Effects of a mutated yeast plus addition of sucrose and nitrogen on the total higher alcohol levels of a plum wine fermentation

Abstract

The brewing process and strain employed can play key roles in controlling the level of total higher alcohols (THA) in plum wine. In this study, fermentations using Saccharomyces cerevisiae XN3 and plum must led to the production of 671 mg/L THA (including 1-propanol, isobutanol and isopentanol). A mutant of XN3, exhibiting a higher activity of lactic acid dehydrogenase, named XN3-3, produced lower levels of THA at 538 mg/L. Further optimization of the brewing process, including rapid nitrogen and sugar fed-batch additions, were conducted with XN3-3. Tests with the addition of 0.4 g/L (NH4)2HPO4 produced a lower level of THA (385 mg/L) than sucrose additions (to a 20°Brix level) using the fed-batch method (452 mg/L). These additions were effective in reducing the higher alcohols and could be combined in application. Copyright © 2014 The Institute of Brewing & Distilling

Introduction

Plums are cultivated throughout the world and have been consumed for many centuries. Among the many products obtained from plums, alcoholic drinks are considered to be very interesting. Plum wine is welcomed by the market for its low alcohol content and nutritional properties, and has even been reported to have antimicrobial, antiviral and antioxidant activities 1-3. In the past few decades, plum plantations and manufacture in China have increased, and plum wines may become increasingly popular in Chinese and world markets in the future.

Plum wines elicit enjoyable tastes and flavours, originating from the fermentation process and fruit juice employed. Organic acids, esters, ethanol and higher alcohols have very important influences on flavours and tastes. Malic acid and tartaric acid comprise the majority of organic acids originating mainly from the fruit juice; higher alcohols (such as propanol, isobutanol, isopentanol, pentanol and phenylethyl alcohol) mainly originate from yeast fermentation. A high level of total higher alcohols (THA) will bring an unpleasant flavour, and cause headaches and intoxication in consumers 4. Over the past few years, acceptable THA levels of some fruit wines have been studied. Typically, for grape wines, 300 mg/L of THA is considered acceptable, with levels above 400 mg/L potentially leading to an unpleasant aroma 5, 6. However, there is still insufficient information regarding THA in plum wines.

For this purpose, we explored the effects of THA on the quality of plum wine by performing experiments controlling the THA levels. Results of the experiments on controlling THA levels by means of breeding, methods of sugar addition and rapid nitrogen addition are reported.

Materials and methods

Yeasts and culture conditions

Saccharomyces cerevisiae XN3 was isolated from an indigenous fermentation of plum wine, exhibiting a tolerance of 10% v/v alcohol and 100 mg/L SO2. A commercially available Anqi active dry wine yeast (commonly employed as a fruit wine yeast) was used as the control in the fermentations. XN3-3 was obtained from XN3 via a UV-induced mutation, which produced less THA than the original strain. The cultures were maintained at 4 °C on YEPD agar slants (yeast extract 10 g, peptone 20 g, glucose 20 g, agar 20 g in 1000 mL). To prepare a starter culture, a loop of yeast was inoculated into 100 mL of plum juice (in 250 mL shake flasks), which had been autoclaved in advance at 115 °C for 20 min, and cultured with shaking at 200 rpm at a temperature of 30 °C for 24 h.

Plum must preparation and fermentation

The plum trees were planted in the hill districts of the Hubei province of China and harvested in August. For the tests, 10 − 50 kg aliquots of fresh ripe plum fruit were rinsed and manually chopped into pieces, leaving out the stones. The pieces were processed into pulp using a commercial food processor. Then, commercial pectinase (Zaozhuang Jienuo Enzyme Co. Ltd, China) was added to the plum pulp at a rate of 40 mg/L, as recommended by the supplier, and SO2 was added (in the form of potassium metabisulphite K2S2O5, 1 g as 0.56 g SO2) to a level of 40 mg/L. The must, obtained by manually pressing through gauze, was then adjusted with sucrose to 15 or 20°Brix. Fermentations were conducted in 1000 mL glass bottles with a rubber plug and U-tube airlock. A quantity of 400 mL of plum must per bottle was inoculated with a starter yeast at a rate of 5% (v/v, to a cell density of about 5 × 106 cells/mL). (NH4)2HPO4 was used as the nitrogen source at levels of 0.2, 0.4, 0.5 or 0.8 g/L. Sugar supplement tests were arranged in four groups: 10 °Brix (no extra sugar added), 15 °Brix (one-step addition), 20 °Brix (one-step addition) and 20 °Brix (two-step fed-batch) without (NH4)2HPO4 addition. Alcoholic fermentation was conducted at 20 °C until the residual reduced sugar reached 4 g/L, at around 1–2 weeks. For wine-making and sensory evaluation, the supernatants of the fermented musts were bottled, keeping a 2.5 cm headspace for the 2-month ageing period at 10 − 15 °C. All fermentation experiments were conducted in triplicate.

