24.58% efficient commercial n-type silicon solar cells with hydrogenation

Ran Chen and Matthew Wright contributed equally to this work.

Funding information: Australian Renewable Energy Agency (ARENA), Grant/Award Number: 2017/RND003

Abstract

Tunnelling oxide passivated contact (TOPCon) solar cells are gaining significant commercial interest, due to the potential for high efficiency. Industrially, this passivated contact scheme is typically coupled with an n-type Czochralski (Cz) wafer. JinkoSolar Holding Co., Ltd. is one of the leading manufacturers that are producing n-type TOPCon solar cells (referred to as ‘HOT’ cells) on a commercial scale. In this work, the influence of a post-cell hydrogenation step, using illumination from an LED light source, on the performance and stability of n-type TOPCon solar cells is investigated. The incorporation of this additional hydrogenation treatment led to an average efficiency enhancement of 0.64%abs on a batch of 50 cells made in an industrial environment. This significant improvement was caused by a 6.9 mV and 1.04%abs increase in open-circuit voltage (VOC) and fill factor (FF), respectively. We also assessed the stability and found almost no light- and elevated temperature-induced degradation (LeTID) in hydrogenated n-type TOPCon cells. Testing at 70 ± 5°C under 1-sun illumination revealed that the maximum degradation is limited to 0.06%rel. Following further stability testing, the efficiency increased beyond the initial value, up to 0.4%rel increase after 120 h. By incorporating this hydrogenation process into the production, an average line efficiency of 24.08% and VOC of 707.5 mV was achieved. The champion cell from the batch displayed an efficiency of 24.58%, as certified by measurement at the Chinese Academy of Sciences.

1 INTRODUCTION

The silicon solar cell market is currently dominated by passivated emitter and rear cell (PERC) solar cells.1 This is due to the relatively low cost and high-efficiency potential for PERC cells in commercial manufacturing. The past 5 years have seen impressive increases in the efficiency of PERC solar cells in mass production, with efficiencies now approaching 24%.2 These advancements mean that PERC solar cells are rapidly approaching the upper practical limit of achievable efficiency for that cell architecture.3, 4 Additionally, the PERC design uses p-type silicon wafers, which are susceptible to light-induced degradation (LID) caused by boron–oxygen (BO) defects.5, 6 This degradation can be mitigated by using hydrogen to passivate BO defects; the incorporation of a hydrogenation step is widely used for commercial production of p-type PERC solar cells. Due to the fast-approaching efficiency threshold and BO LID, it is important to investigate alternative single-junction silicon solar cell architectures that may replace PERC. Of these, the two leading approaches are silicon heterojunction (SHJ)7-9 and tunnelling oxide passivated contact (TOPCon) solar cells.10-12 Both of these technologies typically use n-type silicon wafers, doped with phosphorus, rather than the p-type wafers commonly used in PERC cells. The TOPCon approach appears to be particularly promising due to multiple factors: (i) the efficiency potential is higher than PERC due to the excellent rear-side passivation, (ii) the n-type Czochralski (Cz) wafers used are not susceptible to BO LID and are less sensitive to recombination caused by interstitial iron and (iii) the production cost is less than for SHJ cells. Due to these factors, n-type TOPCon solar cells are gaining significant interest as a potential technology to replace PERC. Although n-type TOPCon solar cells do not suffer BO LID, several reports have shown the presence of light- and elevated temperature-induced degradation (LeTID) in n-type wafers.13-15 Additionally, several studies have also demonstrated a firing-induced degradation in the tunnelling oxide/doped polysilicon passivation scheme employed in TOPCon solar cells.16, 17

The incorporation of a hydrogenation step is critical to achieve the required chemical passivation for the tunnelling oxide, polysilicon contact.18 The chemical passivation at the SiO2/c-Si interface is typically achieved by high-temperature annealing in the presence of a hydrogenated dielectric layer.19 During this process, hydrogen can diffuse from the dielectric layer to the SiO2/c-Si interface, where it passivates interfacial defects. This can also be achieved with a forming gas anneal (FGA)18; however, Lehmann et al. showed that this is less effective than firing in the presence of a hydrogen-containing dielectric.20 As such, this hydrogenation step is incorporated into the TOPCon process flow during the high-temperature firing for metal contact formation. This is also the case for PERC solar cells, where high-temperature firing allows hydrogen to move from the dielectric layers to passivate both bulk and surface defects.21, 22 In p-type PERC solar cells, it is typical to also include a secondary dedicated hydrogenation step on the cell after metallisation. This approach is often referred to as an ‘advanced hydrogenation process’ and involves carrier injection, either via illumination or direct current injection.15 Modulating the carrier density and temperature can alter the charge state of hydrogen in silicon.15 This alteration of the charge state can vastly impact its ability to passivate defects. In PERC cells, the addition of such a process can have the dual impact of increasing the efficiency and improving the stability.2, 22, 23 Although extensive work over the past 10 years has led to the development of hydrogenation processes in p-type technologies,24, 25 far less studies have explored the potential benefits of incorporating hydrogenation processes into the production of high-efficiency n-type passivated contact solar cells.26

