Extrusion-Based Fused Deposition Modeling for Printing Sensors and Electrodes: Materials, Process Parameters, and Applications

ABSTRACT

Integrating extrusion-based fused deposition modeling (FDM) with advancements in conductive thermoplastic materials is fostering innovation in the fabrication of sensors, electrodes, and printable electronics. This review presents an in-depth analysis of the advantages and disadvantages of FDM compared to other additive manufacturing (AM) techniques, focusing on its unique capacity to create functional components. Various materials, including host materials and conductive filaments, both commercial and custom-made, are examined for their suitability in conductive component fabrication. The impact of key process parameters, such as pre-printing settings, printing parameters (e.g., layer thickness, infill density and pattern, print speed, extrusion width, raster angle and orientation, and bed temperature), and post-printing settings on the performance of conductive filaments is also discussed. The review highlights the working principles and applications of different types of sensors printed using FDM, including strain, pressure, temperature, and acceleration sensors, the fabrication of electrodes for physiological and electrochemical monitoring, showcasing the potential of FDM to integrate multifunctional sensing capabilities in a single build. Finally, the review explores the future prospects of FDM in sensor and electrode manufacturing, identifying key challenges that need to be overcome to further enhance the technology's potential in advanced applications.

1 Introduction

Additive manufacturing (AM), often synonymous with 3D printing, has emerged as a disruptive force in modern manufacturing, offering unparalleled versatility in design and production [1-3]. Unlike traditional manufacturing methods that rely on subtractive techniques, AM constructs objects layer by layer directly from digital models, allowing for efficient and original fabrication of complex geometries with minimal material waste [4].

Several AM techniques are available such as stereolithography (SLA) [5], selective laser sintering (SLS) [6], digital light processing (DLP) [7], inkjet printing [1, 8], multi-jet fusion (MJF) [9], and fused deposition modeling (FDM).

Within the spectrum of AM technologies, FDM has gained significant interest due to its simplicity, accessibility, and affordability. Invented in the late 1980s and commercialized shortly thereafter, FDM has become a cornerstone technology in fields ranging from prototyping to producing end-use components [10-12].

FDM working principle is based on the extrusion of thermoplastic filaments through a heated nozzle, depositing material layer by layer to construct three-dimensional structures. Its advantages over conventional manufacturing techniques and other AM technologies include reduced lead times, lower production costs, and the ability to fabricate highly customized designs without the need for expensive tooling. The widespread availability of FDM printers and compatible materials has democratized access to advanced manufacturing capabilities, making it a popular choice for academic research and small-scale production [12].

In recent years, the use of FDM has been significantly explored by the integration of functional materials [13, 14], particularly conductive polymers and composites [14, 15]. These materials incorporate fillers such as carbon nanotubes (CNTs) [16], graphene [17], and metallic particles [18] into a hosting thermoplastic matrix, enabling the fabrication of components with tailored electrical, thermal, and mechanical properties [19]. This has opened new scientific research using FDM for the manufacturing of functional devices, including sensors and electrodes, with potential disrupting applications in wearable electronics, biomedical diagnostics, environmental monitoring, and energy storage. Sensors fabricated using FDM are particularly advantageous due to their low cost, rapid prototyping capabilities, and the ability to integrate complex functionalities into a single build. FDM has been employed to produce strain, pressure, temperature, and chemical sensors [20] with performance characteristics that compete or surpass those of conventionally manufactured devices [21]. Similarly, FDM has been used to fabricate electrodes for electrochemical and physiological monitoring, with precise control over geometry and material composition, allowing for enhanced performance [22]. These innovations highlight the potential of FDM to transform the design and manufacturing of devices in sectors where customization, integration, and cost-effectiveness are paramount.

Despite its many strengths, FDM is not without its challenges [23]. The performance of FDM-printed components is highly dependent on process parameters such as layer thickness, build orientation, infill pattern, nozzle temperature, and print speed. These parameters influence not only the mechanical properties of the printed object (due to surface roughness, dimensional inaccuracies, and poor interlayer bonding) but also its electrical, thermal, and chemical properties, particularly in the case of sensors and electrodes that rely on the uniform dispersion of conductive fillers within the polymer matrix. For example, the percolation threshold of conductive materials must be carefully controlled to ensure reliable electrical pathways while maintaining the structural integrity of the printed part. Addressing these limitations requires a multidisciplinary approach involving material science, process engineering, and computational modeling to optimize both the materials and the printing parameters.

The sustainability of FDM is another area of growing interest [24]. By enabling on-demand production and reducing material waste, FDM aligns well with the principles of a circular economy. Recent advances in biodegradable and recyclable filaments further enhance its environmental appeal, making it an attractive option for industries seeking to reduce their ecological footprint [25]. Additionally, FDM's potential for distributed manufacturing can minimize supply chain complexities, supporting localized production and reducing transportation-related emissions.

Although some recent reviews examine the production of sensors or electrodes using 3D printing and AM techniques [26-29], none of this focuses exclusively on the FDM technique, on the materials available (both custom and commercial), on the process parameters that influence the properties of printed systems, and on the produced sensors and electrodes. To overcome this literature gap, this review aims to provide a comprehensive overview of the current state of FDM in the fabrication of sensors and electrodes, focusing on its advantages, limitations, and applications to guide further research in the field. By examining the interplay between material selection, process optimization, and application-specific requirements, this study seeks to highlight the transformative potential of FDM in advancing functional device manufacturing. Additionally, strategies to address the technical and material challenges associated with FDM will be discussed, with the goal of paving the way for its broader adoption in cutting-edge applications.

2 FDM: Advantages and Disadvantages Compared to Other AM Techniques

FDM is widely used in AM due to its cost-effectiveness, material versatility, and accessibility. Table 1 shortly resumes some of the most important parameters for printing with FDM and the other AM technologies. Compared to SLA and SLS, FDM is significantly more affordable, with printers costing between $300 and $5000, whereas SLA and SLS systems range from $3000–$15,000 and $15,000–$250,000, respectively. This affordability makes FDM an ideal choice for academic research, prototyping, and small-scale production, where ultrahigh precision and superior surface finish are not the primary requirements during printing. FDM achieves layer thicknesses between 50 and 200 µm while SLA's 25–100 µm, making it less suitable for intricate applications but still valid for flexible electronics manufacturing. SLA and SLS, with their laser-based processes, ensure superior accuracy and isotropic properties, eliminating layer adhesion inconsistencies. However, thermal contraction and warping impact FDM's dimensional accuracy, especially with high-temperature materials like acrylonitrile butadiene styrene (ABS). This anisotropic behavior results in weaker z-axis mechanical properties than SLS, which provides nearly isotropic part strength due to powder sintering. FDM also faces challenges regarding surface roughness, producing surface roughness (Ra) values of 10–20 µm, which often require post-processing to achieve smoother finishes and can be adjusted by tuning printing acceleration and flow rate [30]. SLA outclasses in this area, achieving 0.5–1.5 µm Ra values, making it preferable for high-detail esthetic applications. SLS occupies an intermediate position, with Ra values around 3–10 µm.

| Parameter | FDM | SLA | SLS | DLP | Inkjet printing | MJF |

|---|---|---|---|---|---|---|

| Cost of equipment (USD) | 300–5000 | 3000–15,000 | 15,000–250,000 | 2000–10,000 | 10,000–100,000 | 100,000–500,000 |

| Minimum layer thickness (µm) | 50–200 | 25–100 | 60–120 | 25–100 | 20–50 | 80–120 |

| Surface roughness (Ra, µm) | 10–20 | 0.5–1.5 | 3–10 | 1–5 | 0.5–2 | 2–5 |

| Material types | PLA, ABS, PETG, TPU, PC, PA, etc… | Photopolymer resins | Nylon, polyamides, composites | Photopolymer resins | Ceramics, polymers, metals | Nylon, polyamides, TPU |

| Print speed (mm/s) | 25–100 | 10–60 | 20–50 | 20–80 | 10–100 | 30–60 |

| Max build volume (cm³) | 10,000–50,000 | 1000–8000 | 10,000–60,000 | 5000–20,000 | 1000–10,000 | 10,000–80,000 |

| Common applications | Prototyping, education, functional parts | Dental models, high-detail components | Aerospace, medical, industrial parts | Dental, medical devices | Electronics, bioprinting, functional components | High-performance industrial parts |

One of FDM key strengths is its broad material compatibility, including polylactic acid (PLA), ABS, polyethylene terephthalate glycol (PETG), polycarbonate (PC), thermoplastic polyurethane (TPU) and reinforced composites (e.g., carbon black, graphene, and metal powders), making it suitable for functional components, sensors, and conductive elements. SLA is limited to photopolymer resins, while SLS primarily processes nylon, polyamides, and composites, favoring high-performance industrial applications.

