Biomimetic hydrogel-based sensors with dual-mode dynamic-static tactile sensing capability enabling robotic hand for intelligent material property recognition

Yu Lv and Zhaolei Ma contributed equally to this study.

Abstract

The realization of intelligent tactile perception in robotic systems requires multifunctional sensors capable of mimicking the dual-mode sensing mechanisms of human skin. Herein, we present a biomimetic hydrogel-based sensor capable of dynamic tactile detection through triboelectric sensing and static pressure monitoring via ionic-supercapacitive sensing. The triboelectric unit achieves a peak voltage of 14.64 V, with <5% signal decay over 5000 s of cycling, enabling robust detection of transient interactions (e.g., tapping or sliding). Additionally, the ionic-supercapacitive unit exhibits a high sensitivity of 2.69 kPa−1 between 0.8–28 kPa, a rapid response time of 0.5 s, and minimal signal drift of <5% during 7-day continuous operation, providing stable monitoring of static interactions (e.g., touching or pressing). By leveraging a multilayer perceptron neural network, a robotic hand equipped with a biomimetic hydrogel-based bimodal sensor demonstrates intelligent recognition of material types and hardness levels with a high accuracy of 98.5%. This study establishes a paradigm for high-performance electronic skins, which advances human-machine interfaces and artificial intelligence-driven robotics through biomimetic tactile perception.

1 INTRODUCTION

Human skin, the largest sensory organ, can distinguish different tactile stimuli from transient dynamic inputs, such as subtle tapping, to sustained static stimuli, such as hard pressing.1-4 Dynamic signals, such as vibrations or transient touch, are primarily detected by rapidly adapting mechanoreceptors (e.g., Pacinian corpuscles and Meissner corpuscles), while static signals, such as sustained pressure, are processed by slowly adapting mechanoreceptors (e.g., Merkel disks and Ruffini endings). In early studies, the types of sensors used to capture dynamic signals include piezoelectric or triboelectric sensors that respond to high-frequency stimuli by capturing instantaneous charges.5, 6 In contrast, piezoresistive and capacitive sensors, which rely on sensing continuous electrical responses, are mostly used to sense static signals with low-frequency stimuli.7, 8

Motivated by the excellent tactile perception capability of human skin, significant research efforts have been devoted to advancing sensor technologies, aiming to develop artificial systems that can emulate or even surpass the biological tactile sensing system.9-13 Historically, conventional sensors employing one single-mode sensing mechanism have demonstrated remarkable progress in tactile sensing capabilities.14 For example, Tao et al. developed a triboelectric triple-layer sandwich-type woven sensor using ultrahigh molecular-weighted polyethylene and polyimide (PI) fibers for dynamic sensing, which achieved a high open-circuit voltage of 53 V and remarkable durability under extreme environmental conditions, as well as exceptional mechanical, thermal, and chemical stability.15 Similarly, Daniel et al. developed a pressure sensor by constructing a percolated conductive network composed of silicone and carbon nanofibers with ultrahigh conductivity of up to 130 S m−1 for static pressing, which demonstrated an impressive 1200% improvement in pressure-induced strain sensitivity and offered a high responsiveness to minor deformations.16 However, these sensing systems are limited by their reliance on the single-sensing type, which restricts their ability to capture dynamic and static tactile inputs at the same time. Furthermore, challenges such as narrow detection range and limited multifunctionality still exist.17-19

To address the limitations of the single-sensing mode, researchers have explored sensors with multi-sensing modes based on layered and microstructured designs. For example, Li et al. developed a dual-modal tactile sensor that combined the triboelectric and capacitive sensing units in a layered architecture with the triboelectric layer shielding the capacitive layer; this enabled bifunctional sensing with improved pressure data acquisition accuracy and enhanced anti-interference capability.20 Dong et al. utilized the microfluidic three-dimension (3D) bioprinting technique to create a dual-functional sensor patch featuring controllable microstructures and ultrahigh strength, which offered significant potential for clinical applications such as wound healing.21 Zhang and Wei et al. showed that the selection of functional layers in the sensor structure mostly depended on the existing materials, such as using PI, thermoplastic polyurethane (TPU), and other films as flexible substrates, and aluminum foil and copper foil as conductive materials.22, 23 Due to the limitation of surface tension, different materials are prone to separation at the contact surface under external forces or curved surface contacts, hindering the sensor performance and increasing the packaging requirement.24, 25 Moreover, with additional sensing modes, the devices suffer from severe signal crosstalk and complicated manufacturing processes.26, 27

On the other hand, the very recent development of artificial intelligence (AI) in aiding sensors has presented a new frontier in electronic tactile perception.17, 28, 29 For example, Li et al. combined the laser-induced graphene (LIG) and liquid metal alloy (GaInSn) with Ecoflex to develop a stretchable resistive pressure sensor array.30 Paired with a machine learning algorithm, the sensing system could distinguish complex tactile actions, such as tapping, sliding, and grabbing. Similarly, Guo et al. designed a multimodal sensor incorporating a triboelectric layer for material texture recognition and an ion-based hydrogel for zero-bias temperature sensing using the cloud-based machine learning and feature fusion technique.31 These studies showcase the potential of AI for advanced intelligent robotics. Further development is still needed for broader intelligent perception.

