Electrical Properties of Sn-Doped α-Ga2O3 Films on m-Plane Sapphire Substrates Grown by Mist Chemical Vapor Deposition

Abstract

Growth and electrical property of conductive Sn-doped α-Ga2O3 films on m-plane sapphire by mist chemical vapor deposition (mist-CVD) are exhibited. Although the crystallinity is still inferior in comparison with previously reported α-Ga2O3 films on c-plane sapphire, highly crystalline α-Ga2O3 films on m-plane sapphire substrates are grown by applying two-step growth procedure. Carrier concentration of Sn-doped α-Ga2O3 films is controlled in the range of 1017–1019 cm−3 by changing the Sn/Ga concentration ratio in source solution. α-Ga2O3 films on m-plane sapphires with the thickness of 2 μm show mobilities as high as 65 cm2 (V s)−1, which is much higher than previously reported value of 24 cm2 (V s)−1 in the films grown on c-plane sapphire.

1 Introduction

Gallium oxide (Ga2O3) is a promising semiconductor material for various kinds of applications such as transparent conducting layers,1 thin-film transistors,2 ultraviolet sensors,3 and high-power devices4-6 due to its large bandgap energy reported to be around 5.0 eV.7-10 Among the five different types of Ga2O3 polymorphs, β-gallia-structured Ga2O3 (β-Ga2O3) is the most thermally stable.11 Due to the availability of high-quality β-Ga2O3 single-bulk substrates grown by conventional melting growth technique such as floating zone (FZ) or edge-defined film-fed growth (EFG) or Czochralski (CZ) method,12-15 the devices based on β-Ga2O3 have largely progressed in recent years, resulting in the successful demonstration of Schottky barrier diodes (SBDs)16, 17 and metal–oxide–semiconductor field-effect transistor (MOSFET).18-20 In contrast, it is reported that some of the metastable phase of Ga2O3 polymorphs can be obtained on foreign substrates. One example is corundum-structured Ga2O3 (α-Ga2O3) grown on sapphire substrates using mist chemical vapor deposition (mist-CVD)7, 21 or halide vapor phase epitaxy (HVPE).22 α-Ga2O3 is able to form alloys with other corundum-structured oxides, such as α-Al2O3 and α-In2O3, the alloy offering a bandgap energy tunable in wide range of 3.7–8.7 eV.23, 24 The feature is promising for heterostructured device application, such as hetero-FET (HFET). In addition, the use of sapphire substrates is advantageous because they are available at low cost. We previously reported the successful n-type doping of α-Ga2O3 films grown on c-plane sapphire by Sn-doping.25, 26 However, the electron mobility of α-Ga2O3 films in these reports was as low as 24 cm2 (V s)−1. In single-bulk crystal of β-Ga2O3, the mobility at room temperature as high as 150 cm2 (V s)−1 was reported.27 Furthermore, based on first-principle calculation, the effective mass of electron in α-Ga2O3 is reported as 0.274m0, as light as the value in β-Ga2O3,28 0.328m0, where m0 is the electron mass. Therefore, intrinsic mobility in α-Ga2O3 is much higher than 24 cm2 (V s)−1 and comparable to that of β-Ga2O3. Present low mobility in α-Ga2O3 films was attributed to poor crystallinity of the films. For example, α-Ga2O3 grown on sapphire substrates contain high density of dislocations, whose density was estimated as 7 × 1010 cm−2 for the films grown on c-plane sapphire,29 because of lattice mismatch between α-Ga2O3 and sapphire (3.5% and 4.8% for c-axis length and a-axis length, respectively). Therefore, it is important to reduce the density of crystal defects and enhance the electron mobility. In this article, we show the fabrication of conductive Sn-doped α-Ga2O3 films on m-plane sapphire substrates by mist-CVD method and electrical properties of them. Some groups already reported the successful growth of α-Ga2O3 films on m-plane sapphire by laser molecular beam epitaxy (MBE) and mist-CVD.30, 31 However, there are no reports about the fabrication of conductive α-Ga2O3 films on m-plane sapphire and the characterization of electrical property of them. α-Ga2O3 films grown on m-plane sapphire exhibited mobility as high as 65 cm2 (V s)−1, much higher than previously reported value of 24 cm2 (V s)−1 in the films grown on c-plane sapphire, suggesting that the growth direction is important factor to obtain high mobility in α-Ga2O3 films.