In mechanical performance, FDM parts have lower impact resistance and weaker layer adhesion than SLS but outperform SLA in strength and heat resistance. According to Table 1, ABS offers a good balance of printability and strength, whereas PC and nylon (PA) provide superior mechanical properties at the cost of higher print complexity. FDM operates at 25–100 mm/s, generally faster than SLA (10–60 mm/s) but slower than some industrial SLS processes. While SLA and SLS offer higher precision, they often take longer to complete prints, particularly for complex designs. Additionally, FDM large build volumes (10,000–50,000 cm³) allow for cost-effective rapid prototyping and batch production as well as instrumentation of objects via printing of electrodes and sensors, whereas SLA is more suited for small, high-detail parts, and SLS is favored for large-scale industrial applications.

FDM has an environmental advantage, supporting biodegradable and recyclable thermoplastics like PLA [31]. In contrast, SLA resins are toxic and require chemical post-processing, making SLA less eco-friendly. However, FDM generates support material waste, and its extrusion-based process consumes more energy for high-temperature prints.

Despite limitations in precision and surface finish, FDM remains dominant due to its cost-performance balance, material adaptability, and scalability. Ongoing advancements in materials, multi-material printing, and hybrid production techniques are set to further enhance FDM's role and relevance in the future of AM.

3 Materials

The choice of materials in FDM significantly influences printed components' performance, functionality, and applicability. This section discusses the two primary categories relevant to the fabrication of functional devices: host materials and conductive filaments (both commercial and in-house developed).

3.1 Host Materials

From a material standpoint, conductive filaments used in FDM rely on base polymers such as PLA, ABS, PETG, and TPU, which are combined with conductive fillers to achieve electrical conductivity. Each material system offers unique properties that are tailored to specific applications, but their performance is intrinsically entwined with both the composition and the printability challenges posed by the FDM process.

PLA is among the most widely used materials in FDM, and its conductive variants are commonly achieved by incorporating fillers. PLA, and consequently the conductive PLA, is valued for its ease of printing, owing to its low melting temperature and excellent layer adhesion, which ensures consistent structural integrity [32, 33]. These characteristics make PLA-based filaments an accessible choice for fabricating low-power circuits, capacitive sensors, and electrodes. However, PLA inherent brittleness and limited thermal stability restrict its application to low-stress and moderate-temperature environments.

ABS is often used in its conductive form for applications requiring greater mechanical robustness and thermal resistance [34]. Conductive ABS filaments are typically enhanced with fillers such as graphene oxide (GO), reduced GO (rGO) or CNTs, significantly improving electrical conductivity while maintaining the material's well-known toughness and impact resistance. Despite these advantages, ABS's printability is more challenging than that of PLA. ABS requires higher extrusion temperatures and a heated bed to minimize warping and ensure proper adhesion during the printing process [35]. These conditions must be carefully controlled to prevent defects that could compromise the mechanical or conductive performance of the printed components.

PETG has also emerged as a viable base material for conductive filaments. PETG inherent flexibility and chemical resistance make it suitable for wearable sensors and electronic components that operate in harsh or variable environments. Conductive PETG filaments, infused with carbon-based or metallic fillers, provide a balance of electrical conductivity and mechanical flexibility. From a printability perspective, PETG exhibits characteristics similar to PLA, with minimal warping and relatively simple process requirements [36]. However, achieving uniform conductivity in PETG filaments often demands careful filler dispersion and optimization of extrusion parameters.

TPU has also recently emerged as a host material because of its inherent flexibility and elasticity. Unlike PLA and ABS, TPU can stretch, bend, or compress without losing functionality when loaded with conductive particles, making it ideal for dynamic applications such as force-sensitive resistors, flexible touch sensors, and motion-tracking wearables. From a material standpoint, TPU stands out due to its elastomeric properties, which allow it to withstand repeated deformation without fracturing. This durability is coupled with moderate electrical conductivity when loaded with conductive particles, which can be fine-tuned by adjusting the concentration and dispersion of conductive fillers. However, the flexibility of TPU can sometimes limit its conductivity compared to stiffer materials like ABS or PETG, as the fillers may become misaligned under significant mechanical strain. In terms of printability, TPU poses challenges compared to more rigid FDM materials like PLA or ABS. The material flexibility can make extrusion less predictable, leading to issues such as filament buckling or inconsistent flow through the nozzle. To overcome these challenges, printers typically require a direct-drive extruder setup, which provides better control over the filament during extrusion. TPU also requires precise temperature control, with extrusion temperatures typically ranging from 200°C to 250°C, depending on the specific formulation. Bed adhesion can be an issue for TPU, so heated beds (50°C–70°C) and adhesive aids, such as glue sticks or specialized build surfaces, are often employed to ensure consistent layer bonding. Table 2 shortly reports the printability and mechanical properties for the most common host materials used in FDM by merging information already reviewed in [37, 38].

| Property | PLA | ABS | PA | PC | PETG | TPU |

|---|---|---|---|---|---|---|

| Ease of printing | High | Medium | Medium | Medium | Medium | Low |

| Visual quality | Medium | Medium | Medium | Medium | Medium | Medium |

| Tensile strength (MPa) | Medium 50–65 |

Medium 40–45 |

Medium 40–85 |

High 72 |

High 80 |

Low 20–50 |

| Elongation at break | Low < 10% |

Low 3.5%– 20% |

Medium 3.20%– 360% |

Low 3.5%– 110% |

Low 2.5%– 70% |

High 400%– 700% |

| Layer adhesion | Medium | Medium | Medium | Medium | Medium | Medium |

Heat resistance - Heat deflection temperature (°C) |

Low - ~50–60 |

High - ~85–105 |

High - ~65–120 |

High - ~140 |

Medium - ~80 |

Medium - ~45–74 |

3.2 Commercial Conductive Filament

Conductive filaments in the FDM fabrication technique are thermoplastics host filaments infused with conductive fillers, enabling the creation of parts with tailored electrical properties. Both commercial and in-house developed conductive filaments have been explored for their unique advantages and challenges.

Various commercial conductive filaments are designed with a wide range of host materials, doping techniques, and electrical resistivities to meet diverse application needs [39-71] (Table 3). Three technical aspects play a central role: the host material, the doping material, and the resulting resistivity of the filament, as depicted in Table 3. Commonly used host polymers include PLA, ABS, and PETG due to their ease of extrusion in standard temperature ranges, good layer adhesion, dimensional stability, and wide commercial availability (Table 2). Other host materials, like PA, TPU, or PC, can be chosen for demanding mechanical or chemical properties, though the increased viscosity resulting from the conductive fillers may complicate the printing process and require tailored settings or reinforced extrusion systems.

| Reference | Filament commercial name | Host material | Doping | Resistivity | Price per 500 g | Current availability |

|---|---|---|---|---|---|---|

| [39] | Proto-pasta | PLA | CB | SR range: 14.4–19.2 Ω cm in XY direction; SR range = 27.2–33.6 Ω cm in Z direction | ~$50 | Yes |

| [40] | Black Magic Graphene | PLA | Graphene | VR: 0.9 Ω cm | ~$995 | No |

| [41] | Conductive Filaflex | TPU | NA | VR: 3.9 Ω cm | ~$65 | Yes |

| [42] | Multi3D Electrifi | Biodegradable polyester | Copper | VR: 0.006 Ω cm | ~$1100 | Yes |

| [43] | NinjaTek Eel | TPU | CB | VRe: 1.5 × 103 Ω | ~$106 | Yes |

| [44] | 3DXTech | TPU | MWCNT | SR range: 10²–10³ Ω/sq | ~$81 | Yes |

| [45] | ABS | SR range: 10⁴–10⁹ Ω/sq | ~$53 | Yes | ||

| [46] | PLA | SR range: 107–109 Ω/sq | ~$66 | Yes | ||

| [47] | PETG | ~$64 | Yes | |||

| [48] | PEKK | ~$457 | Yes | |||

| [49] | Amolen PLA Conductive | PLA | NA | VR: 1.5 Ω cm; SR: 192 Ω/sq | ~$53 | Yes |

| [50] | Filoalfa Alfaohm | PLA | CNTs and structured CB | R: 15 Ω cm in XY direction; R: 20 Ω cm in Z direction. | ~$140 | Yes |

| [51] | 3dkonductive—electro conductive | PLA | CB | SRe: 23 Ω in printed direction; SRe: 53 Ω vertical to the printed direction; VRe: 24 Ω cm | ~$70 | Yes |

