Acceleration of Biodegradation Using Polymer Blends and Composites

Abstract

Biobased and biodegradable polymers are used in bioplastics as blends or composites of various materials to tune their physical properties but also influence their stability with respect to biodegradation. Biodegradable polymers are often not as biodegradable as they are claimed to be, especially due to different degradation conditions in soil, water, compost, or in vivo. Mixing such polymers with faster degrading polymers (blends) or fillers (composites) is a powerful strategy to adjust degradation rates. This review selects representative examples of bioplastic blends and composites in applications, such as tissue engineering, agriculture, or packaging, with a focus on controlling/accelerating the biodegradation rates. It also focuses on strategies such as hydrolysis enhancement, attraction of microbes for microbial degradation, pore forming fillers, or increase of phase separation in polymer mixtures. A basis for the prevention of microplastic formation or unwanted side effects with too slow degradation rates of biodegradable polymers is set.

1 Introduction

Bioplastics are either biobased or biodegradable (also synthetic) polymers or feature both properties.[1] For several decades now, biobased polymers have been attracting increased attention as substitutes for conventional, petroleum-based polymeric materials.[2] The durability of commodity petroleum-based materials, which has led to a massive plastic pollution, and the release of greenhouse gases by incineration, make the search for biobased polymers attractive.[2-5] Biobased polymers offer an alternative with the potential to improve life cycles, especially when biodegradability is also considered.[6, 7] In general, biobased polymeric materials can remain biodegradable or become nonbiodegradable, depending on their chemical modifications.[5-8] Chemical modification influences biodegradation rates, i.e., the speed at which the polymer backbone can be broken down by microorganisms and metabolized eventually to carbon dioxide (CO2) and H2O (including minerals).[5, 9] A typical drawback of biobased polymers is their lower mechanical performance compared to commodity polymers.[2, 6, 7, 10] A general approach to optimize desired properties of polymeric materials, also bioplastics, is blending or the preparation of composites.[2, 6] Besides physical or chemical properties, blends and composites might also reduce the costs of the final material.[5] Another drawback of several bioplastics is their slow degradation rate and the formation of microplastics.[1, 11, 12] For instance, for polylactide (PLA), that is a synthetic polymer, no degradation in seawater over several years had been reported, while PLA blends and composites showed accelerated biodegradation rates.[13] As nondegradable polymers account for as much as 57% of bioplastics, the development of their biodegradation is a substantial scientific challenge today.[14]

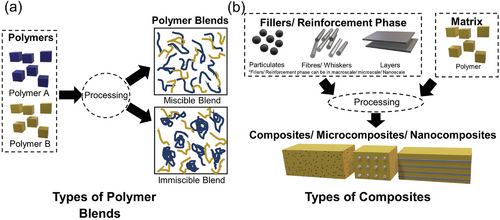

In general, the physical properties of polymer blends depend on the ratio of the constituent polymers, while the limits for property modification highly depend on the compatibility of the polymers. This leads to two types of blends: miscible, or homogeneous blends, and immiscible or heterogeneous blends (Figure 1a).[15, 16] While miscible polymer blends exhibit a single phase as well as a single glass transition temperature, Tg, the immiscible blends consist of polymers that exhibit a high interfacial tension, causing for phase separation with separate Tg’s. The mechanical properties of immiscible blends are generally less desired due to this phase separation, resulting in brittle materials, for example.[16] Such undesired phase boundaries might be reduced by the addition of compatibilizers, improving the interfacial adhesion between polymers.[15] Most of the blends discussed in the review addresses miscible blends.

Polymer composites have at least two separate phases, which are combined physically, e.g., (nano)particles embedded in a polymer matrix. The continuous polymer phase makes up the volume, thus acting as a “matrix”, providing mechanical support while binding the reinforcing components together (Figure 1b).[15, 17] The discontinuous or dispersed phase, on the other hand, acts as the reinforcement, carrying most of the load on the material. The dispersed phase can be, for instance, in the form organic or inorganic particles, and can take different shapes, like fibers/whiskers, meshes, or layers.[15, 17] It is the contribution of filler with a defined shape in the final material, primarily as an inorganic phase, that significantly distinguishes composites from blends. Also based on the size of the filler, polymer composites can be divided into micro- and nanocomposites (Figure 1b).[18] When biobased fillers are used, they often have a complex macromolecular or crystallographic structure, and also can be organic and inorganic, while synthetic biobased fillers typically have a more defined architecture.[19-21]

