Low-Temperature Processing Methods for Tin Oxide as Electron Transporting Layer in Scalable Perovskite Solar Cells

Abstract

Perovskite solar cell (PSC) technology experiences a remarkably rapid growth toward commercialization with certified efficiency of over 25%, along with the outstanding breakthrough in the development of SnO2. Owing to the wide bandgap, high electron mobility, chemical stability, and low photocatalytic activity, SnO2 has been the rising star to serve as electron transporting layer (ETL). More importantly, the low-temperature fabrication process (<200 °C) enables SnO2 a promising candidate for the industry, making it compatible with the plastic substrates and large-scale production, which is crucial for the flexible and scalable devices fabrication. In this review, the processing methods (solution-based, vacuum-based, and vapor-based deposition) of low-temperature SnO2 (LT-SnO2) and the pros and cons of them with a focus on their scalability are discussed. Additionally, the morphologies of obtained LT-SnO2 are investigated to guide the design and performance improvement of devices. The modification strategies to reduce undesired nonradiative recombination and passivate the defects in the bulk or at the interface of LT-SnO2, influencing the quality of perovskite films, together with the efficiency and stability of cells are summarized. This review is a comprehensive overview of the studies on low-temperature SnO2 ETL and provides detailed instructions for scalable PSCs.

1 Introduction

The perovskite solar cell stands out from the state-of-the-art family of solar cells and is rapidly becoming one of the most promising photovoltaic technologies. As of yet, the highest efficiency of this technology has been reported at 25.7%, since the introduction of perovskite photovoltaic absorbing materials based on CH3NH3PbI3 (or MAPbI3) by Miyasaka et al in 2009.[ 1, 2 ] The advantageous properties of perovskite utilization as PV absorber are low recombination loss, low material cost, and the possibility of incorporating different cations and anions in its composition. Moreover, they possess a straight and tunable bandgap as well as a large absorption coefficient and high diffusion length of electrons and holes. Conversely, the major challenges of these cells include lack of control over the morphology of the layer, high moisture and oxygen vulnerability, device instability and degradation, and the presence of toxic substances like Pb in its composition.[ 3, 4 ]

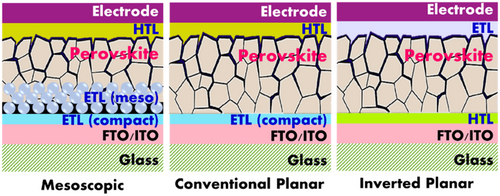

Typically, the most common configuration of PSCs consists of layers deposited on top of each other as follows: electrode/electron transport layer (ETL)/absorbent/hole transport layer (HTL)/counter electrode. The electrons and holes generated in the absorbent layer are extracted through the ETL and HTL layers, respectively, and transported onto the relevant electrodes. As regards, electron transport materials (ETMs) and hole transport materials (HTMs) are applied and deposited either prior or posterior to the absorbing layer (i.e., perovskite) to make for ETL and HTL layers, respectively. The two commonly used device architectures for PSCs include mesoscopic and planar structures where mesoporous PSCs comprise of a scaffold such as TiO2, ZnO, Al2O3, or ZrO2 while planar PSCs contain of a perovskite layer that is sandwiched between ETL and HTL without any scaffold. Based on the arrangement of HTL and ETL in relation to the light illumination in PSCs, both planar and mesoporous device architecture could be fabricated in n–i–p configuration (conventional) and in inverted structure where the irradiated light first passes through HTL (p–i–n), as shown in Figure 1 .[ 5, 6 ]

In this regard, the exploitation and development of methods for manufacturing and scaling up PSCs has increased over time.[ 7-18 ] Although transparent conductive oxide (TCO) is normally utilized as substrates in the preparation of laboratory-scale cells, its utility in the fabrication of large-area modules for commercial applications is curtailed due to their rigidity and high weight. This has triggered the researchers to be in search for flexible polymer substrates such as PET and PEN.[ 19-22 ] Nevertheless, these conductive flexible materials are of limited heat tolerance and thus are incompatible with the high annealing temperatures required in the conventional ETL (e.g., TiO2) treatment. Consequently, the deposition process of subsequent layers on these substrates needs to be accomplished at a temperature <150 °C.[ 23 ] However, there are some reports about the use of higher temperatures (180[ 24-26 ] and 185 °C[ 27 ] on PET substrate) and (180, and 200 °C[ 28, 29 ] on PEN substrate). Considering that all deposited thin films in the conventional structure of PSCs, excluding ETL, could be prepared at low temperatures (less than 150 °C), fabrication of ETL below 150 °C is the main challenge in this field.

The ETL is of the most essential constituent of high-efficiency PSCs profoundly transporting electrons from the absorber layer to the electrode as well as performing as a hole-blocking layer to avoid charge recombination. Hence, ETL electron mobility is an important factor in determining the photovoltaic performance of the device. Therefore, comparatively high electron mobility is desirable for ETL since electrons could be more effectively transported and collected.

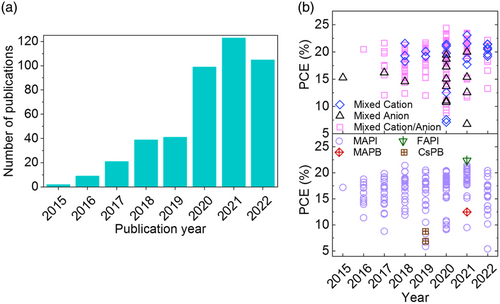

The most commonly employed ETL in the PSCs structures is TiO2 in which albeit the rate of electron injection from the perovskite absorbent into the ETL is expedited, the electron recombination rate is also high due to its low electron mobility and transport properties. Besides, based on the high density of defects and trap sites on its surface stemming from oxygen vacancies, the recombination probability and undesirable transport increases.[ 30 ] Notably, the density of surface/bulk energy traps in TiO2 and SnO2 nanostructures depends on its morphology and crystal phase and can be in the range of 1016 to 1019 cm−3.[ 31-33 ] In contrast, SnO2 is also a pioneering candidate as ETL in PSCs, which represents higher electron mobility than that of TiO2 along with superior optical properties, wide bandgap, high transparency, and higher stability.[ 34 ] In practice, PSCs based on low-temperature TiO2 (LT-TiO2) ETL demonstrate incompetent efficiencies due to poor crystallinity, low electrical conductivity, and high trap sites densities. On the contrary, low-temperature SnO2 (LT-SnO2) (<200 °C) has been widely circulated as ETL in planar PSCs representing highly favored efficiency,[ 35 ] which indicates the promise of this material as LT-ETL since the increasing number of research reports in recent years involving LT-SnO2 (Figure 2a). What is more, Figure 2b exhibits the PCE trend of LT-SnO2-based PSCs by year concerning the perovskite type of absorbent layer. In this view, various synthesis and coating methods for the LT-SnO2 layer employed in the fabrication of PSCs, reported to be solution-based, vacuum-based, and vapor-based/assisted, are briefly reviewed and elaborated in the next section.

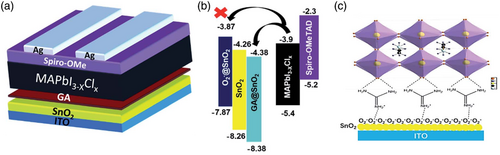

Energy band alignment is another crucial parameter that should be considered when designing a photovoltaic device. The energy band alignment of ETLs so as to better conform to that of the absorbent layer will facilitate electron extraction and transport further increasing J SC and FF. In addition, V OC is typically determined through the energy difference between the ETL and HTL Fermi levels. Therefore, energy-level tuning/adjusting has been extensively applied as s method to increase the V OC of a device. Extraction, transport, and recombination of charges at the interface significantly contribute to determining the performance of the device. Moreover, trap sites in ETL have impact on its charge transport. Therefore, interface engineering has been utilized as an effectual method to enhance charge transporting and further optimize the device performance. Also, various ETL morphologies are designed to improve its contact with the absorbent layer in order to achieve higher device performance. As mentioned above, all parameters influence upon each other and simultaneously determine the characteristics of a device.

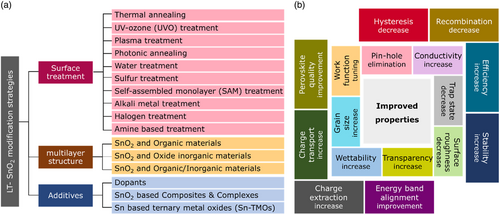

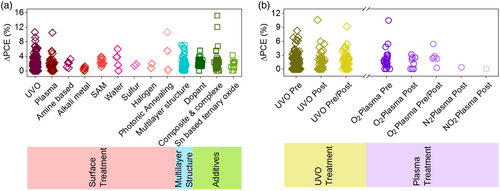

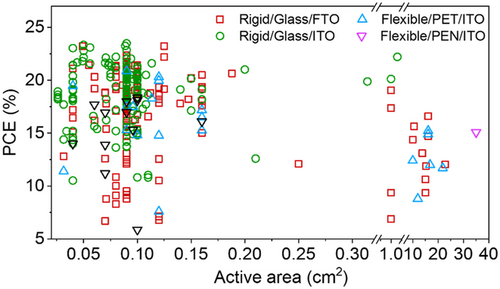

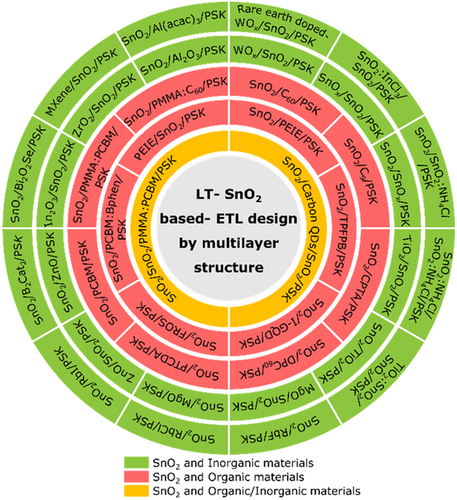

Although SnO2 layers have demonstrated high potentials in the fabrication of efficient planar PSC devices, the practically extreme residual behavior and low stability of LT-SnO2-based PSCs is a major challenge that has made researchers applying a variety of strategies to tackle this issue. Accordingly, the strategies utilized for LT-SnO2 treatment and modification fall into several broad categories, including surface treatment, multilayer, and additive (Figure 3a), which are extensively discussed in this review. According to literature, these procedures improve the structural, electrical, and optical properties of LT-SnO2 through reducing the pinholes, enhancement of the crystallinity via the grain size enlargement as well as diminishing the grain boundaries, tuning the energy level of the work function, and optimizing the electrical conductivity and transparency. Most of which improve the wettability of the ETL so that the perovskite absorbing layer be more perfectly deposited. Utilizing the mentioned methods, the performance of PSCs based on modified LT-SnO2 based is remarkably improved by means of tuning the bandgap alignment between the ETL/(perovskite) absorbing layer, enhancing the charge extraction and transport, alleviating recombination and hysteresis, as well as increasing the device stability (Figure 3b). The efficiency enhancement of the PSC using each method is represented in Figure 4 . The reported results show that UVO treatment has been used more than other methods to modify LT-SnO2 ETL both alone and in combination with other methods. In addition, the PCE of PSCs based on LT-SnO2 according to the active area and the type of TCO used as substrate is shown in Figure 5 . As illustrated, in the highest active area (35.00 cm2), the PCE of the corresponded device is 15.08% using the flexible PEN/ITO substrate,[ 36 ] and the highest PCE, i.e., 24.40%, is reported in the active area of 0.59 cm2 using the rigid glass/ITO substrate.[ 37 ] Moreover, the largest rigid module with an active area of 22.80 cm2 using glass/FTO substrate has been reported to demonstrate a PCE of 12.03%.[ 38 ]

Herein, low-temperature fabrication processes of SnO2 ETL for high efficiency and stable PSC are of great significance, in terms of the tolerance for flexible substrates and upscaling technologies. In this review, the common used LT-SnO2 preparation methods are discussed systematically in the following section. Different morphological studies of LT-SnO2 are reviewed so as to have a much more comprehensive understanding on the overall PSCs. Last but not least, key issues and challenges of LT-SnO2 still demand prompt solutions, where modifications like interface engineering and addictive engineering are concluded.