In this report, the impact of a post-cell hydrogenation process on the performance of n-type TOPCon solar cells fabricated at JinkoSolar is explored. The hydrogenation process was developed at UNSW23 and is incorporated into the production of n-type TOPCon ‘HOT’ solar cells in a fully industrial environment at JinkoSolar. Herein, we detail the impact of the hydrogenation on the performance and degradation properties of HOT solar cells and display the average and champion cell efficiency data for cells incorporating this hydrogenation process.

2 METHODOLOGY

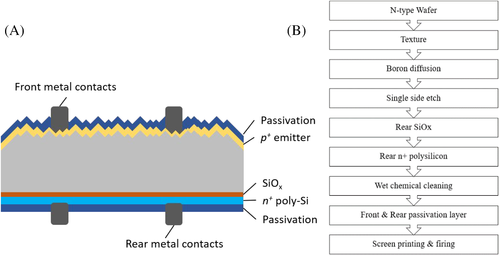

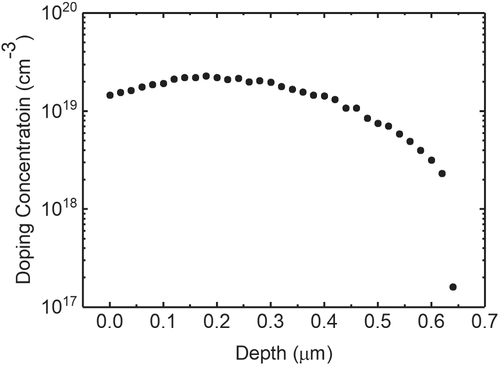

JinkoSolar's HOT cell structure is shown in Figure 1A and is fabricated at JinkoSolar's R&D centre according to the flow chart shown in Figure 1B. The starting wafer is an in-house monocrystalline Cz grown 251.99-cm2 n-type silicon wafer. Wafers are diamond wire cut and pyramid textured using an alkaline texturing solution. A high-efficiency boron-doped emitter is formed using a tube diffusion system using a BBr3 source. The optimised front emitter has a doping profile as shown in Figure 2, for a sheet resistance of 90–100 Ω/ϒ and front p+ emitter saturation current density of J0,front = 14–15 fA/cm2. The doping profile was measured using electrochemical capacitance voltage (ECV). After rear etch, a 1.3-nm SiOx tunnelling oxide is thermally grown on the rear using a thermal oxidation furnace. A 150-nm intrinsic amorphous silicon (a-Si) layer is initially deposited by low-pressure chemical vapour deposition (LPCVD), followed by crystallisation and phosphorus doping in a tube furnace to form a 150-nm n+ polysilicon. The doping concentration in the n+ polysilicon layer was approximately 1 × 1020 cm−3. Both the front and rear are passivated with a stack of ALD-deposited Al2O3 and PECVD-deposited hydrogenated SiNx layers; the front side layer(s) are designed for excellent antireflection. Front silver/aluminium and rear silver contacts are screen printed with nine front busbars. Cells are fired in a belt furnace to form the contacts, which also simultaneously allows hydrogen to diffuse throughout the bulk of the silicon. Cells then undergo a hydrogenation treatment after firing using 30 suns equivalent from an LED light source and heated to 400–600°C in a chamber for ~1 min. This allows hydrogen to bond to dangling bonds and defects increasing the efficiency, as well as clearing out any excess hydrogen that may otherwise cause degradation.23, 27-29 Cells before and after this hydrogenation treatment are investigated in Section 3.1 to demonstrate the importance of this step. LeTID testing of cells is performed at 70 ± 5°C under ~1-sun illumination for 160 h. The champion cell efficiency was measured at the Chinese Academy of Sciences. The sample was contacted with metal probes on the front busbars and a reflective metal chuck on the rear.