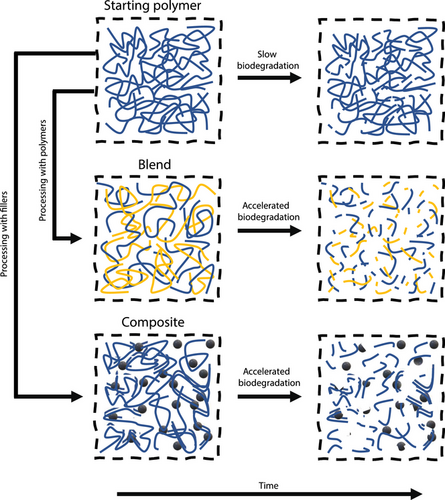

The addition of a biodegradable material, i.e., polymer or particle, to a starting polymer is intended to accelerate the overall biodegradation of the hybrid material, i.e., blends and composites, respectively. For instance, in such a composite, the filler degrades first, which leaves a matrix behind with increased surface area which then also degrades faster as the respective bulk material (Figure 2).[7, 9] Similar mechanisms can be designed for polymer blends as well. Biobased polymers can also contribute to the designing of such hybrids. These bioplastic blends and composites are especially designed to improve sustainability compared to conventional polymer blends/composites and they are a potential pathway to reduce the dependence on fossil fuels and help the transition to a circular economy.[2, 5, 17]

In this review article, we collected representative examples of bioplastic blends and composites, as highlighted in Table 1. We first discuss applications of these materials, and later emphasize on how the addition of a separate material/phase into the polymer matrix alters the biodegradation profiles of the overall polymer materials.[8, 22] The literature was selected by looking at the composition of the polymer blend and composite, and the environment, in which degradation was studied (e.g., soil, water, or compost), also well as the degradation mechanism and the degradation rates. We additionally report if the authors quantified the degree of biodegradation. The discussion involves mostly the following polymers: polylactide, poly- l-lactic acid (PLLA), poly (glycerol sebacate) (PGS), PPS, poly(propylene sebacate); PES, poly(ethylene sebacate), polycaprolactone (PCL), polyhydroxy butyrate (PHB), poly(butylene adipate-co-terephthalate) (PBAT), Ecovio (BASF), polyhydroxyalkanoate (PHA), poly(glycolic acid) (PGA), polybutylene succinate (PBS), polyvinyl alcohol (PVA), and polyethylene glycol (PEG).

| Polymers/fillers | Composition (wt.%) | Environment | Degradation mechanism | Main factors for degradation time | Main factors that accelerate degradation | Outcomes | Ref |

|---|---|---|---|---|---|---|---|

| PLLA/HAP/PGA | 90/10/0, 67.5/10/22.5, 45/10/45, 22.5/10/67.5, 0/90/10 | PBS solution (pH = 7.4) at 37 °C | Hydrolysis | Pore formation/ increase of surface area |

Scaffold degradation creates pores increasing matrix exposure. Hydrophilic, faster degrading PGA decreases pH. |

Blending of (quickly degrading) PGA into the HAP/PLLA accelerated degradation from 3.3% to 25% after 28 days. The degradation of PGA accelerates the degradation of the PLLA/HAP composite due to the creation of an acidic environment. | [38] |

| PLA/CD | 90/10, 80/10, 70/10, 60/10, 50/10 | Soil | Microbial degradation | Physical forces and hydrolysis, soil microbes, and water absorption | Pore formation/ increase of surface area. | Degradation accelerated with increasing CD content. | [43] |

| PLA/PHB | 80/20 | Compost/soil | Aerobic biodegradation | Bacterial community composition, temperature, pH | PHB composition in combination with microbial composition in soil. | After 15 days the blend achieved biodegradation of ≈9.5% vs ≈2% for the control sample showing significant acceleration by the addition of PHB. | [44] |

| PCL/PLA(/TPS) | 30/70, 50/50, 70/30 (/TPS) | Compost | Microbial degradation | Thermophilic phase, addition of TPS | Water vapor permeability. | TPS favored the biodegradation of ternary blends due to TPS acting as carbon source for microorganisms. Also, TPS improved water vapor permeability due to its hydrophilic nature. | [52] |

| PCL/MMT/nanosilica/carbon nanotubes | 2.5 | 0.2 mg mL−1 lipase in buffer solution | Enzymatic hydrolysis | Barrier properties of the nanoparticles | Postponed degradation | Addition of fillers has no effect on enzymatic hydrolysis mechanism of PCL, but these fillers reduce the ability of lipases to biodegradation. | [48] |

| PBS/CM | 75/25 | Compost | Aerobic biodegradation for the biofiller. Enzymatic hydrolysis and microbial bio assimilation for the PBS matrix | Compost composition, pH, temperature | Bio filler composition: Soluble sugars, partially digested carbohydrates and protein acting as nutrients for microbial growth and substrates for enzymatic hydrolysis. | 160 days for 90% biodegradability per ASTM D6400 standard. | [40] |