2 LT-SnO2 Preparation Methods

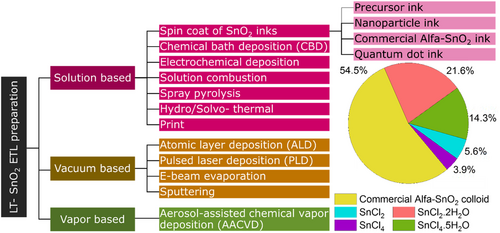

Reports of ETL validation of SnO2 in the fabrication of high-efficiency PSCs have increased in recent times. Among the various utilized methods, low temperature ones operable in flexible substrates, e.g., PET showing 260 °C melting temperature and PEN having that of 270 °C, are of paramount importance. A diagram of the LT-SnO2 preparation methods is depicted in Figure 6 . Besides, the performance and device characteristics of PSCs based on LT-SnO2 ETL prepared through various methods are briefly presented in Table 1 .

| SnO2 deposition method | Cell configuration | JSC [mA cm−2] | V OC [V] | FF [%] | Eff [%] | Ref. | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Solution based | Spin coat | Precursor ink | – | Planar | FTO/SnO2/MAPbI3/Spiro-MeOTAD/Au | 22.19 | 1.04 | 75.40 | 17.30 | [46] | |

| Aged | Planar | FTO/SnO2/Cs0.05(MA0.15FA0.85)0.95Pb(I0.85Br0.15)3/Spiro-MeOTAD/Au | 22.40 | 1.16 | 78.00 | 20.50 | [48] | ||||

| Nanoparticle ink | Hydro/solvothermal | Inverted | ITO/NiO/MAPbI3/C60/SnO2/Ag | 21.80 | 1.12 | 77.00 | 18.80 | [51] | |||

| Microwave | Planar | FTO/SnO2/MAPbI3/Spiro-MeOTAD/Au | 21.24 | 1.01 | 65.90 | 14.20 | [52] | ||||

| Grinding | Mesoporous | FTO/SnO2/SnO2/Cs0.05(FA x MA1−x )0.95Pb(I y BrzCl1−y−z)3/Spiro-MeOTAD/Au | 21.46 | 1.22 | 80.09 | 21.09 | [53] | ||||

| Alfa Aesar colloidal SnO2 | Planar | ITO/SnO2/(FAPbI3)1−x (MAPbBr3) x /Spiro-MeOTAD/Au | 23.86 | 1.12 | 80.60 | 21.64 | [35] | ||||

| Quantum dot ink | – | Planar | FTO/SnO2/MAPbI3/spiro-MeOTAD/Au | 22.95 | 1.14 | 74.50 | 19.41 | [29] | |||

| – | Planar | FTO/SnO2/Cs0.05(MA0.17FA0.83)0.95Pb(I0.83Br0.17)3:Pb(SCN)2/spiro-MeOTAD/Au | 23.05 | 1.13 | 79.80 | 20.79 | [29] | ||||

| CBD | – | Planar | ITO/SnO2/PC70BM/MAPbI3/Spiro-MeOTAD/Au | 21.30 | 1.05 | 66.30 | 14.80 | [58] | |||

| with Spin coat | Planar | FTO/SnO2/Cs0.05(MA0.17FA0.83)0.95Pb(I0.83Br0.17)3/spiro-MeOTAD/Au | 22.59 | 1.17 | 75.00 | 20.73 | [59] | ||||

| Electrodeposited | – | Planar | ITO/SnO2/MAPbI3/Spiro-MeOTAD/Ag | 19.75 | 1.08 | 65.00 | 13.88 | [62] | |||

| – | Planar | PEN/ITO/SnO2/MAPbI3/Spiro-MeOTAD/Au | 20.53 | 1.06 | 66.00 | 14.30 | [61] | ||||

| Dual-fuel combustion | – | Planar | ITO/SnO2/MAPbI3/Spiro-MeOTAD/Ag | 19.01 | 1.08 | 66.00 | 12.93 | [63] | |||

| Spray | Ethanolic precursor ink | Planar | FTO/SnO2/MAPbI3/Spiro-MeOTAD/Au | 21.80 | 1.01 | 73.70 | 15.40 | [65] | |||

| Aqueous nanoparticle ink | Planar | FTO/SnO2/MAPbI3/Spiro-MeOTAD/Au | 21.20 | 1.01 | 78.60 | 16.70 | [65] | ||||

| Planar | ITO/SnO2/Cs0.05FA0.85MA0.15PbI2.9Br0.15/Spiro-MeOTAD/Ag | 23.85 | 1.15 | 69.60 | 18.20 | [64] | |||||

| Hydro/Solvothermal | Planar | FTO/SnO2/MAPbI3/Spiro-MeOTAD/Au | 22.76 | 1.05 | 68.00 | 16.17 | [66] | ||||

| Slot-die method | Solvent→ Water:IPA = 1:1 | Planar | FTO/SnO2/Cs0.05FA0.85MA0.15Pb(I0.85Br0.15)3/Spiro-MeOTAD/Au | 3.28 | 6.73 | 69.00 | 15.22 | [26] | |||

| R2R gravure | Solvent→ Water:IPA = 1:1 | Planar | PEN/ITO/SnO2/Cs0.05FA0.85MA0.15Pb(I0.85Br0.15)3/Spiro-MeOTAD/Ag | 20.31 | 1.05 | 71.78 | 16.95 | [67] | |||

| Solvent→ Water | Planar | PEN/ITO/SnO2/Cs0.05FA0.85MA0.15Pb(I0.85Br0.15)3/Spiro-MeOTAD/Ag | 18.90 | 0.99 | 63.83 | 11.20 | [67] | ||||

| Vacuum based | Atomic layer deposition (ALD) | Thermal-ALD (T-ALD) | Planar | FTO/SnO2/(FAPbI3)0.85(MAPbBr3)0.15/PTAA/Au | 22.74 | 1.11 | 76.00 | 18.37 | [69] | ||

| Planar | FTO/TiO2/SnO2/(FAPbI3)0.85(MAPbBr3)0.15/PTAA/Au | 22.98 | 1.14 | 79.00 | 20.03 | [69] | |||||

| Plasma assisted-ALD (PA-ALD) | Planar | FTO/SnO2/C60/MAPbI3:Pb(SCN)2/Spiro-MeOTAD/Au | 21.50 | 1.13 | 78.96 | 18.80 | [70] | ||||

| Pulsed laser deposition (PLD) | Planar | FTO/SnO2/PCBM/MAPbI3:Pb(SCN)2/Spiro-MeOTAD/Au | 21.51 | 1.11 | 73.00 | 17.29 | [75] | ||||

| E-beam evaporation | – | Planar | FTO/SnO2/Cs0.05(MA0.17FA0.83)0.95Pb(I0.83Br0.17)3/Spiro-MeOTAD/Au | 22.75 | 1.10 | 73.00 | 18.20 | [77] | |||

| sputtering | Planar | FTO/SnO2/Cs0.06MA0.27FA0.67PbI2.7Br0.3/Spiro-MeOTAD/Au | 23.70 | 1.08 | 79.00 | 20.20 | [38] | ||||

| Vapor based | Aerosol-assisted Chemical Vapor Deposition (AACVD) | – | Planar | FTO/SnO2/PCBM/MAPbI3/Ag | 14.70 | 1.03 | 67.51 | 10.20 | [79] | ||

2.1 Solution-Based Deposition Methods

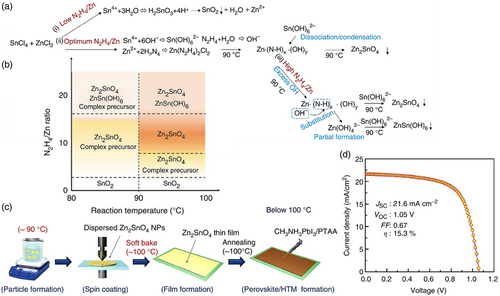

Among the various methods for SnO2 synthesis, solution-based methods take precedence owing to the feasibility of performing the production process at low temperatures, lower materials consumption, as well as the facile manufacturing process. In order to prepare LT-SnO2 layer, either SnCl4, SnCl2, and their hydrates SnCl2.2H2O, SnCl4.5H2O tin precursors, or spin-coating of the as-received commercial SnO2 colloidal solution often the Alfa Aesar product (Alfa-SnO2) is employed.[ 39-43 ] As shown in Figure 6, the commercial Alfa-SnO2 is the most frequently employed in the preparation of LT-SnO2, and in specie, the most utilized solvent for the synthesis is ethanol.

2.1.1 Spin-Coating of SnO2 Inks

The spin-coating technique serves as one of the most conventional methods of SnO2 growth holding out the advantages of controlling the thickness of deposition and allowing the combination of different chemicals.[ 44, 45 ] Classified among the inks utilized in this method is a precursor ink, e.g., the ink obtained from the sol–gel method, which contains tin chloride salt along with a sulfur source in solvents including ethanol, water, and isopropanol (IPA). In this procedure, ever since the ink is prepared, the desired layer is deposited on the substrate through the spin-coating method. However, as regards the deficient crystallization and the presence of organic and chloride residues in the prepared layer of the precursor ink, posttreatment methods such as thermal annealing or UV-ozone (UVO) are required. Yan et al. first used SnCl2.2H2O as tin source to prepare ETL at 180 °C and reached a PCE of 17.2%, thus promoting the rapid development of LT-SnO2. Calabrò et al.[ 46 ] could achieve 17.3% PCE making use of SnO2 ETL prepared through spin-coating of SnCl2.2H2O precursor ink in ethanol. Besides, Murugadoss[ 47 ] investigated the effect of ethanol and water solvents in SnO2 precursors and recognized the superiority of ethanol solvent compared to that of water. In this regard, the utilization of water solvent provokes nonuniform coating of SnO2 layer due to the formation of Sn(OH)2 nanoparticles. Moreover, some reports[ 40, 48-50 ] refer to the aging of the precursor ink prior to the deposition, which often appears to improve the quality of the SnO2 layer. Dong et al.[ 48 ] could manage to realize 20.5% PCE utilizing SnO2 ETL prepared through spin-coating of SnCl2.2H2O precursor ink in ethanol aged for 24 h at room temperature.

