Photoinduced Dehalogenation-Based Direct In Situ Photolithography of CsPbBr3 Quantum Dots Micropatterns for Encryption and Anti-Counterfeiting with High Capacity

Abstract

Fluorescent lead halide perovskite quantum dots (LH PQDs) micropatterns hold great potential for photonic applications. However, current photolithography for LH PQDs micropatterning is hindered by their incompatibility with traditional photolithography methods, which involve development processes using numerous solvents and exhibit poor stability due to the ionic characteristics of LH PQDs. Herein, a direct in situ photolithography to fabricate CsPbBr3 PQDs micropatterns based on ultraviolet-C light-driven debromination is developed. Using this approach, fluorescent CsPbBr3 PQDs micropatterns with high theoretical information storage capacity (up to 10750205) can be achieved in a single step, without the need for tedious development processes. Furthermore, the fabricated CsPbBr3 PQDs micropatterns show high stability, remaining undamaged even after immersion in water for 6 months. The combination of excellent optical properties, development-free process, high stability, and low cost makes the in situ photolithography strategy very promising for patterning LH PQDs toward photonic integrations.

1 Introduction

Lead halide perovskite quantum dots (LH PQDs) have garnered significant attention owing to their exceptional luminescence properties, including high fluorescence quantum yield, narrow emission peaks, large molar absorption coefficient, and high defect tolerance.[1] These characteristics position LH PQDs as a new frontier in luminescent materials. Notably, the precise patterning of LH PQDs into desired structures has emerged as a catalyst for advancements in ultrasensitive sensing, super-resolution displays, lasers, anti-counterfeiting technologies, and more, captivating the interest of scientific researchers worldwide.1, 2

Various methods have been explored for fabricating patterned LH PQDs, including photolithography,2, 3 inkjet printing,[4] direct laser writing,[5] and others.2, 6 Among these, photolithography stands out as one of the most promising techniques due to its ability to achieve uniform patterns with high resolution in a high-throughput manner, as well as its compatibility with integrated optoelectronic devices and suitability for flexible/stretchable applications.1, 2 However, the ionic nature of LH PQDs renders them highly susceptible to the solvents used in traditional photolithography processes, such as photoresist coating, development, and lift-off.3, 7 This susceptibility often leads to a dramatic decrease in the photophysical properties of LH PQDs. To address this challenge, researchers have developed photoresist-free direct patterning strategies. Recently, Talapin's group introduced a ligand-assisted photoresist-free direct photolithography approach based on the design of photoactive ligands or photocrosslinkers for nanocrystals. These ligands or photocrosslinkers interact with the surface of the nanocrystals upon exposure to light, precisely modulating their solubility. Subsequent washing removes the nanocrystals from unexposed regions, resulting in micropattern formation.[8] Inspired by this strategy, various photoactive ligands and photocrosslinkers,3 such as zwitterionic ligand,3 oxime sulfonate ester,[9] poly (2-cinnamoyloxyethyl methacrylate),3 bisazides, as well as nitrene and carbene-based ligand crosslinkers,3 have been developed, providing a universal strategy for patterning LH PQDs. It is important to note that careful design is necessary, as presynthesized LH PQDs are easily photoetched by high-energy UV light.1, 2 Addressing this challenge, Zhong's group developed another direct in situ photolithography technique for patterning LH PQDs.3 This method relies on the photopolymerization of perovskite precursors under UV irradiation. The polymerized region of the perovskite precursor is then heated to form LH PQDs microarrays, thereby avoiding the destruction of LH PQDs by solvents or high-energy UV light. However, this technique requires further refinement, such as substrate modification with vinyltrimethoxysilane and development by washing the unexposed area with chloroform. In summary, the development of a simple and efficient photolithography strategy for fabricating emissive LH PQDs micropatterns with high resolution and high throughput remains a significant challenge.1, 2, 10