| PBS/SM | 75/25 | Compost | 140 days for 90% biodegradability per ASTM D6400 standard. | [40] | |||

| PBS/SG | 75/25 | Compost | 200 days for 90% biodegradability per ASTM D6400 standard. Oxidative degradation is needed for lignin content. | [40] | |||

| PBS/CGM | 75/25 | Compost | 160 days for 90% biodegradability per ASTM D6400 standard. | [40] | |||

| PLGA/PLLA | 75/25 |

Phosphate buffered saline at 37 °C Mice (in vivo) |

Hydrolysis And in vivo study |

Amorphous polymer additive PLGA with faster hydrolysis kinetics compared to crystalline PLLA |

Dissolution and PLGA. Formation of an acidic environment in the bulk by PLGA degradation |

Degradation determined by retained weights and GPC. 75/25 blend had 21.9% weight loss after 8 weeks in PBS. The acceleration is a result of pore formation caused by dissolution and degradation of PLGA. | [47] |

| PLLA/PLCL/PEG | 10, 20, 30, 40, 50, and 60 wt.% PLCL (80:20) -PEG or PLCL (70:30)-PEG | PBS solution (pH = 7.4) | Hydrolysis | Composition, structural changes | Chemical similarity of the blend components and changes in molecular weight | The presence of PLCL-PEG accelerated the degradation. | [55] |

| PHB/PEG |

80/20 50/50 |

Phosphate buffered saline (pH 7.2–7.4) with lysozyme | Enzymatic degradation (lysozyme, 0.2% solution in PBS) | Pore formation/ increase of surface area |

Presence of lysozyme enzymes Hydrophobicity of PEG |

Surface of the blend turns porous, and phase separated. Enzymes can more easily attack resulting in acceleration of the biodegradability. | [46] |

| ST/CF/ Magnesium Stearate (MgSt)/ Arabic gum | 49/45/5/1 | Soil | Microbial | Pore formation/ increase of surface area |

Corn fibers Dispersion of St |

130 days for 90% biodegradability per ASTM D5988 standard. | [42] |

| ST/PVA/CF/MgSt | 45/7/45/3 | Soil | Microbial | Pore formation/ increase of surface area |

Corn fibers Dispersion of St |

130 days for 90% biodegradability per ASTM D5988 standard. | [42] |

| PVA/PCL | 30/70, 50/50 and 70/30 | Seawater | Hydrolysis | Salinity, pH, temperature, microbial concentration | PVA content and grade | PVA content can work as an accelerator for hydrolysis of the PCL matrix. The dissolution of PVA causes cracks which act as highways for water and microorganisms to enlarge the contacting area. | [45] |

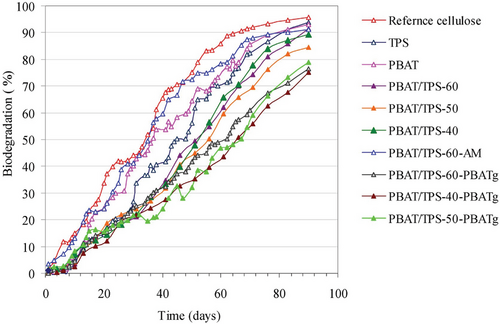

| PBAT/TPS | 40/60, 50/50, 60/40, 40/60-AM, 50/50-AM, 40/60-PBATg, 50/50- PBATg, 60/40- PBATg | Compost | Hydrolysis and microbial degradation | Compost composition, temperature |

Chemical continuity Presence of interfacial domains Continuity index |

Blends show accelerated biodegradability relative to each other based on higher continuity indexes. However, they show equal or lower biodegradability than the pure components as per ISO 14855–2:2018 standard. | [54] |

We believe that this summary of articles will guide future works better on how to increase the biodegradation rates of bioplastics by using the right additives or modifiers and that controlling the biodegradation rates of novel polymers can contribute to the reduction of the microplastics pollution on Earth.

2 Applications of Biodegradable Polymer Blends and Composites

Biodegradable polymer blends and composites are used in applications such as biomedicine, packaging, and agriculture. Controlling the degradation rates of the overall material is essential and was achieved by biodegradable additives, both polymers, and fillers, as outlined below.