3 RESULTS AND DISCUSSION

3.1 Hydrogenated n-type cells and wafers

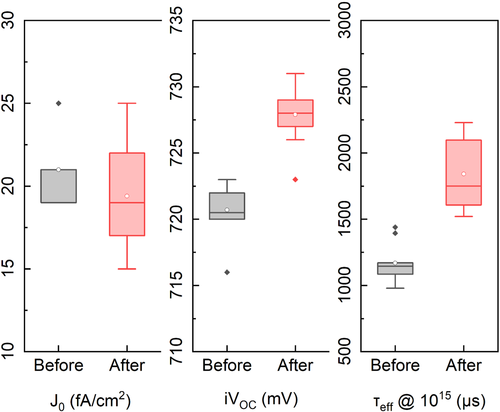

First, to assess the impact of the hydrogenation step on the quality of the TOPCon structure, lifetime structures processed identically to the HOT solar cells but without the screen printing of the metal contacts were measured before and after hydrogenation. The effective lifetime (τeff), saturation current density attributed to the surfaces (J0) and implied VOC (iVOC) values are plotted in Figure 3. The average lifetime improves by more than 50%, from 1.17 to 1.84 ms. As shown in Figure 3, the average J0 decreases slightly from 21 to 19.4 fA/cm2; however, due to wide, overlapping distributions, it is not possible to attribute a statistically significant improvement in surface passivation. This implies that the hydrogenation process is primarily influencing recombination in the bulk of the silicon. Overall, the hydrogenation process leads to an improvement in iVOC of >7 mV, from 720.7 mV before hydrogenation to 727.9 mV. These improvements indicate enhanced bulk passivation and slight surface improvement from the dedicated hydrogenation process, above and beyond the hydrogenation that occurs during the firing process.

JinkoSolar's HOT cells have also undergone hydrogenation treatments to control the hydrogen for enhanced passivation, as well as to mitigate LeTID.27-29 The average of 50 cells' VOC, JSC, fill factor (FF), pseudo-fill factor (pFF) and RS before and after the hydrogenation process is shown in Table 1. The average VOC improves from 696 to 703 mV, and the average FF increases from 82.03% to 83.07%, leading to 0.64%abs average efficiency gain from 23.51% to 24.15%. This increase in FF is very significant. Table 1 shows that the RS reduces slightly following hydrogenation, a reduction of 0.03 Ω·cm2. This corresponds to a relative reduction of 9%. However, this cannot completely explain the observed boost in FF. The pFF is shown to increase by almost 1%abs, indicating that the hydrogenation process is also modulating some other recombination process. This batch of cells was produced specifically to study the impact of hydrogenation, prior to (or in parallel with) optimisation of other processes that in combination led to the results of the following sections.

| VOC (mV) | JSC (mA/cm2) | FF (%) | pFF (%) | RS (Ω·cm2) | Efficiency (%) | |

|---|---|---|---|---|---|---|

| Before | 696.3 | 41.15 | 82.03 | 83.36 | 0.34 | 23.51 |

| After | 703.2 | 41.35 | 83.07 | 84.35 | 0.31 | 24.15 |

| Difference | 6.9 | 0.20 | 1.04 | 0.99 | −0.03 | 0.64 |

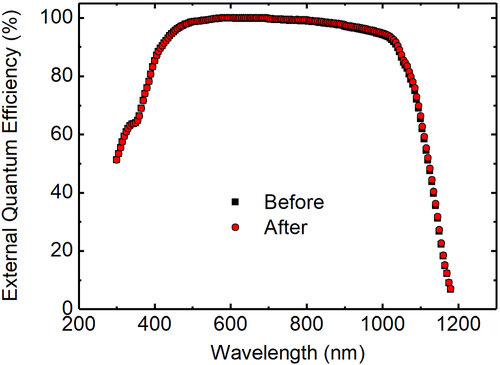

The hydrogenation seems to have almost no impact on the JSC of the HOT cells. Figure 4 displays the external quantum efficiency (EQE) curve for a representative cell before and after hydrogenation. This confirms that the hydrogenation process has little impact on the photocurrent generation. By integrating the EQE with the AM 1.5G spectrum, the calculated JSC for the cell after hydrogenation was 41.89 mA/cm2. This is close to the average batch JSC of 41.35 mA/cm2, which represents a discrepancy of only 1.3%.

