Educational (mis)match in the context of new manufacturing: A qualitative comparative analysis study in five European countries

Abstract

The article examines the interplay between shop-floor employees' educational levels, and firms' training strategies (expressed by the breadth of the training, the extent of the advanced IT training, and skills development in collaboration with local or national technical schools), leading to multinational companies' educational (mis)match in the context of the new model of manufacturing, known as ‘Industry 4.0.’ Following a survey of 26 senior managers from different companies operating in four advanced manufacturing industries (biotech, engineering, fashion and new materials) in five European countries (Germany, Italy, Spain, Sweden and the UK), a fuzzy-set qualitative comparative analysis (fs/QCA) is applied. The results suggest several equifinal paths to corporate educational (mis)match. The findings reveal the need for a more hybridised coexistence between tertiary education and training activities, which can emerge from the cooperation of local actors (education/training institutions and businesses together). Tertiary education, training programmes focused on advanced IT skills, and collaborating with local knowledge providers can reinforce the effect; indeed, their presence (singly or in combination) intensifying the achievement of high levels of educational match. In the absence of these conditions (singly or in combination), a broad training programme can act as a counterbalance and vice versa. Policymakers should put in place tools to enable more inclusive access to collaborations between local businesses and knowledge providers, promoting an upgrade of educational programmes to develop shop-floor workers who are more digitally aware, and better prepared to successfully undertake non-routine cognitive tasks. This would foster the self-sustainability and flourishing of advanced manufacturing in high-income countries.

1 INTRODUCTION

Over recent decades, companies have been reshaped by a disruptive wave of technological change (Sousa & Rocha, 2019b). A host of new technologies (OECD, 2016), ranging from an array of digital technologies (e.g., 3D printing, the Internet of Things, advanced robotics) to new materials (e.g., bio- or nano-based) and new processes (e.g., data-driven production, artificial intelligence, synthetic biology), has emerged. In manufacturing, this shift towards automation and data exchange1 amongst technologies (Atasoy, 2020) has given rise to what has been defined as the ‘fourth industrial revolution’ (Schwab, 2017), or ‘Industry 4.0’ (I4.0). These new enabling technologies have transformed both companies' physical infrastructures and features of their products (Vendrell-Herrero et al., 2021). Nowadays, companies sell products in tandem with digitalized services linked to the products (Neely, 2008; Parry et al., 2012). The increasingly tight intertwining of manufacturing and service functions has brought about a fundamental change in the nature of companies' structures, their business models (Kohtamäki et al., 2019), and the products they sell (Sjödin et al., 2016). Indeed, electronics and internet-connected information and communication technology (ICT) products are being progressively embedded into other machinery, increasing demands for ICT skills and expertise (Holtgrewe, 2014).

The manufacturing sector in advanced economies has been challenged not only by changes to the physical infrastructure and product features but also by the demographic changes of the employees involved (Hertle et al., 2015). In this digital age, labour still has an enduring relevance (Shestakofsky, 2017) and the introduction of cutting-edge technologies into the production process leads to new complementarities between people and skills (Shestakofsky, 2017), involving de-skilling, reskilling2 and upskilling (Autor, 2015). Hence, the development of ‘advanced skills’ (Hertle et al., 2015 p. 2) in production environments becomes a crucial prerequisite for future-oriented production processes. Recent advances in (digital) technology have challenged the organisation and qualifications required in manufacturing industries and, consequently, the collaborations required with knowledge providers (Lund & Karlsen, 2020; Wu & Li, 2020). These challenges concern shop-floor workers in particular, indispensable for the long-term competitiveness of manufacturing firms (Barzotto & De Propris, 2019; Howaldt et al., 2017; Lund & Karlsen, 2020) but difficult to recruit in the labour market, hampering companies' innovation capabilities (Eurostat, 2013). Modern concepts of training, novel industrial learning and knowledge transfer schemes enabling the recruitment and retention of a new generation of manufacturing workers, as well as the provision of the requisite skills for the 21st century for existing workers and new recruits (Snell, 2019), ‘can (all) have a significant impact on the ICT-related innovation performance of the European factories of the future’ (Mavrikios et al., 2013 p. 474).