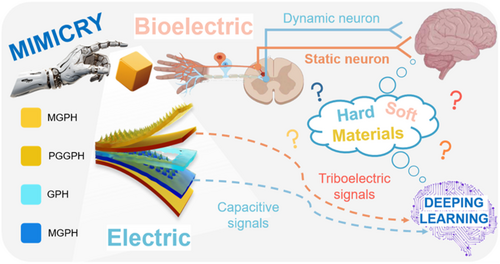

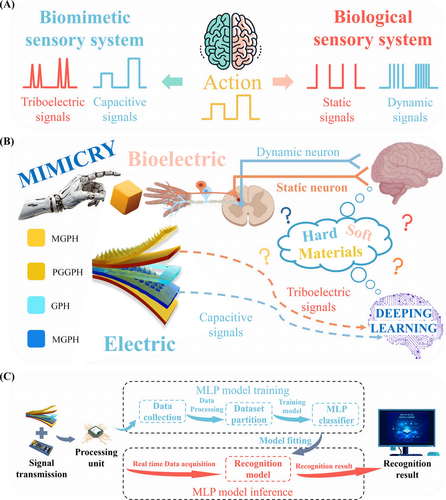

In this work, inspired by the multifunctional human skin (Figure 1A), we present a biomimetic hydrogel-based dual-mode sensor (BHDS) that integrates a triboelectric dynamic sensing unit and an ionic-supercapacitive static sensing unit within a multilayered architecture (Figure 1B). The BHDS employs a dual-network hydrogel matrix doped with functional fillers (e.g., MXene, PEDOT:PSS, graphene, and ionic liquids), and is fabricated via a cost-effective templating method. By optimizing the surface microstructures, the triboelectric unit achieved a high voltage of 14.64 V for dynamic tactile detection with negligible signal decay over 5000 s of cyclic operation. Simultaneously, the supercapacitive unit demonstrated a sensitivity of 2.69 kPa−1 in the low-pressure regime of 0.8–28 kPa, a broad detection range of up to 45 kPa, and rapid response and recovery times of 0.5 s, alongside minimal capacitance drift of <5% during 7-day continuous monitoring. The synergistic operation of the dynamic and static sensing modalities enabled a precise tactile perception, emulating the fast- and slow-adapting mechanoreceptors of human skin, respectively. Coupled with a multilayer perceptron (MLP) neural network, the BHDS-equipped robotic hand achieved a 98.5% accuracy in terms of material type and hardness recognition (Figure 1C). This study advances the intelligent sensing technologies by merging biomimetic design, high-performance materials, and machine learning, offering transformative potential for human-machine interfaces and AI-driven robotics.

2 RESULTS AND DISCUSSION

2.1 Design concept and device preparation

The proposed BHDS adopts an integrated multilayer device configuration consisting of two sensor units: a triboelectric unit on top for fast dynamic detection and an ionic-supercapacitive unit at the bottom for slow static monitoring. From top to bottom, there are five separate layers with unique functions in the dual-mode sensor: the triboelectric layer, upper electrode layer, separate elastic layer, ionic dielectric layer, and bottom electrode layer (Figures 1B and S1).

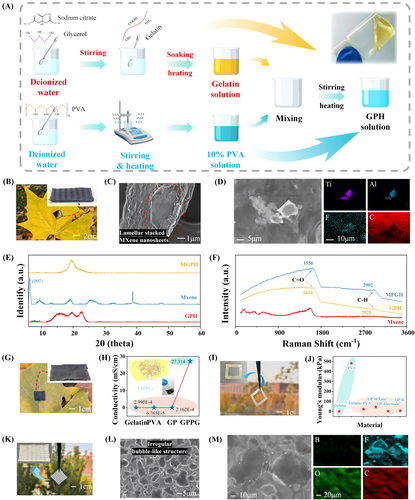

It is known that the human perception of external stimuli is closely associated with the complex structures of the epidermis and dermis, which contain diverse tactile receptors capable of processing extensive information and transmitting it to the nervous system. Hydrogels, composed of three-dimensional (3D) polymer networks and abundant water molecules, are commonly selected as the building block materials for constructing flexible electronics because of their remarkable flexibility, biocompatibility, and water retention.32-34 Among the different network formation mechanisms of physical, chemical, and radiation cross-linking, physical cross-linking is environmentally friendly, reversible, and simple, and is preferred for making wearable hydrogel-based e-skins. Therefore, a double physically crosslinked gelatin-polyvinyl alcohol (PVA) hydrogel (GPH) was prepared as the base material (Figure 2A). Gelatin, a collagen-derived biodegradable material, exhibits excellent biocompatibility but limited mechanical performance owing to its low Young's modulus, despite its skin-like softness.35, 36 The low Young's modulus of gelatin can lead to a loose network structure and weak intermolecular forces, affecting its mechanical properties. PVA, a hydrophilic synthetic polymer, is known for its high mechanical strength, thermal stability, and hydrogen bonding capacity.37-39 When mixed with gelatin, the high mechanical strength and Young's modulus of PVA can significantly reinforce the hydrogel network structure, making it tighter and more stable, thereby increasing the tensile strength, even though the strain capacity may decrease. As shown in Figure S2, when the gelatin ratio was high (e.g., 3:1), the hydrogel exhibited a high elongation at break but a low tensile strength. With an increase in the PVA ratio, especially when it exceeded that of gelatin (e.g., 1:2), the tensile strength of the hydrogel significantly improved. The Young's modulus results for different ratios of GPH hydrogels supported this (Figure S3). With decreasing gelatin and increasing PVA concentrations, the elastic modulus values were 39.053 ± 4.254, 127.694 ± 3.964, 251.425 ± 3.247, and 448.857 ± 3.654 kPa, showing an obvious upward trend. By comprehensively considering the Young's modulus and the self-healing and adhesion properties, a 2:1 ratio of gelatin to PVA was chosen for the GPH hydrogel base solution in subsequent experiments. In addition to the primary gelatin and PVA matrix components, glycerol was incorporated into GPH. The binary solvent system of glycerol and water forms stable hydrogen bonds, creating a “water-locking effect” that effectively resolves the water retention issues of conventional hydrogels while enhancing the efficacy and lifespan of hydrogel-based sensors (Figure 2A). The addition of sodium chloride (NaCl) boosted the ion content in the hydrogel and provided moisturizing and antifreeze effects. As shown in Figures S4 and S5, different NaCl contents (1.65%, 3.5%, and 6.16%) had little effect on the stress–strain curve, with Young's modulus values of 118.996 ± 3.365, 127.694 ± 3.864, and 132.272 ± 4.0521 kPa. This indicated that adding a certain proportion of NaCl had a minimal impact on the mechanical properties of the GPH hydrogel. In this study, 3.5% NaCl was used.

