Synthesis and Effects of Copolymers Polymerized via RAFT Polymerization on the Mechanical Properties of Epoxy Resin Composites

Yejin Heo

Center for Specialty Chemicals, Korea Research Institute of Chemical Technology, Ulsan, Republic of Korea

Department of Polymer Science and Engineering, Pusan National University, Busan, Republic of Korea

Search for more papers by this authorHyejin Kim

Center for Specialty Chemicals, Korea Research Institute of Chemical Technology, Ulsan, Republic of Korea

Search for more papers by this authorSeoyoon Yu

Center for Specialty Chemicals, Korea Research Institute of Chemical Technology, Ulsan, Republic of Korea

Search for more papers by this authorHyeon-Gook Kim

Center for Specialty Chemicals, Korea Research Institute of Chemical Technology, Ulsan, Republic of Korea

Search for more papers by this authorNamju Jo

Department of Polymer Science and Engineering, Pusan National University, Busan, Republic of Korea

Search for more papers by this authorJong-Hyun Kim

Research Institute for Green Energy Convergence Technology, Gyeongsang National University, Jinju, Republic of Korea

Search for more papers by this authorCorresponding Author

Bongkuk Seo

Center for Specialty Chemicals, Korea Research Institute of Chemical Technology, Ulsan, Republic of Korea

Correspondence:

Bongkuk Seo ([email protected])

Choong-Sun Lim ([email protected])

Search for more papers by this authorCorresponding Author

Choong-Sun Lim

Center for Specialty Chemicals, Korea Research Institute of Chemical Technology, Ulsan, Republic of Korea

Correspondence:

Bongkuk Seo ([email protected])

Choong-Sun Lim ([email protected])

Search for more papers by this authorYejin Heo

Center for Specialty Chemicals, Korea Research Institute of Chemical Technology, Ulsan, Republic of Korea

Department of Polymer Science and Engineering, Pusan National University, Busan, Republic of Korea

Search for more papers by this authorHyejin Kim

Center for Specialty Chemicals, Korea Research Institute of Chemical Technology, Ulsan, Republic of Korea

Search for more papers by this authorSeoyoon Yu

Center for Specialty Chemicals, Korea Research Institute of Chemical Technology, Ulsan, Republic of Korea

Search for more papers by this authorHyeon-Gook Kim

Center for Specialty Chemicals, Korea Research Institute of Chemical Technology, Ulsan, Republic of Korea

Search for more papers by this authorNamju Jo

Department of Polymer Science and Engineering, Pusan National University, Busan, Republic of Korea

Search for more papers by this authorJong-Hyun Kim

Research Institute for Green Energy Convergence Technology, Gyeongsang National University, Jinju, Republic of Korea

Search for more papers by this authorCorresponding Author

Bongkuk Seo

Center for Specialty Chemicals, Korea Research Institute of Chemical Technology, Ulsan, Republic of Korea

Correspondence:

Bongkuk Seo ([email protected])

Choong-Sun Lim ([email protected])

Search for more papers by this authorCorresponding Author

Choong-Sun Lim

Center for Specialty Chemicals, Korea Research Institute of Chemical Technology, Ulsan, Republic of Korea

Correspondence:

Bongkuk Seo ([email protected])

Choong-Sun Lim ([email protected])

Search for more papers by this authorFunding: This work was supported by the KRICT, KS2541-10.