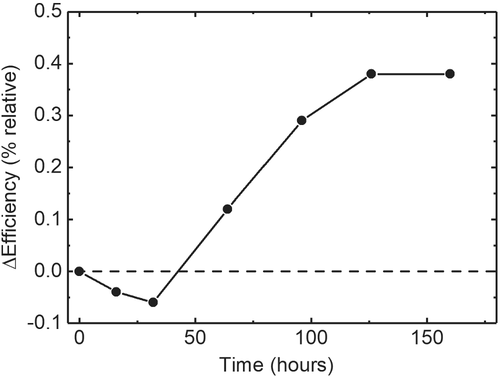

Cell efficiency stability due to testing using typical LeTID conditions (70 ± 5°C under 1-sun illumination30) is shown in Figure 5. A maximum degradation of ~0.06%rel occurs after 32 h. Continued testing sees cells improve to above their starting efficiency by ~0.4%rel (~0.1%abs) within 126 h, likely due to improved hydrogen passivation of defects and dangling bonds and release of any excess problematic hydrogen.15

3.2 Batch performance

The hydrogenation processed explored in 3.1 was then incorporated into cells produced in the production line. Table 2 shows the average cell performance for a large batch of cells from JinkoSolar's HOT production line with the structure shown in Figure 1.

| VOC (mV) | JSC (mA/cm2) | FF (%) | Efficiency (%) | RS (Ω·cm2) | RSH (Ω) |

|---|---|---|---|---|---|

| 707.5 | 41.95 | 82.9 | 24.08 | 0.28 | 2000 |

3.3 Champion cell

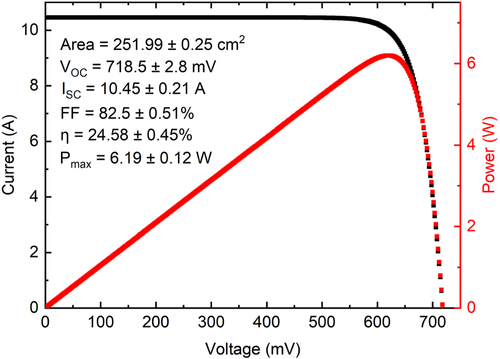

The champion cell for the batch in the previous section of JinkoSolar's n-type passivated contact HOT cell was 24.58% as independently confirmed by the Chinese Academy of Sciences; the I–V and P–V curves are shown in Figure 6. Key parameters to note are a 718.5-mV open circuit voltage (VOC), 10.45-A (or 41.47 mA/cm2) short-circuit current (ISC) and a FF of 82.5%.

4 CONCLUSION

In this report, we show the impact of a post-cell hydrogenation process on the performance and stability of industrially fabricated n-type TOPCon solar cells. The hydrogenation process was developed at UNSW and involves the illumination of the cells using an LED source at temperatures in the range of 400–600°C. This approach was transferred to production of n-type TOPCon solar cells at JinkoSolar Holding Co. Progressive optimisation of in-house grown wafers, high-efficiency boron emitter, SiOx tunnelling oxide, n+ polysilicon and hydrogenated Al2O3 and SiNx layers for passivation (and antireflection on the front) have seen impressive increases in the efficiency of TOPCon cells made at JinkoSolar. First, we show that the hydrogenation process leads to an average efficiency enhancement of 0.64%abs. This improvement was related to an increase in both VOC and FF. Additionally, cells following the hydrogenation displayed almost no LeTID, with a peak degradation of only 0.06%rel. When this hydrogenation step was incorporated into Jinko Solar HOT production line, an average batch efficiency of 24.08% was achieved. The champion cell in this batch displayed an efficiency as high as 24.58%, as measured by the Chinese Academy of Sciences. The VOC for this champion cell was 718.5 mV. This result highlights the potential for incorporating an additional hydrogenation process following firing for the manufacture of commercial n-type TOPCon solar cells.

ACKNOWLEDGEMENT

This work has been supported by the Australian Renewable Energy Agency (ARENA) (2017/RND003). The views expressed herein are not necessarily the views of the Australian Government, and the Australian Government does not accept responsibility for any information or advice contained herein.

Open Research

DATA AVAILABILITY STATEMENT

The data that support the findings of this study are available on request from the corresponding author. The data are not publicly available due to privacy or ethical restrictions.