The triboelectric layer on the top surface of the sensor was fabricated using MXene-composited GPH (MGPH), which acts as an interactive interface between the sensor and external objects (Figure S6). MXene, a two-dimensional (2D) transition metal carbide (Ti3C2Tx), enhances triboelectric output via its high electron affinity and charge storage capacity.40-42 Hydrogen bonding between the surface functional groups (OH, O) of MXene and the amino groups of GPH strengthened the mechanical properties of the composite. Furthermore, pyramid-shaped microstructures were imprinted on the surface via template casting, which increased the effective contact area.

The electrode layers included the upper and lower layers. The upper electrode served as the common electrode for both the top triboelectric unit and the bottom ionic-supercapacitive unit, whereas the bottom electrode was only used to construct the bottom ionic-supercapacitive unit. Its composition was PEDOT:PSS-graphene-composited GPH (PGGPH) (Figure S7), which was fabricated into a thin flat film. As a highly conductive polymer, PEDOT:PSS was introduced into GPH to provide efficient ion transport channels.43-45 In addition, graphene, with its unique 2D structure, was incorporated in this study, enhancing electron transport pathways.46, 47 Within the 3D network of the hydrogel, the polymer chains of PEDOT:PSS were interwoven with graphene sheets. PEDOT:PSS encapsulated graphene surfaces and filled the gaps between the sheets. Through intimate interfacial contact, this configuration reduces the charge transfer resistance, optimizes the charge transport pathways, and accelerates the electron transfer from PEDOT:PSS to graphene. However, excessive PEDOT:PSS disrupts the network, decreasing the conductivity. Similarly, small amounts of graphene build a conductive network, whereas excess graphene causes agglomeration and lowers conductivity. To study the impact of these ratios on the conductivity of the PGGPH hydrogel, five ratios (PEDOT:PSS:graphene = 4:1, 2:1, 1:1, 1:2, and 1:4) were tested with constant gel and total filler masses. As shown in Figure S8, the conductive fillers boosted the hydrogel conductivity. However, excess PEDOT:PSS or graphene was ineffective because of agglomeration. The 2:1 and 1:2 ratios achieved conductivities of 24.6451 ± 0.8621 and 26.6354 ± 0.6854 mS cm−1, respectively, which are close to that of the 1:1 ratio (27.314 ± 0.656 mS cm−1). Considering its effectiveness, a 1:1 ratio of PEDOT:PSS to graphene aqueous dispersion was chosen for subsequent experiments.

The ionic layer serves as the middle functional ionic layer in the construction of supercapacitors. It was composed of 1-butyl-3-methylimidazolium tetrafluoroborate (BMIM-BF4)-composited GPH (BGPH) (Figure S9), which was fabricated into a thin film with a microporous structure on the surface to further increase its effective contact area with the upper electrode layer. The BMIM-BF4 ionic liquid (containing mobile BMIM+ cations and BF4− anions) was incorporated into the hydrogel matrix to enhance ionic performance. Its high fluidity enables uniform distribution within the hydrogel, whereas the ion polarization under electric fields significantly improves the charge storage capacity.48, 49 When structured into a microporous ionic layer, the composite forms an enhanced electrical double-layer (EDL) capacitance through interfacial contact with the upper electrode. This design achieves capacitance values that are orders of magnitude higher than those of conventional electrostatic capacitors under an equivalent compressive pressure. A detailed explanation of the EDL can be found in Figure S16.

To further improve the sensitivity by reducing the initial capacitance value, the GPH was fabricated into a rectangular ring shape (Figure 2I), which was introduced as an elastic spacer between the upper electrode layer and the middle ionic layer. This spacer prevents direct contact between the upper electrode and the middle ionic layer when no load is applied, allowing a subtle deformation of the two so that they contact under small pressures. The sticky nature of the hydrogel spacer ensures the integrity of the entire sensor with an internal void structure.

2.2 Structural and morphological characterization

The MGPH triboelectric layer featured uniformly distributed pyramid-like surface protrusions (Figure 2B). Scanning Electron Microscopy (SEM) imaging (Figure 2C) demonstrated the presence of MXene nanosheets embedded in the dual-network hydrogel matrix, confirming a successful physical cross-linking through aqueous dispersion. Energy-Dispersive Spectroscopy (EDS) analysis (Figure 2D) revealed the characteristic Ti and Al signals, further verifying the incorporation of MXene. X-Ray Diffraction (XRD) characterization (Figure 2E) demonstrated the structural evolution: the amorphous GPH hydrogel exhibited a broad 13°–25° diffraction peak, whereas the pristine MXene showed a distinct (002) crystalline peak. The MXene-doped hydrogel (MGPH) displayed a single broad peak at ~20°, indicating a complete dispersion-induced amorphization of MXene within the hydrogel matrix. Raman spectroscopy (Figure 2F) revealed the interfacial interactions between MXene and GPH. The characteristic MXene signal at 1613 cm−1 (CO/TiC vibrations) shifted upon incorporation into GPH, suggesting the hydrogen bonding. Concurrently, the intensified CO vibration peak (1613 cm−1) and retained CH stretching peak (2925 cm−1) confirmed that the hydrogel matrix integrity was preserved with enhanced interfacial interactions. These multimodal analyses collectively demonstrated an effective MXene integration through physical cross-linking without compromising the structural stability of the hydrogel.