| [52] | Palmiga PI-ETPU 95–250 | TPU | CB | VR < 800 Ω cm | NA | No |

| [53] | Sunlu ABS Conductive Black | ABS | NA | R: 103–105 Ω | ~$32 | Yes |

| [54] | Koltron G1 | PVDF | Graphene | VR: 2 Ω cm | ~$409 | Yes |

| [55] | BlackMagic Flexible | TPU | Graphene | VR < 1.5 Ω cm | ~$399 | No |

| [56] | AIMPLAS Fili | TPU | NA | VR: 27.44 Ω cm | ~$89 | Yes |

| [57] | Kimya ABS-EC CNT | ABS | CNTs | SR: 103–105 Ω/sq | ~$76 | Yes |

| [58] | Fabbrix | PLA | CNTs | SR: 10 Ω | ~$71 | Yes |

| [59] | Reprapper | PLA | Graphene and carbon | Re: 10 kΩ/cm | ~$25 | Yes |

| TPU | NA | ~$30 | Yes | |||

| [60] | ABC3D | PLA | CNTs matrix | SR: 100–1010 Ω cm | ~$104 | Yes |

| [61] | ABS | ~$104 | Yes | |||

| [62] | TPU | ~$130 | Pre-order | |||

| [63, 64] | PEI | ~$493 | Pre-order | |||

| [65] | PC | ~$104 | Pre-order | |||

| [66] | PETG | ~$104 | Yes | |||

| [67] | PEKK | ~$830 | Pre-order | |||

| [68] | Nylon | ~ $154 | Pre-order | |||

| [69] | PPS | ~ $204 | Pre-order | |||

| [70] | Colfeed4Print | PLA | Graphene | R: 0.1 Ω cm | NA per 500 g (~$261 per 10-m length spool) | Yes |

| [71] | Graphite | R: 7.7 Ω cm | NA per 500 g (~$172 per 10-m length spool) | Yes |

- Abbreviations: ABS, acrylonitrile butadiene styrene; PC, polycarbonate; PEI, polyetherimide; PEKK, polyetherketoneketone; PETG, polyethylene terephthalate glycol; PLA, polylactic acid; PPS, polyphenylene sulfide; PVDF, polyvinylidene difluoride; R, resistivity; Re, resistance; SR, surface resistivity; SRe, surface resistance; TPU, thermoplastic polyurethane; VR, volume resistivity; VRe, volume resistance.

Doping a thermoplastic filament involves incorporating conductive particles or fibers into the host material. Carbon black (CB) emerges as a common, relatively cost-effective filler, forming conductive networks above a specific percolation threshold, though high filler content often increases viscosity [72, 73]. Carbon fibers typically achieve better conductivity and introduce added mechanical stiffness, yet fiber length and orientation can yield anisotropic conductivity [74, 75]. CNTs or graphene, when well dispersed, can provide improved conductivity at lower loadings, but they introduce higher production costs and require advanced compounding to ensure homogeneous dispersion [76, 77]. Metallic particles are less common in fully metal-based filaments, as they typically pose significant challenges for FDM; more frequently, commercially available polymers are loaded with metal particles such as copper or silver [78].

Resistivity stands out as the primary parameter for evaluating the feasibility of a conductive filament in specific applications. In commercially available filaments, it can span from approximately 100–102 Ω cm for higher-performance filaments, to 104–106 Ω cm. Several factors influence these ranges, including filler concentration, filler type, and the quality of dispersion. Moisture uptake or thermal degradation can also alter the electrical properties of the filament. Although these conductive filaments typically do not match the conductivity of pure metals or highly charged polymeric pastes, they often allow for the production of resistive sensors, electrodes designed for low-current measurements, and printed circuits operating at relatively low voltages. The key to achieving satisfactory performance is carefully selecting the filament brand and composition based on the required electrical and mechanical properties. Where higher conductivity is needed, filaments loaded with CNTs or graphene at higher concentrations may be more appropriate (see Table 3), while applications that only require antistatic properties often benefit from lower-loading CB filaments.

3.3 In-House Developed Feedstock Conductive Filament

In-house development of conductive filament may overcome some of the limitations associated with commercially available materials and tailor the electrical and mechanical properties of the feedstock to specific requirements. The fundamental concept is to start with a selected polymer matrix and introduce conductive fillers or dopants through custom compounding methods. This approach typically involves either mixing polymer pellets with conductive additives in a twin-screw or single-screw extruder, or systematically blending powdered fillers with the polymer in solution before extrusion, then re-pelletizing and extruding the resulting mixture into filament form [79, 80]. The principal advantages of in-house developed conductive filaments are the possibility of controlling both the nature and the concentration of the filler [80]. By adjusting filler content, type, and functionalization, it is possible to fine-tune the percolation threshold, reduce resistivity, and optimize mechanical strength or flexibility. Fillers such as CB and short carbon fibers are often selected for moderate improvements in conductivity and mechanical reinforcement [81, 82]. At the same time, CNTs and graphene-based additives can potentially yield significantly lower resistivities at reduced filler loadings [83]. However, uniform dispersion of these nanomaterials remains a critical challenge. Inadequate mixing can lead to filler agglomerates, which negatively impact conductivity and compromise the printing process by increasing the risk of nozzle clogging.

In-house filament production does, however, require specialized equipment such as a filament extruder, pelletizer, or injection molder adapted for compounding, along with instruments for characterizing filler dispersion and resistivity [84, 85]. Handling conductive fillers, especially in the case of CNTs or graphene, may also raise safety considerations related to airborne particles, making it important to use proper ventilation or personal protective measures [86]. Despite these challenges, the possibility of tailor-making conductive filaments with targeted resistivities, optimized mechanical performance, and unique functional properties positions in-house development as a compelling alternative for research laboratories and niche industrial applications. This customization is especially beneficial for sensor and electrode fabrication, where slight variations in material composition can significantly influence device performance, sensitivity, or stability. Table 4 summarizes the in-house developed conductive thermoplastic filaments for FDM focusing on host materials, doping substances or treatments, the types of printers used and the corresponding applications [87-115].

| Reference | Host material | Doping | Printer | Application |

|---|---|---|---|---|

| [87] | Polycaprolactone (PCL) | CB | BFB3000 | Production of flexible resistive sensor, capacitive buttons, and smart vessel. |

| [88] | ABS in form of white pellets | Graphene nanoplatelets (GNPs) | Sharebot Next Generation | Thermo-mechanical properties of neat ABS and ABS-GnP nanocomposites have been tested, monitored, and compared. |

| [89] | PS (polystyrene) and ABS | High concentrations of GNPs | NA | Investigated how high concentrations of GNPs affect the mechanical, rheological, and morphological properties of nanocomposites. |

| [90] | ABS powder | Iron and copper powder | Stratasys FDM 3000 | Comparison of thermal conductivity and dynamic mechanical test values of different samples built using new composites with varying metal filler content. |

| [91-93] | ABS | Graphite powder | Divide By Zero's: Model 250i | Investigated conductivity, thermal properties, melt flow rate, and morphology of the composite, revealing its potential for advanced conducting materials in energy storage, biosensors, and tissue engineering. |

| [94] | PLA | MWCNTs | NA | Investigated conductivity, thermal properties, melt flow rate, and morphology of the composite, highlighting its potential for advanced conducting materials in energy storage, biosensors, and tissue engineering. |

| [95] | TPU | CNTs and graphite nanosheet | NA | Developed a flexible piezoresistive “lever-cross” sensor capable of detecting stretching and out-of-plane forces at various magnitudes and frequencies. |

| [96] | Poly(ethylene-comethacrylic acid) (EMAA) as pellets | MWCNT | LulzBot TAZ Pro | Examined piezoresistive strain sensors for structural health monitoring through flexure testing. |

| [97, 98] | Polystyrene pellets | CNFs and graphite flakes | A custom-built 3D-printer | Electrochemical sensor for detecting Zn2+ and Pb2+. |

| [99] | TPU | MWCNT | MakerBot Replicator 2X | Developed a three-axis haptic device using a multiaxial force sensor assembly, which can detect sub-millimeter deflection and corresponding force on each axis. |

| [100, 101] | TPU | MWCNT | MakerBot Replicator 2X | Developed highly elastic strain sensors for wearable electronics, soft robotics, and prosthetics, demonstrated by a sensor-integrated glove measuring finger flexure. |

| [102] | PLA | Nanographite (NG) | ZMorph | Fabricated low-cost electrochemical platforms, characterized via physicochemical and electrochemical methods, featuring macroelectrodes and honeycomb (macroporous) structures to detect lead(II) and cadmium(II). |

