Organizational Models for Managing the Operation of Water Supply Facilities of the Agro-Industrial Complex

ABSTRACT

enEnsuring the efficient operation of water supply facilities in the agro-industrial sector is critical for sustainable resource management. The article streamlines the grouping of works performed during the operation of water supply facilities in six stages, differing in purpose, duration, and frequency of work. A process approach has been applied to manage the operation of water supply facilities, ensuring competent planning and timely implementation of the operation stages, setting clear boundaries for interaction with specialized organizations, and reducing the cost of operating water supply facilities, which together can improve the reliability and increase their useful life. Four organizational models of operation management have been developed, reflecting different degrees of interaction between the owners of water supply facilities and specialized organizations during the implementation of operation stages. The strengths, limitations, and practical applicability of each model were assessed through SWOT analysis. The features, prospects, and possibilities of using the developed organizational models and limiting factors are considered. Developed organizational models reflect the features of interaction between the owners of water supply facilities and specialized organizations during the performance of operation stages. The findings suggest that a hybrid approach, involving both internal management and external specialized support, can optimize reliability and cost-effectiveness. The proposed models provide a structured framework for improving the longevity and efficiency of water supply infrastructure.

摘要

zh确保农工业部门供水设施的高效运行, 对于可持续资源管理至关重要。本文将供水设施运营过程中的工作分为六个阶段, 每个阶段在目的、持续时间和工作频率方面有所不同。采用一项过程方法来管理供水设施的运营, 确保运营阶段的合理规划和及时实施, 明确与专业机构的互动界限, 并降低供水设施的运营成本, 从而提高设施的可靠性并延长其使用寿命。本文提出了四种运营管理组织模式, 反映了供水设施所有者与专业机构在运营阶段实施过程中不同程度的互动。通过SWOT分析评估了每种模式的优势、局限性和实际适用性。考量了所提出的组织模式的特点、前景、应用可能性以及限制因素。所提出的组织模式反映了供水设施所有者与专业机构在运营阶段实施过程中的互动特征。研究结果表明, 涉及内部管理和外部专业支持的混合方法能优化可靠性和成本有效性。所提出的模型为“提高供水基础设施的使用寿命和效率”一事提供了一个结构化框架。

Resumen

esGarantizar la operación eficiente de las instalaciones de abastecimiento de agua en el sector agroindustrial es fundamental para la gestión sostenible de los recursos. El artículo simplifica la agrupación de las obras realizadas durante la operación de las instalaciones de abastecimiento de agua en seis etapas, que difieren en su propósito, duración y frecuencia. Se ha aplicado un enfoque basado en procesos para gestionar la operación de las instalaciones de abastecimiento de agua, lo que garantiza una planificación competente y una implementación oportuna de las etapas de operación, estableciendo límites claros para la interacción con organizaciones especializadas y reduciendo el coste de la operación de las instalaciones. Esto, en conjunto, puede mejorar la fiabilidad y prolongar su vida útil. Se han desarrollado cuatro modelos organizativos de gestión de operaciones que reflejan los diferentes grados de interacción entre los propietarios de las instalaciones de abastecimiento de agua y las organizaciones especializadas durante la implementación de las etapas de operación. Se evaluaron las fortalezas, las limitaciones y la aplicabilidad práctica de cada modelo mediante un análisis FODA. Se consideran las características, las perspectivas y las posibilidades de uso de los modelos organizativos desarrollados, así como los factores limitantes. Los modelos organizativos desarrollados reflejan las características de la interacción entre los propietarios de las instalaciones de abastecimiento de agua y las organizaciones especializadas durante la ejecución de las etapas de operación. Los hallazgos sugieren que un enfoque híbrido, que involucra tanto la gestión interna como el apoyo especializado externo, puede optimizar la fiabilidad y la rentabilidad. Los modelos propuestos proporcionan un marco estructurado para mejorar la longevidad y la eficiencia de la infraestructura de suministro de agua.

1 Introduction

The efficiency of the functioning of organizations and the comfort of living for people largely depend on the uninterrupted water supply in the required quantity and standard quality to meet industrial, household, drinking, and fire-fighting needs (Mishra and Dubey 2023; Zhang et al. 2022; Salehi 2022). Ensuring the reliable operation of water supply facilities with minimal costs at different stages of the life cycle is the main goal of their owners and specialized organizations for the maintenance of buildings and structures.

Water treatment facilities for small settlements that utilize underground sources (Yushchenko et al., 2023a) typically include the following components: (i) An intake well is constructed to access the underground water source. The well is equipped with screens or filters to prevent the entry of sediment or debris (Hurynovich and Ramanouski, 2018). (ii) A pumping system, which may include submersible pumps or above-ground pumps, is installed to lift the water from the intake well and deliver it to the treatment facility. (iii) Presedimentation basins or settling tanks are used to allow suspended particles, sediment, and larger impurities to settle out of the water. This step helps in reducing the load on subsequent treatment processes. (iv) Filtration is an essential component in water treatment. Different types of filters (Yushchenko et al. 2023b), such as rapid sand filters, multimedia filters, or cartridge filters, are used to remove smaller suspended particles, iron and manganese and other dissolved contaminants (Romanovski et al. 2021), turbidity, and some microorganisms that may be present in the water. (v) To ensure the water is safe for consumption, disinfection is applied (Romanovski et al. 2020). Common disinfection methods include chlorination, UV irradiation, or ozonation. This step helps to kill or inactivate harmful bacteria, viruses, and other pathogens. (vi) Treated water is stored in clean and covered reservoirs or storage tanks to ensure a continuous supply during peak demand periods. These tanks also provide a buffer for the distribution system. (vii) The treated water is distributed to the households and community through a network of distribution pipes. Valves, pumps, and pressure control devices are used to regulate the flow and maintain adequate pressure. (viii) Water treatment facilities should have monitoring systems in place to ensure the quality and safety of the treated water. This may include monitoring parameters such as turbidity, disinfectant levels, pH, and flow rates. Automatic control systems and alarms can help operators manage and maintain the treatment process effectively.