PGGPH electrode layers were fabricated by incorporating PEDOT:PSS and graphene into the GPH matrix (Figure 2G), achieving an electrical conductivity of 27.314 mS cm−1. This represents a 5-order-of-magnitude enhancement compared to those of the constituent polymers: gelatin (2.995 × 10−4 mS cm−1), PVA (0.676 × 10−4 mS cm−1), and GPH hydrogel (2.16 × 10−4 mS cm−1) (Figure 2H). Structural characterization revealed the synergistic interactions between components, and XRD analysis (Figure S11) showed the partial masking of PEDOT:PSS and graphene peaks by the hydrogel's broad ~20° amorphous halo, although the residual features confirmed their presence. The right shift of the GPH peak indicated the filler-induced crystallinity modification. The Raman spectra (Figure S12) retained their characteristic PEDOT:PSS vibrations at 1420 cm−1 (CC) and 1500 cm−1 (CC), confirming a molecular-level integration. Graphene fingerprint regions displayed D (1350 cm−1, structural defects), G (1580 cm−1, sp2 lattice), and 2D (2680 cm−1, layer stacking) peaks, verifying the structural preservation during composite formation.

As shown in Figure 2K, the BGPH layer that serves as the supercapacitor sensing unit has an upper surface covered with pyramid-like surface microstructures. The SEM image of the BGPH (Figure 2L) revealed a microstructure with irregularly sized and unevenly distributed pores at the micrometer scale. The edges of these pores were relatively smooth and their formation was attributed to the introduction of BMIM-BF4, which altered the aggregation and curing processes of the GPH gel system, leading to an inhomogeneous phase-separation structure. The porous structure not only enhanced the flexibility and compression properties of the hydrogel, but also provided an effective storage space for BMIM-BF4, facilitating the ion migration and distribution, and thus improving the electrical performance of BGPH as an ionic layer. Elemental mapping (Figure 2M) confirmed the homogeneous distribution of B and F, verifying the successful BMIM-BF4 integration. Crystallographic analysis revealed an ionic state transformation. While pure BMIM-BF4 showed characteristic XRD peaks at 38°/47° (Figure S13), these crystalline signatures disappeared in BGPH, confirming the ionic dissociation within the hydrogel matrix. The retained amorphous GPH peak (~20°) demonstrated structural stability during ionic liquid incorporation. Raman spectroscopy (Figure S14) provided complementary evidence through weakened BF4− vibration modes (773/2708 cm−1), indicating effective cation-anion solvation by the hydrogel networks. A specific comparison of the Young's modulus of each functional gel layer is shown in Figure 2J; the addition of functional materials did not significantly affect the mechanical properties of the mixed gel.

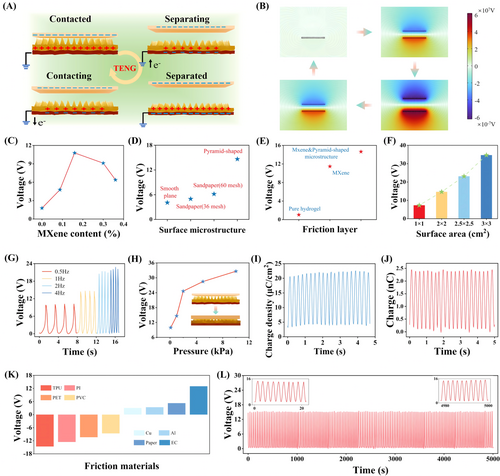

2.3 Triboelectric sensing performance

The single-electrode triboelectric unit employed a TPU contact layer to generate the electrical signals through cyclic contact-separation motions (Figure 3A).50-52 During the interfacial contact, the electron transfer occurs between the TPU (higher electronegativity) and the MGPH, inducing the positive surface charges on the MGPH. The subsequent separation triggers the electrostatic induction, driving electrons to flow from the ground to the PGGPH electrode until an equilibrium is reached. Repeated mechanical stimulation converts the kinetic energy into an alternating current via the coupled triboelectrification and electrostatic induction mechanisms.53, 54 To further analyze the electric potential distribution during the contact-separation process between TPU and MGPH, COMSOL modeling and simulations were conducted. As shown in Figure 3B, the induced electric potential increased with increasing separation distance and vice versa. This trend confirms the dependence of the output characteristics of the triboelectric unit on the contact-separation dynamics. The triboelectric performance of the unit was systematically investigated in vertical contact mode with a TPU contact layer and an effective contact area of 2 cm × 2 cm. Figure 3C illustrates the relationship between the concentration of MXene and the triboelectric sensing performance. Between the MXene concentrations of 0% and 0.4%, the optimal output voltage (10.78 V) occurred at the 0.16 wt% MXene. Additionally, surface topography modulation further enhanced the performance: the pyramid-microstructured MGPH achieved 14.64 V output, outperforming the smooth (ΔV = 7.32 V) and sandpaper-textured (36-grit: 9.45 V; 60-grit: 11.27 V) counterparts due to the amplified effective contact area (Figure 3D,E). Scalability analysis confirmed the linear voltage enhancement with the contact area expansion (1 cm × 1 cm: 7.32 V → 3 cm × 3 cm: 34.67 V, Figure 3F). Dynamic testing revealed a proportional relationship between the output signals and the contact velocity/pressure (Figure 3G,H). Using a triboelectric layer with pyramid-shaped microstructures, the output current density and charge density reached approximately 18 μC cm−2 and 2.3 nC, respectively, under conditions of 1 Hz contact frequency and 2 kPa contact pressure (Figure 3I,J). Different atomic nuclei of different materials have different affinities for electrons. Materials with high electronegativities tend to gain electrons more readily during friction, whereas materials with low electronegativities are more likely to lose electrons. Therefore, when the BHDS undergoes surface friction with different triboelectric materials, the amount of charge generated and its polarity differ, and the peak voltage output of the sensor varies. Eight materials were tested at different positions in the triboelectric series (Figure S15). Positive output voltages were observed when the MGPH triboelectric layer was in contact with materials such as Cu, Al, paper, and ethyl cellulose, whereas negative voltages were recorded for TPU, PVC, PET, and PI. The amplitude of the output voltage was higher for the materials positioned closer to the ends of the triboelectric series (Figure 3K). By exploiting the aforementioned differences in the triboelectric output signals, the triboelectric sensor is expected to achieve a high accuracy rate in identifying different substances. Long-term cycling (5000 s) resulted in a voltage decay of <5% (Figure 3L), validating the operational stability for practical sensing applications.