| [103] | PLA | Graphite powder | Sethi3D S3 | Developed a 3D-printed electrochemical sensor to detect uric acid and dopamine in synthetic urine, also serving as a biosensor platform for SARS-CoV-2 detection. |

| [104] | PLA | Graphite powder | Sethi3D S3 | Developed 3D-printed immunosensors using covalent immobilization for portable electrochemical detection of the SARS-CoV-2 spike S1 protein. |

| [105] | PLA | CB powder | Sethi3D S3 | Constructed a simple electrochemical system from fabricated filaments for detecting catechol and hydroquinone in water samples, and hydrogen peroxide in milk. |

| [106] | PLA | Graphite powder | Sethi3D S3 | Sequential determination of paraquat and carbendazim in food samples: honey, milk, juice, and water samples. |

| [107] | PLA | Reduced graphene oxide (rGO) and CB | Sethi3D S3 | Developed 3D-printed electrochemical sensors to detect TNT and cocaine, with enhanced properties via added rGO. |

| [108] | Recycled PLA (rPLA) | MWCNT and CB | Prusa i3 MK3S+ | Simultaneously detected acetaminophen and phenylephrine using two filaments: commercial CB-PLA and in-house MWCNT-CB-PLA. |

| [109] | PLA + ABS | Graphene | HOF1-X1 | Conducted initial efforts to produce and directly 3D-print graphene-polymer composites. |

| [110] | PLA | MWCNT | Ultimaker S3 | Developed a multi-axis pressure sensor with an integrated temperature sensor, enabling broad applications in human motion monitoring and force sensing. |

| [111] | PLA | CB | Flashforge Creator Pro | Developed a novel conductive biofilament incorporating two types of metallic nanoparticles—biodegradable PLA, PEG dimethyl ether, and bismuth/copper nanopowder oxides. Resulting sensors can detect heavy metals (lead and cadmium) and biomarkers (glucose and uric acid). |

| [112] | rPLA | CB | Sethi3D S3 | Developed a 3D-printed electrochemical portable biodevice for monkeypox virus (MKPV) detection, featuring immuno- and genosensors targeting the A29 protein and a specific MKPV DNA sequence, respectively. |

| [113] | rPLA | Graphite powder + CB | Prusa i3 MK3S+ | Developed an electrically conductive filament by mixing graphite, CB, rPLA, and castor oil without solvents. This filament was used to create a sensing platform for detecting oxalate in synthetic urine and was benchmarked against commercial and CB-only filaments. |

| [114] | Recycled PETG (rPETG) | GNPs + MWCNT + CB | Prusa i3 MK3S+ | Developed a conductive recycled PETG filament for additive manufacturing and electrochemical applications by embedding GNPs, MWCNT, and CB. The filament, produced without a plasticizer, maintains excellent low-temperature flexibility and enhances electrode properties. Electrochemical characterization was conducted using redox probes, comparing its performance to commercially available conductive PLA electrodes. |

| [115] | Developed an enhanced electrically conductive filament using recycled PETG with CB, MWCNTs, and GNPs. The 3D-printed electrodes underwent physicochemical and electrochemical characterization, demonstrating sterilization, reusability, low solution ingress, and potential to reduce healthcare costs and plastic waste. They performed well under UV treatment, detecting uric acid and sodium nitrite in synthetic urine, and compared favorably to conductive CB/PLA electrodes. |

4 Process Parameters

When dealing with conductive filaments printing, process parameters are critical to achieving desired print quality, mechanical, and electrical properties. These parameters can be categorized into three main stages: pre-printing, printing, and post-printing.

4.1 Pre-Printing Parameters

Due to the presence of host material for making conductive filaments, humidity and temperature strongly influence the printability, and as a consequence the electrical performance, and mechanical properties of the final samples.

The hosting materials are typically hygroscopic, meaning they absorb moisture from the environment. Moisture absorption can disrupt the conductive pathways formed by the filler material, reducing the overall conductivity of the printed part. Moreover, the water content can vaporize during extrusion, causing bubbling, popping, or inconsistent extrusion, leading to defects like voids or weak layer adhesion, and making the printed part more brittle or prone to failure. According to datasheets of commercially available filaments, conductive filaments should be stored in a dry environment with humidity levels below 20%–30%. The most common approach is to use filament dryers to remove moisture before printing (e.g., 50°C–70°C for 4–6 h before printing).

The mechanisms and effect of change of mechanical and tribological properties of polymers and polymer composites variations with different environmental conditions has been recently reviewed [116, 117]. With the exception of a few research papers, such as Kalinke et al., [118] the influence of pre-printing parameters on conductive printing remains largely unexplored.

4.2 Printing Parameters

The printing of all conductive materials for FDM is influenced by key process parameters such as extrusion temperature, bed temperature, nozzle diameter, and filler homogeneity. These parameters govern the final sample structural, mechanical, and electrical properties and require precise optimization to ensure the successful fabrication of functional sensors and electronics. A common challenge across all materials is the reduced conductivity at the interfaces between printed layers, limiting printed electronic components performance. Strategies to address this issue include optimizing print parameters, such as slowing extrusion speeds and increasing the overlap between adjacent layers. Additionally, certain materials, such as ABS and polypropylene-based composites, require the use of enclosed or heated printing chambers to minimize warping and ensure consistent layer adhesion. Depending on the host material and filler (e.g., concentration, type), specific tuning of the parameters is required, which often also depends on the type of printer used. This makes the field of sensor and electrode printing using FDM techniques particularly fascinating, allowing for performance tuning of the devices that is rather uncommon with other manufacturing techniques.

4.2.1 Layer Thickness

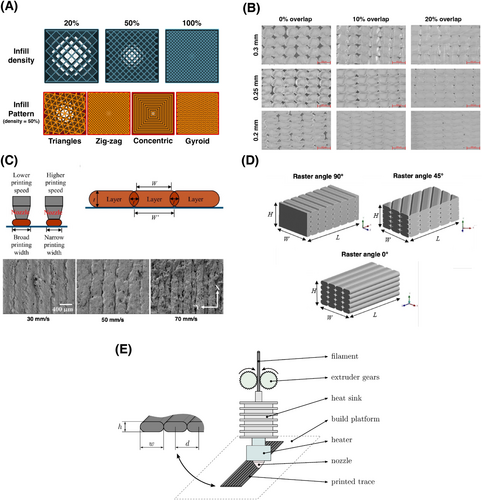

Since FDM parts are built layer by layer, the thickness of each layer determines the degree of interlayer bonding, which influences structural integrity and the formation of conductive pathways within the printed part (see Figure 1B). Conductive filaments require fine-tuned layer thickness to optimize their functionality.

In the context of electrical conductivity, thinner layers enhance the contact area between adjacent layers, promoting stronger interlayer adhesion and improving the continuity of conductive networks [123]. This is particularly important for addressing the well-documented anisotropy of FDM-printed parts, where conductivity along the z-axis is typically lower than that in the x-y plane due to weaker bonding between layers [124].

Experimental studies have demonstrated that reducing layer thickness can significantly enhance z-axis conductivity. For instance, research on CB-filled PLA filaments showed a 40% improvement in z-axis conductivity when the layer thickness was reduced from 0.4 to 0.1 mm [125]. The improved performance was attributed to better filler dispersion and enhanced interlayer connectivity. Similarly, studies on graphene-infused ABS filaments revealed that the volume electrical conductivity increased with the thickness of the printing layer. This increase can be attributed to two factors: a lower number of layers required to achieve the same part height when using thicker layers, and a larger cross-sectional area of printed lines for the same width. Consequently, if the 3D part is modeled as a series of electrical resistances, the overall electrical resistance of the sample becomes greater as the number of layers increases [126].

From a mechanical perspective, thinner layers improve the tensile strength and elongation at break by increasing the diffusion of polymer chains across layer interfaces [127]. This effect is particularly pronounced in flexible conductive materials such as TPU, where thinner layers enhance elasticity and reduce void formation [128]. Experimental results with TPU-based conductive filaments indicate that reducing layer thickness can lead to superior mechanical properties compared to thicker layers [129]. However, for rigid materials like PETG or PLA, excessively thin layers may compromise the structural stability of the part, especially under load-bearing conditions [130].