The life cycle of water supply facilities typically involves several stages, from planning and design to construction, operation, and maintenance (Garcia-Valdecantos et al. 2016). Here is a general overview of the life cycle stages for water supply facilities: (i) Planning and Feasibility Study: This stage involves identifying the need for a water supply facility, conducting feasibility studies, and determining the project's scope and objectives. Factors such as population growth, water demand, source availability, and environmental considerations are assessed (Pahl-Wostl and Kabat 2011; Kareem and Veeriah 2015). (ii) Design and Engineering: Once the project is deemed feasible, detailed design and engineering plans are developed. This includes determining the water sources, designing treatment processes, selecting equipment, and laying out the distribution system. Environmental and safety considerations are also incorporated into the design. (iii) Construction: The construction phase involves building the water supply facility according to the approved design. It includes site preparation, excavation, installation of pipelines, construction of treatment plants, and other necessary infrastructure. Quality control and safety measures are implemented during this stage (Nasirzadeh et al. 2013). (iv) Commissioning and Start-up: After construction is completed, the facility undergoes a commissioning process to ensure all components are functioning as intended. This involves testing the equipment, pipelines, and treatment processes to verify their performance and compliance with standards. Once the facility is operational, it moves into the next stage (BCA 2016; Marrano 2014). (v) Operation and Maintenance: During this stage, the water supply facility is operated to provide a continuous and reliable water supply to consumers. This includes managing water sources, treatment processes, distribution networks, and storage facilities. Regular maintenance activities such as repairs, equipment replacement, and system inspections are performed to ensure efficient operation and prevent failures (Zhang et al. 2018; Jajac et al. 2009). (vi) Upgrades and Expansion: Over time, the water supply facility may require upgrades or expansions to meet changing water demand or to comply with new regulations. Upgrades can include improving treatment processes, installing advanced monitoring systems, or increasing the capacity of storage or distribution infrastructure. Expansion may involve constructing additional treatment units, reservoirs, or pipelines (Dong et al. 2017). (vii) Rehabilitation and Replacement: As water supply facilities age, components may deteriorate and require rehabilitation or replacement. Pipes may corrode, treatment equipment may become outdated, or storage structures may deteriorate. Rehabilitation involves repairing or refurbishing existing infrastructure, while replacement involves replacing worn-out components or entire facilities to ensure continued functionality and efficiency. (viii) Decommissioning: In some cases, when a water supply facility becomes obsolete or is no longer needed, it may be decommissioned. This involves the permanent cessation of operations, dismantling of infrastructure, and proper closure of the site while considering environmental considerations and potential impacts. It is important to note that the life cycle stages may vary depending on the scale and complexity of the water supply facility, as well as specific regional or local factors. Additionally, regulatory requirements, technological advancements, and evolving water management practices can influence the life cycle of water supply facilities.

The duration of the life cycle of water supply facilities depends on compliance with certain norms and rules in the design, construction, and operation of these facilities. During the construction and demolition phase, compliance with the rules and regulations is ensured through the involvement of specialized construction companies and control by the owners of water supply facilities, and the operation phase is completely dependent on the decisions and actions of the owners of the facilities. It should also be noted that the operation stage is the longest and is calculated in decades; for example, the standard service life for water intake structures from surface water sources is 50 years (Typical Equipment Life Expectancy 2023). However, very often water supply facilities or their equipment fails earlier than the standard service life due to untimely or incomplete implementation of measures for their operation. In this situation, the owner of water supply facilities incurs losses and interruptions in water supply only due to the fact that he could not competently assess the technical condition of water supply facilities, develop a plan for the required measures for the operation of facilities, and ensure their implementation.

When operating water supply facilities, owners and specialized organizations face the following problems: lack of reliable, timely, complete, homogeneous, and discrete information about water supply facilities; the use of outdated technologies in the operation of water supply facilities; untimely and incomplete implementation of measures to ensure the reliability of water supply facilities; excessive consumption of electricity and water losses during the operation of water supply facilities; premature failure of water supply equipment and facilities. The solution of the above problems dictates the need to develop scientific approaches to improve the efficiency of operation of water supply facilities.

The purpose of this study, based on the problems identified above, is to develop methodological support for managing the operation of water supply facilities of the agro-industrial complex, which includes grouping into stages of all activities performed during the operation of water supply facilities; development of a diagram of the structure of the process of managing the operation of water supply facilities; creation of organizational models for managing the operation of water supply facilities.

In accordance with the stated goal, the following tasks were set and solved: (i) To analyze the measures that must be taken to ensure the required reliability of water supply facilities, considering the current requirements for environmental protection and rational use of resources. This dictates the need to group all activities into stages of operation, characterized by a common purpose, duration and frequency of implementation. The solution of this problem will allow organizing competent planning of all activities to ensure the required reliability of water supply facilities, taking into account the current requirements for environmental protection and rational use of resources. (ii) Develop a framework for the management of the operation of water facilities to identify the key challenges facing water facility owners and operators. (iii) Analyze and structure the features of interaction between the owners of water supply facilities and specialized organizations to ensure the timely implementation of operations in full. In this case, it is required to develop organizational models for managing the operation of water supply facilities that characterize various options for interaction between owners and specialized organizations.