2 Experimental Section

We fabricated Sn-doped and undoped α-Ga2O3 films on m-plane sapphire by mist-CVD method. Gallium(III) acetylacetonate and tin(II) chloride dehydrate were used as gallium (Ga) and tin (Sn) precursors, respectively. As a reaction source, we used a solution of these precursors in water with the addition of small amount of hydrochloric acid to dissolve these precursors completely. Water also acted as an oxygen source. As a carrier gas, nitrogen was used. Substrate temperature was set at 550 °C. To control carrier concentration of films, we varied Sn/Ga concentration ratio in reaction source. The growth speeds of films were controlled by changing gallium precursors concentration in the source solution. The concentrations of gallium precursor in the source solutions were set at 0.050 and 0.025 mol L−1, resulting in the growth speed around 10 and 20 nm min−1, respectively.

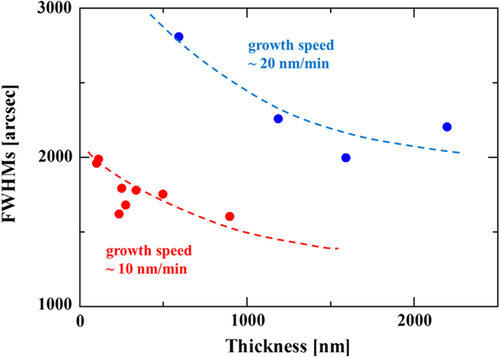

Figure 1 shows full width at half maximum (FWHM) values in X-ray powder diffraction (XRD) ω-scan profiles for the diffraction from symmetric (30–30) plane of α-Ga2O3 films grown on m-plane sapphire as a function of film thickness with different growth speeds around 10 and 20 nm min−1. As shown in Figure 1, irrespective of growth speed, FWHM values decreased with the increase in film thickness and the films grown with lower growth speed of 10 nm min−1 exhibited lower FWHM values compared with films with higher growth speed of 20 nm min−1. These results suggested that growth speed and film thickness were important factors for fabricating highly crystalline α-Ga2O3 films on m-plane sapphire.

Crystallinity of α-Ga2O3 film on m-plane sapphire can be improved with decrease in growth speed and increase in film thickness. However, if we fabricate thick α-Ga2O3 films with low growth speed, growth time becomes large. Therefore, we tried to fabricate α-Ga2O3 films on m-plane sapphire with two-step growth method. Figure 2a shows schematic structure of the samples grown with two-step growth method and Figure 2b shows XRD 2θ/θ-scan profiles of the samples. At first, we grew thin template α-Ga2O3 layer on m-plane sapphire with low growth speed of 10 nm min−1. Typical thickness of low-speed grown α-Ga2O3 under layers was around 100 nm. Then, we grew thick α-Ga2O3 films upon them with high growth speed of 20 nm min−1. To investigate the thickness dependence of crystal quality of α-Ga2O3 films, total thicknesses of α-Ga2O3 layers were set at around 1 or 2 μm. In Figure 2b, the peaks derived from m-axis-aligned α-Ga2O3 were observed. Irrespective of film thickness, no other crystalline phases were observed, suggesting the existence of heterogeneous phases were negligibly small. Table 1 shows FWHM values of XRD ω-scan profiles for the diffraction from both symmetric (30–30) plane and asymmetric (10–14) plane of α-Ga2O3 films grown by two-step growth procedure and α-Ga2O3 films grown by one-step growth procedure with growth speed around 20 nm min−1. By applying two-step growth procedure, FWHM values of XRD ω-scan profiles were largely decreased from the films with one-step growth procedure, which suggested the improved crystallinity of the films with two-step growth procedure. As for films grown by two-step procedure, FWHM values for α-Ga2O3 films with the thickness of 2 μm were smaller than that for films with thickness of 1 μm, which suggested the improved crystallinity in thicker α-Ga2O3 films. FWHM values of XRD ω-scan profiles of α-Ga2O3 films grown by two-step growth procedure were as low as 1200 arcsec for both symmetric plane diffraction and asymmetric plane diffraction. In contrast, as for α-Ga2O3 films on c-plane sapphire in our previous report,26 FWHM values of XRD ω-scan profiles were around 30 arcsec for symmetric plane diffraction and 1000 arcsec for asymmetric plane diffraction. Therefore, because of larger FWHM values for both symmetric and asymmetric plane diffractions, crystallinities of α-Ga2O3 films on m-plane sapphire were inferior than those of films on c-plane sapphire. In addition, the sharpness of XRD ω-scan profiles was influenced by dislocation density and their type. The profiles for symmetric plane diffractions are mainly broadened by screw components, whereas the profiles for asymmetric plane diffractions are broadened by both screw and edge components. Because both of the FWHMs values for symmetric and asymmetric diffractions were as large as 1200 arcsec, α-Ga2O3 films on m-plane sapphire contain both screw and edge dislocations with high density. In this respect, α-Ga2O3 films grown on m-plane sapphire are different from α-Ga2O3 films on c-plane sapphire. For the films on c-plane sapphire, the densities of screw dislocations were quite low, whereas the edge dislocation densities were high, due to the small FWHM value for symmetric diffraction and large FWHM value for asymmetric diffraction.