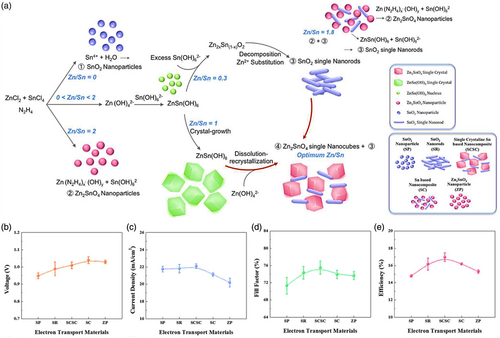

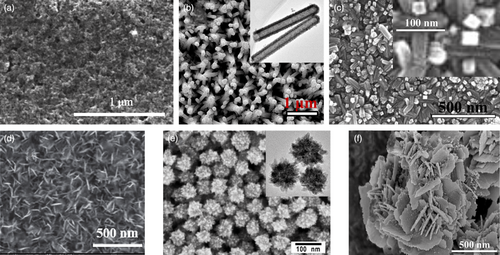

Researchers resolved the issue of enhancing the crystalline quality and removing the organic and chloride residues into the application of nanoparticle inks. In this method, SnO2 nanoparticles are primarily synthesized through solution-based processes including hydro/solvothermal,[ 51 ] microwave,[ 52 ] and grinding.[ 53 ] After subsequent rinsing, the resulting nanoparticles are dispersed in solvents such as ethanol, isopropanol, or water and then deposited through spin-coating on the substrate. Miyasaka et al. first used SnO2 nanoparticles, which is purchased from chemical company, to prepare ETL and achieved a PCE of 13.0%. In the same manner, Zhu et al.[ 51 ] first synthesized SnO2 nanoparticles using hydrothermal method and then spin-coated nanoparticles dispersed in IPA on C60 as a bilayer ETL in an inverted structure and achieved the PCE of 18.8%. Abulikemu and coworkers[ 52 ] utilized the microwave method to synthesize SnO2 nanoparticles (with an average particle size of 3 nm). In the microwave method, the synthesis of SnO2 nanoparticles is progressed more rapidly than that of the hydro/solvothermal method due to the high temperatures by microwave radiation, and besides, it enables the precise monitoring of the reaction parameters, i.e., temperature, time, and pressure. Furthermore, the grinding technique is based on physical ball milling which the latter has been broadly utilized in mechanical alloying processes. In this technique, the ball is employed not only as a mill but also as a means to form a cold welding between the powder particles so as to fabricate the desired alloy. In this light, Singh et al.[ 53 ] similarly utilized this novel procedure to produce SnO2 nanoparticles. They prepared nanoparticles dispersed in IPA solvent and deposited on the FTO substrate through spin-coating method and could obtain the devices of 16.46% PCE. Moreover, this group could manage to further increase the PCE to 21.09% through the addition of a compact layer of SnO2 prepared via the precursor ink spin-coating method beneath the grinding SnO2 layer.

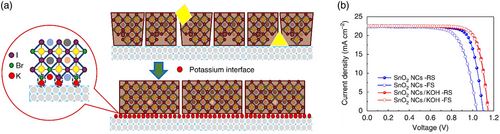

In recent years, researchers have been using a commercially available colloidal solution of SnO2 nanoparticles, often from Alfa Aesar, to prepare LT-SnO2 ETL. As indicated in Figure 6, more than half (54.5%) of the LT-SnO2 research articles reported since 2015 have employed this solution. In the commercial Alfa-SnO2, a small amount of KOH has been added to the solution for colloidal stability. The presence of this substance triggers the passivation of perovskite/ETL interface, which results in remarkable performance and significant reduction of PSCs hysteresis built upon Alfa-SnO2 ETL.[ 26 ] The desired layer prepared using the Alfa-SnO2 is uniform and pinhole free through which Jiang et al.[ 54 ] could fabricate PSCs of 20.54% PCE based on SnO2 ETL making use of them. In addition, in 2017, they reported PSCs of an active area of 0.07 and 1 cm2 rendering PCEs of 21.6% and 20.1%, respectively.[ 35 ] Xu et al.[ 55 ] used DMF and ethanol as Alfa-SnO2 aqueous diluents to improve the morphology of the ETL layer. The presence of ethanol as the diluent (Water: Ethanol:1: 1) has not only increased the stability dispersion of the solution but also increased its wettability on the substrate, whereas DMF was the opposite and reduced the wettability of the ETL layer and the crystalline quality of the perovskite layer. They compared three different solvents of pure water, water–ethanol, and water–DMF and found that when ethanol was the solvent, SnO2 films were formed with uniform grain sizes without agglomeration, yielding 18.84 % reached a yield of 16.35% under the same conditions and with water as a diluent solvent.

The reproducibility of the SnO2 layer process is a requirement for the commercialization and large-scale production of PSCs. Wang and colleagues[ 56 ] used Alfa-SnO2 aqueous solution to improve ETL quality by adding oxygenated water (H2O2). They showed that the addition of H2O2 reduced the density of oxygen traps and defects and increased electron extraction, as reported by a yield of 22.15% with a 94% stability improvement after 1000 h.

Nevertheless, part of the challenges of solution-based methods for tin oxide films is the low quality of the crystallinity of the layer, which causes a relative decrease in electron mobility. The utilization of small colloidal nanoparticles of quantum dot (QD) effectively has been successfully addressed this barrier. In 2018, Yang et al.[ 29 ] could synthesize SnO2 QDs forming energy levels that well-aligned to that of the perovskite layer and demonstrated long-term stability of up to several months. The Xu group[ 57 ] also synthesized SnO2 QDs using radiowaves in a fast reaction (3 minutes) without additives and reported a PCE of 20.24%.

2.1.2 Chemical Bath Deposition

CBD is a solution-based method consisting of two stages of nucleation and particle growth and is based on the formation of a solid phase of the solution. In the CBD method, the substrate is immersed in a solution containing precursors. This method is influenced by parameters including bath temperature, pH and concentration of the solution, and time which does not cause physical impairs to the substrate. Furthermore, the CBD method demonstrates strong points over other techniques such as lower cost and temperature as well as higher quality and production volume. Barbe et al.[ 58 ] employed a single-stage CBD method with SnCl4 precursor at 55 °C without requiring annealing in order to prepare the amorphous LT-SnO2 layer and achieved a PCE of 14.8%. Also, Anaraki et al.[ 59 ] innovated the combined method of spin-coating and CBD technique to produce SnO2 bilayer ETL in which the spin-coated film played the role of seed in the CBD process. By means of this combined method, they could manage to achieve devices of superior photovoltaic parameters, longer stability, and lower hysteresis exhibiting a PCE of 20.73%. One of the reasons for using CBD method in LT-SnO2 synthesis is to reduce the agglomeration of SnO2 precursor, but the use of CBD is limited due to the time-consuming synthesis process. Ko et al.[ 60 ] attributed the cause of agglomeration to the concentration and effect of common ions. They investigated SnO2 provinces by rapid CBD method at low temperature and control of the precursor concentration. They deposited the SnO2 film at 70 °C by CBD and reported a PCE of 20.12%. Surprisingly, Seo et al. conducted a two-step CBD method to tune the electronic, physical, and morphological properties of the obtained SnO2 film by adjusting the pH and time of reaction, thus leading to a breakthrough certified PCE of 25.2% (0.0937 cm2) and 23.0% (0.984 cm2). However, due to large consumption of solution during the preparation, whether this method is suitable for large-scale production remain a challenging problem.

2.1.3 Electrochemical Deposition

Regardless of the trends of the methods mentioned earlier, they are not suitable for large-scale production. Consequently, the short-reaction electrodeposit technique has been regarded in the industry for converting electrical energy into chemical potential. Apart from the low-temperature production capability, this method initiates excellent adhesion between the deposited layer and the substrate and is an economical way to produce a vacuum-free uniform surface coating. Besides, morphology and layer thickness might be controlled through modifying the deposition conditions. The electrochemical deposition method takes place in a three-electrode cell containing a tin chloride precursor solution, e.g., SnCl2, which includes a platinum counter electrode, an Ag/AgCl reference electrode, and a working electrode as a substrate on which the deposition is directly applied. Therein, the deposition temperature and duration (time) are of paramount importance for layer properties where the best reported temperature was 50 °C not requiring post-deposition annealing.[ 61, 62 ] Chen et al.[ 62 ] could achieve the PCE of 13.88% using this method. Likewise, Lam et al.[ 61 ] recognized the 14.3% PCE under similar conditions through the addition of a PCBM layer between SnO2 ETL and perovskite.

2.1.4 Solution Combustion

The solution combustion method is based on the exothermic disposition of self-reactions, and the heat is generated through the exothermic redox chemical reaction, although this method is mostly employed for the NiOx synthesis. In this manner, Liu et al.[ 63 ] utilized different ratios of urea and acetone acetyl (ACAC) as dual-fuel and compared it with the ACAC single-fuel case, in which the urea behaved as an oxidizer. They could produce SnO2 nanoplates in the single-fuel case and SnO2 spherical nanoparticles in that of the dual-fuel case and achieve 12.93% PCE using dual-fuel combustion method.

2.1.5 Spray Coating

The utilization of spray pyrolysis has been quite widespread in the preparation of thin films. In this method, the solution droplets (aerosols) are expelled from the spray gun into the hot surface at high velocity and deposited on the surface with desired uniformity and surface coverage rendering thicknesses of even to 10 nm. In comparison to that of spin-coating method, spray pyrolysis provides the controlling and manipulation of the deposited layer and produces a continuous, uniform coating of higher optical properties. Wang et al.[ 64 ] indicated that the use of chloride precursors in the SnO2 layer deposition by spraying results in undesirable optical properties. To overcome this issue, they employed aqueous SnO2 nanoparticle ink for ETL deposition and could acquire a PCE of 18.2%. Besides, Taheri et al.[ 65 ] could realize PCSs of 15.4% and 16.7% PCE, respectively, applying a comparison between those of ethanol and aqueous SnO2 nanoparticle ink precursors as the solution utilized in the spray pyrolysis method.

2.1.6 Hydro/Solvothermal Method

In addition to the other solution-based techniques, the hydro/solvothermal method has been introduced as a deposition applied directly to the substrate. This method might be considered as a set of chemical reactions in a closed chamber in the presence of aqueous or nonaqueous solvent at temperatures beyond the boiling point of the solvent. Moreover, this process also takes place at high pressures and the selected temperature depends on the reaction required to obtain the targeted material. Thermodynamic parameters such as temperature, pressure, and time might enhance the solubility and assist the growth process. The advantageous features of this method include high efficiency, desired controllability, user-and-environmental-friendliness, manufacture of uniform-size-distributed products, and less energy consumption. With the aim of tackling one of the remarkable challenges of PSCs, i.e., low stability, Liu et al.[ 66 ] utilized hydrothermal growth method could obtain nanohierarchical SnO2 ETLs as compact and mesoporous ETLs, which could prevent moisture penetration and improved the stability of devices.

2.1.7 Print

Printing is a versatile technique that pushes the envelope of laboratory-scale deposition works much further toward large-scale and enables the commercial production of PSCs and modules involving deposition on flexible substrates such as PET and PEN. The foremost printing methods include: Roll-to-Roll Gravure (R2R Gravure), slot-die coating, and inkjet printing. What is more, the noncontact feature of this technique offers privilege of substrate delegation including rigid (glass, FTO, ITO, etc.) and flexible (plastic/metal foil, etc.). Among them, the R2R Gravure method is the most far reaching in the industry. In ETL printing method, the concentration of precursor and the solvent type are of fundamental importance in forming a uniform and pinhole-free layer. Bu et al.[ 26 ] could achieve the PCE of 15.22% through slot-die coating of Alfa-SnO2 solution in water/IPA solvent (1:1 ratio) on large-area flexible PET/ITO substrate with 16.07 cm2 (active) area. In a similar vein, Gong and coworkers[ 67 ] made use of Alfa-SnO2 solution in water and water/IPA solvent (1:1 ratio) through R2R Gravure printing method on flexible PET/ITO substrate at 0.07 cm2 scale and could achieve 11.2% and 16.95% PCE, respectively.