In this paper, SWOT analysis was used to analyze organizational models of water supply facility operation management, because it is a universal tool for strategic analysis that allows structuring the strengths and weaknesses of various models, as well as identifying external opportunities and threats that affect their effectiveness. Alternative methods, such as the TOWS matrix, SOAR analysis, SWOC analysis, and SCOPE model, were not used for the following reasons: The TOWS matrix is focused on developing strategies, while the main goal of the study is to structuring the advantages and disadvantages of management models; SOAR analysis excludes the analysis of threats and weaknesses, which is important in the context of water supply facility operation; SWOC analysis replaces threats with challenges, but it is the consideration of potential risks (equipment wear and tear, changes in regulatory requirements) that plays a key role; the SCOPE model is difficult to implement and is less common in this area. The choice of SWOT analysis is due to its clarity, ease of use, and high adaptability to the tasks of water supply facility operation management.

Effective management of water supply facilities in the agro-industrial complex faces a number of practical difficulties, including deterioration of infrastructure, inefficient resource allocation, lack of a concept for planning and managing the operation of local water supply systems in the absence of a clear mechanism for public–private partnership (PPP). These problems are aggravated by gaps in water management policies, such as insufficient regulatory framework for monitoring the organization of private partnerships in the operation of water supply systems, and the lack of incentive mechanisms for infrastructure modernization. This study describes the existing problems and proposes a comprehensive approach to address them. This study will be useful both for owners of water supply systems in the agro-industrial complex and for water policymakers, as it contains practical solutions for improving the efficiency of water supply systems and water resources management.

2 Methodology

2.1 Characteristics of the Objects of Study

Four organizations were selected as objects for obtaining information on the research topic: SPK “Vishnevka-2002,” OJSC “Staritsa-Agro,” a branch of OJSC “BELAZ” SPK “Pervomaisky,” a branch of the Republican Unitary Enterprise “Plempticezavod Belorussky,” located in the Minsk region of the Republic of Belarus. The water supply of the represented organizations is carried out from underground sources of water supply.

SPK “Vishnevka-2002” is an agricultural organization specializing in the cultivation of grain, vegetables, perennial grasses and the production of pork, beef, and milk. The organization has five water supply systems on its balance sheet, which provide water to four dairy farms, two pig farms, one livestock complex for fattening cattle, and a mechanized yard. Data on the water supply facilities of the SPK “Vishnevka-2002” are presented in Table 1.

| Location | Characteristics of water supply facilities |

|---|---|

| Uglyany | Well water intake with one well, water tower, water supply network |

| Luskovo | Well water intake with one well, water tower, water supply network |

| Solomorechie | Well water intake with one well, water tower, water supply network |

| Gatovino | Well water intake with one well, water tower, water supply network |

| Vishnevka | Well water intake with two wells, water tower, water supply network, second lift pumping station, clean water tank |

JSC “Staritsa-Agro” is an agricultural organization specializing in the cultivation of grain, sugar beets, potatoes, corn, and perennial grasses, as well as the production of pork, beef, and milk. On the territory of JSC “Staritsa-Agro,” there are five dairy farms, one pig farm, one dairy complex, a plant growing shop, and a construction site (a woodworking and joinery shop, a mortar concrete unit). To meet the needs of the organization, there are 10 water supply systems on the balance sheet. Data on the water supply facilities of Staritsa-Agro OJSC are presented in Table 2.

| Location | Characteristics of water supply facilities |

|---|---|

| Androsovshchina | Well water intake with one well, water tower, water supply network |

| Kalinovka | Well water intake with three well, water tower, water supply network |

| Bor | Well water intake with one well, water tower, water supply network |

| Rusaki | Well water intake with one well, water tower, water supply network |

| Badezhi | Well water intake with one well, water tower, water supply network |

| Staritsa | Well water intake with one well, water tower, water supply network |

| Chernichnoe-1 | Well water intake with one well, water tower, water supply network |

| Chernichnoe-2 | Well water intake with three well, water tower, water supply network |

| Salki | Well water intake with one well, water tower, water supply network |

| Svidichi | Well water intake with one well, water tower, water supply network |

The branch of JSC “BELAZ” SPK “Pervomaisky” is a full-cycle agricultural production: Crop products provide fodder for its livestock farms, which in turn supply raw materials for meat and milk processing areas. The total land area of the branch is 4628 hectares of land. The branch has four water supply systems for two commercial dairy farms, one pig farm, and a processing site (production of sausages). Data on water supply facilities of the branch of JSC “BELAZ” SPK “Pervomaisky” are presented in Table 3.

| Location | Characteristics of water supply facilities |

|---|---|

| MTU Vorot | Well water intake with one well, water tower, water supply network |

| ZhU Zakazinets | Well water intake with one well, water tower, water supply network |

| Sloboda MTF-1 | Well water intake with one well, water tower, water supply network |

| Sloboda MTP | Well water intake with one well, water tower, water supply network |

The branch of the Republican Unitary Enterprise “Plempticezavod Belorussky” is an organization of the processing industry of the agro-industrial complex, carrying out the cultivation and breeding of poultry (chickens, turkeys). To ensure the organization's water supply, one water supply system is used, which includes a well water intake with three wells, a water tower and a water supply network.