In this study, we have devised a novel photoinduced dehalogenation-based direct photolithography (PDDP) strategy for the in situ synthesis of high-resolution LH PQDs micropatterns. The procedure entails just by preparing the LH PQDs precursor/polymer film by blending LH PQDs precursors with polymer, and then irradiating the obtained film with 254 nm UV light (belonging to Ultraviolet-C, UVC) through a mask. This irradiation induces photo-dehalogenation, thereby triggering the in situ generation of LH PQDs micropatterns owing to the low formation energy of LH PQDs. Overall, the PDDP strategy offers a development-free route to cost-efficient patterning that the PQDs micropattern directly nuclei and grow in the polymer matrix, bypassing additional development and etching steps. Presently, employing this approach, we can fabricate ultra-stable CsPbBr3 PQDs micropatterns comprising square pixel arrays with a diameter of 2.0 μm, boasting a theoretical information storage capacity of up to 10750205 (Figure S1, Supporting Information). These CsPbBr3 PQDs micropatterns have been successfully applied to encryption and anti-counterfeiting measures. Furthermore, the fluorescent anti-counterfeiting CsPbBr3 PQDs micropattern can be read under UV light excitation in both a static channel of 365 nm and a dynamic channel of 254 nm. The encoded information can be read repeatedly under the 365 nm UV channel for more than 200 times without compromising its integrity, while the encoded information could be eliminated under the 254 nm channel in “burning after reading” manner, significantly enhancing counterfeit resistance.

2 Results and Discussion

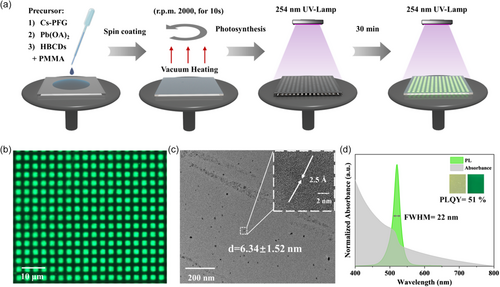

In the PDDP strategy, CsPbBr3 PQDs were utilized as the sample for developing high-resolution fluorescent CsPbBr3 PQDs micropatterns. Figure 1a schematically illustrates the preparation process of CsPbBr3 fluorescent microarrays film based on the PDDP strategy. The process involved thoroughly mixing the perovskite precursor containing cesium perfluoroglutarate (Cs-PFG),[11] lead oleate (Pb(OA)2), and hexabromocyclododecane (HBCDs) with poly (methyl methacrylate) (PMMA), followed by spin-coating to obtain a homogeneous perovskite polymer precursor film. Subsequently, polar organic solvents, such as DMF, were removed from the film by vacuum drying. Upon UVC irradiation with a photomask, HBCDs debrominated to release Br−,[12] triggering the reaction with Cs-PFG and Pb(OA)2 to in situ form CsPbBr3 PQDs micropatterns due to the low formation energy of CsPbBr3 (ΔEform = −6.45 eV). This process is straightforward and highly cost-efficient in that the PQDs micropattern directly nuclei and grow in the polymer matrix, avoiding the complex implementation of photoresist, development, and etching procedures in traditional photolithography (Figure S2, Supporting Information). Figure 1b displays the corresponding patterned CsPbBr3 PQDs pixel arrays of square shape with a size of 2 μm encapsulated in the PMMA film, exhibiting uniformly bright green fluorescence under 365 nm UV irradiation. The CsPbBr3 PQDs structure was analyzed through cross-section transmission electron microscopy (TEM) measurements, revealing homogeneously dispersed CsPbBr3 PQDs in the micropatterns with an average particle size of approximately 6.34 nm. High crystallinity of the obtained CsPbBr3 PQDs was evident, with continuous lattice fringes observed in the high-resolution TEM (HRTEM) image inset in Figure 1c. The optical properties of the CsPbBr3 PQDs microarrays film were further characterized, showing exciton absorption and corresponding maximum fluorescence emission peaks located at 515 and 521 nm, respectively, with a full width at half maximum (FWHM) of 22 nm and a fluorescence quantum yield of 51% (Figure 1d).