| Total thickness and growth procedure | FWHM value for XRD profiles for symmetric (30–30) plane (arcsec) | FWHM value for XRD profiles for asymmetric (10–14) plane (arcsec) |

|---|---|---|

| Two-step growth, 1 μm | 1350 | 1450 |

| Two-step growth, 2 μm | 1200 | 1230 |

| One-step growth, 2 μm | 2000 | 2200 |

To confirm epitaxial alignment of α-Ga2O3 films to sapphire substrates, we conducted pole figure analysis. Figure 3 shows pole figures of diffraction from (10–12) plane for α-Ga2O3 films and m-plane sapphire substrates (α-Al2O3). Note that both α-Ga2O3 and α-Al2O3 are corundum-structured crystals, which have threefold symmetry along c-axis. Three spots of diffraction observed in both pole figures of α-Ga2O3 and α-Al2O3 are reflecting threefold symmetry of corundum-structured crystal. No rotational domains were observed from pole figure of α-Ga2O3. Diffraction spots of α-Ga2O3 and α-Al2O3 were located at same in-plane directions and same tilt angles, indicating both of the crystals, α-Ga2O3 and α-Al2O3, were aligned in the same in-plane direction as well as out-of-plane direction.

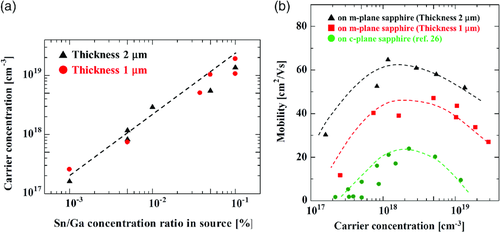

We next tried Sn-doping to α-Ga2O3 films grown on m-plane sapphire. Sequence of sample creation was based on the two-step growth method schematically shown in Figure 2a. Sn-doping was only applied to α-Ga2O3 upper layers. Therefore, thin α-Ga2O3 under layers remained undoped. Thicknesses of each α-Ga2O3 layers were same as those shown in Figure 2a. We conducted Hall measurements of Sn-doped α-Ga2O3 samples with van der Pauw configuration. Homemade Hall measurement system was used and magnetic fields as high as 1 T were applied for the measurements. Note that electrical properties of undoped α-Ga2O3 under layers were highly resistive. Therefore, only Sn-doped upper α-Ga2O3 layers were conductive. As contact electrodes, Ti/Au electrodes were fabricated at the corners of samples. Thickness of Ti and Au electrodes were 50 and 20 nm, respectively. As a deposition method of Ti/Au electrodes, we used electron beam evaporation. Figure 4a shows carrier concentration in α-Ga2O3 films at room temperature as a function of Sn/Ga concentration in source and Figure 4b shows the relationship between Hall mobility and carrier concentration at room temperature in α-Ga2O3 films grown on m-plane sapphire. In Figure 4b, we also show our previous results of films on c-plane sapphire reported by Akaiwa et al.26 for comparison. As shown in Figure 4a, carrier concentrations were almost proportionally varied with the change of Sn/Ga concentration ratio, indicating successful control of carrier concentration. At the same Sn/Ga concentration ratio, there were only small differences in carrier concentration between the films with different thicknesses of 1 or 2 μm, which suggested uniformity of carrier concentration along depth direction in Sn-doped α-Ga2O3 films. Table 2 shows the comparison of Sn atomic concentration and carrier concentration in two different samples evaluated by secondary ion mass spectroscopy (SIMS) and Hall measurement. Note that the samples were grown with two-step growth procedure and total thicknesses of the samples were 2 μm. Although there were slight differences, carrier concentrations and Sn atomic concentration in the films were comparable. We considered that carrier concentrations and Sn atomic concentration were differed as a result of unintentional incorporation of donor such as Si impurity or compensating defects. As shown in Figure 4b, Hall mobilities of films on m-plane sapphire become larger with the increase in film thickness at the same carrier concentration, partly due to the improved crystal quality of the films. Irrespective of film thickness and substrate orientation, Hall