2.2 Vacuum-Based Deposition Methods

2.2.1 Atomic Layer Deposition

ALD is a vapor-phase vacuum-based pulse technique that could be employed to produce high-quality metal oxide thin mineral films. Principally, ALD is performed in two procedures: thermal-ALD (T-ALD) at relatively low temperatures (<200 °C) and plasma-assisted-ALD (PA-ALD) in the presence of plasma. In the first half of the pulse, both of which are based on the self-limiting reactions between the surfaces edged –OH and the Sn precursor, whereas in the second half, the main reactant in the T-ALD is water (H2O) and in the PA-ALD is oxygen (O2).[ 68 ] Moreover, the manufacturing of thin and controllable films of up to monolayer order could be realized through ALD method. Due to the presence of plasma in the PA-ALD method, the heating temperature of the substrate during the process is lower and the plasma employed in which is the reaction outputs of O2, N2 and H2 gases or their combination. Lee et al.[ 69 ] could fabricate uniform and pinhole-free SnO2 layers at 120 °C using T-ALD method and exhibit a PCE of 18.37%, which could be further elevated to 20.03% through adding a compact TiO2 layer under that of the SnO2 layer. Likewise, Wang and coworkers[ 70 ] could realize the PCE of 18.8% and 16.8% utilizing PA-ALD method for SnO2 deposition layer at 100 °C on rigid and flexible substrates, respectively. In turn, Kuang and coworkers[ 68 ] employed RF with oxygen plasma (i.e., RF inductively coupled O2 plasma) as a reactant to fabricate the SnO2 layer through ALD. As a versatile and robust deposition technique, ALD is capable of producing high-quality inorganic metal oxide thin films. In the first half of the cycle, self-limiting reactions take place between the surface leading to -OH groups and the Sn precursor. Subsequently, in the second half of the cycle, the main reactant in T-ALD and PA-ALD is water (H2O) and O2, respectively. The utility of an O2 plasma reactant renders the deposition of SnO2 thin films at low temperatures possible. Therein, the research group utilized tetrakis(dimethylamino)tin (TDMASn) as a Sn precursor as well as O2 plasma to cleanse the substrate surface (ITO) prior to the deposition. Besides, after the ETL deposition and right before the perovskite layer deposition, the SnO2 layer was exposed to O2 plasma. In conclusion, champion PSCs showing a PCE of 17.5% using SnO2 deposited by O2 plasma-assisted ALD at 50 °C and 17.8% at 200 °C were obtained.

2.2.2 Pulsed Laser Deposition

In pulsed laser deposition (PLD), once the laser pulses hit the solid target material, the surface of which becomes so hot that leads to local evaporation of the material from the target as a plasma plume, the so-called ablation. In consequence of the collision of the plume with the substrate surface, a thin layer is formed on the substrate surface.[ 71, 72 ] In the light of PLD application, the scattering of the ablated material from the target is avoided that provides favorable conditions for a vacuum-based unspotted deposition. If the laser ablation takes place in the air, the plasma would instantly collide with the air molecules and cease moving further. Moreover, the ablated atoms and ions react easily with oxygen, water, and other molecules in the air in a way that they chemically transform.[ 72 ] What is more, it is possible to grow a broad range of materials extending from dielectrics, semiconductors, and metals, to superconductors via the PLD method. These materials might consist of a single element or a combination of several elements such as oxides, nitrides, carbides, and sulfides. The most prominent cause behind this versatility lies in the nature of the laser pulse, which allows the stoichiometric transfer of the target material composition onto the formed layer far from the thermal equilibrium and underoptimized conditions.[ 73, 74 ] Besides, the PLD is a physical deposition technique for the preparation of thin films at low temperatures, which avoids the requisite of further thermal posttreatment. Theretofore, this method holds the potential to be applied for SnO2 deposition on flexible substrates. Chen et al.[ 75 ] utilized the PLD and could achieve devices of rigid and flexible substrates demonstrating PCEs of 17.29% and 14%, respectively.

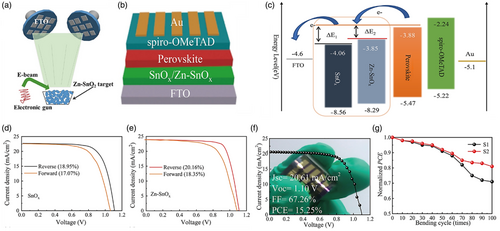

2.2.3 E-Beam Evaporation

E-beam evaporation is a vacuum-based method performed by means of an electron beam. The energy required for evaporation is provided through the transport of energy from the electron beams to the target material. The presence of air molecules in the route of metal vapor transport from the target material to the substrate might decrease the deposition rate and prevent the formation of compact coating, indicating the essentiality of a high vacuum. The E-beam evaporation method has been proven to enable the large-scale and cost-cutting production of LT-SnO2 with uniform coverage. Thereupon, SnO2 films prepared through this method demonstrate high electron mobility, desired antireflection, and directional crystallization that takes a leading role in high-efficiency PSCs.[ 76 ] Ma et al.[ 77 ] utilizing LT-SnO2 prepared through E-beam evaporation method as ETL in PSC could obtain the PCE of 18.2% on a large active area of 1 cm2. Since it works at vacuum condition, time and energy cost should be considered for the industrial production.

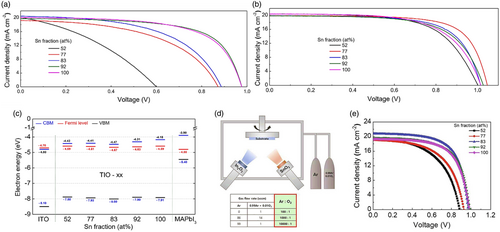

2.2.4 Sputtering

The sputtering process involves the ablation of target atoms/molecules through the plasma of an inert gas accelerating under the field and deposited on the substrate. In the same manner to that of other vacuum-based physical deposition methods, the sputtering method comprises three steps: ablation of the target material, transporting of atoms/molecules from the target to the substrate, and formation of a thin film on the substrate. In this method, the physical interaction of particles colliding with the target material serves for the ablation of the target material.[ 38, 78 ] Qiu et al.[ 38 ] employed different ratios of reactive O2 and inert Ar gas and altered the power and time of the deposition for SnO2 ETL, which ultimately could manage to achieve 20.2% PCE on a small scale of 0.09 cm2 and that of 12.03% on a large scale of 22.8 cm2.

2.3 Vapor-Based Deposition Methods

2.3.1 Aerosol-Assisted Chemical Vapor Deposition

In the AACVD method adapted from CVD, a thin film of solid material is formed on the substrate as a consequence of a chemical reaction in the vapor phase. In this manner, CVD involves of a stream of gas or gaseous compounds containing a precursor chemical composition in a chamber including one or more hot surfaces (substrates). Conventionally, the CVD method exhibits a high reaction temperature in which AACVD is employed as a modification to reduce the deposition temperature. In the AACVD method, the precursor is generated through ultrasonic using a liquid/gas aerosol and subsequently introduced to the substrate surface. Noh et al.[ 79, 80 ] implied that the application of AACVD at low temperatures to produce SnO2 leads to oxygen vacancies thereof. Notwithstanding, the report demonstrated that the presence of oxygen vacancies improved charge transport in the SnO2 layer through elevating the density of free carriers. Consequently, they could successfully obtain the 10.2% PCE on a small scale of 0.07 cm2 (utilizing PCBM as an interlayer between perovskite and SnO2 ETL)[ 79 ] and that of 1.4% on a large scale of 1 cm2.[ 80 ]

3 LT-SnO2 Modification Methods

Although various methods have been developed to deposit high-quality LT-SnO2, the physical and electrical properties of SnO2 films and the photovoltaic performances of devices widely vary. Thus, a great variety of strategies have been applied to modify the SnO2 films, including surface treatment, multilayer, and addictive engineering. With these optimizations, the defects in the bulk or at the grain boundaries of LT-SnO2 will be passivated, along with the increasing crystallinity and fewer pinholes. Moreover, the charge accumulation and recombination at ETL/perovskite interface will be hindered by the well-aligned energy level. LT-SnO2 modification also benefit for the nucleation and growth of perovskite films, tailoring the growth direction and grain sizes.

3.1 Surface Treatment

The interface between perovskite layer and charge transport layer, particularly ETL, has played a crucial task in reducing nonradiative recombination losses through efficiently transporting photogenerated charges. The application of an engineered interface between ETL and perovskite is of the most efficient ways to eliminate these parasitic charge carrier compounds. Such an engineered interface could also pave the way for a high-performance electron conductor of a reduced band-offset. Moreover, it could also assist the formation of a compact perovskite layer so as to improve the efficiency and stability of the prepared PSCs.[ 81 ] In this regard, extensive research works have been devoted to these issues that will be reviewed in the following subsections. Besides, the PCE and performance parameters of PSCs based on LT-SnO2 ETL modified through the surface treatment method are summarized in Table 2 .

| SnO2 modification | Cell configuration | J SC [mA cm−2] | V OC [V] | FF [%] | Eff [%] | Ref. | |||

|---|---|---|---|---|---|---|---|---|---|

| Surface treatment | Thermal annealing | Air ambient | Planar | ITO/SnO2/(FAPbI3)1−x (MAPbBr3) x /Spiro-MeOTAD/Au | 23.86 | 1.12 | 80.60 | 21.64 | [35] |

| O2 | Planar | ITO/SnO2/(FAPbI3)0.85(MAPbBr3)0.15/Spiro-MeOTAD/Ag | 24.40 | 1.14 | 73.40 | 20.40 | [89] | ||

| Ethanol vapor | Planar | ITO/SnO2/MAPbI3/Spiro-MeOTAD/Au | 21.85 | 1.08 | 74.28 | 17.66 | [90] | ||

| Air/N2 two steps | Planar | FTO/MDCN-SnO2/MAPbI3/Spiro-MeOTAD/Au | 24.16 | 1.07 | 74.05 | 19.14 | [91] | ||

| Air/Alkali-gas two steps | Planar | ITO/SnO2/FA0.15MA0.85PbI3/Spiro-MeOTAD/Au | 24.71 | 1.10 | 77.91 | 21.10 | [92] | ||

| Hot air flow (HAF) | Planar | ITO/SnO2/Cs0.05FA0.79MA0.16PbI2.45Br0.55/Spiro-MeOTAD/Au | 22.16 | 1.14 | 72.19 | 18.93 | [93] | ||

| UV-Ozone (UVO) treatment | UVO pretreatment | Planar | FTO/SnO2/MAPbI3/Spiro-MeOTAD/Au | 23.27 | 1.11 | 67.00 | 17.21 | [97] | |

| UVO/humidity pretreatment | Planar | FTO/SnO2/Cs(FAMA)Pb(I,Br)3/Spiro-MeOTAD/Au | 22.40 | 1.16 | 78.00 | 20.50 | [48] | ||

| UVO posttreatment | Planar | ITO/SnO2 QDs/MA0.7FA0.3PbI3/Spiro-MeOTAD/Au | 22.99 | 1.11 | 77.00 | 20.11 | [94] | ||

| Planar | ITO/SnO2/MAPbI3/Spiro-MeOTAD/Au | 20.11 | 1.11 | 64.30 | 14.36 | [96] | |||

| Planar | FTO/SnO2/MAPbI3−x Cl x /Spiro-MeOTAD/Ag | 21.95 | 1.07 | 69.00 | 16.21 | [95] | |||

| Plasma treatment | O2 plasma | Planar | ITO/SnO2/FA x MA1−x Pb(I y ,Clz,Br1−y−z)3/Spiro-MeOTAD/Au | 24.06 | 1.12 | 80.20 | 21.68 | [123] | |

| Planar | PET/ITO/SnO2/(FA0.83MA0.17)0.95Cs0.05PbI2.5Br0.5/Spiro-MeOTAD/Au | 12.81 | 5.68 | 42.00 | 3.09 | [25] | |||

| RF inductively coupled O2 plasma | Planar | ITO/SnO2/Cs0.05(MA0.17FA0.83)0.95Pb(I0.9Br0.1)3/Spiro-MeOTAD/Au | 22.10 | 1.08 | 75.00 | 17.80 | [68] | ||