2.2 Approach

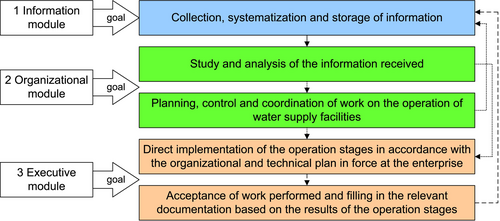

To study the structure of the management process, a process approach was applied, which makes it possible to present this process in the form of three interrelated modules: informational, organizational, and executive.

When developing organizational models for operating management, the method of organizational modeling was applied, which made it possible to graphically display the distribution of functions and tasks between the participants in the operation of water supply facilities, as well as the sequence of their implementation and the relationship between them.

The developed models were assessed using SWOT analysis, a strategic analysis method that helps to identify the strengths and weaknesses of each model, as well as determine external opportunities and threats. The SWOT analysis procedure included the following: (i) collecting data on current approaches to the operation of water supply facilities in the organizations under study; (ii) determining internal factors (strengths and weaknesses) by analyzing the resource capabilities of the organizations, management structure, and operational efficiency; (iii) identifying external factors (opportunities and threats), taking into account regulatory aspects, availability of specialized organizations, technological trends, and economic conditions; (iv) forming SWOT matrices for each model and interpreting them in order to identify the most sustainable and effective management approaches. Thus, the applied methodological tools provide a comprehensive analysis of the effectiveness of organizational models and allow us to assess their practical applicability in managing the operation of water supply facilities.

3 Results

- Inspection allows you to timely identify malfunctions in water supply facilities, determine the timing of the subsequent stages of operation, and define the list and scope of work by assessing the technical and sanitary condition of the facilities. The visual inspection and measurements of the control parameters of the structure operation were included in the inspection. Depending on the type of structure, its technical condition, and degree of automation, inspections can be carried out every day, once a week, or once a month.

- Maintenance allows you to increase the overhaul period of operation of structures and allows you to reduce the wear rate of the main structures, parts, and components of structures, reduce energy consumption, ensure the maintenance of the required sanitary condition, and prevent failures and malfunctions. Maintenance included fixing, lubricating, adjusting, and other work performed without dismantling the main parts and assemblies of water supply facilities and designed to maintain the facility in working condition. Maintenance, depending on the type of structure and its standard service life, is advisable to be carried out once a month or once every 3 months.

- The current repair is aimed at eliminating individual minor faults that do not lead to a stop in the operation of facilities but reduce the efficiency of water supply as a whole. Performing routine maintenance will ensure the required sanitary condition, increase the overall period of operation of the structure, and reduce the likelihood of malfunctions and damage. The current repair included works on cleaning structures and their equipment from mechanical, biological, chemical formations, partial disassembly of the main parts, and assemblies to eliminate leaks and other works aimed at restoring the partially lost operability of structures. The frequency of current repairs is determined by the type of structure, its service life, and the recommendations reflected in the technical passport. It is recommended to carry out current repairs every 6 months or once a year.

- Overhaul is intended to fully restore the lost performance of water supply facilities by disassembling or replacing individual parts and assemblies. Overhaul includes the replacement of a well filter, pipes, fittings, fittings, and other works to bring water supply facilities into proper technical condition. The frequency of overhaul depends on the type of water supply facility, its service life, and the recommendations of the manufacturer (construction organization). Major repairs are carried out as needed, but as a rule, at least every 3–5 years.

- Elimination of damage is necessary for the prompt restoration of uninterrupted water supply as a result of the destruction of individual parts of water supply facilities and is an unscheduled event. Therefore, the timing and list of repair work in the elimination of damage will be individual for each specific case.

- Seasonal work is related to the preparation of water supply facilities for the autumn–winter and spring–summer period in order to exclude the negative impact of natural and climatic conditions on them. The timeliness of seasonal work is ensured by monitoring meteorological conditions. Seasonal work is associated with the insulation (deheating) of water supply facilities, draining, and pumping water from water supply facilities.

The timeliness and completeness of the implementation of the considered stages of operation are the main conditions for ensuring the reliability of water supply facilities, extending their useful life and reducing the cost of their operation. The proposed grouping of works on the operation of water supply facilities allows organizing competent planning of activities for the operation of facilities, taking into account the established requirements for environmental protection and rational use of resources, as well as reserving financial resources for their implementation.

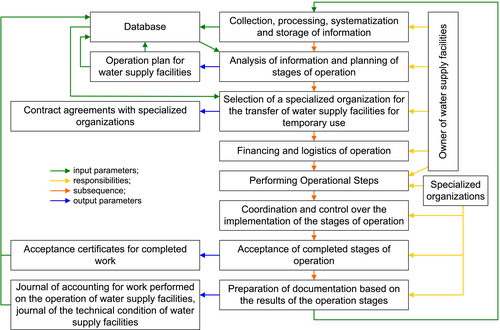

In order to effectively manage the operation of water supply facilities, in addition to grouping works into operation stages, it is necessary to analyze the very structure of the management process. From the point of view of the process approach, the management of the operation of water supply facilities can be represented as three interrelated modules: informational, organizational, and executive (Figure 1).

The information module characterizes the formation of a data bank in order to collect, systematize and store information necessary to manage the operation of water supply facilities. The organizational module includes the study and analysis of information to form a list of works for each stage of operation for the corresponding water supply facility with the establishment of deadlines for their implementation, as well as planning. This module allows you to create a plan for the operation of water supply facilities, as well as assess the availability of the owners of water supply facilities with personnel of the required qualifications and technical means to perform the relevant stages of operation. The executive module is required to control the execution and acceptance of work, as well as the preparation of documentation and filling in the necessary information for the information module.