Thinner layers offer additional benefits in terms of surface finish and dimensional accuracy. For components such as sensors or printed electronics, smooth surfaces are essential for consistent contact resistance and functional reliability. Reducing the layer thickness minimizes the step effect [131], improving surface quality and enabling finer feature resolution. However, the trade-off lies in the increased printing time associated with thinner layers, as more layers are required to complete the part. For example, while a layer thickness of 0.1 mm may yield optimal electrical and mechanical properties, it could double the print time compared to a layer thickness of 0.3 mm. Layer thickness also influences the material deposition process and the distribution of conductive fillers. Thicker layers may lead to inconsistent filler dispersion, creating localized resistive zones that disrupt conductivity. In contrast, thinner layers allow for more uniform deposition of conductive materials, ensuring continuous pathways for electron flow. However, excessively thin layers (e.g., below 0.05 mm) can introduce practical challenges, such as nozzle clogging or under-extrusion, particularly for filaments with a high filler content [132].

Experimental evidence highlights the importance of balancing layer thickness to achieve the desired performance in conductive parts. For example, research on PETG-based conductive filaments infused with metallic fillers found that reducing layer thickness from 0.3 to 0.15 mm improved conductivity by nearly 50% [133, 134]. However, further reduction to 0.05 mm resulted in extrusion instability, demonstrating the need for careful optimization.

Despite the clear benefits of thinner layers, there are challenges associated with their implementation. Reducing layer thickness increases the number of layers in a print, leading to longer build times and higher material usage, especially for infill-dense parts. Additionally, the need for precise printer calibration becomes more critical, as even minor inaccuracies in layer height can compromise the quality of the final part [135, 136]. Moreover, it is crucial to emphasize the role of slicing software in FDM printing. Shim and Hou [137] examined how different software options provide varying degrees of control over printing parameters, significantly influencing the quality of the final part. This highlights that choosing appropriate slicing software and optimizing its settings are critical steps in improving dimensional accuracy, surface finish, and overall structural integrity of printed components.

4.2.2 Infill Density and Pattern

Infill density (i.e., percentage of material filling the interior of a 3D-printed part) and pattern (i.e., geometric arrangement of material inside the 3D-printed part) significantly affecting both the mechanical properties and electrical performance of the final printed part (Figure 1A). Since conductive filaments consist of a polymer matrix infused with conductive fillers, the internal structure of the printed object influences not only its strength and weight but also its ability to maintain continuous conductive pathways. Proper optimization of infill density and pattern is essential for ensuring functional conductivity while maintaining the required structural integrity.

Infill density directly impacts the electrical conductivity of FDM-printed conductive materials by determining the number of interconnected pathways available for charge transport. Higher infill densities provide more material volume for conductive fillers to align and form continuous conductive networks. Studies on CB-enhanced PLA have shown that increasing infill density from 20% to 80% reduced bulk resistivity by nearly 50%, as the higher density allowed more contact points between conductive fillers [138-140]. Similarly, research on graphene-infused ABS indicated that an infill density of 60% provided the best balance between mechanical stability and electrical conductivity, while lower infill densities resulted in discontinuous conductive paths, increasing resistance [141].

Infill pattern selection further influences conductivity by affecting the alignment and continuity of conductive fillers within the printed structure. Linear and grid-based infill patterns generally promote better conductivity, as they allow for more direct and uninterrupted pathways for electron flow. Honeycomb and gyroid patterns, while mechanically efficient, introduce more interruptions in conductive pathways, increasing overall resistance [142]. Experimental results with PETG-based conductive filaments revealed that a rectilinear infill pattern with 75% density resulted in the lowest electrical resistivity, while a honeycomb pattern with the same density showed a 20% increase in resistance due to the discontinuous nature of the filament deposition [143].

Mechanical properties are also affected by infill density and pattern. Higher infill densities improve tensile strength, making the printed part more robust [144]. However, excessive density can lead to increased material usage and longer print times. Studies on TPU-based conductive filaments indicate that an infill density of 50%–70% provides an optimal balance between flexibility and strength, with a grid infill pattern enhancing mechanical durability while maintaining stable conductivity [145]. In contrast, lower densities below 30% resulted in weak mechanical performance and unreliable electrical continuity due to inconsistent filler distribution [145].

Thermal expansion and contraction must also be considered when optimizing infill density for conductive filaments. Lower infill densities tend to exhibit higher thermal contraction, leading to potential warping or delamination, especially in materials such as conductive ABS. Increasing infill density [146] to at least 50% has been shown to mitigate these effects, improving layer adhesion and dimensional stability. Additionally, for filaments containing metallic fillers, infill patterns that provide uniform material distribution help prevent localized thermal stresses that could otherwise affect conductivity.

While higher densities improve both conductivity and mechanical strength, they also extend the duration of the printing process.

Empirical data from multi-layer conductive structures suggest that varying infill density strategically within a part can optimize performance. For instance, in printed circuit elements, regions requiring high conductivity can be printed with 100% infill using a linear pattern, while nonconductive sections can be produced with lower infill to reduce weight and printing time. Hybrid approaches such as variable-density infill structures have been explored in research to enhance efficiency while maintaining functionality [147].

4.2.3 Print Speed

Print speed is a crucial parameter in FDM printing, particularly for conductive filaments, as it influences extrusion consistency, layer adhesion, filler distribution, and overall electrical performance (see Figure 1C). Conductive filaments require precise control of print speed to balance mechanical integrity and electrical conductivity.

The influence of print speed on conductivity is primarily linked to its effect on filament deposition and filler alignment [148]. At higher speeds, material extrusion becomes more inconsistent, increasing the likelihood of gaps and defects in conductive pathways. Studies on CB-enhanced PLA have shown that increasing print speed beyond 60 mm/s resulted in a 25% increase in resistivity due to reduced interlayer bonding and misalignment of conductive fillers [149]. Similarly, research on graphene-infused ABS demonstrated that higher print speeds disrupted filler dispersion, leading to nonuniform conductivity across printed layers [126].

Interlayer adhesion is another critical factor influenced by print speed. Faster print speeds reduce the time available for each layer to bond with the previous one, weakening the structural integrity of the printed part. This effect is particularly pronounced in conductive materials, where weak interlayer adhesion can disrupt the continuity of conductive networks, further increasing electrical resistance.

Optimal print speeds vary depending on the material composition and the intended application of the printed part. For most conductive filaments, moderate speeds in the range of 30–50 mm/s provide the best balance between mechanical performance and conductivity. Printing at speeds below 30 mm/s can improve layer bonding and electrical pathways [150], but excessive reductions in speed may lead to material overheating, nozzle clogging, or unwanted filament swelling. In TPU-based conductive filaments, for example, excessively slow print speeds caused material deformation and uneven extrusion, compromising both conductivity and mechanical flexibility [151].

Filler dispersion is also influenced by print speed. At lower speeds, conductive fillers have more time to distribute evenly within the polymer matrix, improving the consistency of conductive pathways. In contrast, higher speeds can lead to filler aggregation or separation from the polymer matrix, creating resistive zones within the printed structure [152].

The trade-off between speed and resolution must also be considered. Slower print speeds contribute to finer detail and better feature resolution, which is beneficial for printed electronics and sensors requiring precise geometries. However, these benefits must be weighed against longer production times, which may not be practical for large-scale manufacturing.

Empirical studies highlight the need for careful optimization of print speed in conductive FDM printing. While optimizing print speed can significantly impact the performance of conductive FDM prints, achieving the ideal balance requires consideration of other parameters such as extrusion temperature, layer thickness, and cooling settings. Printing too slowly can cause overheating and excessive spreading, while printing too quickly can lead to weak interlayer adhesion and disrupted filler alignment.

4.2.4 Extrusion Width (Nozzle Diameter)

The nozzle diameter is another critical parameter in the FDM printing of conductive filaments, as it directly influences extrusion consistency, layer adhesion, filler distribution, and the electrical conductivity of printed components. Its careful selection allows to balance material flow, structural integrity, and the formation of continuous conductive pathways in conductive filaments.

The influence of nozzle diameter on electrical conductivity stems from its effect on filament extrusion and filler alignment. Larger nozzle diameters enable higher material flow rates, reducing shear forces on the conductive fillers and allowing for better dispersion throughout the printed structure (Figure 1E). Studies on graphene nanoplatelet (GNP)-reinforced ABS have shown that increasing the extrusion width improves both volume and surface electrical conductivity by enhancing the cross-section area of each printed line. Wider lines increase the contact surface between adjacent lines and layers, which helps reduce electrical resistance [126]. A study on CB-loaded PLA has shown that smaller nozzle diameters (0.4 mm) produced components with lower porosity, as smaller nozzles generate higher shear stress between the filament and the printing bed, compacting the material more effectively. Moreover, samples printed with a 1-mm nozzle exhibited consistent mechanical properties, including stiffness, across various printing angles and layer heights while those printed with a 0.4-mm nozzle demonstrated more variability, particularly in stiffness, depending on the layer height and printing direction [153].