Despite the call for an integrated (internal and external) competency development system on the shop floor of manufacturing environments, it remains unclear which specific employee training and qualifications should be put in place in advanced factories (Hertle et al., 2015) to match the skill sets needed to implement connected and digital manufacturing. Such a competency development system would enable the complete utilisation of these workers' potential. Thus, there is a need to identify which are the new approaches manufacturing education should follow in order to foster its growth and prepare this sector for next-generation innovation (Mavrikios et al., 2013).

Looking at shop-floor level, where manual workers, supervisors and engineers (co)operate in product development activities (Jürgens & Krzywdzinski, 2015), being also where the value is created (Suzaki, 1993), should shed light upon these issues. Building on skill-biased technological change (SBTC), educational (mis)match, and the emerging I4.0 literature, the present study: (i) identifies the interplay between shop-floor employees' educational attainment and companies' training strategies that would allow firms to achieve successful educational alignment in the context of I4.0; and, (ii) compares this with the situation that pertains when firms suffer educational mismatch. It does this by focusing on two interrelated research questions: which combinations of shop-floor employees' educational levels, companies' training initiatives, and their engagement with local vocational training institutions are going to be able to deliver the required educational matching? And, what are the combinations that instead result in educational mismatch?

I address this issue empirically by surveying senior managers of multinational companies in five advanced European economies (Germany, Italy, Spain, Sweden and the UK), operating in four advanced manufacturing industries (biotech, engineering, fashion, and new materials). A configurational, case-oriented approach (Ragin, 1987; Ragin, 2008) called fuzzy-set qualitative comparative analysis (fs/QCA) is used to detect different paths of educational attainment, and company training strategies, that enable companies to achieve the same outcome (Braumoeller & Goertz, 2000; Grandori & Furnari, 2008) in terms of educational (mis)match. I complement this with a descriptive analysis in which two groups of companies, those with high levels of educational match and those with educational mismatch,3 are compared in relation to their skills' awareness. In particular, I examine companies' awareness of their skills' needs in terms of: (i) which skills they find most difficult to recruit to; (ii) which skills are required to increase companies' future competitiveness; and, (iii) which skills companies will recruit most to in 3 years' time.

The contribution of the study is threefold. Firstly, it adds to the literature on SBTC and advances the debate amongst continuity theorists (e.g., Autor, 2015; Davenport & Kirby, 2016) by identifying which factors associated with shop-floor employees' educational attainment and companies' training strategies lead to high levels of corporate educational match, comparing these with those that lead to educational mismatch. Secondly, the study contributes to the emerging I4.0 literature by identifying holistic industrial learning strategies that underpin the complex interactions between technology and employment (Shestakofsky, 2017), and which will support factories of the future in improving their educational match and, consequently, their performance.4 Thirdly, the use of fs/QCA enables the identification of alternative but equally effective industrial learning strategies. This allows for a focus on the complementarity between educational attainment and companies' training strategies, rather than their net effects (Ben Jabeur et al., 2021; Ho et al., 2016) on educational (mis)match.

The article is structured as follows: the main conceptual framework is discussed in the next section; the methodology and the conditions under investigation are then defined, followed by a discussion of the results. Finally, managerial and policy implications are presented in relation to educational and training programmes for companies pursuing a I4.0 model.

2 THEORETICAL FRAMEWORK

2.1 Educational (mis)match

Existing research concerning mismatch in general is, as yet, relatively scarce (Desjardins & Rubenson, 2011). However, amongst the concepts of mismatch, a growing literature has emerged in the economic literature around the notion of educational or qualification mismatch (Dolton & Vignoles, 2000; Groot & Van Den Brink, 2000; Korpi & Tåhlin, 2009; Oosterbeek, 2000; van der Meer, 2009). Educational mismatch has been defined as a lack of coherence between the offered and required educational levels in relation to performance of a given job (Betti et al., 2011). It has been measured mainly in terms of over-education (or over-qualification), where the skills which an employee brings to a job exceed the skills required for that job, or under-education (or under-qualification), where workers have inadequate skills for the tasks they must carry out.