The mechanism of preparing CsPbBr3 PQDs microarrays based on the PDDP strategy is depicted in Figure 2a. When irradiated by UVC light, the CBr bonds in HBCD begin to break, releasing Br− ions to react with Cs-PFG and Pb(OA)2 to generate CsPbBr3 PQDs. The selection of the HBCD precursor is crucial in this PDDP strategy, as it is a classical flame retardant known for its good photo and thermal stability. It decomposes and releases HBr when exposed to UVC conditions (λmax 220–260 nm) and heated to temperatures between 240 and 270 °C.[12] In the high-resolution X-ray photoelectron spectroscopy of Br (Figure 2b), the fitted peak observed at 70 eV before irradiation is attributed to the CBr bond of HBCD. Following irradiation, a new fitted peak emerges at 68.3 eV, indicative of the initiation of CBr bond cleavage, releasing Br−. Subsequently, the released Br− interacts with Cs-HFG and Pb(OA)2, leading to the formation of CsPbBr3 PQDs within the PMMA matrix. This process is well supported by the X-ray diffraction (XRD) spectra (Figure 2c). Notably, no XRD peaks corresponding to CsPbBr3 are observed before UVC irradiation. However, characteristic peaks at 2θ = 15, 21, 29, 33, 37, and 43° emerge postirradiation, corresponding to the crystal planes {100}, {110}, {200}, {210}, {211}, and {220} of cubic CsPbBr3. These peaks, consistent with the cubic phase (JCPDS 054-0752), confirm the formation of CsPbBr3 PQDs. Meanwhile, the nucleation and growth of CsPbBr3 PQDs are dependent on both the UVC power density and irradiation time. Figure S3, Supporting Information, demonstrates that at a power density of approximately 0.163 mW cm−2, the power density is insufficient to drive the nucleation and growth of CsPbBr3 PQDs. However, at a power density of about 0.515 mW cm−2, we observe a gradual increase in photoluminescence (PL) intensity with a broad FWHM from 54 nm to 31 nm. Conversely, at a power density of 0.945 mW cm−2, the PL intensity progressively increases with a narrower FWHM from 44 to 21 nm. This phenomenon suggests that higher power density yields more crystal nuclei, fostering a more uniform growth process in subsequent crystal growth stages, in accordance with classical nucleation theories.[13] Under the optimized UVC irradiation conditions of 0.945 mW cm−2 power density, CsPbBr3 PQDs exhibit higher PL intensity. Under these optimized conditions, with the increase of UVC irradiation time, the intensity of its emission peak increased (Figure 2d). In the meanwhile, as depicted in Figure S4, Supporting Information, the PL increased with the peak range from 513 nm to 521 nm and with lifetime decreased from 20.7 ns to 17.3 ns; additionally, a characteristic absorption peak of CsPbBr3 PQDs gradually emerged at 515 nm under 254 nm ultraviolet irradiation (Figure S5, Supporting Information), suggesting small variation in PQD sizes based on PDDP strategy, which might due to spatial confinement and the local depletion of precursors in the PMMA matrix.5 Furthermore, control experiments employing radical trapping reagents 2, 2, 6, 6-tetramethylpiperidine-1-oxyl (TEMPO) and oxygen were conducted to gain a deeper understanding of the PDDP strategy.[14] As depicted in Figure 2e, the light-induced in situ growth of CsPbBr3 PQDs was notably impeded within the same 60-min timeframe in the presence of TEMPO. This inhibition occurred as TEMPO reacted with the radical intermediate of HBCD, consequently obstructing electron transfer from the radical intermediate of HBCD to Br•, thus inhibiting the release of Br−. This observation suggests that photogenerated radicals primarily facilitate the formation of CsPbBr3 PQDs by liberating Br−.[15] Moreover, solid-state electron paramagnetic resonance (EPR) spectra of precursor film (Figure 2f), subsequent to the addition of TEMPO and exposure to 254 nm UV light for various durations, consistently exhibited a reduction in the EPR signal of TEMPO. This decrease is attributed to the reaction between TEMPO and the radical intermediate of HBCD,[15] further corroborating the proposed mechanism. Moreover, given that oxygen is a potent radical scavenger, similar UVC light-induced reactions were conducted under different atmospheres to elucidate the “oxygen effect” on CsPbBr3 PQDs formation.[12, 14] As shown in Figures 2g–i, CsPbBr3 PQDs exhibited the fastest growth in pure nitrogen, followed by air, and the slowest growth occurred in pure oxygen. This observation can be attributed to oxygen's ability to form stable free radicals by combining with free radicals of HBCDs after UVC irradiation, thereby inhibiting the cleavage of CBr bonds to form Br−.[12, 15]

