Electrospun Membranes of Poly(butylene succinate) and Poly(butylene/2-butyl,2-ethyl-propylene succinate)

Abstract

Poly(butylene succinate) (PBS) and poly(butylene/2-butyl,2-ethyl-propylene succinate) (PBSBEPS) membranes are prepared by electrospinning technique. In recent years, interest in biodegradable aliphatic polyesters, including PBS and its copolymers, is increasing as they have potential applications in various sectors such as mulching films, food packaging, tissue engineering, and drug delivery. In this work, the synthesized polymers are dissolved in different solvents, namely acetone, chloroform (CHCl3), methanol, dichloromethane (DCM), and dimethylformamide in order to obtain the best solvent system. These solutions are then electrospun at room temperature to produce micron-sized fibers. The variables examined in determining the optimal solution and electrospinning conditions are the solvent system used, the concentration of PBS and PBS-based random copolymer, applied voltage, flow rate, humidity, and the distance between the needle tip and the collector, all of which have a meaningful effect on the fiber morphology. Among the various solvents used, the DCM and the less toxic CHCl3 result in fewer bead defects among fibers. Besides, an increase in PBS and PBS-based random copolymer concentration determines the reduction of bead defects, which from 12 to 14 wt% results in bead-free uniform fibers, when suitable processing parameters are set. Promising results, which can pave the way for the production of membranes loaded with appropriate anticancer molecules for targeted biomedical applications, are obtained.

1 Introduction

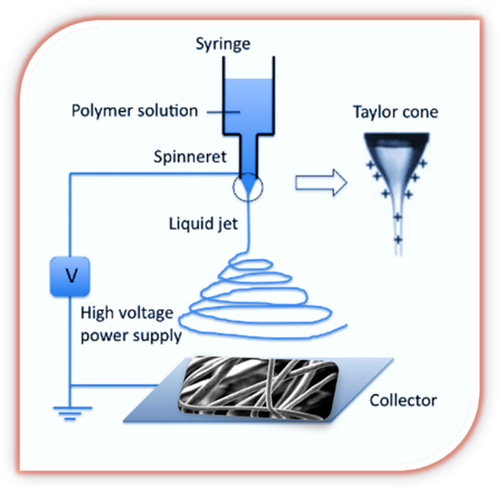

To solve the problems caused by plastic waste, many efforts have been done to obtain an environmental friendly material.[1] In a reality where global levels of carbon dioxide increase considerably and production of huge quantities of plastic waste is generated, biodegradable aliphatic polyesters,[2-4] including poly(butylene succinate) (PBS) and its copolymers, are becoming increasingly important and popular in various sectors such as food packaging, pharmaceutical, and biomedical applications.[5-8] In particular, these polymers are ideal for biomedical applications[9] concerning implant devices, tissue scaffolds, and wound dressings because of their biodegradability, biocompatibility, and high capacity for drug loading.[5] Electrospinning is a versatile and appealing technology for the production of ultrafine nano or microfibers with the diameter ranging from a few micrometers to sub-nanometers by applying an electrostatic field to a polymer solution, driven by the supply of high voltage between a needle tip and a collector.[10-14] The polymer jet is formed when an applied electrostatic charge overcomes the surface tension of the solution. The polymer or filler solution protrudes from the syringe needle under sufficient electric field to generate the Taylor cone, which lands on the appropriate ground collector at a suitable distance, to produce the resultant membrane, as shown in Figure 1. Although this technique is very popular and highly studied and a variety of polymers are electrospun nowadays and the nanofibers from these electrospun polymer solutions have been used in various applications; however, the electrospinnability of poly(butylene/2-butyl,2-ethyl-propylene succinate) (PBSBEPS) has been never investigated to date. PBS has been previously electrospun,[15-17] but in the present work a sample of PBS is again subjected to investigation for sake of comparison. For medical applications, it is important for fiber to be without beads because fiber diameters need to mimic the natural extracellular morphology and, thus promote optimal cell growth.