| Ar/O2 plasma | Planar | FTO/SnO x /MAPbI3/Spiro-MeOTAD/Au | 21.36 | 1.13 | 76.90 | 18.64 | [124] | ||

| Ar plasma | Mesoscopic | ITO/SnO2/m-TiO2/MAPbI3/Spiro-MeOTAD/Au | 24.91 | 0.98 | 62.04 | 15.17 | [290] | ||

| N2 plasma | Planar | PET/ITO/SnO2/(FA0.83MA0.17)0.95Cs0.05PbI2.5Br0.5/Spiro-MeOTAD/Au | 21.82 | 1.12 | 83.00 | 20.30 | [25] | ||

| N2O plasma | Planar | PET/ITO/SnO2/(FA0.83MA0.17)0.95Cs0.05PbI2.5Br0.5/Spiro-MeOTAD/Au | 21.90 | 1.10 | 83.00 | 19.96 | [25] | ||

| Photonic Annealing | IPL Annealing | Planar | FTO/SnO2/MAPbI3/PTAA/Au | 21.40 | 1.06 | 67.00 | 15.30 | [39] | |

| Planar | FTO/SnO2/Cs0.05(MA0.85FA0.15)0.95PbI3/PTAA/Au | 15.78 | 1.02 | 78.30 | 12.56 | [110] | |||

| Planar | FTO/SnO2/MAPbI3/Spiro-MeOTAD/Au | 20.68 | 1.10 | 77.87 | 17.68 | [130] | |||

| Water treatment | Hydrothermal treatment | Planar | ITO/SnO2/Cs0.05FA0.81MA0.14PbI2.55Br0.45/Spiro-MeOTAD/Au | 22.60 | 1.14 | 79.10 | 20.30 | [131] | |

| Water-bath treatment | Planar | FTO/SnO2/Cs0.05(MA0.15FA0.85)0.95Pb(I0.85Br0.15)3/Spiro-MeOTAD/Au | 22.76 | 1.09 | 77.30 | 19.17 | [121] | ||

| Water-spin coat treatment | Planar | ITO/SnO2/Cs0.10FA0.75MA0.15Pb(Br0.15I0.85)3/SpiroMeotad/Au | 22.58 | 1.14 | 76.33 | 19.68 | [99] | ||

| Sulfur treatment | Potassium O-hexyl xanthate | Planar | ITO/SnO2/Potassium O-hexyl xanthate/MAPbI3/Spiro-MeOTAD/Au | 22.61 | 1.06 | 76.85 | 18.41 | [102] | |

| (NH4)2S | Planar | ITO/SnO2/(NH4)2S/FAMAPb(I,Br)3/Spiro-MeOTAD/Ag | 22.95 | 1.15 | 75.95 | 20.03 | [137] | ||

| SAM treatment | Si-based (APTES) | Planar | FTO/SnO2/APTES SAM/MAPbI3/Spiro-MeOTAD/Au | 21.93 | 1.16 | 72.00 | 18.32 | [141] | |

| C60 | Planar | ITO/SnO2/C60 SAM/MAPbI3/Spiro-MeOTAD/Ag | 21.53 | 1.07 | 65.00 | 15.18 | [63] | ||

| Zwitterion | Planar | FTO/SnO2/NDSB-201/Cs0.05(MA0.15FA0.85)0.95Pb(I0.85Br0.15)3/Spiro-MeOTAD/Au | 23.60 | 1.16 | 78.40 | 21.43 | [148] | ||

| Planar | ITO/SnO2/DETAPMP/(FAPbI3)0.95(MAPbBr3)0.05/Spiro-MeOTAD/Ag | 23.14 | 1.14 | 81.90 | 21.65 | [149] | |||

| Choline chloride | Planar | FTO/SnO2/Choline Chloride/MAPbI3/Spiro-MeOTAD/Au | 22.80 | 1.15 | 72.41 | 18.90 | [150] | ||

| Thiol Silane | Planar | ITO/SnO2/MPTMS/FAMAPb(I,Br,Cl)3/Spiro-MeOTAD/Au | 23.60 | 1.11 | 76.32 | 20.03 | [143] | ||

| Carboxylic acid | Planar | ITO/SnO2/3-thiophenepropanoic acid/MAPbI3/Spiro-MeOTAD/MoO3/Ag | 22.49 | 1.08 | 76.79 | 18.67 | [151] | ||

| Planar | ITO/SnO2/3-thenoic acid/MAPbI3/Spiro-MeOTAD/MoO3/Ag | 22.68 | 1.11 | 77.89 | 19.59 | ||||

| Planar | ITO/SnO2/thiophene-3-acetic acid/MAPbI3/Spiro-MeOTAD/MoO3/Ag | 23.03 | 1.12 | 80.12 | 20.61 | ||||

| Planar | ITO/SnO2/PDI-P/MAPbI3/Spiro-MeOTAD/Au | 20.43 | 1.05 | 72.53 | 15.57 | [152] | |||

| Planar | ITO/SnO2/PDI-LP/MAPbI3/Spiro-MeOTAD/Au | 22.57 | 1.08 | 72.81 | 17.83 | ||||

| Planar | ITO/SnO2/PDI-LAS/MAPbI3/Spiro-MeOTAD/Au | 22.88 | 1.11 | 73.98 | 18.77 | ||||

| Alkali metal treatment | KCl treatment | Planar | ITO/SnO2/KCl/MAPbI3−x Cl x /Spiro-MeOTAD/Au | 21.82 | 1.12 | 79.30 | 19.44 | [156] | |

| KOH treatment | Planar | FTO/SnO2/KOH/Cs0.05(FA0.85MA0.15)0.95Pb(I0.85Br0.15)3/Spiro-MeOTAD/Au | 22.60 | 1.15 | 79.00 | 20.50 | [26] | ||

| KCl treatment | Planar | ITO/SnO2/KCl/MAPbI3/Spiro-MeOTAD/Au | 22.50 | 1.06 | 76.86 | 18.29 | [105] | ||

| LiCl treatment | Planar | ITO/SnO2/LiCl/MAPbI3/Spiro-MeOTAD/Au | 22.12 | 1.06 | 78.97 | 18.53 | [105] | ||

| NaCl treatment | Planar | ITO/SnO2/NaCl/MAPbI3/Spiro-MeOTAD/Au | 22.73 | 1.06 | 77.59 | 18.67 | [105] | ||

| Halogen treatment | Chlorine treatment | Planar | FTO/SnO2/1,2-dichlorobenzene/Cs0.10FA0.75MA0.15Pb(Br0.15I0.85)3/Spiro-MeOTAD/Au | 20.68 | 1.14 | 75.30 | 17.81 | [120] | |

| Bromine treatment | Planar | FTO/SnO2/1-Butyl-3-methylimidazolium bromide/MAPbI3/Spiro-MeOTAD/Au | 21.74 | 1.12 | 77.50 | 18.80 | [157] | ||

| Amine-based treatment | Guanidinium treatment | Planar | ITO/SnO2/Guanidinium chloride/MAPbI3−x Cl x /Spiro-MeOTAD/Ag | 19.87 | 1.17 | 80.47 | 18.72 | [162] | |

| NH4F treatment | Planar | FTO/SnO2/NH4F/(FAPbI3)0.95(MAPbBr3)0.05/Spiro-MeOTAD/Au | 24.60 | 1.16 | 81.40 | 23.20 | [104] | ||

| Glycine treatment | Planar | ITO/SnO2/Glycine/Cs0.05MA y FA0.95−y PbI3−x Cl x /Spiro-MeOTAD/Ag | 24.15 | 1.10 | 78.00 | 20.68 | [34] | ||

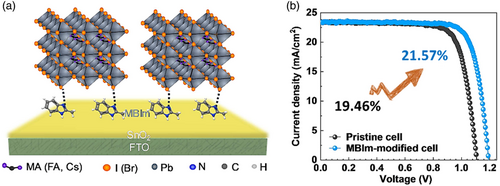

| 2-Methylbenzimidazole (MBIm) treatment | Planar | FTO/SnO2/MBIm/Cs0.05(MA0.15FA0.85)0.95Pb(I0.85Br0.15)3/Spiro-MeOTAD/Au | 23.41 | 1.20 | 77.40 | 21.57 | [81] | ||

| p-Amino benzenesulfonic acid (ABSA) treatment | Planar | ITO/SnO2/ABSA/MAPbI3/Spiro-MeOTAD/MoO3/Ag | 22.93 | 1.13 | 78.75 | 20.32 | [168] | ||

3.1.1 Thermal Treatment (Annealing)

Due to the widespread utilization of solution-based methods to fabricate the SnO2 layer, thermal decomposition of Sn precursors and the conversion to SnO2 require thermal annealing.[ 40, 82-85 ] Thermal annealing under air decreases charge transport imbalance in the ETL/perovskite and HTL/perovskite interface, leading to a reduction in J–V hysteresis.[ 86 ] It should be mentioned that the temperature and environment, i.e., atmosphere pressure and humidity, of thermal annealing is of considerable importance. Annealing temperature should be below 200 °C. Although high-temperature annealing (>400 °C) might enhance the film crystallinity, it could result in more oxygen vacancies as well as pinholes and cracks in the film and generating gaps between the ETL and the substrate due to thermal stress and overcrystallization.[ 87 ] This in turn would increase the recombination and reduces the device performance.[ 88 ] In 2017, Jiang et al.[ 35 ] successfully ascertained 21.52% PCE of the devices using low temperature (150 °C) annealing of spin-coated SnO2 film from a commercial colloidal suspension of SnO2 nanoparticles as ETL in the planar PSC cell structure. Far from it, the realization of flexible PSCs requires flexible films such as PET or PEN as substrates incompatible with such high-temperature treatment and thus the deposition of the layers on these substrates must be processed at temperatures below 150 °C.[ 23 ] However, some reported performing at higher temperatures (180 °C[ 24-26 ] and 185°[ 27 ] for PET) and (180 and 200 °C[ 28, 29 ] for PEN). The presence of moisture is a prerequisite for the thermal decomposition process; therefore, the annealing process in practice is carried out under medium-humidity air.[ 88 ] Nevertheless, it has been reported that this thermal process is performed under a special atmosphere such as oxygen, nitrogen, alkali gas, and ethanol vapor.