Both of these situations may have negative consequences not just for employees and employers (e.g. Feldman & Turnley, 1995; Sicherman & Galor, 1990), but also for the economies of many industrialised countries (e.g. Alba-Ramirez, 1993; Groot, 1996; Sevinc et al., 2020). Conversely, effective skills' utilisation could improve job quality (Findlay et al., 2017). In examining over-education, Tsang (1987) shows that it significantly and negatively affects workers' job satisfaction, which in turn negatively and significantly affects firms' outputs. Greater attention has been devoted to over-education than to under-education; only a few studies have examined the effects of the latter on companies' performance and training activities (Allen & Van Der Velden, 2001; Verhofstadt & Omey, 2003).

Technological change may generate a mismatch as a result of adjustments to the set of tasks which workers are required to perform (for a review of technological change theory, see Quintini, 2011). Skills-based technological change may increase demand for skilled labour (Autor et al., 2003; Krueger, 1993) because companies seeking to adopt new technologies efficiently in rapidly changing and uncertain markets may hire employees with qualifications higher than those actually needed, ignoring the negative impact that skill under-utilisation (Desjardins & Rubenson, 2011), and educational mismatch, can have on corporate performance. From the perspective of the supply side of the labour market, workers should perform jobs which match with their educational levels (see Section 2.2 below), while from the perspective of the demand side of the labour market, one path that employers can follow to overcome educational mismatch is to provide employees with additional education (Desjardins & Rubenson, 2011 p. 21, Sousa & Rocha, 2019a). According to this strand of the literature, employers play a crucial role in tackling mismatch because they are the single most important source of financing adult education/training (see Section 2.3 below).

2.2 Educational attainment levels of shop-floor employees

Formal educational attainment (whether general or vocational), that is, ‘qualifications and knowledge acquired through formal education’ (Broersma et al., 2016), is a measure of potential talent or skill (Florida et al., 2008). Technological changes in advanced manufacturing are pushing companies to reconsider their workers' engagement with new technologies (Bayo-Moriones et al., 2017; Boxall & Winterton, 2018; Edwards & Ramirez, 2016), and, in turn, their educational requirements (Haley-Lock et al., 2013). Highly educated, highly skilled workers undertake new tasks and adopt high-level technologies more rapidly and efficiently, which has a positive impact on innovation (e.g., Bishop, 1994; Blundell et al., 1999; Bosworth & Wilson, 1993). Educated workers are found to be not only more productive, but also able to improve the productivity of the less well-educated workers with whom they collaborate (Blundell et al., 1999), fostering positive production externalities from which companies may benefit (Gemmell, 1997; Redding, 1996). Conversely, low levels of manpower skills negatively affect companies' labour productivity, the deployable types and uses of machinery, and the implementation of new technologies (Blundell et al., 1999).

The educational level of workers directly associated with production processes is critical to the effective implementation of the automation, and data-exchange technologies, required in advanced factories. To be competitive, manufacturing companies need shop-floor workers capable of processing information to achieve advanced, and sustainable production environments (Hannola et al., 2016). Thus, in the context of I4.0, shop-floor workers are considered to be knowledge workers, and expectations in terms of their skills' sets are rising (Armbruster et al., 2007; Krzywdzinski, 2017). To carry out their jobs efficiently, such workers are required to process increasingly complex bundles of information and knowledge.

Building on these arguments, firms which employ a higher proportion of shop-floor workers with tertiary degrees are expected to use new technologies more effectively, because workers' ability to be innovative on the job increases accordingly. This, in turn, should lead to greater corporate satisfaction in relation to the workforce (demonstrating high levels of educational match).