The copolyester under study contains alkyl side groups, randomly distributed along the linear main chain, thus contributing to increase the material flexibility, reducing the crystallizing macromolecular chain ability.[6] In fact, it is well known that PBS has a high stiffness, which hinders its use in the field of soft tissue engineering, due to its high crystallinity degree. In this regard, it is worth noting that copolymerization with a glycol containing enough long side alkyl groups could represent an efficient tool to improve the mechanical properties.[6] Specifically, in this paper, various spinning parameters like polymer concentration, applied voltage, tip to collector distance, and flow rate were effectively adjusted to avoid bead formation and to get fibers with uniform diameter. In fact, this work proves the effectiveness of electrospinning technique to obtain mats composed of uniform fibers with the synthesized polymers. Summing-up, the results here obtained prove that electrospun membranes of PBS and P(BS70BEPS30) can be ideal candidates for targeted biomedical applications.

2 Experimental Section

2.1 Materials

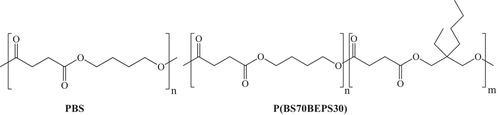

The electrospun membranes were prepared using a biodegradable aliphatic polyester PBS and a PBS-based random copolymer, namely P(BS70BEPS30), containing two different glycol subunits: 70 mol% butylene and 30 mol% 2-butyl,2-ethyl-propylene. Both polyesters were synthesized through solvent free bulk polycondensation process. PBS was prepared from dimethyl succinate (DMS) and 1,4-butanediol (BD), while P(BS70BEPS30)) random copolymer was prepared starting from DMS together with BD (70 mol%) and 2-butyl-2-ethyl propanediol (30 mol%). For the preparation of these synthetic polymers, glycols 20 mol% excess with respect to diester content was used.[6] Figure 2 shows the chemical structures of PBS and P(BS70BEPS30). Both materials were obtained with high molecular weight.[6] To carry out solubility tests with the aim of identifying an efficacious solvent system for the electrospinning of PBS and P(BS70BEPS30) thus leading to obtaining bead-free nanofibers, different solvents (acetone, chloroform [CHCl3], methanol, dichloromethane [DCM], and dimethylformamide), all purchased from Sigma–Aldrich (Italy), were utilized without additional purifications.

2.2 Methods

2.2.1 Electrospinning Procedure

Various polymeric solutions have been prepared considering lower concentrations of PBS and P(BS70BEPS30) until the best concentration range (from 12% to 14% w/w) was found to obtain optimized morphological parameters of the nanofibers in the membranes. PBS and P(BS70BEPS30) were dissolved at 40°C under magnetic stirring for about 2 h in the CHCl3 and DCM solvents, which were found, through solubility tests, to be the most suitable. Before the dissolution in DCM and CHCl3, PBS and P(BS70BEPS30) powders were previously milled in the solid-state in a Retsch (Germany) centrifugal ball mill (model PM100). The milling process was carried out in a cylindrical steel jar of 50 cm3 with five steel balls of 10 mm of diameter. The rotation speed used was 560 rpm and the milling time was fixed to 60 min. The spinning mixed solutions were positioned into a 5 mL plastic syringe. An electrode lead of a high voltage power supply (HV Power Supply, Gamma High Voltage Research, Ormond, FL) was connected to the needle tip (internal diameter 0.84 mm) of the syringe. A constant positive DC voltage potential was fixed at the following different values: 11, 16, 21, and 25 kV. For collecting of the fibrous mats, aluminum plates of 10 × 10 mm2 were placed on a grounded aluminum collector. The distance between the needle tip and the collector was selected from 10 to 20 cm. A syringe pump (NE-1000 Programmable Single Syringe Pump, New Era Pump Systems Inc., NY) was used to feed the needle with polymer solution at a volumetric flow rate of 1 up to 2 mL h−1. The solutions were electrospun in a closed chamber, where the temperature was controlled at 24°C and the relative humidity (r.h.) at 35%.

2.2.2 Morphological Characterization

Micrographs of the electrospun membranes were obtained using Field Emission Scanning Electron Microscope (FESEM) (mod. Zeiss EVO MA10, Carl Zeiss SMT AG, Oberkochen, Germany) after gold coating.