UV mutation and screening

UV irradiation was conducted with 12 h aged yeast cells (washed once in distilled water) under UV light (254 nm) of 20 V at 20 cm distance and a dosage period of 100 s to achieve a 70 − 80% death rate. The cells were then spread on lactate solid medium (lactic acid, 40 g; (NH4)2SO4, 5 g; KH2PO4, 1 g; NaCl, 0.1 g; MgSO4.7H2O, 0.5 g; CaCl2, 0.1 g; yeast extract powder, 0.2 g; agar, 20 g in 1000 mL; adjusted to pH 6.0 with NaOH) and cultured at 28 °C for 3 days in the dark. Relatively large colonies, compared with the original, were selected and spot-planted onto malt extract–CaCO3 agar plates (malt extract powder, 20 g; CaCO3, 1.5 g; agar, 20 g in 1000 mL) with toothpicks and grown for 3 days. The colonies that exhibited transparent (dissolving) zones in the agar were transferred and spot-planted onto lactate solid agar for another 3 days of growth, onto which TTC agar (2,3,5-triphenyltetrazolium chloride, 0.5 g; glucose, 5 g; agar, 15 g in 1000 mL) was then poured, for colour development in the dark, after 3 h. The red colonies, as candidates for high fermentation activities, were selected for secondary screening using a plum must liquid fermentation, as described above, at 20 °C. Mutants with a lower production of THA were selected for further tests.

Analytical methods

The acidity was measured by titration with a 0.1 mol/L standard NaOH solution to pH 8.1 and expressed as malic acid. Volatile acids were also assayed using titration after being distilled from wine samples. Total soluble solid contents were determined using a digital refractometer (WYT-J, Sichuan, China) at 20 °C and the results expressed as °Brix. The pH value was measured with a Mettler Toledo pH meter S20K. l-Lactic acid was determined enzymatically using a commercially available kit (R-Biopharm, Germany). The reducing sugar content was measured by standard indirect iodometry and the wine alcohol content was tested using the density bottle method, after being distilled from the samples. Total amino acids were determined using the formol titration method and expressed as aspartic acid.

For the analysis of higher alcohols, 0.5 mL of plum wine was mixed with 4.5 mL methanol and centrifuged at 12000 rpm for 10 min. Supernatants were filtered through a 0.45 µm microporous filter membrane. As an internal standard, 10 μL of 1% (v/v) tert-amyl alcohol was added per millilitre. Analysis was carried out using a Hewlett Packard 5890 Series II GC coupled to an HP 7673 autosampler injector and an HP 3396A integrator. The column used was a Lab Alliance organic-coated, fused silica capillary (dimensions of 30 m × 0.32 mm internal diameter) with a coating thickness of 0.25 µm. Nitrogen was used as the carrier gas for the flame ionisation detector held at 280 °C. The injector temperature was 250 °C and the split ratio was 30: 1 with a flow rate of 1.5 mL/min. The injection volume was 1 μL. The oven temperature programme was: 50 °C (5 min) to 100 °C (0 min) at a rate of 10 °C/min, then to 180 °C (2 min) at a rate of 40 °C/min. The internal standard and chemicals (1-propanol, isobutanol and isopentanol) were sourced from Sigma (USA) or Sinopharm Chemical Reagent Co. Ltd (China).

Sensory evaluation test

Sensory evaluation was performed, after the completion of fermentation, by six trained panellists. The Buxbaum system was used, where colour (2 points), clarity (2 points), smell (4 points) and taste (12 points) were evaluated 7.

Results

The main chemical characteristics of the plum pulp associated with the fermentation process were determined. Titratable acidity, total amino acids, reduced sugar and total soluble solids were 13.2 g/L, 3.21 g/L, 78.5 g/L and 11.9 °Brix, respectively, which is in accordance with many other cultivars, but varies from other studies using wild plums 8, 9.