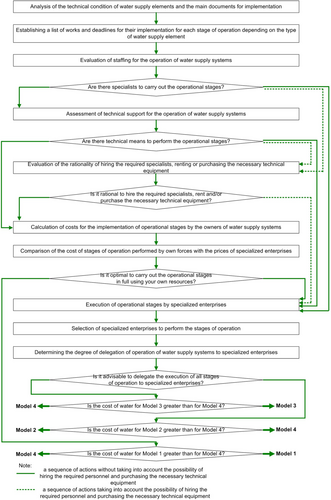

The proposed approach to interpreting the structure of the process of managing the operation of water supply facilities makes it possible to form a holistic view of the management process itself, the main goals and objectives of the operation of water supply facilities, and to simplify the planning and control functions. The timely and full implementation of the operation stages at minimal cost requires the owners of water supply facilities to have specialized machinery and equipment, use advanced technologies, have a certain list of employees with the required qualifications in the state, and solve organizational issues (collecting the necessary information, developing an operation plan, coordinating works and control over their implementation, and maintaining the required documentation). Thus, the owners of water supply facilities face the question of operating the water supply facilities themselves or attracting specialized organizations. When operating water supply facilities, it is necessary to take into account the economic feasibility of the participation of specialized organizations, as the use of advanced technologies, modern and efficient equipment, and highly qualified personnel may make the implementation of operational stages more cost-effective than relying on the resources of the facility owners.

In the course of the study, an analysis was made of the activities of four agricultural organizations (SPK “Vishnevka-2002,” OJSC “Staritsa-Agro,” a branch of OJSC “BELAZ” SPK “Pervomaisky,” a branch of the Republican Unitary Enterprise “Plempticezavod Belorussky”), which revealed the uniformity of approaches to management operation of water supply facilities. So, the director and chief engineer deal with the planning and organization of the operation of water supply facilities in agricultural organizations, and the direct implementation of the operation stages is carried out by a team of labor-intensive processes.

As a rule, the team consists of electricians, repairmen, and a repair plant operator. This team can fully perform inspections, maintenance, seasonal work, current repairs and partly work to eliminate accidents and overhaul for all elements of the water supply. It is difficult to carry out emergency work and overhaul in full by a team for labor-intensive processes, because some activities require the involvement of special equipment and personnel for a short time, and are rarely performed (once every 5–10 years). For example, to replace a filter in a well, a drilling rig, a driver and an assistant driver are needed, the need for which is needed no more than 1 day every 3–5 years, depending on geological conditions and water quality.

Thus, a labor-intensive process team can successfully perform all stages of operation for water supply facilities for several years, but the time will come when it will be necessary either to rent specialized machines and train personnel, or to turn to specialized organizations.

As practice shows, agricultural organizations try as much as possible to carry out the stages of operation on their own. Relationships with specialized enterprises are of an unsystematized nature and are carried out through the conclusion of work contracts for the agreed volumes and list of works. Four operational management organizational models have been developed to demonstrate the potential for cooperation between water facility owners and specialized organizations.

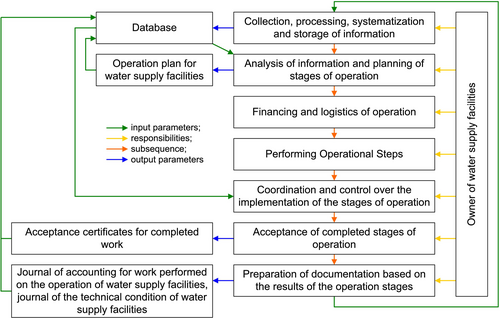

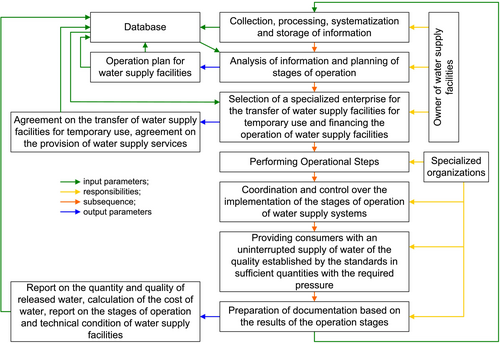

Model 1 “autonomous operation” assumes that the operation of water supply facilities is carried out only by their owners. A block diagram of this organizational model is shown in Figure 2.

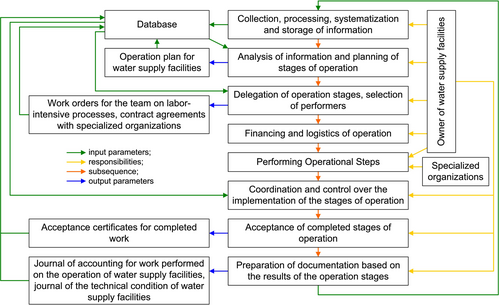

Model 2 “partially delegated operation” assumes that the owners of water supply facilities involve specialized organizations in the implementation of individual stages of operation. The block diagram of the considered organizational model of operation management is shown in Figure 3.

Model 3 “fully delegated operation” is based on the fact that the owners of water supply facilities outsource the execution of all stages of operation to specialized organizations. A block diagram of this organizational model of operations management is shown in Figure 4.

Model 4 “operation by a specialized organization” describes the situation when the owners of water supply facilities enter into an agreement for the gratuitous transfer of their water supply facilities to a specialized organization for a specified period (at least 3 years) and at the same time conclude an agreement with it for the purchase of the required amount of water of the required quality, according to established tariffs (prices). A block diagram of this organizational model of operations management is shown in Figure 5.