2.3 Corporate training strategies

2.3.1 Internal training in smart factories

As standards and requirements change, companies are obliged to identify training opportunities to keep employees' skills current (Curnow & Mcgonigle, 2006 p. 292) and, ultimately, maintain competitive advantage (Ellinger & Ellinger, 2014). Previous studies have shown that employers' decisions in relation to investment in the education/training of their employees depend on the expected benefits, such as increased productivity, quality, and/or competitiveness (Vignoles et al., 2004). According to human capital theory (Becker, 1964), employers have no incentive to invest in training workers in (general) skills that are fully transferable and valued by other employers. Conversely, employers are keen to train their employees in specific skills that are completely non-transferable and valuable only to themselves (Galanaki et al., 2008). By investing in customised labour training (Hodson et al., 1992) to develop specific skills, employers reduce the risk of failing to recoup the costs of the training, because their workers are unlikely to be able to use their skills elsewhere. Nevertheless, companies may be willing to invest in developing general skills under specific circumstances (Lazear, 2009), in the context of individual and/or structural characteristics such as previous educational attainment, literacy skill levels, gender, age and immigration status (Desjardins & Rubenson, 2011; Eide & Showalter, 2010). Thus, for example, firms tend to be more inclined to train workers who already have high educational credentials or high levels of literacy. These are the workers from whom companies stand to gain most from training (Vignoles et al., 2004), offering better chances of optimising cost/benefit ratios, as well as reducing payback periods (Desjardins & Rubenson, 2011, p. 50). According to production system theories, modern lean production systems demand the constant cooperation of actors from all functional areas and hierarchy levels (Jürgens & Krzywdzinski, 2015), which requires the development of ‘shared codes and language’ as a vehicle of communication (Collins & Smith, 2006). To accomplish this, internal training needs to be put in place. In advanced manufacturing environments, tasks that require flexibility, creativity, intuition, situational adaptability, judgement, spoken language, interpersonal interaction, and persuasion are not yet automated and are unlikely to be automated any time soon (Shestakofsky, 2017). Thus, it can be predicted that being active in a large number of developmental interventions (Ellinger & Ellinger, 2014), in terms of both specific and general training initiatives (such as computer literacy, communication skills, customer-handling skills, and technical, practical or job-specific skills), should allow companies to source from a larger spectrum of skills that, in turn, reflects positively in their educational match.

The implementation of new technologies in production processes in the context of I4.0 has transformed traditional, isolated production systems into integrated, automated, optimised flows, requiring new skills' sets. For effective implementation of the I4.0 technologies essential to these new industrial processes, firms must train their workforces to master these interconnected systems in which humans and machines interact closely and human labour complements smart machines (Shestakofsky, 2017).5 For companies seeking to be competitive in the future, the adoption of I4.0 technologies seems inevitable. Therefore, I predict that those firms which adopt workforce upskilling strategies by training their employees in a wide range of advanced IT subjects will be more satisfied with their workforce and its outputs, and will demonstrate higher levels of educational match.

2.3.2 Company collaboration with vocational education institutions

The implementation of new manufacturing technologies can tie industry to vocational educational institutions (Lund & Karlsen, 2020) such as technical schools, colleges of further education, universities, and polytechnic institutes. Recent evidence shows how collaborations between industry actors, and vocational educational institutions, in developing new educational programmes tailored for contemporary and future manufacturing are critical to manufacturers' competitiveness (Lund & Karlsen, 2020). Digitally based competences will be increasingly pivotal to the upgrading of advanced manufacturing processes, but both companies and educational institutions are currently relatively unfamiliar with such skill sets.

Given the uncertainty around the ‘digital skills curriculum,’ and drawing upon the varieties-of-capitalism framework (Busemeyer & Trampusch, 2012), the present study explores how effective it could be to build cooperation between employers and local vocational institutions in a process of localised learning (Maskell & Malmberg, 1999) and skills' development. Involving companies in defining a competence-based curriculum in line with I4.0 requirements (Pfeiffer, 2015) should lead to a better match with the skills required in the labour market.