Interlayer bonding and mechanical strength are also influenced by nozzle diameter, particularly in conductive filament printing. A larger nozzle diameter generally improves interlayer adhesion due to the greater contact area between deposited layers, enhancing the mechanical integrity of the printed object. Smaller nozzle diameters provide advantages in resolution and surface finish, which are critical for printed electronics and fine-feature conductive components. For applications such as conductive traces in flexible circuits, a 0.2–0.3 mm nozzle enables finer details and more precise filament deposition. However, the trade-off is increased resistance along the conductive pathways due to thinner traces and potential filler misalignment.

The effect of nozzle diameter on material flow must also be considered, particularly for conductive filaments with high filler content. Conductive TPU, for example, tends to exhibit better flow characteristics with larger nozzles as it reduces backpressure and filament buckling, ensuring more uniform extrusion [154, 155].

Print speed and extrusion rate must be optimized alongside nozzle diameter to prevent under- or over-extrusion. Larger nozzles require higher extrusion rates to compensate for the increased material output, while smaller nozzles demand precise control to avoid under-extrusion and filament starvation. Thermal considerations also play a role in nozzle diameter optimization. Generally, larger nozzles require higher extrusion temperatures to ensure complete filament melting and avoid under-extrusion, while smaller nozzles may require lower temperatures to prevent overheating and degradation of conductive fillers. In all cases, selecting the appropriate nozzle diameter depends on the specific requirements of the application. For printed conductive traces and fine-detail electronics, a 0.2–0.3 mm nozzle is preferred, while for general conductive components requiring strong interlayer bonding and robust conductive networks, a 0.4–0.6 mm nozzle provides better performance. Nozzle diameters exceeding 0.8 mm are rarely used in conductive FDM printing due to the challenges in achieving fine feature resolution and maintaining uniform material distribution.

4.2.5 Raster Angle and Orientation

The arrangement and direction of the raster deposited lines in FDM determine how conductive pathways form within the structure. Raster angle influences conductivity by determining how conductive fillers are deposited relative to the direction of electrical flow (Figure 1D) [119-122]. Conductive pathways tend to form along the raster lines, meaning that the raster angle should align with the primary direction of current flow. Studies on GNP-loaded ABS demonstrated higher value of surface electrical conductivity along the x-axis (0°) because of the electrical anisotropy of the samples due to both the preferential orientation of the GNPs along the printing direction and the directionality of the manufacturing process [126]. Parallel to the printed lines (x-axis), the system acted as resistances in parallel while perpendicular to them (x-axis), the system geometry is like resistances in series. Similar results have been obtained using CNTs-loaded ABS [38]. Dog bones samples printed with a 90° raster angle have lower electrical conductivity due to disrupted conductive pathways and weaker CNT alignment than those printed at 0°. This disruption causes more electrical interruptions, affecting how current flows through the material. Interestingly, despite this lower conductivity, samples with a 90° angle exhibit greater sensitivity to strain, as indicated by a higher gauge factor. This is attributed to reduced electrical contacts between adjacent filaments, amplifying the deformation response. From a mechanical point of view, the 90° orientation results in lower material compactness and weaker filament bonds, making the samples more susceptible to micro-damage under stress.

The effect of raster angle on conductivity could be particularly evident in multi-layer printed structures, where interlayer connectivity is a limiting factor. The raster angle significantly affects the conductivity of MWCNT-TPU composites [156] by altering the alignment and connection of conductive paths across rasters. Samples printed with a 0° raster angle show better conductivity than those printed at 90°. This difference arises due to the increased number of voids and weaker inter-filament bonding in the 90° orientation, which disrupts the percolation network of CNTs. The reduced contact between adjacent layers and rasters in the 90° configuration leads to lower conductivity values and higher resistance at these interfaces [156].

Mechanical properties also depend on the interaction between raster angle and infill patterns. Thermal effects must also be considered when optimizing raster angle for conductive materials. Uneven heat distribution in FDM-printed parts can lead to thermal contraction and warping, particularly in materials like ABS and PETG. Raster orientations that minimize stress concentrations and ensure even heat dissipation contribute to better adhesion and dimensional stability, indirectly improving conductive performance by reducing layer separation. Moreover, the raster angle can be beneficially used to increase the sensitivity of resistance temperature detectors (RTDs) printed using CB-PLA composites [157]. Two-layer CB-PLA with different raster orientations such as [0°/0°], [−45°/45°], and [0°/90°] affect resistivity behavior significantly. Structures printed with [0°/0°] rasters exhibited increased resistivity by 320% across a temperature range from −15°C to 50°C compared to the single CB-PLA filament. Similarly, the [−45°/45°] and [0°/90°] orientations showed resistivity increases of about 346% and 330%, respectively. The [0°/90°] orientation demonstrated high stability with minimal variation during repeated thermal cycles, making it the preferred configuration for RTD fabrication [157].

The electrical and mechanical performance trade-off suggests that raster angle optimization must be application specific. A 0° raster angle aligned with current flow is preferred for printed circuits and sensors to maximize conductivity. For structural components incorporating conductive pathways, printing strategies combining 0° and 90° orientations in alternating layers may balance mechanical strength with electrical performance.

4.2.6 Bed Temperature

Proper bed temperature control ensures consistent layer bonding, reduces warping, and maintains electrical conductivity. The influence of bed temperature on adhesion is primarily linked to the thermal expansion and contraction of the polymer during printing. Conductive filaments, like their nonconductive counterparts, tend to contract as they cool. If the bed temperature is too low, this contraction can cause warping or delamination, leading to structural defects that disrupt the continuity of conductive pathways. Studies on TPU-based filaments reveal that setting the bed temperature to 50°C optimized adhesion without causing excessive softening, which can lead to deformation in flexible materials. However, Boltežar et al. [122] demonstrated that the variation of the print-bed temperature (30°C–90°C) did not produce any visual differences between the printed Electrifi (copper doped filament, see Table 3) samples. It should be noted that there are not many papers in the literature that analyze the direct effect of this parameter, partly because its impact on resistivity can be significantly mitigated in the case of multilayer sensors or electrodes, while the impact of bed temperature on host materials is well documented [158]. In general, bed temperature impacts the adhesion that directly affects the mechanical integrity of printed conductive components. A poorly adhered first layer can lead to layer shifting or part detachment during printing, compromising surface finish and structural stability. Lower bed temperatures may result in weak adhesion, causing inconsistent electrical conductivity due to gaps and voids at layer interfaces.

The choice of print surface further influences adhesion in conductive filament printing. While providing a clean and flat print bed, smooth glass surfaces often require adhesives such as glue sticks, or specialty build surfaces to improve first-layer bonding. On the other hand, polyetherimide (PEI)-coated beds have been shown to enhance adhesion in materials such as conductive ABS and PETG by maintaining a consistent thermal profile [159].

Bed temperature also interacts with other printing parameters such as print speed and nozzle temperature. A higher bed temperature allows slower cooling, reducing internal stresses that may otherwise lead to part delamination. In multi-layer conductive structures, maintaining a stable bed temperature throughout printing has been shown to improve electrical performance by ensuring continuous filler distribution and reducing the formation of high-resistance interfaces.

While optimizing bed temperature improves adhesion and conductivity, excessive temperatures can lead to undesirable effects such as filament softening, deformation, or excessive spreading of the first layer. In TPU-based conductive filaments, for example, bed temperatures above 60°C may result in over-softening due to the TPU properties (see Table 2), causing loss of dimensional accuracy and reduced electrical performance due to uneven filament deposition.

Although scarcely investigated, the bed temperature can contribute significantly to the post-processing of printed conductive elements, particularly through annealing (see Section 4.3).

4.3 Post-Printing Parameters

Post-printing parameters may efficiently enhance the electrical, mechanical, and functional properties of parts printed with conductive filaments, especially annealing. Annealing is a heat treatment process that has been tested for enhancing particle connectivity within the polymer matrix, thereby improving electrical conductivity, as demonstrated in CB-PLA [160]. However, excessive temperatures may cause polymer degradation, leading to decreased conductivity [161]. Moreover, improved crystallinity after annealing contributes to increased thermal resistance. This effect may be particularly beneficial for filaments in sensor applications requiring stable performance under temperature fluctuations [162]. Although this post-printing parameter has been extensively explored across various host materials [163, 164], its effect on the electrical properties of sensors and electrodes remains under-documented. Research addressing these impacts is sparse, leaving a significant knowledge gap that warrants further investigation.