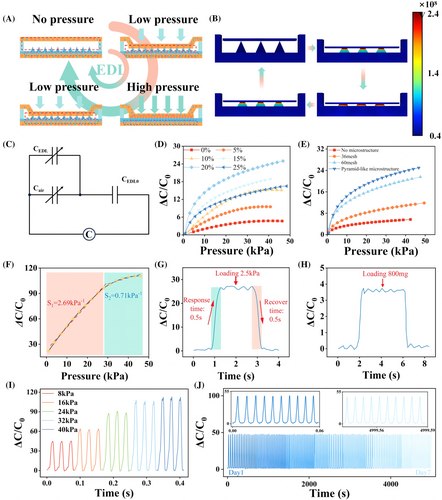

2.4 Ionic-supercapacitive sensing performance

The BGPH ionic layer contains a high density of freely mobile cations (BMIM+) and anions (BF4−). When the BGPH ionic layer contacts the PGGPH electrode layer, a significant number of free electrons aggregate at the electrode surface, inducing opposite ionic migration within the BGPH layer. This interaction establishes a capacitive interface between the BGPH and PGGPH layers, forming an EDL. The EDL effectively creates countless nanoscale parallel capacitors at the interface, therefore enhancing the areal capacitance and improving charge transport efficiency. The integration of the pyramid-shaped microstructure further amplifies this effect by increasing the effective contact area at the macroscopic scale, thereby augmenting the contribution of the EDLs to the overall capacitance. This structural design ensures that the capacitive sensing unit not only rapidly forms dynamic capacitance to respond to external pressure, but also exhibits heightened sensitivity to minute pressure variations. The spacer fabricated from the hydrogel plays a crucial role in ensuring the structural and functional robustness of the e-skin. This layer exhibits excellent elasticity and compressibility, specifically enabling the accurate detection of subtle pressure changes under low pressure, and serves as a buffer to prevent the irreversible deformation of the microstructure on the upper surface of the ionic layer under high pressure. By synergizing the structural design of the elastic layer with the EDL-based capacitive response, the capacitive sensing unit achieved high precision and rapid responsiveness across a wide pressure range. To further verify the sensing mechanism based on ionic-electronic coupling effects, COMSOL simulations were conducted to model the capacitive response of the sensor under varying external forces. The results, shown in Figure 4B, demonstrate the dynamic changes in capacitance across the interface, corroborating the theoretical principles of EDL-based sensing. The influence of the BMIM-BF4 content on the performance of the ionic-supercapacitive sensing unit is shown in Figure 4D. As the BMIM-BF4 content increased from 0% to 25%, the performance initially increased, then decreased. Optimal performance was achieved at 20% BMIM-BF4, suggesting a balance between ionic conductivity and structural stability at this concentration. Excessive BMIM-BF4 likely disrupted the structural integrity of the ionic layer, resulting in reduced sensitivity. The effect of the surface microstructure on the capacitive sensing performance was consistent with its influence on the triboelectric performance, with pyramid-shaped microstructures yielding better results (Figure 4E). This enhancement is attributed to the increased effective contact area provided by the pyramidal structures, which amplified the contribution of the EDLs to the capacitance. The capacitive response of the BHDS in the pressure mode is presented in Figure 4F. At pressures below 28 kPa, the sensor demonstrated a maximum sensitivity of 2.69 kPa−1, indicating its ability to detect subtle pressure variations. At 45 kPa, the relative capacitance change reached approximately 110 kPa, indicating a broad detection range. Benefiting from the low Young's modulus of the hydrogel ionic layer and the elastic support of the underlying structure, the BHDS exhibited rapid response and recovery. As shown in Figure 4G, under an applied force of 2.5 kPa, the sensor achieved both a response and recovery time of 0.5 s. Notably, the sensor maintained the same response and recovery times, even under a higher pressure of 25 kPa (Figure S17), demonstrating consistent dynamic performance over a wide pressure range. The detection limit, defined as the minimum pressure detectable by the sensor, was then evaluated. As shown in Figure 4H, TPU particles weighing approximately 800 mg were placed on the surface of the BDGE. Despite the low contact pressure, the ionic-supercapacitive sensing unit exhibited a significant and measurable capacitance change, highlighting its high sensitivity to minute forces. To assess the dynamic monitoring performance of the BHDS under varying pressure conditions, the relative capacitance changes were recorded during repeated loading and unloading cycles at pressures of 8, 16, 24, 32, and 40 kPa (Figure 4I). The sensor exhibited excellent stability across all the tested pressures, with the amplitude of the relative capacitance change increasing proportionally with the applied pressure. The consistent shape and repeatability of the capacitance change curves demonstrate the robustness of the sensor during cyclic loading. The long-term stability and durability of the BHDS were also examined. As shown in Figure 4J, the relative capacitance changes were monitored over a 5000 s testing period under a constant pressure of 10 kPa, which was repeated daily for seven consecutive days. The results revealed negligible fatigue or drift in the signal amplitude, highlighting the outstanding durability and reliability of the sensor. Furthermore, as shown in Figure S18, the mass change of the sensor over the same period was negligible, confirming the structural integrity of the hydrogel-based components.