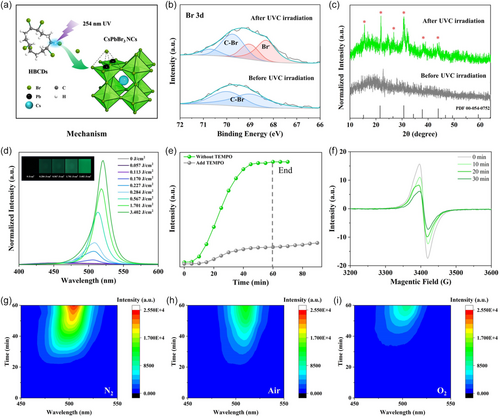

Utilizing the PDDP strategy, we have successfully fabricated a diverse array of CsPbBr3 PQDs micropatterns ranging from mesoscale to microscale. Leveraging the high bonding energy of CBr in HBCD, exposure to 254 nm UVC irradiation induces CBr cleavage, releasing Br− ions and initiating the growth of CsPbBr3 PQDs. Conversely, 365 nm UVA light irradiation fails to trigger CBr bond cleavage, as depicted in Figure S6a, Supporting Information, thereby enabling fluorescence information reading under 365 nm light excitation. Figure 3a showcases a 3 × 3 cm micropattern film comprised of circular pixel dots with a diameter of 20 μm, exhibiting distinct contrast between bright green and dark states under 365 nm UV light. These micropatterns can be easily adjusted according to the array patterns on the masks, as illustrated in Figure 3b–d. In addition to the matrix pixels, various intricate patterns such as school and college logos, cartoons, and letters have also been successfully produced (Figure 3e–h). Notably, the minimum line width of these patterns reaches as low as 14 μm, ensuring uniform photoluminescent patterns with clear edges. Additionally, fluorescent micropatterns of CsPbClxBr3-x and FAPbBr3 PQDs can also be synthesized by modifying the precursors (Figure S7, Supporting Information). However, attempts to obtain iodide-based PQDs micropatterns were unsuccessful due to iodine radicals generated by the radiolysis of iodine compounds, which readily coupled to produce elemental I2 rather than undergoing hydrogen extraction reactions. Hence, this comprehensive validation underscores the feasibility of fabricating both macroscopic and microscopic patterned CsPbBr3 PQDs using the PDDP strategy. In contrast to CsPbBr3 PQDs micropatterns developed via traditional photolithography, the constructed CsPbBr3 PQDs microarrays are fully encapsulated in the PMMA matrix based on our PDDP strategy (Figure S2, Supporting Information). Consequently, they exhibit outstanding stability, with the lithographic CsPbBr3 PQDs pattern remaining intact and the fluorescence essentially unchanged even after immersing the CsPbBr3 PQDs microarray film in water for 6 months (Figure S8, Supporting Information). Furthermore, the cost of fabrication was estimated under reasonable assumptions, based on the materials utilized, with detailed calculations provided in Table S1, Supporting Information. The calculated capital cost is calculated to be US$ 0.23 cm−2 for a 3 × 3 cm micropattern film, highlighting the highly cost-effective nature of the PDDP strategy. Additionally, a comparison of photolithography parameters between our study and previously reported methods is presented in Table S2, Supporting Information. It is noteworthy that fabrication in our study is accomplished in a single step with high pattern resolution, obviating the need for laborious development processes or presynthesis PQDs.