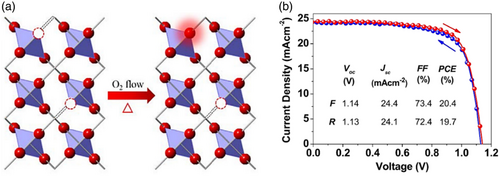

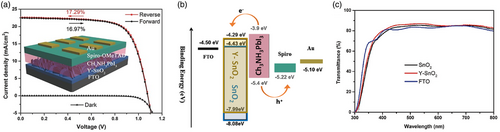

Thermal Annealing Under O2 Gas

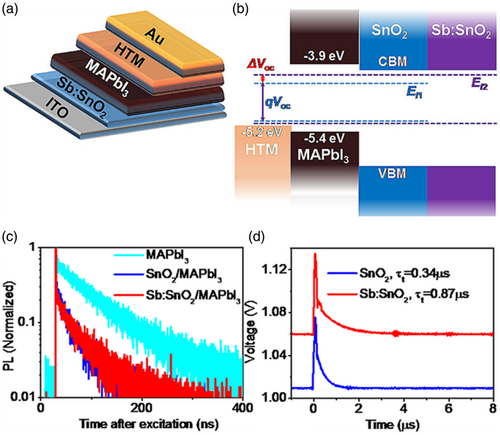

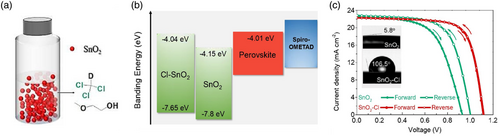

According to the literatures, annealing SnO2 films under O2 makes the oxygen in SnO x films dramatically increase and the oxygen vacancies to reduce leading to more perfect and larger SnO x rutile crystals. Besides, annealed SnO x films under O2 gas have been reported to have lower surface roughness and higher compactness that favors the perovskite growth. The reduction in surface roughness could be attributed to the reduction of the defect density in SnO x thin films and the migration of Sn and O atoms to the defects during the annealing process.[ 89 ] Jiang et al.,[ 89 ] after which the SnO2 films were dried at 100 °C under air, evaluated the thermal annealing effect (e.g., 180 °C) under N2/O2 gas flow with different O2 percentages on the performance of the SnO2 layer in PSC. They could successfully adjust the oxygen content, electron mobility, and trap state density in SnO x films (Figure 7 ). To investigate the effect of self-passivation, they analyzed the charge transport dynamics (i.e., transport and carrier recombination processes) of SnO x -based PSCs. The results demonstrated that the SnO x films annealed under 100% O2 gas flow presented the best carrier collection performance in PSCs.[ 89 ]

Thermal Annealing Under Ethanol Vapor

Wang et al.[ 90 ] utilized ethanol vapor during the annealing process in order to improve the performance of the LT-SnO2 ETL. They placed the spin-coated SnO2 film at 200 °C for 1 h on a hot plate sealed by a large glass chamber. Also, a vessel containing ethanol to produce ethanol vapor was included inside the chamber. Compared to the traditional annealing method (i.e., under air), this method has significantly augmented the electrical properties of SnO2 film. Moreover, annealing under ethanol gas resulted in higher light absorption and lower trap state density in the perovskite layer. Therefore, PSCs were fabricated using ethanol-annealed SnO2 film as ETL and demonstrated a facilitated electron injection and transport as well as a reduced charge recombination.

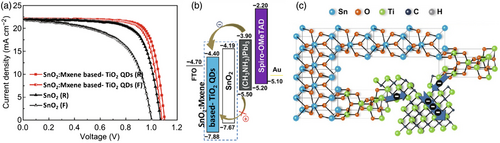

Two-Step Thermal Annealing

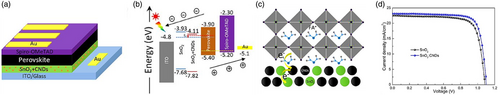

Huang et al.[ 91 ] combined the TiO2 QDs in the anatase phase along with MXene in solution-based with SnO2 nanoparticle colloid and deposited through spin-coating method. The prepared ETL was then annealed in a two-step process at 150 °C under air (5 min) and N2 gas (25 min). According to the results, in the two-step annealing, SnO2 nanocrystals and quantum dots of TiO2 were formed and grew due to oxidation in the first step of air annealing. In the second step of annealing under N2 gas, the crystals resumed growing; however, the source of the oxygen element was supplied by –OH functional groups and preformed TiO2 crystals due to oxygen deficiency in the annealing atmosphere. This, in turn, has led to the formation of defective TiO2 crystals that inclined to assemble with vicinal SnO2 crystals and eventually formed a more stable phase of TiO2/SnO2 heterojunctions. Conclusively, utilizing a two-step thermal annealing process with the formation of TiO2/SnO2 nanoscale heterojunction and the enhancement of ETL conductivity due to the presence of MXene as conductive bonded bridges as a multidimensional conductive network (MDCN).

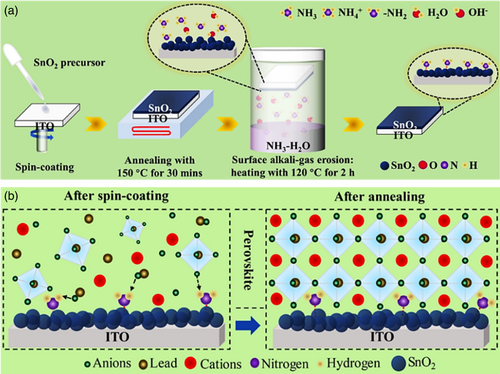

Huang and coworkers[ 92 ] also employed a versatile two-step annealing process to improve SnO2 ETL. In the first step, annealing was performed at 150 °C and then the samples were kept in a reaction chamber containing a certain amount of ammonia solution in which the samples were separated from the solution. Consequently, the chamber was sealed and heated for 2 h at a temperature of 120 °C, during which time the layer was exposed to the alkaline gas produced (Figure 8a). Regarding the corrosion caused by alkaline gas during the second step of annealing, the surface of SnO2 film was polished, and also ─NH2 group was chemically adsorbed onto the surface of the SnO2 layer. The surface polishing resulted in the ETL surface smoother. According to the results, the crystallinity quality of the perovskite film has significantly excelled after applying SnO2 annealing under alkaline gas. The justification behind these effects was presented in two pathways. As shown in Figure 8b, the ─NH2 groups adsorbed onto the SnO2 surface would firmly interact with the perovskite halide anions through hydrogen bonding providing germination sites for further nucleation of perovskite crystals by accelerating atoms in the preheating of perovskite film. As viewed by the classical nucleation theory, during the nucleation process, the reduction in volumetric free energy caused by a temperature decrease could merely recompense 2/3 of the surface energy of the nucleus and the rest has to be supplied through the conditions stemmed from local energy fluctuations of the perovskite films preheating. The presence of hydrogen bonds formed between perovskite halide anions and the ─NH2 group could efficiently increase local energy fluctuations and accelerate crystal nucleation. Furthermore, ─NH2 groups are of smaller molecular dimensions than that of the perovskite organic molecule which comes to their aid to incorporate into the inorganic perovskite framework and substitute the perovskite organic molecule at the bottom of the film as the annealing process resumes. As a consequence, the rate of perovskite crystals nucleation would be enhanced and a bridge link between SnO2 and perovskite is constructed. By and large, utilizing a two-step thermal annealing process with polishing and adsorption of ─NH2 group, they could manage to improve mobility, charge transport in the perovskite/ETL interface, and crystallinity of the perovskite layer with the achievement of a 21.1% PCE.

Thermal Annealing Under Hot Air Flow

Smith et al.[ 93 ] made use of a fast roll-to-roll (R2R) compatible process for SnO2 ETL annealing. In this method, to rapidly anneal SnO2 ETL at 120 °C in 1 minute, a heat gun of control capability is employed for rendering a hot HAF. They found that elevating the duration of the HAF thermal annealing process up to 5 minutes made the roughness of the ETL surface enhance due to the increment in grain radius that was favored for the perovskite deposition.

3.1.2 UV-Ozone Treatment

Since the conventional methods of the preparation of SnO2 films demand the application of precursor ink (i.e., tin chloride) that requires high temperature, they are not suitable for upscaling. To tackle this issue, UVO posttreatment has been presented as a suitable method that will further overcome the technical rigors of the manufacturing process and production costs and facilitate the large-scale fabrication of SnO2 films. Generally, UVO treatment is always considered to remove the surface contaminants, improve the wettability, and change the states of surface oxygen. The major wavelengths of the ultraviolet rays radiated from a well-known low-pressure mercury vapor lamp are 184.9 and 253.7 nm. During the process of formation or decomposition of O3, atomic oxygen (O) having a strong oxidizing ability is generated. Organic compounds can be decomposed by irradiating them with energy stronger than the bond energy. These excited contaminants, or the free radicals of the contaminants formed by photolysis, react with atomic oxygen to form simple molecules such as CO2, H2O, N, and O2, which are removed from the surface.[ 94-96 ] Generally, UVO treatment is applied as pretreatment and posttreatment, before and after the ETL deposition, respectively.

UV-Ozone Pretreatment

In the majority of research works utilizing low-temperature SnO2 films as ETL in PSC, the UVO pretreatment time was reported to be between 5[ 26, 97 ] and 30[ 98-100 ] minutes, among the 15 minutes to be dominant.[ 39, 64, 90, 93, 96, 101-105 ] The principal purpose of performing this treatment was to clean-up the surface of the substrates from volatile organic compounds as well as the enhancement of wettability.

(UV-Ozone/Humidity) Pretreatment

Dong et al.[ 48 ] produced moisture molecules adsorbed onto the surface through the utility of UVO pretreatment under humidity on substrates prior to the SnO2 layer deposition (Figure 9a). They managed to harness the water adsorbed onto the substrate surface through ambient humidity and UVO pretreatment duration monitoring.

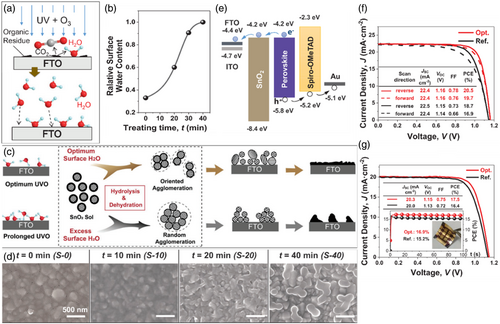

The results of the systematic studies demonstrated that the optimal amount of surface adsorbed water molecules throughout the deposition of SnO2 nanocrystals using the sol–gel method at room temperature on UVO pretreated substrates facilitates optimal hydrolysis-condensation reactions for SnO2 regrowth (Figure 9b). Furthermore, UVO pretreatment of the substrate makes for a perfect coverage of SnO2 of desired morphology and crystallization along with superior optical and electrical properties as well as optimized roughness that provokes a more perfect bonding of the interface with the perovskite layer. The sight of pinholes and cracks will be vanished in UVO pretreated samples, resulting in a thin and compact film of ideal coverage and low roughness. Nevertheless, UVO pretreating of longer than optimized time drives the SnO2 grains to agglomerate and further surface roughness increment and a defective coating in the films is obtained (Figure 9c,d). Employing the UVO pretreatment, Dong et al.[ 48 ] could manage to simultaneously optimize crystallinity, trap state density, and surface roughness in the SnO2 ETL employed in PSCs fabricated at room temperature. The structural advantages of the treated SnO2 film made for further improvements in charge transport dynamics and minimized energy loss in the PSCs that significantly enhanced their PCE (Figure 9f,g).

UV-Ozone Posttreatment

As viewed by the literature, the duration of UVO posttreatment has been reported to vary between 5[ 27 ] and 60[ 95, 96, 106 ] minutes, with that of 15 minutes to be more frequent.[ 40, 65, 92, 93, 104, 107-110 ] UVO posttreatment, through wiping out the organic residues on the surface of SnO2 film, would lead up to the increased hydrophilicity and wettability of the SnO2 layer and improved surface adhesion between the SnO2 layer and perovskite. All but most of the SnO2-based PSCs reported heretofore are freshly employed with that of a few minute treatments under UVO, which appears as an essential step before the perovskite deposition.[ 111 ] Furthermore, posttreatments of the ETL using UVO have an impact on perovskite growth.[ 30 ] In particular, as regards the decrease in the concentration of oxygen vacancies making a downward change in the Fermi levels, the work function of metal oxides might be elevated upon UVO posttreatment. Surface UVO posttreatment improves the interface properties between the ETL and the perovskite that promotes the interaction between the ETL and the perovskite layer, thereby facilitating expeditious electron injection from the perovskite layer to the ETL.[ 87 ]

In UVO treatment, ultraviolet light is simultaneously generated at two wavelengths of 253.7 and 184.9 nm possessing high energy and the corresponding photon energy of which is 472 and 647 kJ mole−1, respectively. Both photon energies are higher than those of Sn–Cl and O–H bonds having bond energies on the order of 350 and 459 kJ/mole, respectively. Also to be found, they are higher than those of C–C, C–H, and C–O bond energies thereabouts 346, 411, and 358 kJ mole−1, respectively. Therefore, UV light is capable of readily breaking down these chemical bonds so that the reaction perpetuates. Meanwhile, UV light of 184.9 nm wavelength could convert O2 oxygen molecules to active O3 ozone molecules, which facilitates the formation of SnO2, decomposition as well as the oxidation of organic compounds, and the final by-products are released as Carbon monoxide (CO2) and water (H2O).[ 94 ] So too did, Liu et al.[ 94 ] studied the deposition of SnO2 quantum dot colloidal solution to construct the QD SnO2 layer as ETL. High-temperature sintering is customarily applied to remove contaminants albeit in might lead to some defects in the SnO2 QD film. Nevertheless, to curb this issue, the research group utilized UVO posttreatment at room temperature to detach ethyl groups from SnO2 QD film and managed to obtain a PCE of 20.1%.