The yeast strain XN3 was selected from an indigenous fermented plum must and determined primarily to be S. cerevisiae using morphological and physiological properties 10 (including carbon and nitrogen source utilization and fermentable carbohydrate tests). XN3 could survive in fermentation conditions comprising 250 g/L sugar, 10% (v/v) alcohol and 100 mg/L SO2, and start-up fermentation in 20 h at 20 °C, with the ability of maintaining more fruit flavour in wine than Anqi active dry yeast. Fermented plum must contained 10.4% ethanol, 3.37 g/L residual sugars, 7.8 g/L titrated acidity (as malic acid) and 671 mg/L THA. The sensory evaluation of the plum wines suggested that the level of THA should be lower. Mutations of XN3 and fermentation process modifications were undertaken.

The theory of Harris, proposed in 1953 11, suggested that a high concentration of sugar in the fermented musts would lead to the production of alpha keto-acid intermediates, and finally lead to the production of higher alcohols. We screened mutants exhibiting a high level of lactate dehydrogenase, in order to decrease the production of higher alcohols from sugar substrates 12. For this, 12 h log-phase yeast cells were UV-irradiated at a dosage causing a 75 − 80% death rate, as described above. Cells spread onto agar plates with lactate as the sole carbon source resulted in colonies of various sizes. It was speculated that the larger colonies had higher activities of lactate dehydrogenase, which could transfer lactate to pyruvate for growth. One-hundred large colonies were then spot-planted onto malt extract–CaCO3 agar plates for dissolution zone presentation over a period of 3 days; 53 colonies were selected for the growth ability test and, finally, 16 red colonies were picked for THA level tests using plum wine fermentation.

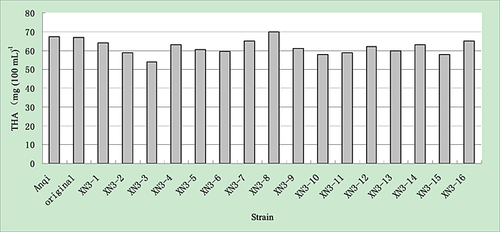

The THA levels, including 1-propanol, isobutanol and isopentanol, of the plum wines were assayed. Fifteen strains produced less THA (538 − 670 mg/L) than the Anqi yeast (673 mg/L) and the original XN3 strain (671 mg/L) (Fig. 1). XN3-3 was selected for further tests and produced 538 mg/L THA, which was 19.8% lower than the original strain. As a result, the lactic acid production of all 16 strains was found to rise from 125.1 to 162.3 mg/L, demonstrating an increase in the range of 1.0 − 29.7% (data not shown). Among them, XN3-3 produced 15.4% more lactic acid than XN3, but did not show significant differences in the levels of other parameters such as residual sugars, alcohol and volatile acids, and also did not change the flavour of the must significantly, as shown in Tables 1 and 2.

| Strain | THA (mg/L) | Reducing sugar (g/L) | Titrating acid (g/L) | Alcohol (%, v/v) | Volatile acids (g/L) |

|---|---|---|---|---|---|

| XN3 | 671 | 3.37 ± 0.15 | 7.8 ± 0.2 | 10.4 ± 0.3 | 0.46 ± 0.05 |

| XN3-3 | 538 | 3.39 ± 0.16 | 8.2 ± 0.3 | 10.4 ± 0.5 | 0.48 ± 0.03 |

- Titrating acid indicated as malic acid. Volatile acids indicated as acetate. Each data point represents the mean of three replicates.

| Starter | Rapid N (g/L) | Total soluble solid level and sugar addition | Colour | Clarity | Smell | Taste | Sum of sensory evaluationa | Percentage ethanol(v/v) | THA level (mg/Lb) |

|---|---|---|---|---|---|---|---|---|---|

| XN3 | — | 20 °Brix, one-step | 2.0 | 2.0 | 2.8 | 8.4 | 15.2 | 10.4 | 671A |

| XN3-3 | — | 20 °Brix, one-step | 2.0 | 2.0 | 2.7 | 8.9 | 15.6 | 10.4 | 538B |

| XN3-3 | — | 20 °Brix, fed-batch | 2.0 | 2.0 | 3.5 | 8.9 | 16.4 | 10.3 | 452C |

| XN3-3 | 0.4 | 20 °Brix, one-step | 2.0 | 2.0 | 3.2 | 9.3 | 16.5 | 10.0 | 385D |

- Different letters indicate a significant difference between the samples.

- a Sensory evaluations are presented as the means of six panellists.

- b THA levels were statistically analysed through the method of Duncan's shortest significant ranges; α = 0.01 was considered as the significance level.