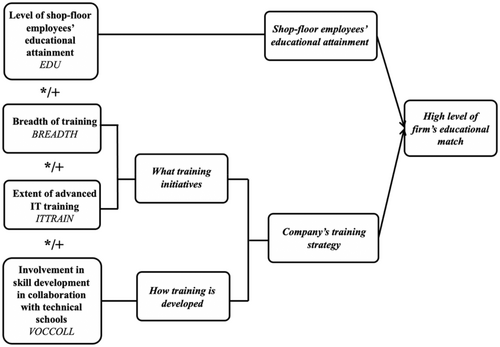

Educational levels tend to change very little after a worker reaches the age of 25 (Card, 1999). Nevertheless, thereafter, many workers receive additional training for new and/or different jobs. In a multidimensional view of skills' acquisition (Ingram & Neumann, 2006), workers acquire skills through education but also through on-the-job training and general work experience. By following distinct developmental paths, workers with different levels of education might seem to have similar skills endowment; indeed, workers can compensate for a lack of formal education by developing skills through training or experience. On the other hand, some workers might compensate for a lack of relevant productive skills necessary to a job via over-education (Groot & Van Den Brink, 2000). For these reasons, it is crucial to explore the mix of shop-floor employees' educational attainments, and those corporate training strategies which create the greatest explanatory power for high levels of educational match in firms and, conversely, the mix that leads to educational mismatch. Figure 1 provides an overview of the configurational model under investigation.

3 METHODS AND DATA

3.1 Methodology

This article employs a qualitative comparative strategy (e.g., Armanios et al., 2017; Greckhamer, 2016; Halme & Korpela, 2014; Jenson et al., 2016; Park, 2013; Sjödin et al., 2016; Walker et al., 2015) to explore: (i) which configurations of shop-floor employees' educational attainments and corporate training strategies are associated with high levels of educational match in firms; and, (ii) which configurations lead to low levels of educational match (or educational mismatch). I use a case-oriented methodology called fs/QCA, a research design based on a systematic comparison of a small number of cases (Andreas et al., 2017; Collier, 1993; Federo & Saz-Carranza, 2018; Iannotta et al., 2016; Lankoski & Thiem, 2020; Marx, 2010; Rihoux, 2006; Shin et al., 2020; Vink & Van Vliet, 2009) such as ‘micro-sociological, non-causal, hermeneutically oriented analysis of interview data’ (Rantala & Hellström, 2001 p. 88) and/or questionnaires (Blackman et al., 2011; Ito & Gehrt, 2014; Pahl-Wostl & Knieper, 2014), with the aim of providing new insights into interrelations between the explanatory factors. This methodology combines case-based research with Boolean algebra and a set-theoretical approach to carry out systematic and formalised cross-case comparisons (Ragin, 1987; Ragin, 2008) by looking at interactions between the explanatory factors.

QCA is a method of causal inference based on a difference-making theory of causation (Andreas et al., 2017), and has been applied to a growing number of disciplines and, for more than three decades, has been extensively used in management, political science and sociology (Shin et al., 2020). More recently, it has been increasingly employed in economics (e.g., Andreas et al., 2017; Bukkavesa et al., 2021; Shin et al., 2020; Villamayor-Tomas, 2018) and finance (e.g., Federo & Saz-Carranza, 2018; Iannotta et al., 2016; Ponomareva et al., 2022).

Fs/QCA conceptualises a case as a combination of causal conditions and the outcome (Schneider et al., 2010). Cases are configurations of qualitatively distinct causal conditions. Configurations are typically represented in terms of the presence or absence of the multiple conditions under consideration (Soda & Furnari, 2012). The aim of this methodology is to identify which configurations are most consistently associated with the outcome of interest – in this case, which sets of conditions are necessary, and/or jointly sufficient, to produce high levels of educational match in firms making QCA ‘a powerful tool [in] testing hypotheses or existing theories’ (Berg-Schlosser & De Meur, 2009, p. 16). Identification of the conditions is based on available theoretical or substantive knowledge of the cases and settings.