The developed organizational models characterize the features of the operation management process and the relationship between the owners of water supply facilities and specialized organizations, which makes it possible to distribute powers, duties, and responsibilities between the participants in the operation.

An analysis of activities in the field of water supply of SPK “Vishnevka-2002,” OJSC “Staritsa-Agro,” a branch of OJSC “BELAZ” SPK “Pervomaisky,” a branch of RUSP “Plemptice plant Belorussky” showed that these organizations are in a state of choice between the organizational model “autonomous operation” and the “partially delegated operation” model. This situation is due to the fact that every year water supply structures are subject to physical and moral wear and tear, which means a decrease in their reliability with an increase in time and financial costs for performing operational stages. Therefore, owners of water supply systems are beginning to understand that in order to maintain structures in working order, the need for the required personnel and technical means is growing, the list of which is growing as the systems wear out. It should be noted that market relations contribute to an increase in the number of private specialized organizations that use the most available technologies, reducing the time and cost of performing work for the purpose of competition. All this contributes to the abandonment of single-handed solutions to problems in the operation of water supply facilities and the participation of specialized organizations.

As a result, it turns out that in order to ensure efficient operation of water supply facilities when using Model 1, it is necessary to invest in hiring personnel and acquiring (purchase, rental, leasing) technical means to perform all stages of operation, and when using other models, spend money on attracting specialized enterprises. For example, for OJSC “Staritsa-Agro,” which has 10 water supply systems on its balance sheet, model 1 “autonomous operation” may be more effective than Model 2 “partially delegated operation.” However, to confirm or refute this assumption, it is necessary to take into account internal and external factors and calculate opportunity costs.

The application of Model 3 “fully delegated operation” of Model 4 “operation by a specialized organization” in the agricultural production complex “Vishnevka-2002,” OJSC “Staritsa-Agro,” a branch of OJSC “BELAZ,” a branch of the RUSP “Belorussky breeding plant” is currently not is being considered, but there are all the prerequisites for their use: a sufficient number of specialized enterprises of different forms of ownership. This is primarily due to the reluctance of owners of water supply systems to pay specialized organizations for what can be done on their own. Secondly, there is a lack of legislative regulation of relations between the owners of water supply systems and specialized organizations during the operation of water supply facilities: now everything is regulated simply by contractual relations of the parties without providing benefits, subsidies, subsidies, and additional guarantees.

The choice of the optimal organizational model of operation management will help to increase the reliability of water supply facilities, increase the overhaul period, and reduce the cost of their operation. Each of the presented organizational models for managing the operation of water supply facilities has its own advantages and disadvantages that need to be summarized and analyzed. For this purpose, SWOT analysis was applied, which is a universal tool for identifying and structuring the weaknesses and strengths of the object of analysis, taking into account the factors of the external and internal environment (Weihrich 1982). Because SWOT analysis carries a certain element of subjectivity, in this work, SWOT analysis was used not as a tool for making a specific decision on choosing the optimal organizational model for managing the operation of water supply facilities, but for structuring and visualizing information on each of them. SWOT-analysis of organizational models describing the options for interaction between the owners of water supply facilities and specialized enterprises in the performance of the stages of operation of water supply facilities is presented in Tables 4–7.

| Strengths | Weak sides | |

|---|---|---|

| External environment | Possibilities | Threats |

|

|

|

| Internal environment | Advantages | Disadvantages |

|

|

| Strengths | Weak sides | |

|---|---|---|

| External environment | Possibilities | Threats |

|

|

|

| Internal environment | Advantages | Disadvantages |

|

|

| Strengths | Weak sides | |

|---|---|---|

| External environment | Possibilities | Threats |

|

|

|

| Internal environment | Advantages | Disadvantages |

|

|

| Strengths | Weak sides | |

|---|---|---|

| External environment | Possibilities | Threats |

|

|

|

| Internal environment | Advantages | Disadvantages |

|

|

The analysis of the activities of the studied organizations showed that various models of interaction between the owners of the facilities and specialized organizations are used in the management of water supply facilities. Based on the identified patterns, four organizational models of operation management were developed: autonomous operation, partially delegated operation, fully delegated operation, and operation by a specialized organization. SWOT analysis showed that autonomous operation ensures the efficiency of decision-making and cost control but requires significant resources for maintaining personnel and equipment, and also carries the risk of suboptimal performance of work. Partially delegated operations reduce the burden on owners by engaging specialized contractors but increase administrative costs and requires the development of a contractor evaluation and selection system. Fully delegated operation allows the use of advanced technologies and qualified personnel of specialized organizations but reduces the efficiency of management and increases dependence on third-party contractors. Operation by a specialized organization minimizes the management burden on the owner of the facility, but requires legal registration of the transfer of assets and may lead to an increase in tariffs. The results of the study show that the optimal model depends on the scale and condition of the infrastructure, the availability of contractors, and economic feasibility. In particular, small and medium-sized enterprises more often use autonomous or partially delegated operation, while large organizations and municipal structures tend to fully transfer management to specialized organizations. The identified features and limitations of each model can serve as a basis for developing recommendations for optimizing the management of water supply facilities in the agro-industrial complex.

