Battery Cathode Recycling With Superior Dissolution Kinetics by Laser Augmentation

Abstract

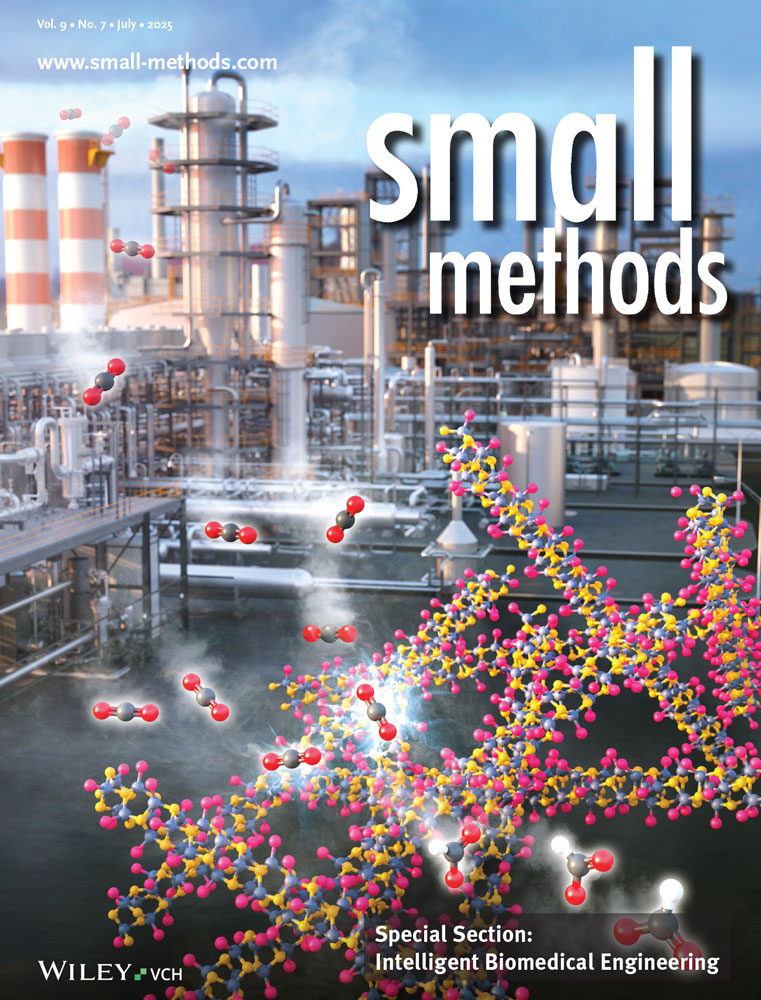

The application of lithium-ion batteries challenges environmental sustainability and calls for efficient recycling toward circular economics. Hydrometallurgical recycling, despite being commercialized, still faces challenges such as harsh chemicals, high secondary waste generation, and low efficiencies. Intuitively, higher temperature leads to exponentially higher reaction kinetics (following Arrhenius's law), yet the dissolution temperature is limited to below 100 °C while heating the solution means more energy consumption. This study presents a laser-assisted wet leaching (Laser-WL) method that enables decoupled particle/solution temperatures, where the cathode particles are effectively heated by laser adsorption (30 W) to accelerate the dissolution kinetics (7–10 fold) while the solution remains cool for energy saving. Besides, physical laser ablation helps remove the robust solid electrolyte interface and cracks the particles to expose active materials, shortening the diffusion pathways and further enhancing the leaching kinetics. Therefore, Laser-WL can achieve an extraction rate of 95.6% in 15 min (traditional method >3 h). It reduced the consumption of concentrated HCl by 87%, and water consumption by 27%. The method is applicable to various cathode materials and works for weak acids, thus presenting a sustainable and economically viable solution for metal recycling.

Conflict of Interest

The authors declare no conflict of interest.

Open Research

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.