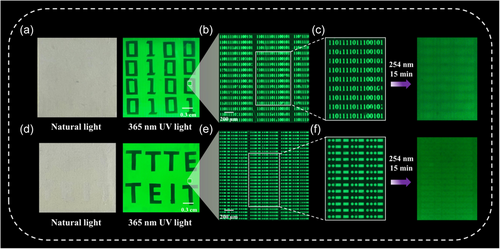

Based on the preceding research, we have devised two encryption–anti-counterfeiting methods that integrate macroscopic and microscopic information. Following the completion of photolithography under a specific mask plate, two encryption patterns are generated. As depicted in Figure 4a, under natural light, the surface appears as a pale-yellow transparent film with a white paper underlying background, devoid of discernible information. However, under 365 nm UV light, the macroscopic sequence “0100”, “0100”, “0100”, “0101” becomes visible. Furthermore, upon observation of the green region through an optical microscope, it reveals thousands of microscopic fluorescence sequences, such as “1101111011100101” (Figure 4b), theoretically capable of accommodating a substantial amount of data according to Carro–Temboury's theory. Decryption involves acquiring both macroscopic and microscopic information. Initially, within the microscopic pattern, the overall sequence is divided into four groups of numbers, each consisting of four digits from left to right: 1101/1110/1110/0101. Subsequently, by combining the first row of the macroscopic pattern with the corresponding first group of digits from the microscopic pattern, an eight-digit sequence is formed: “01001101”, “01001110”, “01001110”, “01010101”. Finally, through ASCII decoding of these four columns, the correct information, in this case, the letters “MNNU”, can be obtained. Upon retrieving the information, irradiation with 254 nm UVC light triggers the growth of CsPbBr3 PQDs in the masked area of the original mask plate, resulting in the permanent disappearance of the patterned array and irreversible erasure of the information (Figure 4c). Microscopic information is destroyed within a mere 15 min and becomes unreadable, contrasting with the capability of 365 nm light to repeatedly read the information over 200 times with a single reading time of 10 s (Figure S6b, Supporting Information). This underscores the flexibility and heightened imitativeness of the anti-counterfeiting strategy. In addition to binary encoding, Morse code can be employed for encoding macro-micro information. For instance, in Figure 4d, decoding the macro pattern necessitates Morse code conversion. The process involves converting the two sets of letters “TTTE” and “TEIT” into Morse code groups “- - - ·” and “- · · · -”. respectively. Then, regrouping every two characters from the first group yields “- -” and “- ·”, which upon Morse code decoding, results in the letters “MN”. Regrouping the first two characters and the last three characters from the second group produces “- ·” and “· · -”, which, when decoded via Morse code, yields “NU”. Moreover, by examining the green area (Figure 4e), the microscopic Morse code “· · - - · · - · · · -” array can be discerned, with the information segmented into four groups based on pattern spacing: “· · -”, “-”, “· · -”, and “· · · -”, each of which can be decoded using Morse code shorthand to obtain the four-digit sequence “2023”. Ultimately, the final code reads “MNNU 2023”. Similarly, irreversible erasure can be achieved as depicted in Figure 4f, where, after 15 min of lithography without a mask, the microscopic information becomes virtually unreadable.

3 Conclusion

In this study, we have devised a direct in situ photolithography for fabricating CsPbBr3 PQDs micropatterns with high resolution, based on UVC light-induced debromination of HBCDs within the PMMA matrix. This fabrication process can be accomplished in a single step, eliminating the necessity for labor-intensive development procedures, thus rendering it highly cost-effective and readily scalable. The resultant CsPbBr3 PQDs micropatterns film exhibits remarkable stability against water for up to 6 months. Moreover, it has been successfully utilized for information encryption and anti-counterfeiting with high capacity. Furthermore, this approach can be extended to nonlead and core-shell PQDs micropatterns, presenting promising prospects for broadening the applications of PQDs micropatterns in various fields such as micro-LEDs, sensing, lasers, and beyond. With its favorable scalability and considerable application potential, this strategy holds considerable promise for advancing the field of PQDs micropatterns.

Acknowledgements

The authors gratefully acknowledge the financial support of the National Natural Science Foundation of China (No. 22004055) and the Natural Science Foundation of Fujian Province of China (2020J05165).

Conflict of Interest

The authors declare no conflict of interest.

Open Research

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.