than the overall displacement value (3D), and significant differences were observed among the four types of the abutment (P < .05) (Table 1). An interaction effect was observed between analysis methods (2D, 3D) and among the implant-abutment connection types (IS, IC, IZ, and ES) (P = .004). In the 2D analysis, the IZ group (39.6 ± 10.9 μm) showed the most displacement in the vertical direction, whereas the ES group (2.6 ± 0.8 μm) showed the least displacement in the vertical direction. Similarly, in the 3D analysis, the IZ group (20.3 ± 6.8 μm) showed the most displacement in the vertical direction, whereas the ES group (4.4 ± 1 μm) showed the least displacement in the vertical direction. Figure 3 shows the 3D displacement.

Conclusion and Clinical Implications

In the limited results of this in vitro study, significant differences were observed in axial displacement according to the type and material of implant-abutment connection (P < .001). Displacement according to connection type and material should be considered in choosing an implant abutment. Tightening the screw at the manufacturers’ recommended torque is advisable, rather than using hand tightening, when adjusting a prosthesis.