mobility at high carrier concentration increased with the decrease in carrier concentration due to the decrease in ionized impurity scattering, whereas Hall mobility at low carrier concentration decreased with the decrease in carrier concentration due to the increase in dislocation scattering. The mechanisms of dislocation scattering was also discussed for some materials such as germanium,32, 33 gallium nitride (GaN),34 in our previous report.26 α-Ga2O3 films on m-plane sapphire showed much higher mobility compared with those on c-plane sapphire. As a maximum value, Hall mobility of 65 cm2 (V s)−1 were obtained at carrier concentration of 1.2 × 1018 cm−3 in films with total thickness of 2 μm. The reason why higher mobility was obtained in α-Ga2O3 films on m-plane sapphire is controversial issue. It is reported that the effective mass of electron at the conduction band minimum of α-Ga2O3 is isotropic.28 Therefore, higher motility in α-Ga2O3 films on m-plane sapphire than that in films on c-plane sapphire was not resulted from the anisotropy of electron effective mass in α-Ga2O3, suggesting it can be attributed to the reduction of scattering caused by crystal defects. In contrast, as mentioned previously, crystallinity of α-Ga2O3 on m-plane sapphire examined by XRD ω-scan measurements was not superior than that of films on c-plane sapphire. Table 3 shows the concentration of several typical impurities incorporating in the films on m-plane and c-plane sapphire revealed by SIMS. Note that the concentration of each impurity contained 40% errors from true value. There were no large differences of concentrations in each impurity between the films on m-plane and c-plane sapphire except for the concentrations in Al and Cl elements, which showed the differences with one order of magnitude, suggesting that the scattering originating from impurities should be similar. Therefore, despite higher mobility, crystallinity and each impurity density of α-Ga2O3 on m-plane sapphire were not largely improved from α-Ga2O3 films on c-plane sapphire. Effort will be continued to clarify the reason for the differences in mobility between α-Ga2O3 films on m-plane and c-plane sapphire.

| Sample 1 | Sample 2 | |

|---|---|---|

| Sn concentration in the sample | 9.8 × 1017 cm−3 | 2.5 × 1017 cm−3 |

| Carrier concentration in the sample | 1.1 × 1018 cm−3 | 1.6 × 1017 cm−3 |

| Element | Impurity concentration in the films on c-plane sapphire | Impurity concentration in the films on m-plane sapphire | Detection limit of each element |

|---|---|---|---|

| Al | 1 × 1016 cm−3 | 2 × 1015 cm−3 | 9 × 1014 cm−3 |

| H | 3 × 1018 cm−3 | 2 × 1018 cm−3 | 7 × 1017 cm−3 |

| C | 7 × 1017 cm−3 | 4 × 1017 cm−3 | 2 × 1017 cm−3 |

| Si | 2 × 1017 cm−3 | 3 × 1017 cm−3 | 1 × 1017 cm−3 |

| Cl | 2 × 1016 cm−3 | 4 × 1015 cm−3 | 1 × 1015 cm−3 |

3 Conclusion

We showed the fabrication and characterization of conductive Sn-doped α-Ga2O3 films on m-plane sapphire. Although the crystallinity was still inferior in comparison with previously reported α-Ga2O3 films on c-plane sapphire, highly crystalline α-Ga2O3 films were obtained on m-plane sapphire substrates by applying two-step growth method. Carrier concentration of Sn-doped α-Ga2O3 films is controlled in the range of 1017–1019 cm−3 by changing the Sn/Ga concentration ratio in source solution. Compared with the previous report of α-Ga2O3 films on c-plane sapphire, much higher mobilities with a maximum value of 65 cm2 (V s)−1 were obtained in the films on m-plane sapphire with the film thickness of 2 μm grown by two-step procedure.

Acknowledgements

This work was supported by Sasakawa Scientific Research Grant from the Japan Science Society.

Conflict of Interest

The authors declare no conflict of interest.