The level of 538 mg/L THA was still too high according to studies using grape wines 5, 6. As suggested, plum fruit had a relatively low level of total amino acids (3.21 g/L in this study), compared with other wine materials such as grapes and apples, which led to a higher production of THA from the carbon sources. For this purpose, a rapidly utilizable nitrogen source (NH4)2HPO4 was applied to decrease the THA level.

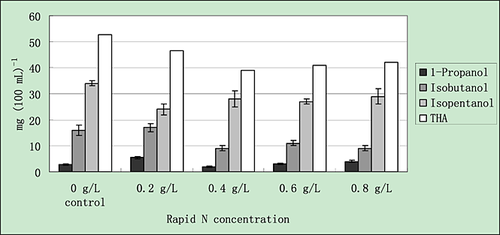

Rapid nitrogen tests were carried out with XN3-3 as the starter. THA levels shown in Fig. 2 suggest that the extra nitrogen indeed decreased THA levels at the rapid N levels of 0.2–0.8 g/L. The persistent rise in rapid nitrogen levels had a different effect on the individual higher alcohols, which was in accordance with another report 13. On the whole, at the concentration of 0.4 g/L rapid N, the THA level dropped to 385 mg/L, a 22.1% decrease, compared with the 0.2 g/L addition (470 mg/L), and ethanol was still maintained at 10.0% (v/v) in the wine samples.

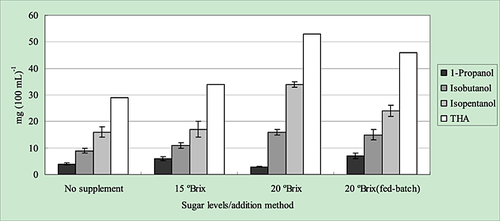

Sugar addition tests were conducted with mutant XN3-3, without the addition of a rapid nitrogen source. As showed in Fig. 3, tests using crude musts as the material showed a lower THA production, with a rather low production of ethanol (6.6%). When sugar was added (to the level of 15 and 20 °Brix) in one step, THA and ethanol levels increased. Two-step fed-batch sugar addition decreased THA levels from 538 mg/L (20°Brix in one step) to 452 mg/L, an 18.8% lower level compared with the one-step method.

Discussion

Many factors influence THA formation in fermentations using S. cerevisiae. Temperature can influence THA formation and has different effects on individual alcohols 14. Though 15 − 25 °C is usually applied, 20 °C was used for our tests. Oxygen is crucial for the formation of higher alcohols; semi-aerobic fermentation produces higher THA compared with anaerobic conditions 15. Hence, plum or grape wine fermentation should be maintained anaerobically to control the THA level and to favour ethanol fermentation.

In this study, several methods were applied in an attempt to control the THA levels of plum fermentation musts, based on the theory of grape/apple wine fermentations. Results showed that the yeast strain, sugar level and method of addition, and the rapid nitrogen source helped to control the level of THA, which decreased from 671 to 385 mg/L, without a substantial side effect on the yield of ethanol and several other important parameters (as shown in Table 2).

A yeast that produced lower THA was obtained using UV-irradiation; the theory of using intracellular pyruvate effluent control to govern the level of THA (via the regulation of the intracellular NADH pool by lactic acid dehydrogenase and alcohol dehydrogenase) 16 was shown to be effective in plum wine fermentation, and did not lead to any notable negative effects on ethanol production. This method has been reported elsewhere in Saccharomyces cerevisiae breeding for beer manufacture 12. In contrast, auxotrophic mutants of Ile−, Leu− and Val− have been reported to decrease the formation of isobutanol, active amyl alcohol and isoamyl alcohol, but these mutants were of no commercial use, as their growth and fermentation rates were suppressed 4.

Methods of sugar addition and utilization of the rapid nitrogen source were also shown to have significant influences on the THA levels of plum wine, and were practically applied in the production of white/red grape wines. A rapid nitrogen source, acting as yeast assimilable nitrogen, has been shown to have a beneficial modifying effect on the THA levels in plum wine fermentations. Two-step fed-batch fermentation instead of a one-step method for sugar addition also decreased THA production.

Vidrih and Hribar 7 reported that the sensory evaluation score of cider made from apple juice correlated negatively with the amount of higher alcohols. In this study, the results show that reduced THA was beneficial in reducing the rough and fierce tastes, and overall increased the acceptability of the produced wines.

Acknowledgements

This work was funded by National Natural Science Fund Project (No. 31071594) of China and by the open fund of the Key laboratory of Fermentation Engineering, Ministry of Education (no. 337013).