2.1 Polymer Blends and Composites in Bone and Tissue Engineering

There is much interest in polymer blends for tissue engineering, because of their adjustable mechanical properties and their ability to adjust the degradation rates to the regrowth of a specific tissue. For this application, a high control of biodegradation is important, e.g., when the speed of bone reconstruction completion is quicker than the time of bone scaffolds degradation to be more suitable for the repair of bone defects or for other tissue.[23, 24] Currently, often porous polymers are used in tissue engineering applications if the polymer matrix can be suitable as a scaffold for tissue growth and can serve as a provisional aid for the cell growth during the regeneration of the target tissue. The polymer can be implanted into the body via minimal operations using small equipment. A small cross-sectioned polymer can be intercalated into the body via a small incision through a catheter. When in the demanded anatomy, with the aid of the body heat, this can be deployed into a greater preordained shape.[23, 24] A promising biocompatible base polymer, of which the biodegradation can be controlled by blending, is PLA.[25] PLA has been used in various biomedical applications due to its biocompatibility and biodegradability in vivo. However, PLA's degradation rate is often too slow,[26] and was accelerated by blending with various polymers and will be discussed in this review. Biodegradable composites were, for example, used by Huang et al. for bone tissue engineering.[23] The authors prepared composites using fibers of nano-hydroxyapatite in a matrix of polymers with different degradation rates. Scaffolds demonstrated preferred structural integrity for constant growth of new bone, however, if scaffold biodegradation occurs too fast it causes a loss in cellular orientation out of a loss in adhesion or cell viability. The result of this study can help to simulate the dynamic microenvironment of biological processes. In another study, Alan et al. studied PLA scaffolds filled with conductive and magnetic fillers obtained by fused filament fabrication (3D printing).[27] It was shown that especially the PLA with conductive fillers (carbon fibers and graphene nanoplatelets) enhanced the bioactivity of the composites and accelerated its biodegradation. It was suggested that these materials could act as potential candidates for tissue engineering such as a scaffold for bone replacement and regeneration. Also, interesting research was reported by Liu et al.[28] they aimed at scaffold preparation using PGS/PCL blends, as the PGS alone would limit an application in tissue engineering because the time needed for its biodegradation is less than the time needed for cartilage regeneration. Thus, they blended PCL with PGS to adjust the time of biodegradation and enhance the mechanical strength of the final material.

2.2 Polymer Blends and Composites as Packaging and Agricultural Films

Polymer blends and composites have also been implemented for the development of consumer products that exhibit short lifetimes, such as shopping bags, packaging, and films.[29, 30]

For instance, Qin et al. have studied PLA blends with essential oils, for example, bergamot, lemongrass, and rosemary, and suggested their application for active packaging films.[31] The authors found the best compromise between mechanical, barrier, thermal, and antimicrobial properties at 9 wt.% of the oils content. Some properties of the blends were found superior to pure PLA, i.e., samples with bergamot and lemongrass essential oils exhibited high plasticizing effect and showed a noticeable two-step degradation process, respectively. Tabasi and Ajji studied up to 45 days of degradation of PLA and PHB blended with PBAT as 35 µm films in a simulated lab scale composting setup.[32] As the research selective degradation of the PLA or PHB components in the blends, the films were suggested in food packaging and agricultural applications as well as medical devices.

Another example is Ecovio (commercialized by BASF) that consists of a compostable PBAT (commercialized by BASF under the name Ecoflex), PLA as well as other additives, such as starch, to accelerate biodegradation.[33] Due to the fact of added organic filler, this blend is also a composite at the same time (note that further on we also describe similar “blend-composite” systems, but try to retain the authors' original nomenclature in the works cited, thus mostly calling them as blends). The biodegradation starts with the components in the blends that attract microorganisms most, e.g., starch. After the quickly degraded polymer also the others, slowly degrading components, are broken down in the soil or during composting. As soon as the microorganisms digest the fragments of polymer chains, CO2, water, and biomass are generated. Monomers in Ecovio have been changed in such a way that the specific material properties (e.g., high puncture resistance) are very suitable for, among others, biowaste, or shopping (carrier) bags. It has sufficient mechanical performance (e.g., toughness, impact resistance) and is proven by Life-Cycle Assessments (LCA). The latter entails that the potential impacts that the product can have on the environment throughout their life cycle have been analyzed and deemed minimal impact. The continuous Ecoflex component enhances the temperature resistance of Ecovio to >60 °C providing good stability during storage as well as biowaste collection. Ecovio bags can be described as compostable, tear-resistant, and waterproof.[33] Recently Ecovio was modified by adding ZnO nanoparticles resulting in an effective acceleration of the disintegration process of this blend-composite under a composting environment.[34] Other reports can be found as well, for instance, by La Mantia et al., in which carbon black was used as a filler and loaded into the Ecovio blend and studied the degradation behavior in the soil (agricultural films).[35]