In order to select the optimal organizational model of operation considering the factors of the external and internal environment, an algorithm was developed that describes the sequence of actions of the owners of water supply systems (Figure 6). The algorithm is based on the following stages of decision-making: (i) problem identification (analysis of the technical and sanitary condition of the water supply elements in order to establish a list of works and deadlines for their implementation for each stage of operation with the development of an annual organizational and technical plan); (ii) problem diagnostics (identification of difficulties in the implementation of operation of agricultural water supply systems by agricultural organizations—assessment of personnel and technical support for the operation process, determination of the cost of performing work by own forces and comparison with the prices of specialized organizations); (iii) formulation of criteria and constraints for the optimal solution to the problem (availability of the required personnel and technical means at agricultural organizations, rationality of delegation of operation stages, minimum cost of water); (iv) determination of alternative solutions (assessment of organizational models of operation taking into account the formulated criteria and constraints); (v) selection of the optimal solution (determination of the optimal organizational operating model that will ensure uninterrupted supply of water in the required quantity, established quality and at minimal cost).

4 Discussion

The results of the study show that the efficiency of water supply facilities operation largely depends on the chosen management model. The identified patterns are consistent with the data of other studies in the field of water supply and operations management. Optimal management of water supply facilities requires a balance between the internal resources of the organization and the involvement of specialized contractors (Fletcher et al. (2017)). This is confirmed by the trend we identified: autonomous operation is effective for enterprises with developed infrastructure and qualified personnel, while delegating management to specialized organizations is justified when it is necessary to implement advanced technologies and reduce operational risks. Studies (Cherchi et al. 2015; Coelho and Andrade-Campos 2014; Mamaghani et al. 2023; Herstein 2009) point to the importance of using modern monitoring technologies and automated water supply management systems. In our analysis, this is manifested in the advantages of fully delegated operation, where specialized organizations use advanced technical solutions that ensure increased efficiency and reduced costs. However, as noted by Oke et al. (2018) and Gurel (2017), a high degree of dependence on contractors can lead to increased operating costs and decreased management flexibility, which is confirmed by our SWOT analysis. Another important aspect is the influence of the regulatory framework and economic factors. According to previous works (Grimshaw et al. 2002; Cordella and Willcocks 2012; Marvel and Marvel 2009), government support and legislative incentives can contribute to a wider implementation of outsourcing models, especially in agriculture and the municipal sector. Our study noted that the lack of clear regulatory mechanisms hinders the transition of organizations to a fully delegated model and operation by specialized organizations. Thus, our findings confirm and complement previous studies, identifying the specifics of applying various models of operation management in the agro-industrial complex. Future research can be aimed at a more detailed economic analysis of each model, as well as developing recommendations for their adaptation, considering technological and legal factors.

The issues of planning and organizing the operation of water supply facilities in agricultural organizations are handled by specialists from these organizations. This situation is due to the use of local water supply systems located near agricultural organizations and small volumes of water consumption relative to the occupied area. If the issue concerns large settlements or industrial enterprises with a large volume of water supply, then in this case centralized water supply systems will be used, which will be serviced by specialized enterprises.

Thus, the proposed organizational models for managing water supply facilities eliminate critical gaps in the PPP policy. The use of the developed organizational models allows for a more efficient distribution of labor, technical and financial resources in managing the infrastructure. These models define the roles and responsibilities of the participants in the operation and owners of water supply facilities, establish mechanisms for cost-effective provision of services and create opportunities for planning and investing in water infrastructure.

Partially delegated and fully delegated operation models provide a structured basis for PPP, defining clear responsibilities between facility owners and specialized organizations. As a rule, there are no comprehensive guidelines for the principles of interaction between the owner of the water supply system and private specialized organizations at the legislative level, which leads to untimely and inefficient performance of work on the operation of water supply facilities (Pahl-Wostl and Kabat 2011). The introduction of standardized models of interaction in the operation of water supply facilities will reduce risks and costs for public authorities (development and financing of support and development programs at the expense of budgetary funds), stimulate the volume of private investment in the modernization of technologies and equipment for water supply systems. In addition, the “operation by a specialized organization” model formalizes long-term contractual relations, ensuring compliance with the quality of service, environmental standards, and established tariffs. In water resources management, there is often an inefficient allocation of financial, technical and labor resources in the operation, and expansion of water infrastructure (Garcia-Valdecantos et al. 2016). The autonomous operation model allows organizations with sufficient capacity to maintain full control over resources, ensuring direct accountability and faster response times. All subsequent delegation models offer a cost-sharing mechanism where public or private organizations take over maintenance, reducing the burden on resource-constrained agricultural enterprises. These models provide scalable solutions for different levels of resource availability, while ensuring long-term sustainability of the infrastructure.

All presented organizational models are aimed at timely and high-quality performance of water supply system maintenance, infrastructure modernization, and life-cycle cost management. Typically, many water management policies focus primarily on the construction and expansion of water supply systems, neglecting long-term sustainability and performance optimization (Zhang et al. 2018). In this way, the organizational models integrate the issues of planning the timing and volume of work, monitoring the technical condition and costs, which allows for a transition from reactive infrastructure management to proactive and sustainable practices.

By addressing key governance issues, the proposed organizational models align operational strategies with policy needs, ensuring that water supply systems remain efficient, financially viable, and sustainable, considering external and internal factors.

In order to strengthen the water governance framework, a number of changes and additions to existing regulations are needed. First of all, it is necessary to develop a legislative framework for the implementation of public–private cooperation (terms and conditions and contractual obligations for partially and fully delegated operation models, service quality standards, tariff rules and dispute resolution mechanisms). Secondly, it is necessary to develop incentives to encourage private sector investment in water infrastructure management and the introduction of technologies to improve service reliability while reducing operating costs (preventive maintenance schedules, monitoring systems using modern technologies, real-time leakage monitoring, etc.). By implementing these policy recommendations, governments can close regulatory gaps, improve efficiency and ensure sustainable management of water infrastructure by balancing public and private interests.