Rationales for the use of fs/QCA are threefold (Misangyi et al., 2017). Firstly, fs/QCA differs from ‘conventional, variable-based approaches’ because it does not ‘disaggregate cases into independent, analytically separate aspects but instead treat[s] configurations as different types of cases’ (Fiss, 2011, p. 401). Compared with multiple regression analysis, fs/QCA represents a promising new direction for empirical research because it helps to address issues with some statistical techniques (e.g., heterogeneity, multicollinearity, and data normality) which can produce misleading results (Ben Jabeur et al., 2021; Woodside, 2014). It handles significant levels of causal complexity, unlike linear regression analysis and multivariate techniques that cannot go beyond two- or three-way interactions that are difficult to interpret (Fiss et al., 2013, cited in Grauvogel & Von Soest, 2014). Fs/QCA identifies combinations of conditions that lead to a given outcome (conjunctural causation, Federo & Saz-Carranza, 2018), rather than individual variables. Such analyses identify different configurations that can predict both the presence, and the absence, of an outcome. In doing so, using fs/QCA overcomes the limitation of the net-effects analyses present in econometric models that assume symmetrical relationships between variables (Ho et al., 2016), neglecting asymmetric causal relations (Hervas-Oliver et al., 2015). Secondly, fs/QCA can detect equifinal casual paths. Equifinality (Fiss, 2007) describes the situation in which multiple combinations of causal conditions lead to the same outcome. The possibility of capturing multiple paths that produce the same outcome could enable the identification of alternative actions that companies of the future might take to achieve the desired educational match. Identifying multiple causes and causal paths affecting an outcome of interest is one of the QCA's advantages (Andreas et al., 2017), as it allows for an understanding of highly complex causal structures (Ragin, 2000). Thirdly, fs/QCA allows the identification of which conditions, if implemented, will be sufficient to obtain high levels of educational match in a firm.

Fs/QCA treats each case as a member of multiple sets and conceives both explanatory conditions and outcome assets (Aversa et al., 2015). The researcher carefully converts the data into measures of set membership, anchored and grounded in decisions using theoretical or substantive knowledge from sources external to the empirical data. This process, known as calibration, requires the investigator to convert the empirical data in such a way that the resulting assignment of set membership is conceptually grounded and reflects meaningful variations. Theory guides the choice of meaningful cut-off (threshold) values (Ragin, 2008). In fs/QCA, the data are calibrated into set membership with values ranging from 0 (full non-membership) to 1 (full membership).6 In this case, a given company can be coded ‘in’ or ‘out’ of the set of ‘high levels of educational match’. Further information about the questionnaires and the coding used for calibration in this study can be found in the Appendix A.

The first step in an fs/QCA study is to test whether any of the four causal conditions and their negations are necessary for the outcome to occur. A condition is deemed necessary if whenever the outcome is present, the condition is also present (Schneider & Wagemann, 2012). Conventionally, a condition or a combination of conditions are ‘necessary’ or ‘almost always necessary’ if the consistency score exceeds a threshold of 0.9 (Schneider et al., 2010, p. 254).7 The second step is to run a sufficiency analysis. A causal condition is considered sufficient for the outcome to occur if whenever we observe condition (X), we also see outcome (Y).

In fs/QCA, consistency and coverage are two parameters that define the extent to which the results ‘fit’ the data (Ragin, 2008), analogous to the correlation and the coefficient of determination (R2) measures in regression analysis (Ben Jabeur et al., 2021). Consistency assesses the degree to which cases sharing a given combination of conditions agree in displaying the outcome of interest. It is measured as the number of cases featuring both a given configuration and the outcome, divided by the number of cases featuring the same configuration but not featuring the outcome (Ragin, 2008). Overall solution consistency refers to the same measure but as an aggregate of all of the identified configurations. I used a consistency threshold of 0.80, which is the recommended standard (Ragin, 2008). Coverage of a solution term represents the degree to which a cause or causal combination explains the outcome of interest. Raw coverage is the number of cases that present both the outcome and a given configuration, divided by the number of cases featuring the outcome. Unique coverage is computed as the number of cases featuring the outcome which are covered uniquely by a given configuration; that where no other configurations cover those cases. It controls for overlapping explanations by partitioning the raw coverage. Finally, overall solution coverage represents the coverage measure aggregated across all identified configurations (Barzotto & De Propris, 2021).

3.2 Data

A survey targeting senior managers in EU countries was administered to 26 participants8 (six CEOs, seven human resources managers, five managing directors, and eight operations managers), each from a different multinational company, operating in four advanced manufacturing industries based in five high-income European countries. A purposive sampling method was used to allocate companies to the various subgroups so as to ensure maximum diversity of individual cases (Billing & Bryson, 2019). Cases were ‘selected in proportion to one or more characteristics in the population’ (Gorard, 2013, p. 81): firstly, their size measured by the number of employees (50–249, or ≥250); secondly, their location (Germany, Italy, Spain, Sweden or the UK); and, thirdly, the sector in which they operate (biotech, engineering, fashion or new materials).