Besides Ecovio, other biodegradable polymer composites have been found that show the potential to help reduce the need for polyethylene (PE) in packaging, e.g., PHA. PHA composites demonstrated full and rapid biodegradation in the natural environment.[26] Another example is chitosan-based nanocomposites for films used in food packaging with diverse antibacterial and antioxidant properties.[36] Additionally, these nanocomposites can be employed as coatings and directly applied to food by, e.g., casting or spraying. Arrieta et al., studied nanocomposites containing PLA–PHB blends as the matrix for cellulose nanocrystals at 5 wt.%. The obtained composite films were found to improve thermal stability and stretchability, and presented disintegration in compost, thus suggesting their possible applications as biodegradable packaging materials. Similar studies were conducted by Moustafa et al.[37] The authors prepared nanocomposites from PLA-PBAT blends with expanded organoclays. Due to their antimicrobial properties, the materials were also proposed in food packaging, and also for biomembranes.

3 Acceleration of Biodegradation

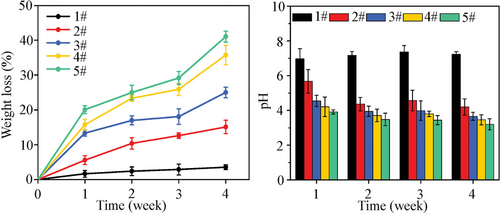

3.1 Acceleration by Promoting Local Acid Hydrolysis

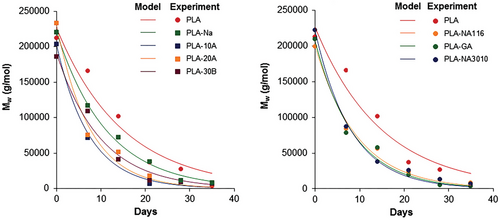

By blending two or more polymers together the degradation of one can influence a potentially accelerate the degradation of the other. A way to do this is described in the work of Cijun et al.[38] The authors blended PGA into PLLA/hydroxyapatite (HAP) matrix, which was used as a 3D-printed scaffold for bone regeneration. The PLLA/HAP matrix degrades by hydrolysis, which was accelerated by the blending with PGA. PGA has a higher rate of hydrolysis than PLLA and releases glycolic acid, which acts as a catalyst in ester cleavage. Figure 3 shows the increased acidic environment during the degradation process, which resulted in faster degradation.

Stloukal et al. studied the kinetics and mechanism of the biodegradation of PLA nanocomposite films with varied montmorillonites (MMT) prepared by melt blending at the constant weight ratio (5 wt.%).[39] The clay-contained PLAs were found to biodegrade faster than pure PLA particularly by shortening the lag phase at the beginning of the process. The hydrolysis rate constants were found to be higher for organo-modified MMT. The degradation rate depended on the interlayer distance of MMT (Figure 4).

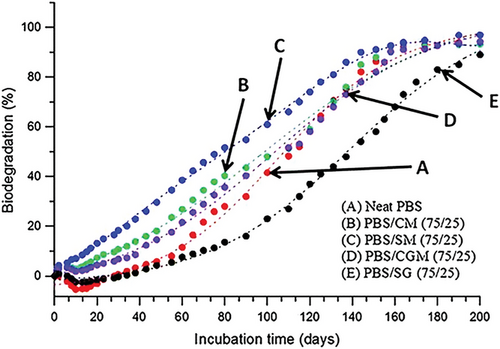

3.2 Accelerated Polymer Degradation by Microbe Attraction

Anstay et al. investigated the biodegradability of bio-composites based on the bioplastic PBS in compost.[40] The authors explored the processability and biodegradability of composites of PBS with meal-based fillers. The additives considered were Canola Meal (CM), soy meal (SM), switchgrass (SG), and Corn Gluten Meal (CGM), which are all by-products of the biofuel production. In Figure 5 the results can be found in the form of a biodegradation versus incubation time plot. The authors concluded that the introduction of a biological filler can accelerate the biodegradation rate of such bioplastic to a certain extent. However, it could also decelerate as can be seen in curve E (Figure 5), even at a 25 wt.% load of the additive SG. The acceleration in the compost environment arises from the filler's high protein content, while the deceleration was attributed to the high lignin content of SG which requires oxidative degradation instead of enzymatic hydrolysis. This research concluded that the presence of protein-rich meals in the bio-fillers enhanced the initial growth of microorganisms in the compost which resulted in a faster hydrolysis process that degrades the PBS polymer matrix.