5 Printed Sensors

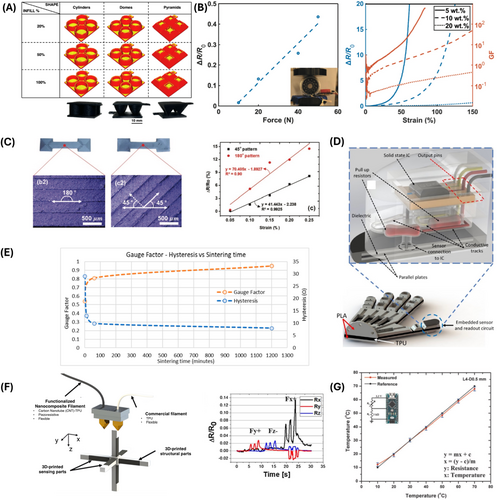

This section explores recent strain, pressure, temperature, and force sensor advancements, highlighting key technologies, materials, and performance metrics (Table 5).

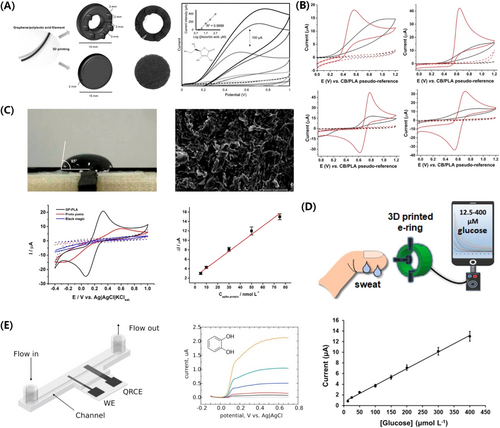

| Reference | Sensor/working mechanism | Filament material (Commercial name) | Sensors shapes | Specific application | Printer | Properties |

|---|---|---|---|---|---|---|

| [165] | Pressure sensor | CB-TPU (Filaflex Conductive) | Planar smooth shape for element A. Different shapes (cylinders, domes, and pyramids) and infill (20%–50%–100%) for element B. | Variation of the output sensor caused by mass (10 g) and water (20 mL). Rapid tapping made with fingertip. Respiratory monitoring with sensor inserted in a rigid belt. | Sovol SV04/double extruders and nozzles with diameters of 0.4 mm. Build volume of 300 mm length, 300 mm width, 400 mm height and a maximum speed of up to 180 mm/s. | Pressures up to 22 kPa, high sensitivity. Increasing the infill R0 increases and varies across different shapes. Highest sensitivity (S) in range 0–1 kPa, −6.3 kPa−1 for pyramid extrusion and 100% infill. Average highest GF of 99.61% for dome with 100% infill. Response time of 135 ms and recovery time of 88 ms (dome with 100% infill). |

| [166] | Pressure sensor | PLA and PEDOT:PSS | Substrate of PDMS. Coating PEDOT by drop-casting for electrical conductivity. | Wrist pulse, swallowing, and pronunciation of words. | GUIDER IIs, FlashForge Co. | S increases as the printing layer height increases. With 0.16 mm PLH, S is 160 kPa−1 for a linear pressure range of 0 − 0.577 kPa. Good linearity R2 = 0.978. The sensor shows stable behavior for 4000 cycles under 6.56 kPa. |

| [167] | Strain and pressure sensor | CB-TPU | Biaxial strain rosette, which has two orthogonal circuits in each layer. The circuit and substrate have a thickness of 1 and 0.5 mm, respectively (first application). | Biaxial strain sensor, smart tire, and cable-driven soft finger with multiple sensing capabilities. | Multimaterial FDM 3D printer was utilized with such BMG direct-drive extruder equipped on both printing heads (TENLOG TL-D3 Pro, Tenglong 3D Technology Co. Ltd) to resolve the printing issues. | Conductivity increases with the amount of CB particles. Cyclic loads. Response time of 0.16 s. The strain sensor should be insensitive to the strain that is perpendicular to the direction of the gauge length. Static and dynamic test for smart tire. |

| [168] | Pressure sensor (capacitive structure) | CB-PLA (Proto-pasta) | Embedded capacitive pressure sensor (19.6 mm wide, 2.6 mm thick, and 28 mm high). | Intrinsic tactile sensing for robotic hand. | Open-source desktop 3D printer (RepRap Ormerod 2). The printer was customized to be able to extrude also conductive pastes. | For Eco-PLA, the sensitivity is 0.00218 kPa−1 and the linearity is 0.99. Linear response in range 0–50 kPa. |

| [21] | Pressure/Force. For a capacitive structure, the pressure will induce a variation of the TPU thickness used as dielectric RTD. The microstructure of the CB-PLA composite changes, altering the distribution and contact points of CB particles. | CB-PLA | Parallel plate structure for capacitive sensor. Bone shape for RTD. |

Finger touch | Ultimaker S5 | The best electrical behavior was found when the electrical current was applied along the printed lines direction. Sensitivity of 0.088%/N for capacitive sensor (linear behavior in range 0–40 N) Sensitivity of 2.2%/°C for temperature transducer (20°C–40°C range) |

| [169] | Capacitive sensor water has a higher dielectric constant than air, so the capacitance increases as the void fraction decreases | CB-ABS | Parallel concave capacitors with a gap of 0.2 mm. Samples of different thicknesses and widths are tested. | Void fraction of two-phase flow (water and air). | Ultimaker S3 with dual nozzle system. | The addition of CB improves Tg value of ABS. ΔC, when the change in void fraction is given, is less compared to traditional copper sensor, but it is measurable. Response time of 6.9 s. |

| [170] | Capacitive sensor | CB-TPU (Palmiga PI) | Auxetic metamaterial array with 6 × 6 sensors. Sinusoidal segments and row-columns configuration.55.65, 55.65, and 1.7 mm. | Universal jamming gripper. Human elbow. | BCN3D dual-nozzle printer. | Different designs to obtain negative (auxetic), normal, and positive Poisson's ratios. For gripping, capacitance spatial map shows force distribution on object's surface and proximity detection. Elbow pressed on table. Capacitance change map shows a force distribution profile concentrated at the bony tip, with elbow pressed on table. |

| [100] | Strain/deformation induces a variation in the conductive pathways within the polymer matrix. Percolation theory and tunneling effect. | MWCNT-TPU | Samples for both stress–strain and resistance–strain tests were dimensioned at 1.6 mm × 1.6 mm with a length of 100 mm. For percolation behavior is used disks of 14 mm in diameter and 3.17 mm in thickness. For electrical conductivity square samples with 10 mm sides and 3 mm thickness. | General purpose | MakerBot Replicator 2× Experimental printer (MakerBot Industries LLC, Brooklyn, New York). | Increasing MWCNT filler, the material strength, initial elastic modulus, and electrical conductivity all increased. Furthermore, the cyclic response showed strong and consistent behavior over a range of strain loadings. |

| [171] | Strain sensor | CB-TPU | Test on conductive filament (conductivity, Young modulus, and fracture strain for different content of CB). Standard strain gauge sensor. |

General purpose | Dual nozzle FDM 3D printer (FUNMAT PRO 410, Intamsys Technology Co. Ltd, China) | Conductivity dramatically rises by adding more CBs due to formation of the conductive pathway. Instead, Young's modulus increases from 1.535 to 4.301 MPa. As for gauge factor, 0.365 and 0.068 for 10% CB-TPU and 20% CB-TPU (10% of strain). |

| [172] | Strain sensor | Graphene-PLA (Blackmagic) | Dog-bone shaped tensile specimens were printed with a width, length, and thickness of 5, 200, and 2 mm, respectively. | Weak and strong tapping. | Ender-3Pro 3D printer with a print volume of 220 mm × 220 mm × 250 mm. | Two strain sensors with different deposition angle (45° and 180°). The 180° sensor shows lower precision and higher output amplitude compared to the 45°. Strain range 0.05%–0.25%. GF is 32 and 58 for the 45° and 180° patterns. The zigzag shape in the 45° pattern has a stronger bonding force, leading to a lower degree of crack deformation. |

| [173] | Strain sensor. Piezoresistive element. |

CB-TPU (Ninjatek Eel) | Sensors integrated on the surface of an elastomer strip in TPU. After the printing of the gripper, silver wires were inserted at the gripper to act as tendons. | Soft robotic gripper. | 3D printer Pro2 Dual Extruder 3D Printer (Raise 3D, Irvine, USA). | Both the robotic gripper with 82A and 95A are able to distinguish between open and closed positions, when holding an object and when not, as well as if there is an obstacle preventing it from moving properly. The relative change of the sensor signal was slightly higher for the TPU gripper with higher shore hardness (95A). |

| [174] | Strain sensor | CNT-TPU | Dog-bone shape for tensile test 75 mm × 15 mm × 1 mm. Strip of 50 mm × 10 mm for electrical test. |