2.5 Dual-mode dynamic-static haptic perception verification

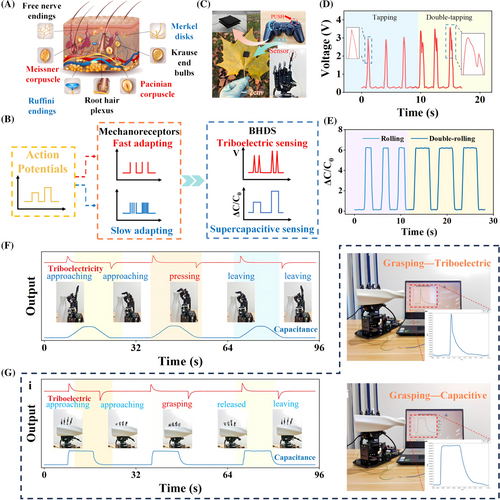

Figure 5A shows that the skin, a highly sophisticated sensory organ in the human body, perceives external stimuli through mechanoreceptors. These mechanoreceptors can be classified into fast-adapting (FA) and slow-adapting (SA) types, which differentiate between dynamic and static signals (Figure 5B). Inspired by this dual-sensing mechanism, we integrated the BHDS into the fingertips of an intelligent mechanical hand to differentiate between dynamic and static signals. The triboelectric sensing mechanism simulates the dynamic sensing of transient touch signals, whereas the ionic-supercapacitive sensing mechanism simulates the static response to sustained pressure to enable it to distinguish and respond. To validate the dual-mode sensing capability of the BHDS, we conducted experiments by integrating the BHDS into a gaming controller and robotic finger (Figure 5C). The responses were monitored under different actions, such as tapping, double-tapping, and rotating the controller knob for one and two full turns, to evaluate its performance. As shown in Figure 5D, distinct voltage peaks corresponding to each tapping action were observed in the triboelectric sensing mode, effectively capturing the dynamic pressure. Specifically, for double-tapping, two sequential voltage peaks were clearly distinguishable, as highlighted in the enlarged view of the black box. Meanwhile, as shown in Figure 5E, rotation of the controller knob was used to simulate prolonged static pressure, where the capacitive sensing mode exhibited stable and continuous capacitance changes over time, reflecting the duration and magnitude of the applied pressure. Additionally, under varying forces ranging from 1 to 10 kPa, both the triboelectric and ionic-supercapacitive modes displayed consistent and stable signal outputs, as illustrated in Figures S19 and S20. To explore the practical applications of the BHDS, such as real-time monitoring of objects grasped by robotic grippers, we integrated the BHDS onto the fingertips of a robotic hand (Figure 5F). When the robotic hand performed a “close-contact-press-release” sequence with a vase, the triboelectric sensing unit produced transient voltage peaks upon touch and release, thereby capturing dynamic interactions. Concurrently, the ionic-supercapacitive sensing unit recorded stable capacitance signals during the pressing phase, indicating static pressure. The response curves of the triboelectric and ionic-supercapacitive units, shown in Figure 5G (ii) and Figure 5G (iii), correspond to distinct stages of the robotic grasping process depicted in Figure 5G (i). These results demonstrate that the BHDS effectively tracked the entire sequence of the robotic hand interaction with the vase by simultaneously sensing triboelectric and capacitive signals. This dual-mode capability not only enables the BHDS to distinguish between dynamic and static tactile stimuli, but also highlights its potential for diverse applications in human-machine interfaces, robotic systems, and intelligent object manipulation.

2.6 Demonstration of intelligent material property recognition

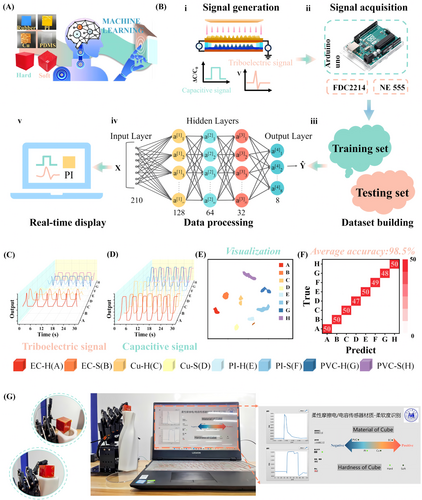

Human perception relies heavily on tactile sensing and learning to discern the physical properties of objects such as size, shape, texture, and hardness. This complex process involves the integration of sensory inputs and cognitive functions, enabling the precise and adaptive recognition of the external environment. Machine learning (ML) has emerged as a powerful tool for mimicking human perception, leveraging data-driven algorithms to learn and predict object properties from sensory inputs.42, 62-65 Inspired by this biological mechanism, a biomimetic dual-mode enhanced intelligent recognition system can be developed by integrating the prepared BHDS with an MLP neural network model (Figure 6A). Under the dual-mode sensing mechanism, robotic hands integrated with the BHDS can simultaneously output triboelectric and capacitive sensing signals in real time during the “touch-press” interaction with objects. In this process, dynamic and static perceptions correspond to triboelectric sensing and ionic-supercapacitive sensing, respectively. The triboelectric signal arises because of the differences in the electrification levels when the two materials come into contact. The amount and polarity of the triboelectric charge vary with the material properties at the moment of contact, laying the theoretical foundation for the application of triboelectric sensors in material characteristic recognition. For objects of identical shape and size, the softness or hardness of the material determines the force feedback from the sensor during pressing under the same applied external force. This difference in force leads to variations in the inter-electrode spacing of the ionic-supercapacitive sensor, which manifests as differences in the capacitive signal. Soft materials with a higher cushioning ability deform more under pressure, resulting in smaller feedback forces and weaker capacitive signals. In contrast, harder materials exhibit smaller deformations and generate larger feedback forces, thereby producing stronger capacitive signals. Therefore, the softness of an object can be accurately evaluated by analyzing the differences in the capacitive signals. By combining the BHDS with an MLP neural network, the system processes multimodal tactile data and learns to classify material properties, hardness, and softness. This approach enables intelligent recognition of object surface materials and hardness by equipping robotic systems with human-like tactile perception.