The possibility of altered biodegradation by using polymer blends was also reported, when jute fibers were added to a blend of thermoplastic starch (TPS), PLA, and PBAT.[41] Not only in compost environments can these meal-based bio fillers be used, but also in soil. The soil-based studies investigated the addition of Corn Fibers (CF) to a St and PVA blend and the polymer blend PLA/Cow Dung (CD).[42] The first study reported similar findings to the aforementioned, that the microorganisms in the soil were attracted to a specific component of the corn fibers, namely lignocellulose. Further, these microorganisms accelerated the degradation process; or in other words: the lignocellulose component acted as promoting agent for biodegradation.

Yusefi et al. reported the accelerated biodegradation of PLA through a CD reinforcement.[43] This material mixture proved to improve inferior product quality and develop a green bio-composite. The composites biodegradation was assessed in the soil by visualization of the morphological changes of the mixture by Scanning Electron Microscopy (SEM). The micrographs showed accelerated biodegradation of higher CD wt.% polymer composites. This effect results from both microbes in the soil as well as microvoids creation (because of water absorption) indicating poor interfacial bonding between PLA and CD and therefore poor stress transfer between the filler and the matrix. The polymer composite was completely biodegradable over a period; however, the CD dispersion and the quality of the interfacial bonding could be improved. A decrease in tensile strength of 8.8%, 17.4%, and 20% was observed with increasing CD contents of 10, 30, and 50 wt.%. However, in contrast to a decrease in tensile strength, an increase in flexural modulus was observed with increasing CD content with a maximum of 40 wt.%, having a 62% improvement compared to the base case, which is a good result.

Acceleration of biodegradation was also achieved by blending PLA with 20 wt.% PHB. Under composting conditions, the blend led to a significant increase of ≈2% to 9.5% biodegradation after 15 days. The biodegradation was accompanied by a decrease in tensile strength. The rate of this decrease was correlated to the amount of biodegradation, meaning that the tensile strength decrease faster under composting conditions than in soil.[44]

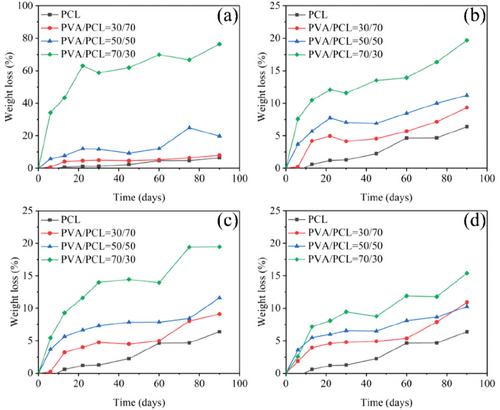

3.3 Acceleration by Pore Creation and Phase Separation

Huang et al. reported that PVA acted as a degradation accelerator for PCL in seawater.[45] PVA at different grades were studied, primarily at different ratios between the degree polymerization and the degree of alcoholizes, i.e., 500/88%, 500/99%, 1700/88%, and 1700/92%, and coded as PVA0588, PVA0599, PVA1788, PVA1792, respectively. PVA and PCL were blended at different w/w ratios. The highest increase in accelerated degradation for the PCL-based specimen was observed for PVA0588/PCL (70/30). The increase in degradation compared to pure PCL was from 6% to 78%. The immersion in seawater led to the dissolution of PVA by causing cracks. These cracks increased the surface of the remaining PCL and hence increased the water uptake and accessibility for microorganisms. This resulted in higher degradability as compared to pure PCL (Figure 6). It should be noted that no standard of testing was mentioned too, for example, measure CO2-contents, so it is unclear if we can attribute the weight loss to full biodegradation or only the hydrolysis of chains into low-molar mass segments.

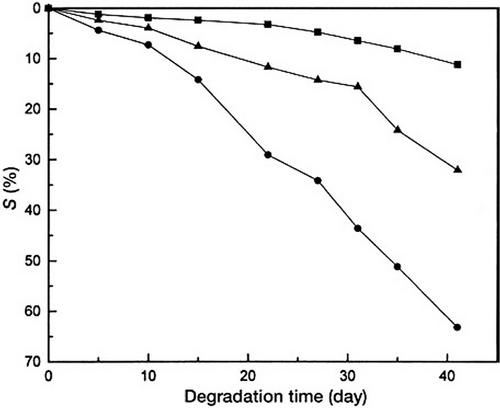

Acceleration by pore creation and phase separation is also being investigated for use in biomedical applications. Cheng et al. studied blends of PHB and PEG and found that the incorporation of the hydrophilic and water-soluble PEG was able to accelerate the biodegradation of the PHB-chain.[46] With such increased surface area, the enzymatic degradation of the PHB-chain was accelerated in a buffer solution consisting of PBS/lysozyme (pH: 7.2–7.4) at 37 °C from ca. 10% weight loss for pure PHB to 30% for PHB:PEG = 80:20 or 65% for a PHB:PEG = 50:50 blend (Figure 7). Comparable results were found for poly(lactic-co-glycolic acid) (PLGA)/PLLA blends, as PLGA has a faster degradation rate compared to the highly crystalline PLLA. After degradation of PLGA, a porous PLLA scaffold is left, which also degraded faster compared to bulk-PLLA, however lower compared to the PHB/PEG blends mentioned above, achieving only 21.9 wt.% after 8 weeks in PBS.[47]

