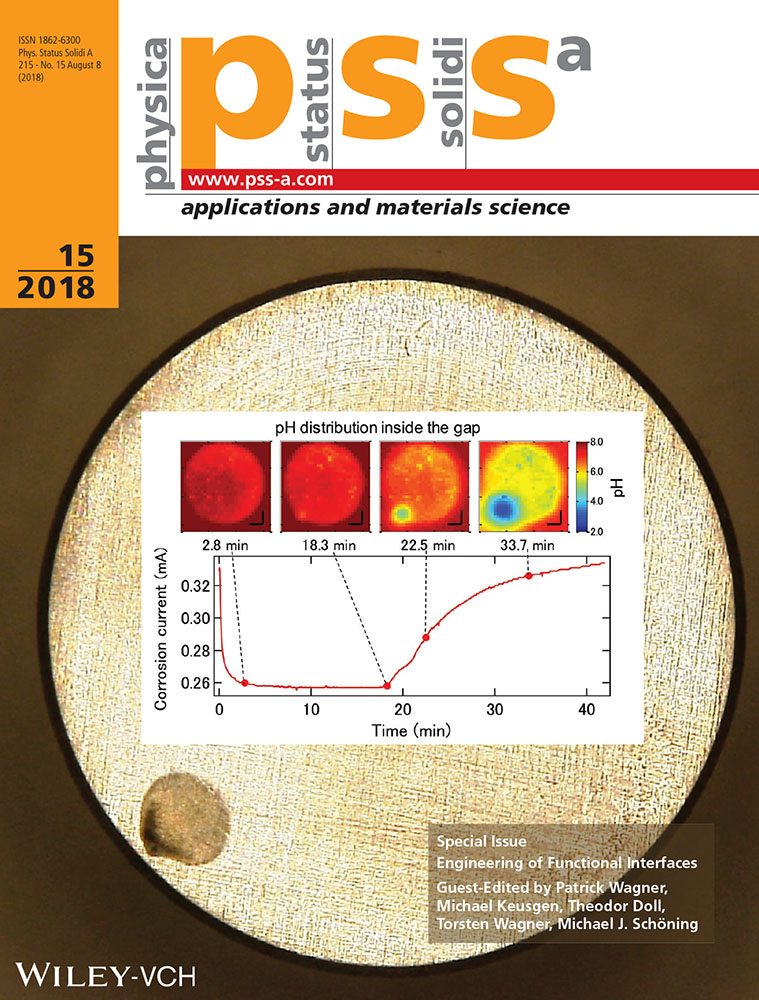

A Modified Chemical Imaging Sensor System for Real-Time pH Imaging of Accelerated Crevice Corrosion of Stainless Steel (Phys. Status Solidi A 15∕2018)

Graphical Abstract

Chemical Imaging Sensors

In spite of the high corrosion resistance, a surface of stainless steel placed in a narrow gap of the order of microns is known to corrode, which can be a potential hazard, for example, in marine infrastructures. A direct interrogation of this “crevice corrosion” has been difficult due to the very limited accessibility of the confined space. A novel technique visualizes the temporal change of pH distribution inside the gap during corrosion in a geometry where a chemical imaging sensor is placed in the proximity of a steel surface. The observed local decrease of pH down to 2 corresponds to the location where the corrosion is initiated. This is reported by Ko-ichiro Miyamoto and co-workers in article number 1700963.