3 Results and Discussion

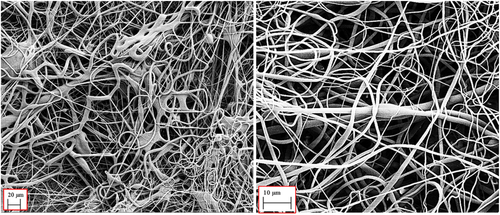

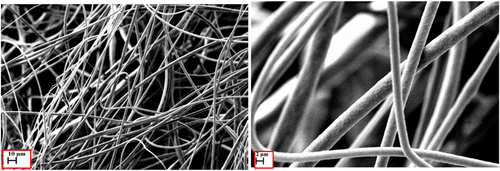

Figure 3 shows FESEM micrographs of PBS (12 wt%)/CHCl3 solution (electrospinning conditions: 10 cm, 11 kV/−4 kV, 1 mL h−1, 0.84 mm ø, 24°C, 35% r.h., t = 15 min) (see on the left), and PBS(14wt%)/CHCl3 solution (electrospinning conditions: 10 cm, 16 kV/−4 kV, 2 mL h−1, 0.84 mm ø, 24°C, 35% r.h., t = 10 min) (see on the right). Figure 4 shows FESEM micrographs of PBS(12wt%)/CHCl3 solution (electrospinning conditions: 10 cm, 25 kV/−4 kV, 1 mL h−1, 0.84 mm ø, 24°C, 35% r.h., t = 15 min) (see on the left), and PBS(12wt%)/CHCl3 solution (electrospinning conditions: 10 cm, 21 kV/−4 kV, 1 mL h−1, 0.84 mm ø, 24°C, 35% r.h., t = 1h) (see on the right).

Figure 5 shows FESEM micrographs of PBS (12 wt%)/DCM solution (electrospinning conditions: 10 cm, 11 kV/−4 kV, 1 mL h−1, 0.84 mm ø, 24°C, 35% r.h., t = 10 min).

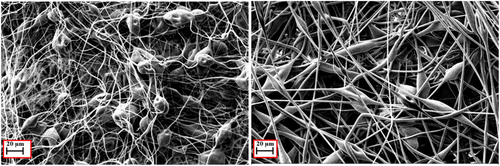

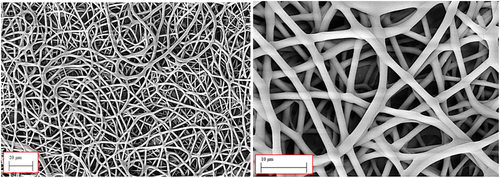

Figure 6 shows FESEM micrographs of P(BS70BEPS30) (12 wt%)/CHCl3 solution (electrospinning conditions: 10 cm, 21 kV/−4 kV, 1 mL h−1, 0.84 mm ø, 24°C, 35% r.h., t = 30 min).

Figure 7 shows FESEM micrographs of P(BS70BEPS30) (14 wt%)/CHCl3 solution (electrospinning conditions: 20 cm, 25 kV/−4 kV, 1 mL h−1, 0.84 mm ø, 24°C, 35% r.h., t = 20 min).

Through a preliminary FESEM morphological investigation, it can be easily observed how the optimization of the electrospinning process parameters allowed to gradually pass from membranes with typical defects such as the formation of beads that are very evident (Figure 3 on the left) to membranes where the presence of defects in the nanofibers appears statistically significantly reduced (Figure 3 on the right). Figure 4 on the left shows the formation of some ribbons indicative of the collapse of the fibers with slow evaporation of the solvent. Figure 4 on the right highlights bead-free uniform fibers. The fibers appear further improved in Figure 5 as they are uniform in diameter and free of structural defects, such as beads and ribbons. Also in Figures 6 and 7, we can clearly observe fibers with excellent morphological characteristics as they are free of the defects typical detected for electrospun membranes.

4 Conclusionww

In this paper, through the optimization of the solutions and apparatus parameters, the authors prove that the electrospinning of the synthetized polymers PBS and P(BS70BEPS30) was successfully done. In fact, the preliminary results are very promising suggesting a medical use of electrospun membranes, characterized by bead-free uniform fibers. In this regard, it is worth anticipating that the production of membranes loaded with appropriate anticancer molecules for targeted biomedical applications will be our next target to be achieved and that the results will be the subject of future work. (see Supporting Information).

Conflict of Interest

The authors declare no conflict of interest.

Open Research

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.