The enzymatic degradation of bioplastics was also reported in other works. Nerantzaki et al. studied the effect of nanofillers at moderate contents of 2.5 wt.% in a PCL-matrix on enzymatic degradation.[48] They found that the hydrolysis rate of PCL films was controlled (postponed) by the type of the nanofiller added, i.e., MMT, fumed nanosilica, and carbon nanotubes. In another work, the same group studied the rates of the enzymatic degradation of poly(propylene sebacate) (PPS) in the presence of the same nanofillers, but at a lower content (2.0 wt.%), and found that PPS and its nanocomposites followed identical hydrolysis mechanisms.[49] In more recent studies they studied the hydrolysis rate of poly(ethylene sebacate) (PES) composites with graphene oxide.[50] An interesting overview of the effect of different nanofillers on enzymatic hydrolysis and biodegradation of polyesters has been published previously.[51]

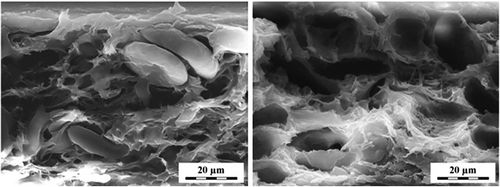

Bulatović et al. reported on the accelerated biodegradation of the ternary polymer blend PCL/PLA/TPS as a potential replacement for conventional synthetic polymers (PE, PP, PS etc.).[52] The biodegradation of the materials was assessed in compost by weight loss as well as morphological changes in the blend. Weight loss measurements and SEM micrographs showed considerably accelerated biodegradation of ternary blends by the addition of TPS. Infrared spectroscopy confirmed the degradation mechanism to be based on PLA hydrolysis with protic (macro)molecules like amines.[53] These protic (macro) molecules come from the production of the microbial population consuming biodegradable organic matter in the composting process. The accelerated biodegradation in the compost was assumed to be based on the hydrophilicity and carbohydrate structure (food source) of starch. As soon as the microorganisms degrade the carbohydrates of starch, access to other ingredients in the blend was facilitated (Figure 8). This increased the water permeability and enhanced the biodegradation of the overall material.

3.4 Acceleration by Increasing the Continuity Index of a Phase

Dammak et al.[54] investigated a series of blends using PBAT as the polyester matrix. Different ratios of TPS and PBAT were blended and additional effects of maleic anhydride or malleated PBAT (PBATg-MA) as compatibilizers were investigated. The authors reported that PBATg-MA functioned as an effective reactive compatibilizer promoting the interfacial adhesion between the phases of TPS and PBAT with a beneficial effect on tensile strength and elongation at break. Concerning the biodegradation rates (studied over a period of 90 days at 58 °C, Figure 9), most blends exhibited similar stability. However, biodegradation kinetics were affected by the presence of compatibilizers, with a decrease in the degradation rate noted when PBATg-MA was used as a compatibilizer. Another point is, as pure PBAT is more expensive than commodity plastics (≈4 times more expensive than low-density polyethylene),[54] blending with relatively cheap TPS increases the competitiveness of this biodegradable plastic. Further, blending biodegradable polymers with TPS, in general, accelerates the overall biodegradation rates, which is caused by an increase in the continuity index of TPS, indicating that the PBAT is more accessible to the external medium and vice versa for the decrease in biodegradability. Of the blends they studied, for the desired application one should consider the mechanical performance, price, or biodegradability, as these can be fine-tuned (Figure 9).

Oosterbeek et al.[55] reported that accelerated biodegradation of PLLA blended with polyethylene glycol functionalized poly(l-lactide-co-ε-caprolactone) (PLCL-PEG) to tailor the mechanical properties and degradation behavior of the polyester matrix. The polymer hydrolysis was assessed in PBS and measured by a decrease of the molar mass via gel permeation chromatography (GPC) and morphological changes by SEM imaging. The authors found a nonlinear dependence of the degradation time on compositions, showing an accelerated biodegradation of the polymer blend PLLA:(PLCL)-PEG. This effect was accounted for the autocatalytic behavior during polyester hydrolysis. As soon as the faster degrading PLCL-PEG hydrolyses, the increased amount of acidic end groups facilitated the degradation of the rest of the matrix.