Furthermore, it has been reported that the surface temperature of the layers throughout UVO upraises to about 60 to 70 °C due to the effect of UV light.[ 95, 96 ] Case in point, Li et al.[ 96 ] spin-coated a commercial Alfa-SnO2 ink followed by annealing at 50 °C for 5 minutes. Thereby, the layers were treated with UVO for 60 minutes. The results of temperature measurement using an infrared thermometer demonstrated that the temperature of the layers increased by about 60 °C during UVO due to its light radiation. According to them, UVO posttreated SnO2 layers displayed superior compactness, purity, and transparency.

Moreover, Huang et al.[ 95 ] compared the performance of UV-sintered SnO2 films with that of 180 °C annealed films in the PSC architecture. Thereby, UV-sintered SnO2-based PSCs possessed 16.21% PCE, whereas annealed SnO2-PSCs displayed 11.49% at 180 °C. Likewise, it was reported therein that the UVO treatment process imposes a thermal process in the meantime and that the temperature in the entire UVO process is normally below 100 °C. From the findings of the experiment, in the short periods, the layers were of pinholes which could undermine the hole blocking performance of SnO2. Besides, it was demonstrated that the –OH bond density increased and then further decreased upon increasing UVO treatment duration. These findings implied that after which the UVO treatment was applied the hydroxyl groups were formed on the SnO2 surface, and the more –OH groups on the SnO2 surface the lower the recombination rate. These results are schematically summarized in Figure 10 .

3.1.3 Plasma Treatment

One of the utilities of plasma treatment involves surface activation, which offers numerous benefits including higher efficiency, cost-effectiveness, and environmentally friendliness over traditional methods of wet physical and chemical activation. When the plasma comes in contact with the surface, the induced energy transferred by the plasma engenders subsequent reactions on the surface of the material.[ 112 ] In consequence, the wettability of the surface increases and the water contact angle decreases owing to plasma treatment, and thus the surface is rendered more hydrophilic. Besides, it curtails the concentration of C–C or C–H bonds.[ 112-114 ] Each gas type possesses variant characteristics that affect the surface properties of an object within different respects. As regards, neutral or inert argon (Ar) plasma has reportedly displayed no chemical effects on the surface.[ 115 ] The major difference between Ar and O2 plasma lies in the mechanism of the surface activation, i.e., physical etching and chemical reaction, respectively.[ 116 ] Moreover, the chemical interaction of oxygen-based plasma systems can form strong carbon–oxygen (C–O) covalent bonds of higher polarity than those of carbon–hydrogen (C–H) bonds.[ 112, 114, 117 ]

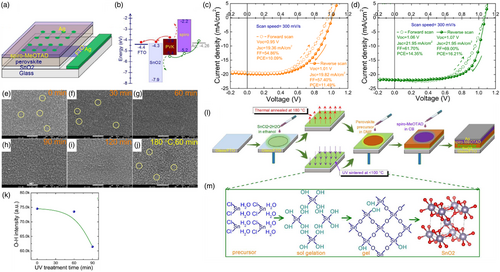

In recent times, plasma utilization has been acknowledged to be an efficient posttreatment procedure. In particular, the impacts of plasma treatment on metal oxide-based semiconductors to control carrier concentrations associated with oxygen vacancies have enormously attracted research interests.[ 118, 119 ] The reports have demonstrated that the O2 and N2 plasma treatment reduced the carrier concentration which was also accompanied by some oxygen vacancies. By comparison, the oxygen vacancies population is significantly higher in Ar plasma treatment. In the case of O2 plasma, bulk traps are treated through filling the oxygen vacancies even though the surface is damaged by ion bombardment.[ 119 ] O2 plasma treatment has been more frequently utilized compared to the other gases in both pre- and posttreatment methods, i.e., before and after SnO2 ETL deposition. In the cases of O2 plasma utilization as pretreatment, the duration of pretreatment was reported to extend between 3[ 68 ] and 20[ 110, 120 ] minutes in which the 5-minute time was more frequent.[ 24, 121, 122 ] Besides, in the case of O2 plasma utility as posttreatment and an alternative of thermal annealing, the posttreatment duration was reported to vary between 2.5 and 15 min and likewise, the 5-min time was dominant.[ 25, 68, 123-126 ] In these reports, the main purpose of functioning the posttreatment was to modify the roughness, activate the surface, tune the energy level of the conduction band (E CB), and enhance the work function of SnO2 ETL. Luan et al.[ 123 ] applied O2 plasma to posttreat the surface of trifluoroethanol-incorporated SnO2 (T-SnO2). They investigated the effect of O2 plasma power on PSC performance in which a champion efficiency of 21.68% was achieved at 60 watts. Yu et al.[ 124 ] were of the pioneers that reported the utilization of the Ar/O2 plasma atmosphere as the major energy source to activate the sol–gel film to form a compact SnO2 thin film of SnCl2 precursor at a record rate of ≤5 min. The amorphous SnO2 thin films employed as ETL in PSC were prepared through anhydrous SnCl2 spin-coating solution followed by thermal annealing (T-SnO2) or plasma (P-SnO2) (Figure 11a). In turn, the T-SnO2 thin film was prepared slowly under thermal stress of 180 °C temperature for 1 h, whereas the P-SnO2 thin film was fabricated very rapidly in 5 min under Ar/O2 plasma atmosphere along with undesired heat (i.e., ≈50 °C) as well as plasma ion bombardment (Figure 11a). Even though the undesired thermal energy is involved to some extent, its effect is negated owing to the degree of oxidation caused by the oxygen flow rate and the duration of the radiation. Therein, the duration of plasma irradiation in the range of 15 to 600 s was examined (Figure 11e). In the semi-oxidized state of the SnO2 thin film (i.e., <450 s), the remaining Sn+2 and Cl− ions might incorporate into the perovskite lattice and undermine the PSC performance since Sn+2 ions are prone to facile oxidization under ambient air.

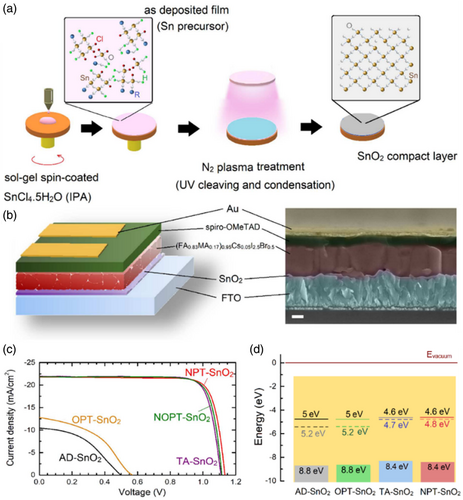

Also been demonstrated, the formation of metal–oxygen–metal (M–O–M) and hydroxyl metal (M–OH) bonds in P-SnO2 thin film was higher and lower, respectively, than that of T-SnO2 in which M–OHs plays the role of shallow trap sites. The widespread presence of M–OH indicated the deficient oxidation of the oxidative network, which reduces the mobility of the SnO2 thin film, decreases the electron life, and hinders desired electron transport. Furthermore, thermal annealing is given to make for more grain boundaries due to the activation of necking between SnO2 particles wherein a high density of shallow trap sites is generated owing to network mismatch. Moreover, due to the passivation of the surface stemming from the treatment of inherent defects and the substitution of carbon impurities with oxygen during plasma annealing, the conduction band minimum can be moved upward (Figure 11b).[ 124 ] Therefore, with the use of plasma annealing, the research group was capable of fabricating a denser oxide network compared to that of thin layers oxidized under thermal annealing resulting in supreme electrical conductivity along with lower trap densities. As concluded by these findings, plasma annealing is a cost-effective and efficient fabrication procedure of high-quality thin films for various metal oxides that can be prepared using the sol–gel route.[ 124 ] Also, Shekargoftar et al.[ 127 ] used argon plasma (atmospheric pressure and power density 2.5 W cm−2, 5 min, <60 °C) for the treatment of SnO2 films and its performance by thermal annealing (30 min, 180 °C) compared. The O1S peak of the XPS spectrum of their samples was fitted by three compounds with binding energies of 530.5, 531.6, and 532.9 eV, which correspond to the oxygen contained in SnO2/SnO, Sn–OH hydroxides, and water adsorbed on the surface, respectively. Thermal annealing was more effective in removing water due to higher temperatures. But the plasma-treated sample showed more Sn–OH hydroxides, which the group attributed to the formation of surface defects by high-energy plasma argon species bombardment. Subbia et al.[ 25 ] reported that compared to PSCs with heat-annealed SnO2, PSCs with SnO2 treated with N2 plasma had higher efficiencies of 20.3% on rigid substrates and 18.1% on flexible PET/ITO substrates. These flexible PSCs were extremely stable since they could maintain 90% of their initial PCE after 1000 cycles. The result demonstrated that deep UV (DUV) radiation employing N2 and N2O plasma emissions plays a prominent role in achieving high attribute metal oxide thin films at lower temperatures. In this line, this group[ 25 ] reported a novel strategy for the production of SnO2 metal oxide semiconductors at near-RT temperatures including low-power inductively coupled radio frequency (RF) plasma. In this method, sol–gel-coated SnO2 thin films are activated using nitrogen plasma to break down the alkoxy and hydroxy groups allowing the formation of a M–O–M network (Figure 12a). Besides, the performance comparison among the as-deposited/annealed SnO2 thin films and that of deposited through RF coupled with O2, N2, and N2O plasmas (i.e., AD-SnO2, OPT-SnO2, NPT-SnO2, and NOPT-SnO2, respectively) and also that of thermally annealed SnO2 (TA-SnO2) in PSCs was conducted (Figure 12c). According to the results, the chlorine-containing residues in the thermally annealed samples and treated-under-nitrogen-plasma samples were less than that of the treated-under-oxygen-plasma sample. It is remarkable that the formation of SnO2 film from Sn metal-halide precursor merely takes place in the presence of N2 plasma, whereas reactive species of O2 plasma fared poorly. Studies in this group have represented that the formation mechanism in the presence of ultraviolet (UV) rays involves breaking down the metal alkoxy-hydroxyl bonds to form the M–O–M structure followed by film thickening and compactness. In the described mechanism, the plasma emissions containing DUV photons provide the energy required to initiate the breakage of alkoxy-metal bonds although the RF power is relatively low. In the case of O2 plasma, the emission spectrum at an operating pressure close to 1 torr does not contain the UV component required to initiate the bond cleaving process, therefore, the produced film retains the original composition of the deposited layer to a greater extent. The favorable outcome of NOPT-SnO2-based PSCs verifies that DUV emission from N2 plasma is indispensable for the initial cleavage of metal alkoxy and metal hydroxyl bonds and the resulting formation of SnO2 thin films.[ 25 ]