To validate this concept, we designed an experimental setup using four materials with smooth surfaces and minor differences in their surface properties: PVC, TPU, Cu, and PDMS. These materials were applied as surface layers on two types of cubic objects (solid and hollow) of identical size and material to simulate materials with different degrees of hardness and softness (Figure 6A). Figure 6B illustrates the structure of the dual-mode enhanced intelligent recognition system, which includes a robotic hand integrated with the developed dual-mode sensing e-skin, hardware circuits for signal acquisition and data transmission, a four-layer MLP neural network model, and a user interaction interface. The process begins by positioning the BHDS-equipped robotic hand close to the target object, where it performs a “touch-press” action to collect triboelectric and capacitive signals. These signals are captured by a high-precision multi-channel FDC2214 data acquisition system, processed by a 555 multi-harmonic oscillator circuit, and transmitted to a computer via an Arduino control board for real-time learning and prediction using the deep learning model. The acquired signals undergo feature extraction, and a feature matrix [X] and labels [Y] are used to train the four-layer MLP neural network model. This model is iteratively trained to optimize its ability to classify the material properties of objects. The MLP neural network comprises an input layer, three hidden layers, and an output layer. The input layer consists of 210 neurons representing 210 data points, with 126 and 84 data points from the triboelectric and capacitive modes, respectively. The output layer contains eight neurons, each representing the output recognition probability for one of the eight possible target categories. The input and hidden layers use Rectified Linear Unit (ReLU) activation functions to introduce nonlinearity and improve model performance. The output layer employs a softmax activation function to provide probabilistic classification outputs. The three hidden layers contain 128, 64, and 32 neurons, respectively, which gradually extract features to refine the data and produce more compact and effective representations. In the experimental setup, eight cubic objects, each with different material or hardness properties, were subjected to 250 “touch-press” actions, yielding 2000 data points. These data points were split into training and testing datasets in a 4:1 ratio, providing 1600 samples for training and 400 for testing. As the model iterates and receives more data, it progressively improves in accuracy. The classification results are displayed on the user interface, providing immediate feedback on material recognition and hardness evaluation. Figure 6C,D show the triboelectric and ionic-supercapacitive characteristic curves collected for cubes with eight different attributes under the contact and pressure modes, respectively. The characteristic curves of the same material exhibited cyclic behavior and high consistency, whereas significant differences in the triboelectric and capacitive response curves were observed between different materials. In particular, the triboelectric response demonstrated stronger signal outputs and higher amplitude waveforms for materials located at the extremes of the triboelectric series compared with those in the middle range. In contrast, under the same external force, the capacitive change for a rigid material (e.g., PDMS) was more pronounced than that for a soft material, reflecting the sensitivity of capacitive sensors to material hardness. Building on this, a unified comprehensive dataset was constructed by integrating the features derived from different sensing modes, including the triboelectric response characteristic curve based on contact electrification and the capacitive response curve related to material softness. This fusion of multimodal features significantly enhanced the representation of the characteristics of the detected object. Through t-distributed stochastic neighbor embedding (T-SNE) dimensionality reduction and visualization analysis, the output results of the model exhibited a clear clustering structure in the feature space (Figure 6E), indicating good separation between the different attribute characteristics in high-dimensional space.

This effective separation is further reflected in the classification accuracy of the feature model. By combining both the triboelectric and capacitive features, the recognition accuracy reached 98.5% (Figure 6F). Figure 6G illustrates the recognition performance of PI, which is a rigid material. The integrated BHDS-equipped robotic finger performs a “touch-press” action to identify the surface material and softness of an unknown object, and the recognition results are displayed in real time at the interface. This multimodal sensing approach significantly improves the tactile perception capabilities of the robot, enabling it to accurately classify material types and mechanical properties through a combination of contact electrification and capacitance-based features. This system demonstrates the potential of sensors integrated with deep learning models to perform intelligent tactile recognition and enhance the robot's ability to perceive and interact with objects in a human-like manner.

Although the BHDS with the aid of MLP performs excellently in the recognition of materials with varying hardness values, it should be noted that the range of the target material type is limited for accurate sensing purposes. Materials that are too soft, such as sponges or gels, have extremely low Young's moduli and deform excessively under pressure; therefore, the sensing electrodes may come into complete contact with them, leading to capacitance signal saturation and a reduction in detection sensitivity. For materials that are too hard, such as ceramics or steel, the degree of deformation is too small and much lower than the minimum detection limit of the ionic-supercapacitive sensor, which also affects the accuracy of identification.

3 CONCLUSION

In this study, we successfully developed a BHDS, which is a sensor that mimics the tactile ability of human skin by simultaneously detecting dynamic and static pressures through combined triboelectric and ionic-supercapacitive sensing. The triboelectric part captures the dynamic stimuli, and the ionic-supercapacitive part, optimized by ionic liquid doping and microstructures, uses EDL amplification for high static pressure detection. Performance-wise, for dynamic tactile perception, 14.64 V was achieved with negligible attenuation for 5000 s of cyclic operation. In the low-pressure range of 0.8–28 kPa for static tactile perception, the sensitivity was 2.69 kPa−1, the detection range was 0.8–45 kPa, response and recovery times were around 0.5 s, and ionic supercapacitance signal drift was under 5% in a 7-day test. Using machine learning, the accuracy of identifying materials and differentiating the hardness of target objects reached 98.5%. Characterizations demonstrated the wide pressure detection range and high durability of the BHDS. Integrating it into game controllers and robotic grippers demonstrated its ability to distinguish dynamic stimuli from static stimuli and monitor real-time object interactions. Therefore, the BHDS has great potential in human-machine interfaces and soft robotics. When paired with AI, it enables intelligent object recognition and is expected to be crucial for future applications.