4 Conclusions

The acceleration of biodegradation is crucial in medicine, as well as agricultural and packaging applications. We have reviewed the acceleration of biodegradation in these materials by using blends and composites. Blending and particle in matrix-content can alter the physicochemical properties, the costs, and the stability of the final polymer mixture. Different additives result in faster biodegradation compared to the bulk material and by adjusting the amount of the additive, the mechanical properties of the polymer mixtures, as well as the degradation kinetics, can be controlled.

We have focused on the most common bioplastics, like polylactide, polyhydroxy butyrate, poly(butylene adipate-co-terephthalate), polyhydroxyalkanoate, or polycaprolactone. The accelerated biodegradation of polyester matrices was for example achieved by blending in protein meals coming from organic waste to attract and accelerate the microbial processes. In addition, blends that possess compounds that crack in the process of evaporation or other migration processes and, in results, enhance the accessibility and degradability of the polymer matrix. In addition to that, the continuity index of a blend also influences the mechanisms for biodegradation.

In addition, fillers, both organic and inorganic, might be added to bioplastics matrices to control (accelerate, postpone) their biodegradation, i.e., different types of starches, hydroxyapatite or allotropes of carbon, in forms of micro- and nanoparticles.

There are some remarks to be made about the amount of literature quantifying the biodegradability of polymer blends and of polymer composites. The literature that discussed the biodegradable blends often has not assessed the biodegradability of the product or did so in a way where distinguishing biodegradability from degradability was not possible., e.g., weight loss of the material does not per se mean that it is converted into CO2 and water and therefore a conclusion that it is biodegradable needs to be carefully evaluated in each case. In addition, literature examples sometimes follow a certain standard for biodegradability or use home-built setups. In both cases, statistical and other possible errors in the results are often not mentioned, making the comparison of different samples difficult and even more difficult to compare data from different research labs.

Seeing how much potential there is in the use of polymer blends and polymer composites for enhancing biodegradation, we expect the research to continue in this field. Together with this further research, we hope that a more structural approach is developed, allowing in turn, further collaboration between researchers in this field.

Conflict of Interest

The authors declare no conflict of interest.

Biographies

Zhong H. W. Easton is in the final part of her M.Sc. in chemical science and engineering at the University of Twente (Enschede, the Netherlands). She graduated with her B.A.Sc. in chemistry at the Inholland University of Applied Sciences (Amsterdam, the Netherlands). During her studies, she obtained a talent program certificate in analytical sciences from the HAN University of Applied Sciences and the Top Institute for Comprehensive Analytical Science and Technology. In the summer of 2019, she participated in the Future Chemist International Summer Camp at the University of Science and Technology of China in Hefei, China.

Mike A. J. Essink is a master's student in chemical science and engineering at the University of Twente and is expected to graduate in 2023 (Enschede, the Netherlands). During his studies, he specialized in chemical and process engineering, molecular and materials engineering, and materials science and engineering. Earlier published work involves CO2 capture using semiclathrate in the framework of the Interreg2Seas Carbon2Value (2S01-094) project.

Laura Rodriguez Comas is a master's student in chemical science and engineering at the University of Twente, expecting to graduate in 2023 (Enschede, the Netherlands). Throughout her studies, she has been specializing in molecular and materials engineering, with an emphasis on biomedical applications. Before her master's studies, she followed the multidisciplinary bachelor's program in advanced technology at the same university.

Frederik R. Wurm leads the Sustainable Polymer Chemistry Group at the University of Twente (Enschede, NL) and acts as an editor for the European Polymer Journal. His broad research interests cover the molecular design and synthesis of functional and biodegradable polymers and the modification of biopolymers, especially focusing on polyphosphoesters and lignin. Frederik received his Ph.D. in 2009 (Mainz, Germany). After two years at EPFL (Switzerland) as a Humboldt fellow, he joined the Max-Planck-Institute for Polymer Research (Mainz), where he habilitated in macromolecular chemistry (2016). He has published more than 200 peer-reviewed articles and his research was awarded several times.

Hubert Gojzewski is currently an assistant professor in the Sustainable Polymer Chemistry Group at the University of Twente (Enschede, the Netherlands), where he has been working since 2015 as a researcher. He received his Ph.D. from the Poznan University of Technology in 2011 (Poland) and also received his habilitation there in materials engineering in 2021. He did his pre- and postdoctoral research at the Max Planck Institute for Polymer Research (Mainz, Germany) and the Max Planck Institute of Colloids and Interfaces (Potsdam, Germany). His research interests include micro- and nanostructured polymers and sustainable functional polymers.