ABSTRACT

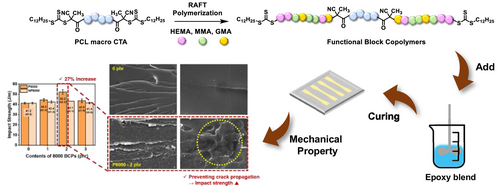

Epoxy resins are used in various industries because of their excellent physical and chemical properties. However, they exhibit low toughness, which is attributed to the high crosslinking density of the epoxy matrix. Controlling the crosslinking reaction is challenging. In this study, functional copolymers are used as additives to overcome these limitations. We combine 2-hydroxyethyl methacrylate, methyl methacrylate, and glycidyl methacrylate with polycaprolactone macro-CTA via RAFT polymerization. Four types of functional copolymers are polymerized by varying the molecular weight of the main chain and the ratio of the synthesized functional monomers, and successful polymerization was confirmed by 1H-nuclear magnetic resonance spectroscopy (NMR) and gel permeation chromatography (GPC). The tensile, flexural, and impact strengths are measured to evaluate the effect of these functional copolymers on performance enhancement. As a result, the mechanical properties are improved, and the reductions in Tg and modulus are minimized. Furthermore, FE-SEM image analysis of the cured epoxy resin fracture surface reveals a smooth transition to a rough surface, verifying the enhanced mechanical properties of the epoxy resin.

Graphical Abstract

Conflicts of Interest

The authors declare no conflicts of interest.

References

- 1 C. May, ed., Epoxy Resins: Chemistry and Technology (Routledge, 2018).

10.1201/9780203756713 Google Scholar

- 2Y. Du, G. Zhao, G. Shi, Y. Wang, W. Li, and S. Ren, “Effect of Crosslink Structure on Mechanical Properties, Thermal Stability and Flame Retardancy of Natural Flavonoid Based Epoxy Resins,” European Polymer Journal 162 (2022): 110898, https://doi.org/10.1016/j.eurpolymj.2021.110898.

- 3T. Shiraishi, H. Motobe, M. Ochi, Y. Nakanishi, and I. Konishi, “Effect of Network Structure on Thermal and Mechanical Properties of Cured Epoxide Resins,” Polymer 33, no. 14 (1992): 2975–2980, https://doi.org/10.1016/0032-3861(92)90084-A.

- 4H. Q. Pham and M. J. Marks, “ Epoxy Resins,” in Ullmann's Encyclopedia of Industrial Chemistry (Ullmann's encyclopedia of industrial chemistry, 2000).

- 5S. G. Prolongo, G. del Rosario, and A. Ureña, “Comparative Study on the Adhesive Properties of Different Epoxy Resins,” International Journal of Adhesion and Adhesives 26, no. 3 (2006): 125–132, https://doi.org/10.1016/j.ijadhadh.2005.02.004.

- 6A. Baldan, “Adhesively-Bonded Joints and Repairs in Metallic Alloys, Polymers and Composite Materials: Adhesives, Adhesion Theories and Surface Pretreatment,” Journal of Materials Science 39 (2004): 1–49, https://doi.org/10.1023/B:JMSC.0000007726.58758.e4.

- 7S. A. Bello, J. O. Agunsoye, S. B. Hassan, M. G. Zebase Kana, and I. A. Raheem, “Epoxy Resin Based Composites, Mechanical and Tribological Properties: A Review,” Tribology in Industry 37 (2015): 500.

- 8Y. Lin, X. Huang, J. Chen, and P. Jiang, “Epoxy Thermoset Resins With High Pristine Thermal Conductivity,” High Voltage 2, no. 3 (2017): 139–146, https://doi.org/10.1049/hve.2017.0120.

- 9J. C. Huang, Y. P. Chu, M. Wei, and R. D. Deanin, “Comparison of Epoxy Resins for Applications in Light-Emitting Diodes,” Advances in Polymer Technology 23, no. 4 (2004): 298–306, https://doi.org/10.1002/adv.20018.

- 10A. Toldy, B. Szolnoki, and G. Marosi, “Flame Retardancy of Fibre-Reinforced Epoxy Resin Composites for Aerospace Applications,” Polymer Degradation and Stability 96, no. 3 (2011): 371–376, https://doi.org/10.1016/j.polymdegradstab.2010.03.021.

- 11L. Guadagno, M. Raimondo, V. Vittoria, et al., “Development of Epoxy Mixtures for Application in Aeronautics and Aerospace,” RSC Advances 4, no. 30 (2014): 15474–15488, https://doi.org/10.1039/C3RA48031C.