3.1.4 Photonic Annealing

The long processing time is a bottleneck for fast and large-scale production, which is a major motivator and financial incentive for the widespread deployment of PSCs. In this regard, intense pulsed light (IPL) annealing holds the convincing potential to significantly enhance the performance and compatibility of the manufacturing process. In this method, broadband light pulses in a short scale of milliseconds and of high intensity, normally xenon flash lamp, are employed for swift and selective annealing of light-absorbing materials. The short duration of this process causes the temperature in the absorbent material to ascent locally devoid of damaging the temperature-sensitive substrates such as flexible plastics. Moreover, the intrinsic feasibility of utilizing this method for large-area production, along with the short processing time as well as its simpatico with the substrates, makes it favorable for roll-to-roll (R2R) manufacturing platforms. Besides, light-based fast annealing strategies in PSCs, in addition to ETL, have been utilized for annealing the absorbent layer.[ 39 ] In a related study, near IR light was employed to anneal the Al2O3-MAPbI3 absorbing layer for 2.5 s and resulted in a PCE of 10.0% in comparison with that of PSC using 45-min thermal annealing yielding 10.9% PCE.[ 128 ] Furthermore, photonic annealing for TiO2 has been utilized and a 15% PCE was obtained[ 129 ] Likewise, Zhu et al.[ 39 ] utilized this method for annealing SnO2 ETL films prepared through a solution-based low-temperature process on the FTO substrate. As stated by their findings, IPL annealing triggered the formation of SnO2 films through the following reaction: (SnCl4 + 2 H2O → SnO2 + 4 HCl). According to their results, IPL annealing has reduced the surface roughness and increased layer compactness. In addition to the hydroxyl groups (–OH), small amounts of chlorine were also observed in IPL annealed SnO2 films indicating the presence of chlorinated compounds such as SnCl4. So too did, Ghahremani et al.[ 110 ] applied the IPL method (5 pulses of IPL, each carrying 2.1 kJ energy) for SnO2 annealing and also made use of this method to anneal the perovskite absorbing layer. Also, Oh et al.[ 130 ] used IPL for 30 seconds (120 pulses of IPL, each carrying 1.84 J cm−2 energy) for sintering of amorphous SnO2. It should be noted that before photonic annealing, the ETL layer was dried for 1 min at 100 °C. They reported the IPL annealing reduces hydroxyl groups and increases conductivity and electron mobility. Also, their results showed that IPL annealing can effectively control the ETL/perovskite interface in a short time by regulating intrinsic perovskite (MAPbI3) properties such as stress and nucleation density. Thus, they improved the PCE from 7.06% (amorphous SnO2) to 17.68% by using photonic annealing.

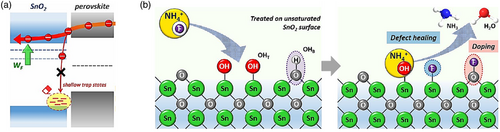

3.1.5 Water Treatment

The enhancement of SnO2 ETL through water treatment has been undertaken in three avenues comprising hydrothermal treatment, water-bath treatment, and water-spin coat treatment. In the first two methods, SnO2 ETL is initially deposited and thereafter treated with water. However, in the water-spin coat treatment method, water pretreatment is performed prior to the SnO2 ETL deposition.

Hydrothermal Treatment

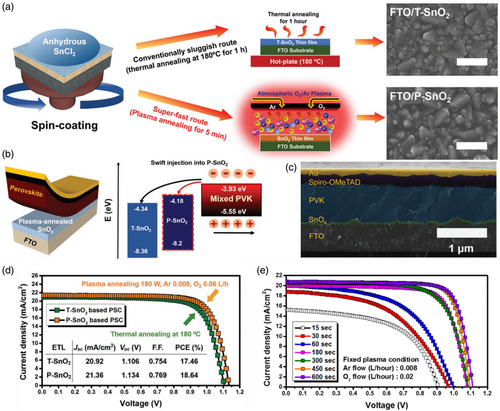

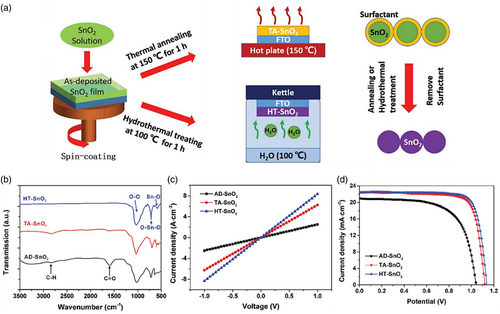

SnO2 film destitute of treatment suffers from poor crystallinity, which leads to low conductivity and inferior charge transport at the interface between the ETL and the perovskite adsorbing layer. Notwithstanding, surfactants are normally added to colloidal SnO2 solutions to maintain the dispersion of SnO2 nanoparticles. These surfactant coatings on the surface of SnO2 nanoparticles typically lay behind high resistance in SnO2 film and are required to be discarded appropriately. In this line, thermal annealing is a prevailing procedure; however, annealing at low temperatures (<200 °C) fails to perfectly eliminate surfactants and leads to poor PSC performance. Moreover, the majority of surfactants include organic carbon (R) compounds that could be decomposed into gaseous hydrogen fuels through hot water steam: R + H2O = R(O) + H2. Therefore, SnO2 water steam treatment might be capable of eliminating carbonaceous surfactants. Nevertheless, conventional water-gas shift reactions require relatively high-temperature (i.e., >200 °C) treatment steps. However, the thorough abolishment of the surfactants might be met by means of the high vapor pressure of water steams in the hydrothermal process which could proceed completely at low temperatures (≤100 °C). Hot water steam thoroughly annihilates the organic surfactants coated on the surface of SnO2 nanoparticles facilitating the formation of a ligand-free SnO2 ETL (Figure 13 ).[ 131 ]

Recently, Liu et al.[ 131 ] exploited a novel low-cost process to prepare high-quality SnO2 ETLs at low temperatures (100 °C) by integrating spin-coat SnO2 nanocrystalline solutions with hydrothermal treatment. As reported from their results, the performance of SnO2 on the rigid ITO/Glass substrate showed that the hydrothermal treated SnO2 ETL (HT-SnO2) at 100 °C was furthermore higher in characteristics than that of SnO2 ETL heat annealed (TA-SnO2) at 150 °C. They also employed this process to fabricate SnO2 ETLs on flexible PEN/ITO substrates and achieved an outstanding champion PCE of 18.1% for PSC devices (Figure 13).

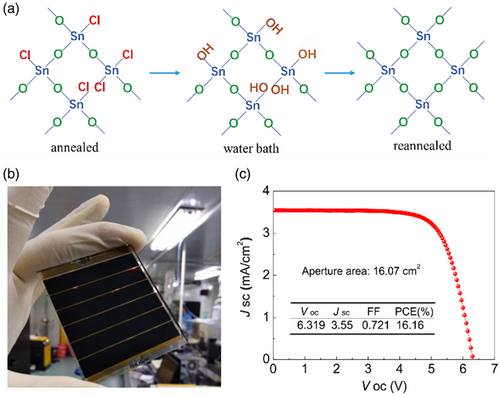

Water-Bath Treatment

In the water-bath treatment method, irrespective of the ambient humidity, SnO2 crystalline films are to be acquired using a sol–gel thin film water bath. The precursor residues in SnO2 films prepared in ambient air are incapable of being thoroughly hydrolyzed to form SnO2 and yet thermal annealing was applied. However, during the water-bath treatment process, the extant precursors undergo complete hydrolysis with the aid of large water molecules in the environment along with thermal energy. Thus, SnO2 films treated with the water-bath method are composed of almost perfect crystalline SnO2 nanocrystals, which facilitate the rapid extraction of electrons from the perovskite and the minimization of surface defects (Figure 14a). Therefore, the performance of the perovskite device is also remarkably improved.[ 121 ] In this line, Li et al.[ 121 ] applied this treatment on SnO2 films prepared through spin-coating of SnCl4.5H2O/isopropanol solution in the air under diverse humidity range of 0–75% RH followed by thermal annealing at 180 °C and realized PSCs of 19.17% PCE, compared with that of devices fabricated of sol–gel thin films in the absence of water-bath treatment (i.e., 17.59%), possessing high reproducibility. Besides, using this method, they could manage to produce 16.16% PCE for the large-area PSC module with an area of 16.07 cm2 (Figure 14b,c).

Water-Spin Coat Treatment

In the water-spin coat treatment method, ≈1—3 mL of DI water is spin-coated on the surface of the substrate preceding the SnO2 ETL deposition not requiring subsequent annealing. The features of the SnO2 layer largely depend on the hydrophilicity of the substrate. Moreover, SnO2 film of fewer pinholes makes for a perovskite film having a uniform coating and a high-performance PSC. Eventhough the predominant ways such as UVO treatment are conventionally employed to produce the hydrophilicity, Wan and coworkers[ 99 ] made it through spin-coating the DI water on the substrate surface. The basis for this is, in the main, that the hydrophilic groups (–OH) are added through a water-spin coat on the substrate surface, which simultaneously favors the ductility of SnO2 slurry to form a smooth film of high crystallinity and the enhancement of interface between SnO2 and the substrate. Making use of this method and the consequent annihilation of pinholes and improvement of SnO2 ETL films quality and its interface with the absorbing layer, they could successfully manage to reduce and increase the defects and charge transport in the perovskite/SnO2 ETL interface, respectively, and realize PSC of 19.68% efficiency.

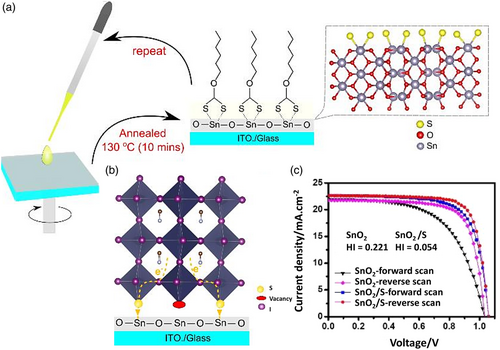

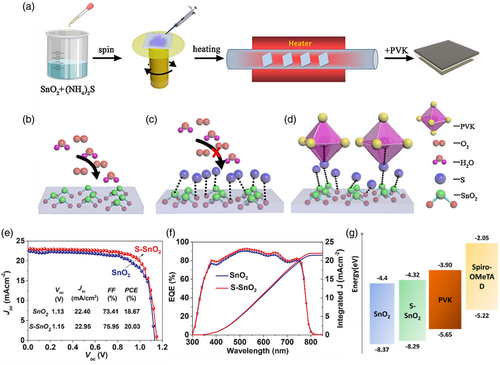

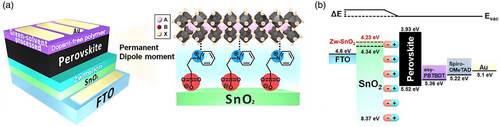

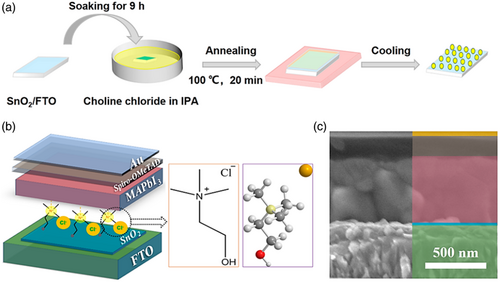

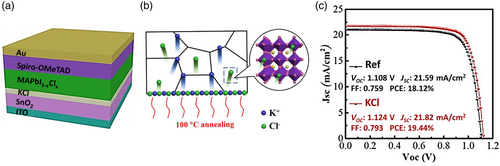

3.1.6 Sulfur Treatment