The results of this study highlight the importance and relevance of developing public–private cooperation to improve the quality of water supply and sustainable development of infrastructure. Structured approaches to water supply system management, described by the presented organizational models, allow us to see the gaps that exist in the management of operation and formulate key policy recommendations for their use.

The key policy recommendations obtained as a result of the study are as follows: establishing a framework for the implementation of contractual obligations in the operation of water supply systems at the legislative level; defining standards and criteria for the quality of work performed and services rendered; establishing criteria and defining procedures for selecting the contractor for operation; developing a supervision policy for partially and fully delegated operation models.

The implementation of these recommendations will eliminate existing gaps in the management of water supply systems, improve operational efficiency, and ensure long-term sustainability of water supply infrastructure. The conducted research contributes to the development of a water resources management structure, ensuring their adaptability, accountability, and reliability.

The findings of this study have direct policy implications for improving equitable resource allocation and promoting sustainable water management. The proposed organizational models provide structured governance approaches that can be used to address inefficiencies, inequalities in resource allocation, and long-term sustainability issues in water supply management.

One of the key challenges in water resource management is to ensure equitable and efficient allocation of water resources, particularly in the rural and agricultural sectors where infrastructure and service levels often lag behind those in urban areas. Partially delegated and fully delegated operating models create opportunities for more inclusive access to water services by allowing specialized organizations to fill gaps where public infrastructure is ineffective. By introducing cost-sharing mechanisms, these models reduce the costs of allowing small-scale agricultural enterprises to access high-quality water services that would otherwise be unavailable. In addition, resource allocation is directly linked to improving the efficiency and reliability of water supply, thereby avoiding monopolization of services and ensuring equitable resource allocation to water infrastructure. The state and water supply system owners are interested in creating a sustainable water resources management system in the long term, and the private sector is interested in increasing demand for their services and stability. Grouping and analyzing the stages of operation and developing organizational models of operation allow us to form a long-term sustainable management system for water supply systems aimed at systematization and prevention of activities on operation, modernization, and reliability of water supply systems considering internal and external factors. Each model describes a possible strategy for an organization to operate its water supply systems. An autonomous model of operation is beneficial for organizations with strong internal potential but may require additional political support in the form of training programs and access to modernization funds to ensure its viability in the long term. The viability of delegated models of operation largely depends on advanced ideas and the effectiveness of the private sector in resource management, giving water supply system owners a choice to involve specialized organizations. At the national level, integrating these models into water resources management policies can improve public–private cooperation, regulatory transparency, fairness of resource distribution, and investment flows in water infrastructure. The developed organizational models will allow the management structure to be adapted based on local needs, development potential and infrastructure conditions. At the regional level, these models encourage decentralized water management, allowing local authorities and water supply system owners to develop operational management strategies considering public and private interests. The use of the developed organizational models at the national and regional levels will allow for the creation of more sustainable, effective, and inclusive water management systems both to address immediate operational issues and to achieve long-term sustainable development goals.

5 Conclusions

The issues discussed in the article will be of interest to both the owners of water supply facilities and specialized enterprises that perform work on their operation or work on outsourcing terms. For competent planning and timely implementation of activities that ensure the required reliability of water supply facilities, a grouping of all activities into stages that differ in purpose, duration and frequency of implementation was developed: inspection, maintenance, maintenance, overhaul, damage elimination, and seasonal work. This approach allows you to clearly structure the activities carried out to ensure the required reliability, determine the frequency of their implementation, the required resources, performers, and amounts of funding. The timeliness and completeness of the implementation of the considered stages are the main conditions for ensuring the reliability of water supply facilities throughout their entire useful life.

To determine the key tasks facing the owners of water supply facilities and operating organizations, the structure of the management process for the operation of water supply facilities was developed, presented in the form of three interrelated modules: informational (collection, systematization and storage of the required information), organizational (information analysis and planning for the implementation of operation stages), and executive (implementation and acceptance of the stages of operation, filling in the relevant documentation).

An analysis of the activities of five agricultural organizations allowed the author to develop four organizational models for managing the operation of agricultural water supply systems: Model 1 “autonomous operation,” Model 2 “partially delegated operation,” Model 3 “fully delegated operation,” and Model 4 “operation by a specialized organization.” The developed organizational models make it possible to distribute powers, duties, and responsibilities between the participants in the operation, to ensure control over their implementation, maintaining the necessary documentation and reporting, which helps to ensure the reliability of water supply facilities and the formation of a rational cost of water. Each of the presented organizational models has its own advantages and disadvantages, for the generalization of which a SWOT analysis was used.

The information presented in the article will help improve the reliability of water supply facilities, increase their total and overhaul useful life, competent planning, and timely completion of operation stages, building clear boundaries for interaction with specialized organizations and reducing the cost of operating water supply facilities.

Author Contributions

Ekaterina Khmel: investigation, formal analysis, data curation, writing – original draft, writing – review and editing. Anatoly Hurynovich: conceptualization, methodology, investigation, formal analysis, data curation, writing – review and editing. Volha Holubava: formal analysis, data curation. Valentin Romanovski: formal analysis, data curation, visualization, validation, writing – review and editing.

Ethics Statement

The authors have nothing to report.

Consent

The authors have nothing to report.

Conflicts of Interest

The authors declare no conflicts of interest.

Open Research

Data Availability Statement

All data employed in support to the outcomes in the study are included in this article.