- 12J. Ke, X. Li, S. Jiang, et al., “Critical Transition of Epoxy Resin From Brittleness to Toughness by Incorporating CO2-Sourced Cyclic Carbonate,” Journal of CO2 Utilization 26 (2018): 302–313, https://doi.org/10.1016/j.jcou.2018.05.020.

- 13N. Tian, R. Ning, and J. Kong, “Self-Toughening of Epoxy Resin Through Controlling Topology of Cross-Linked Networks,” Polymer 99 (2016): 376–385, https://doi.org/10.1016/j.polymer.2016.07.038.

- 14D. Ratna and A. K. Banthia, “Rubber Toughened Epoxy,” Macromolecular Research 12, no. 1 (2004): 11–21, https://doi.org/10.1007/BF03218989.

- 15H. Zhou and S. Xu, “A New Method to Prepare Rubber Toughened Epoxy With High Modulus and High Impact Strength,” Materials Letters 121 (2014): 238–240, https://doi.org/10.1016/j.matlet.2014.01.160.

- 16N. Ning, W. Liu, Q. Hu, et al., “Impressive Epoxy Toughening by a Structure-Engineered Core/Shell Polymer Nanoparticle,” Composites Science and Technology 199 (2020): 108364, https://doi.org/10.1016/j.compscitech.2020.108364.

- 17G. Giannakopoulos, K. Masania, and A. C. Taylor, “Toughening of Epoxy Using Core–Shell Particles,” Journal of Materials Science 46, no. 2 (2011): 327–338, https://doi.org/10.1007/s10853-010-4816-6.

- 18S. Liu, X. Fan, and C. He, “Improving the Fracture Toughness of Epoxy With Nanosilica-Rubber Core-Shell Nanoparticles,” Composites Science and Technology 125 (2016): 132–140, https://doi.org/10.1016/j.compscitech.2016.01.009.

- 19R. P. Singh, M. Zhang, and D. Chan, “Toughening of a Brittle Thermosetting Polymer: Effects of Reinforcement Particle Size and Volume Fraction,” Journal of Materials Science 37 (2002): 781–788, https://doi.org/10.1023/A:1013844015493.

- 20H. Harani, S. Fellahi, and M. Bakar, “Toughening of Epoxy Resin Using Synthesized Polyurethane Prepolymer Based on Hydroxyl-Terminated Polyesters,” Journal of Applied Polymer Science 70 (1998): 2603–2618, https://doi.org/10.1002/(SICI)1097-4628(19981226)70:13<2603::AID-APP6>3.0.CO;2-4.

- 21J. Zhang, S. Deng, Y. Wang, and L. Ye, “Role of Rigid Nanoparticles and CTBN Rubber in the Toughening of Epoxies With Different Cross-Linking Densities,” Composites Part A Applied Science and Manufacturing 80 (2016): 82–94, https://doi.org/10.1016/j.compositesa.2015.10.017.

- 22J. Long, C. Li, and Y. Li, “Enhancement of Mechanical and Bond Properties of Epoxy Adhesives Modified by SiO2 Nanoparticles With Active Groups,” Polymers 14, no. 10 (2022): 2052, https://doi.org/10.3390/polym14102052.

- 23L. Tao, Z. Sun, W. Min, H. Ou, L. Qi, and M. Yu, “Improving the Toughness of Thermosetting Epoxy Resins via Blending Triblock Copolymers,” RSC Advances 10 (2020): 1603–1612, https://doi.org/10.1039/c9ra09183a.

- 24L. Wang, J. Zhou, H. Zhang, et al., “Nanostructure Transformation in Epoxy/Block Copolymer Composites With Good Mechanical Properties,” Reactive and Functional Polymers 176 (2022): 105299, https://doi.org/10.1016/j.reactfunctpolym.2022.105299.

- 25S. Ma, W. Liu, C. Hu, Z. Wang, and C. Tang, “Toughening of Epoxy Resin System Using a Novel Dendritic Polysiloxane,” Macromolecular Research 18, no. 4 (2010): 392–398, https://doi.org/10.1007/s13233-010-0408-1.

