Does implant thread geometry influences the stress distribution in the bone -An In-vitro study

GOQX1 ePOSTER BASIC RESEARCH

Background: An important factor that affects the success of implant therapy is the way occlusal forces are transferred to the bone-implant interface. The transmission of these occlusal forces depends on the design of the implant, type of implant-abutment connection and the presence or absence of threads (Misch et al 2008).Therefore, stress distribution in the bone caused by various implant designs with different types of implant-abutment connections have been evaluated in this study.

Aim/Hypothesis: The aim of this study was to investigate the stress distribution observed in alveolar bone surrounding the dental implants of different designs and thread geometries.

Materials and Methods: 20 implants were utilized in this study, based on the thread geometry the implants were divided into two groups, implant with micro threads (Myriad Plus, Equinox Medical Technology, Amersfoort, NL) (Group 1) and an implant with buttress thread design (Biohorizons Tapered Internal, Biohorizons Inc, Alabama, USA) (Group 2).

20 Photoelastic resin models (30 × 20 × 10 mm) containing the implants was prepared as per manufacturer's recommendations.

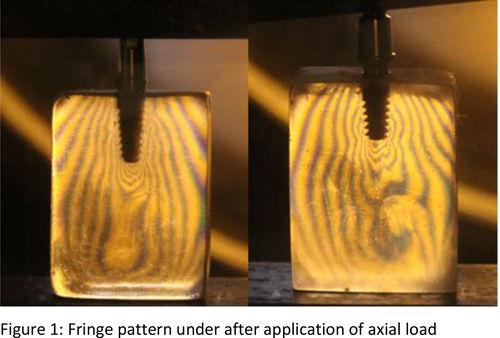

Respective standard abutments were connected to the implants by torquing the abutment screws to 25N cm. The models were positioned in a circular polariscope, and 450N of axial (Figure 1) and oblique (15°) loads were applied on the abutments.

Qualitative analysis was performed by evaluating the number of fringes generated in the resin. The higher the fringe order (N) and number of fringes the greater the stress intensity. Similarly, principal stresses were calculated depending on the fringe order (N) (Da Silva et al 2010).

Results: The analysis was carried out according to the area of fringe concentration (cervical, middle and apical) under axial and oblique load as determined by fringe order (N). According to Area of Fringe Concentration

Axial load : All models showed areas of stress concentration at the coronal, middle and the apical third of the implant, however implants belonging to group 2 (mean -15) demonstrated statistically significantly higher stress pattern (P < 0.05) as compared to group 1 (mean - 11) Oblique load: Similarly irrespective if the group, all models showed areas of stress concentration at the apical, middle and the coronal third of the implant, however implants belonging to group 2 (mean - 21) demonstrated statistically significantly higher stress pattern (P < 0.05) as compared to group 1 (mean- 16)

Conclusions and Clinical Implications: Implant with microthreads showed favorable stress distribution as compared to the implant with buttress thread design. Higher stresses were encountered in the apical region as compared to coronal region irrespective of the type of load and implant used. Oblique load generated highest stress in all the models as compared to axial load. However clinical studies should be conducted in order to confirm these findings.

Keywords: Stress Distribution, Implant Design, Thread Geometry, Stress analysis