4 EXPERIMENTAL SECTION

4.1 Materials

Titanium aluminum carbide (Ti3AlC2) (mesh ≥99 wt%, MW: 194.6) was purchased from Laizhou Kai Kai Ceramic Materials Co., Ltd. Lithium fluoride (LiF) (AR: 99%, MW: 25.94) and hydrochloric acid (0.01 mol L–1) were purchased from Shanghai Macklin Biochemical Technology Co., Ltd. A-type gelatin powder (~250 Bloom) was purchased from Shanghai Bide Pharmaceutical Technology Co., Ltd. Poly(vinyl alcohol) 1799 was purchased from Shanghai Yuan Ye Biotech Co., Ltd. Sodium chloride (AR: ≥99.5%) was purchased from Tianjin KeMiOu Chemical Reagent Co., Ltd. Glycerol (AR: 99%) was purchased from Shanghai Yien Chemical Technology Co., Ltd. PEDOT:PSS was purchased from Zhuhai KaiWei Optoelectronic Technology Co., Ltd. The graphene dispersion was purchased from Sinode Material Technology Co., Ltd. 1-Butyl-3-methylimidazolium tetrafluoroborate (BIMI-BF4) (AR: 99%) was purchased from Lanzhou Greenchem ILs. All chemicals purchased were of analytical grade.

4.2 Preparation of the molds

All the functional layers of the sensors were fabricated using a mold-casting method with molds produced by 3D printing using a Raise Pro2 Plus 3D printer (Shanghai Fusion Technology Co., Ltd.). As shown in Figure S21, the SolidWorks models were exported as STL files and imported into the slicing software IdeaMaker V5.1.4 for configuration of the parameters. The printing tasks were then transferred to a Raise Pro2 Plus printer for production.

4.3 Preparation of the 8% MXene dispersion

- A reaction flask containing a magnetic stir bar was placed on a magnetic stirrer set to 30°C and 300 rpm. Sequentially, 2.5 mL of deionized water and 7.5 mL of concentrated hydrochloric acid were added to the flask. Then, 0.8 g of lithium fluoride (LiF) was quickly introduced, and the flask was loosely sealed for a 5-min reaction;

- Subsequently, 0.5 g of Ti3AlC2 was added gradually in small portions to the reaction flask. The flask was loosely sealed, and the reaction proceeded at 47°C for 24 h;

- The resulting solution was equally distributed into four centrifuge tubes and centrifuged at 10000 rpm for 5 min. After each cycle, the supernatant was removed, deionized water was added, and the process was repeated eight times. The final solution was ultrasonicated for 10–15 min;

- To further purify the dispersion, the solution was centrifuged at 3000 rpm for 20 min. The supernatant collected after this step was the desired MXene-water dispersion.

4.4 Preparation of the GPH solution

The GPH solution was prepared as follows (Figure 2A): (1) A mixture of 0.46 g of sodium chloride and 3 g of glycerol was dissolved in 4 mL of deionized water while stirring at 1000 rpm for 30 min; (2) To the solution, 2 g of gelatin was added and allowed to rest for 2 h; the mixture was heated in a water bath at 75°C while stirring at 3000 rpm for 1 h, yielding gelatin solution A; (3) Separately, 1 g of polyvinyl alcohol (PVA) granules was dissolved in 9 g of deionized water at 90°C under stirring at 3000 rpm for 2 h, yielding 10% PVA solution B; (4) Solutions A and B were mixed in a 2:1 mass ratio and heated while stirring at 90°C and 3000 rpm for 2 h to obtain the desired GPH solution.

4.5 Preparation of the modified hydrogel solutions

- MGPH solution: To prepare the MGPH, the GPH preparation protocol was followed, except that 4 mL of deionized water in Step (1) was replaced with 4 mL of an 8% MXene-water dispersion (Figure S6);

- PGGPH solution: For the PEDOT:PSS–graphene-doped hydrogel (PGGPH), 4 mL of deionized water in Step (1) was replaced with 2 mL of the PEDOT:PSS solution and 2 mL of the graphene dispersion (Figure S7);

- BGPH solution: For the PGGPH, 4 mL of deionized water in Step (1) was replaced with 2 mL of the BMIM-BF4 solution and 2 mL of deionized water (Figure S9).

4.6 Fabrication of the functional layers

As shown in Figure 2A, the prepared GPH solution was poured into prefabricated molds and allowed to solidify. After solidification, the elastic layer was demolded. The fabrication of the other functional layers, such as the friction, electrode, and ionic layers, followed the same procedure, which is detailed in Figures S6, S7, S9, and S10.

4.7 Assembly of the BHDS

The BHDS was fabricated by sequentially stacking the layers of the triboelectric sensing unit and capacitive pressure sensing unit from top to bottom. Silver wires were used to extract connections from the electrode layers of each sensing unit, thereby successfully constructing the electronic skin.

4.8 Characterization and measurements

The hydrogels were characterized using high-resolution emission scanning electron microscopy (HRFE SEM & EDS, JEOL 7610F, JEOL Ltd.), X-ray diffraction (XRD, Rigaku Corp.), and high-speed high-resolution micro confocal Raman spectroscopy (HORIBA LabRAM Odyssey, HORIBA Jobin Yvon). The performance of the hydrogel-based TENG sensor was characterized using an oscilloscope (TBS2104B C010957), scanning signal generator (DH1301, Jiangsu Donghua Testing Technology Co., Ltd.), power amplifier (DH5872, Jiangsu Donghua Testing Technology Co., Ltd.), and programmable electrostatic meter (Model 6514, Keithley Instruments Inc.). The tensile properties, Young's moduli, and electrical conductivities of the hydrogels were measured using a full computer tensile peel tester (Guangdong ZHONGYE Precision Science Co., Ltd.), an electrochemical workstation (CS235OH, Wuhan Corrtest instruments Corp., Ltd.), and a full digital high-frequency Q meter (AS2853A, Shanghai AIYI Electronic Instruments Corp., Ltd.). The performance of the capacitive sensors was also characterized using instruments such as a high-precision Inductance-Capacitance-Resistance (LCR) Tester (LCR-6300, GWINSTEK).

ACKNOWLEDGMENTS

This study was supported by the China National Key Research and Development Program (No. 2022YFC3601400), Tianjin Science and Technology Plan Project (No. 22JCZDJC00630), and Higher Education Institution Science and Technology Research Project of Hebei Province (No. JZX2024024).

CONFLICT OF INTEREST STATEMENT

The authors declare that they have no conflict of interest.