Bending and unbending of index finger and wrist at 30° and 90°. Breathing. Speaking “go”, “belong,” and “important.” | ET-K1 (ET Co. Ltd., China) desktop FDM 3D printer. | 1-pyrenecarboxylic acid (PCA) was introduced to non-covalently modify the CNTs and improve the polymer nanofiller interactions. Better mechanical properties, electrical conductivity, and strain sensing performance. GF = 117,213 at a strain of 250%. Large detectable strain (0%–250%). Good stability up to 1000 loading unloading cycles. Wide frequency response range 0.01–1 Hz. |

| [175] | Strain sensor | CB-PLA (Proto-pasta Conductive) | PLA substrate with thickness of 0.2 mm. Strain gauge with U-shape and thickness of 0.3 mm. | Experimental stress analysis. | Prusa MK3s, Prusa Research a.s., Prague, Czech Republic, with a nozzle diameter of 0.4 mm. | Bending load 0–30 N. The sensitivity of the 3D-printed SG is four times higher than that of conventional metal foil strain gauges. The linearity error of the loadings is within ±4%. |

| [176] | Strain sensor. Piezoresistive effect | CNT-PLA | Sensing element of 50 mm × 4 mm, with two rectangular pads situated at both ends (area of 225 mm2). | Fabricating low-cost sensors for the marine industry. | Ultimaker S3 | Thermal treatment at high temperature to enhance the diffusion and sintering of CNT, creating more electrical paths. GF and linearity are improved for samples sintered for 1 and 20 h, while hysteresis decreases. Maximum ΔR 2.5% with displacement of 1.2 mm. |

| [177] | Strain sensor bending the sensor allowed the MWCNT fillers dispersed in the polymer matrix to come closer together, which led to lower resistance with bending | MWCNT-TPU | Rectangular shape 20 mm long, 4 mm wide, and 0.6 mm thick. | Bending. | N.A. | The sensor exhibited a change of resistance of ~30% at 90° bending. The use of 50% infill showed the highest change in resistance values at the same bending angle. |

| [178] | Piezoelectric sensor | PVDF from Shanghai 3F New Material Co. Ltd, China. DMF Guangdong Xilong Science Co. Ltd., China. IL-[C2mim] [BF4] Aladdin biological technology in Shanghai. |

Four structures for cells: standard, cross, sandwich, and pyramid. | Lighting LEDs subject thanks to continuous impacting force. Different human motion such as finger tapping, hand beating, walking, and jumping with sensor embedded into the shoe insole. |

RepRap X350pro printer (Feldkirchen, Germany). | Force range 10–100 N for piezoelectric performance, maximum output of 8.6 V for sandwich at 100 N. Stable behavior for 1000 cycles. Fastest response time of 85 ms for sandwich type at 10 N. Linearity up to 700 kPa. Sandwich shows highest S of 11.87 mV/kPa. |

| [179] | Conductive filaments for circuit | Conductive filaments with thermoplastic resins and carbon nanostructures (CNT, CB, and graphene) | N.A. | Electronic circuits. | Prusa Mendel–I3, USA | Filaments obtained present values of resistivity and conductivity ranging from 0.2 to 1.4 Ω cm and 0.71 to 5.0 S/cm, respectively. |

| [180] | Vapor detection. The vapor swells the polymer matrix, causing a separation of MWCNTs and an increase in resistance. |

MWCNT-PVDF | Standard dog-bone shaped sensing strips (1, 2, 3 layer). | Low-cost chemical vapor sensing platform. | MakerBot Replicator 2X Experimental Printer. | The resistance decreases with the increase in % MWCNT, and the percolation threshold is found in the 1%–5% range. When the dog-bone sensor is exposed to different organic solvent vapors, the resistance increases and then decreases during the vacuum phases (four cycles). The maximum variation of 26% is observed with acetone, while benzene has no effect on the sensor. A greater variation in resistance is observed with a lower % MWCNT in the polymer matrix. |

| [181] | Accelerometer Hyperbolic differential capacitive structure for each axis; this means that differential capacitances Cp, Cn, which have complementary values, change their capacitance in function of the plates distance, which in turn varies due to the movements of the mobile intermediate plate towards one of the boundary plates. |

CB-PLA (Proto-pasta Conductive) | Cubic structure hosts a six-faced proof mass free to move in all the directions and connected to the chassis through springs. | General purpose | E3D Tool Changer platform. Since it is a multi-tool platform, it is possible to use different tools for each material, therefore minimizing oozing and mixing of the different materials. | Sensitivity, resolution, and linearity error are better for higher value of infill %. Sensitivity and resolution are 0.2009 V/g and 20 mg (100% infill). The density mass decreasing induces a higher resonant frequency and a larger flat band region. |

| [99] | Single beam and multiaxial force sensor Force applied on each axis is measured by the resistance change (piezoresistivity) |

CNT-TPU | 3D cubic cross shape. The dimensions (width × thickness × length) of the sensing part are 3 mm × 0.6 mm × 20 mm and that of the structural part 3 mm × 2.4 mm × 30 mm. |

Haptic device for finger forces from 0 to 5 N. | Makerbot 2X replicator, USA. There is a dual nozzle system, and each nozzle has a diameter of 0.4 mm. |

For single beam sensor, the initial resistance of 10.92 kΩ was decreased to 9.76 kΩ (10.6% decrease) after 1-mm deflection by a load of Fz = 2.11 N. During the 1–1000 cycles, the base resistance decreased by 0.65%. For multiaxial force sensor, when we applied a load to the sensor, the deflection and force showed a linear relationship. |

| [182] | Temperature influence on force sensor | CB-PLA (Proto-pasta) | Cantilever beam with four conductive traces, traditional strain gauges in Wheatstone bridge configuration. | Effect of annealing on properties of conductive PLA. | Ultimaker S5 with dual nozzle system. | Sensitivity model to predict Vout. The variation in balance (zero-load output) was reduced by annealing and the measured sensitivities were reduced, but they had better agreement with the analytical sensitivity model. Furthermore, as a result of annealing, there was less uncertainty in the measured sensitivity. |

| [183] | Resistive temperature sensor When the temperature rises, there is physical expansion of the polymer matrix at microscopic level that reduces the contact between the conductive GNRs and the resistance increases. |

Graphene nano rods-PLA (BACKMAGIC3D) | Cylindrical sensor body in ABS with a conductive trace in G-PLA. | Embedded temperature sensor for both terrestrial and aquatic environments. | AMMs single-build fabrication setup, a rotatable multihead 3D printer that can be fitted with multiple tool heads for faster fabrication of large, complex parts. | The sensors show excellent linearity and stability when tested both in air and under water up to 70°C. The sensitivity of the linear sensors was calculated to be 13 Ω/°C, while the response and recovery times were 6 and 14 s, respectively. |

| [157] | RTD The increase in resistance of PLA/CB might be due to the increased gap between adjacent CB particles dispersed in the composite as the PLA matrix expands with increasing temperature. The increased gap not only leads to breakage of the conducting chains, but also interferes with the electron tunneling through the gap. |

CB-PLA | Square PLA shape with a thickness of 0.6 mm and a sensitive pad in the central part with a side of 5.6 mm. | 3 × 3 array of P-RTDs to allow an indication of the temperature profile of the surface in contact with the temperature source. | Homemade 3D FDM printer with dual nozzle extruder. | The temperature-dependent resistivity change of PLA/CB was evaluated for different stacking sequences of PLA/CB layers printed with [0°/0°], [−45°/45°], and [0°/90°] plies. With [0°/90°] plies stacking sequence, TCR of 6.62%/°C with high stability over repeated cycles. Reaction and recovery times of 4 and 3.5 min. |

| [184] | Temperature detection sensor | CB-TPU (PI-ETPU 85-700+, Palmiga Innovation, Sweden). | Circular channel 3 mm diameter. The heater is located at the center of the channel and has a width of 2 mm. The two sensors also have a width of 2 mm and are placed symmetrically at a 3-mm distance from the heater. | Fully 3D printed thermal mass flow meter (calorimetric flow sensing). | Creator Pro, FlashForge Corporation, China 3D FDM printer. | Temperature range from 40°C to 120°C and back to 50°C. nonlinear relation between TCR and temperature. TCR ranging from 0.002 to 0.024°C−1. The sensor shows a sensitivity of 20 mV/(mL min−1); pseudo linear range for flows below 3 mL/min with power of 1 W and temperature up 58°C. |