- 26L. Luo, Y. Meng, T. Qiu, and X. Li, “An Epoxy-Ended Hyperbranched Polymer as a New Modifier for Toughening and Reinforcing in Epoxy Resin,” Journal of Applied Polymer Science 130, no. 2 (2013): 1064–1073, https://doi.org/10.1002/app.39257.

- 27V. Pang, Z. J. Thompson, G. D. Joly, F. S. Bates, and L. F. Francis, “Adhesion of Silica and Block Copolymer Toughened Epoxy Composites,” ACS Applied Polymer Materials 4, no. 8 (2022): 6169–6178, https://doi.org/10.1021/acsapm.2c00948.

10.1021/acsapm.2c00948 Google Scholar

- 28T. Li, M. J. Heinzer, L. F. Francis, and F. S. Bates, “Engineering Superior Toughness in Commercially Viable Block Copolymer Modified Epoxy Resin,” Journal of Polymer Science Part B: Polymer Physics 54, no. 2 (2016): 189–204, https://doi.org/10.1002/polb.23894.

- 29J. Liu, Z. J. Thompson, H. J. Sue, et al., “Toughening of Epoxies With Block Copolymer Micelles of Wormlike Morphology,” Macromolecules 43, no. 17 (2010): 7238–7243, https://doi.org/10.1021/ma902471g.

- 30K. S. Anderson and M. A. Hillmyer, “The Influence of Block Copolymer Microstructure on the Toughness of Compatibilized Polylactide/Polyethylene Blends,” Polymer 45, no. 26 (2004): 8809–8823, https://doi.org/10.1016/j.polymer.2004.10.047.

- 31C. Declet-Perez, E. M. Redline, L. F. Francis, and F. S. Bates, “Role of Localized Network Damage in Block Copolymer Toughened Epoxies,” ACS Macro Letters 1, no. 2 (2012): 338–342, https://doi.org/10.1021/mz200219y.

- 32M. Larrañaga, P. Arruti, E. Serrano, et al., “Towards Microphase Separation in Epoxy Systems Containing PEO/PPO/PEO Block Copolymers by Controlling Cure Conditions and Molar Ratios Between Blocks. Part 2. Structural Characterization,” Colloid & Polymer Science 284, no. 12 (2006): 1419–1430, https://doi.org/10.1007/s00396-006-1515-6.

- 33R. Yu, S. Zheng, X. Li, and J. Wang, “Reaction-Induced Microphase Separation in Epoxy Thermosets Containing Block Copolymers Composed of Polystyrene and Poly(ε-Caprolactone): Influence of Copolymer Architectures on Formation of Nanophases,” Macromolecules 45, no. 22 (2012): 9155–9168, https://doi.org/10.1021/ma3017212.

- 34A. Klingler and B. Wetzel, “Fatigue Crack Propagation in Triblock Copolymer Toughened Epoxy Nanocomposites,” Polymer Engineering and Science 57, no. 6 (2017): 579–587, https://doi.org/10.1002/pen.24558.

- 35J. J. P. Pereira Barros, I. D. d. S. Silva, N. G. Jaques, M. V. L. Fook, and R. M. Ramos Wellen, “Influence of PCL on the Epoxy Workability, Insights From Thermal and Spectroscopic Analyses,” Polymer Testing 89 (2020): 106679, https://doi.org/10.1016/j.polymertesting.2020.106679.

- 36M. S. A. Bhuiyan, K. Wang, F. Razaviamria, and B. P. Lee, “Salicylhydroxamic Acid Containing Structural Adhesive,” RSC Applied Polymers 2, no. 5 (2024): 838–846, https://doi.org/10.1039/D4LP00139G.

- 37G. Moad, Y. K. Chong, A. Postma, E. Rizzardo, and S. H. Thang, “Advances in RAFT Polymerization: The Synthesis of Polymers With Defined End-Groups,” Polymer 46, no. 19 (2005): 8458–8468, https://doi.org/10.1016/j.polymer.2004.12.061.

- 38G. E. Dieter and D. Bacon, Mechanical Metallurgy, vol. 3 (McGraw-Hill, 1976).

Online Version of Record before inclusion in an issue