Data was collected through Qualtrics, a third-party online survey administration company (Long et al., 2011). Recent research has used Qualtrics as a reliable means of gathering data (e.g., Courtright et al., 2016; DeCelles et al., 2012). All participants invited into the study were provided with random identifiers generated by Qualtrics, to guarantee confidentiality and anonymity (Courtright et al., 2016).9 This procedure generated a total sample of 26 cases, which corresponds to a 19% response rate, in line with the overall expected participation rates in internet research using long (30–45 min) questionnaires (Deutskens et al., 2004, Marcus et al., 2007; 17.1% and 18.6% response rates, respectively).

Participants were asked to describe their corporate role, provide some general information about their company (e.g., country and region, ownership status, employee numbers, sector, profit growth), describe the level of educational attainment of their employees, and comment on how satisfied they were with their qualification levels (particularly in relation to their shop-floor workers). Furthermore, these managers were asked to outline the training strategy their companies had decided to undertake (mainly in terms of the subjects involved, and whether the company was collaborating with local/national technical schools to develop the skills they would need in 3 years' time). Finally, the participants were interrogated as to the array of skills for which they experienced difficulties in recruiting to, the set of skills that they believed would foster their future competitiveness, and the list of skills that they were most likely to recruit to in the near future.

Of the 26 companies, 4 operated in the biotech sector, 14 in the engineering sector, 4 in the fashion industry, and 4 in new materials. These manufacturing sectors were chosen because they account for a large part of the EU's innovation effort, which in turn contributes to the EU's overall productivity and real income growth (European Commission, 2013).10 The majority (19) of the companies were domestically-owned firms, five were subsidiaries of wholly foreign-owned companies, and the remaining two were subsidiaries of partially foreign-owned companies (minority foreign ownership). The companies were located in five advanced European countries, representing Northern Europe (five in Sweden), Central Europe (five in Germany), Southern Europe (six in Italy and five in Spain) and Western Europe (five in the UK). These countries differ in terms of their educational systems, enabling an exploration of the impact of a variety of vocational training regimes on educational (mis)match within firms. In liberal skills systems such as in the UK, vocational education and training (VET) plays a marginal role and is considered inferior to the academic route (Chankseliani et al., 2016). It is more relevant in statist skill regimes such as those in Sweden and France, and particularly in collective skill systems such as in Germany, Austria and Switzerland (Busemeyer & Trampusch, 2012). Table 1 shows the main characteristics of the companies surveyed.

| QCA MNE's id | Employees | Sector | Ownership | Country | Region (NUTS2) | County (NUTS3) | Headquarters | Headquarters location | Skill formation system | Person surveyed |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 50–249 | Fashion | Domestically-owned firm | Italy | Veneto | Vicenza | Yes | Mixed | CEO | |

| 2 | 250 or more | Biotech | Domestically-owned firm | Italy | Campania | Napoli | No | Europe | Mixed | CEO |

| 3 | 50–249 | New Material | Domestically-owned firm | Spain | Illes Balears | Mallorca | Yes | Mixed | Managing Director | |

| 4 | 250 or more | Fashion | Domestically-owned firm | Spain | Cataluña | Barcelona | Yes | Mixed | Operations Manager | |

| 5 | 250 or more | Engineering | Domestically-owned firm | Spain | Región de Murcia | Región de Murcia | Yes | Mixed | Managing Director | |

| 6 | 250 or more | Fashion | Domestically-owned firm | United Kingdom | Derbyshire and Nottinghamshire | Nottingham | Yes | Liberal | CEO | |

| 7 | 250 or more | Biotech | Domestically-owned firm | United Kingdom | Northern Ireland | Belfast | Yes | Liberal | CEO | |

| 8 | 250 or more | Fashion | Domestically-owned firm | United Kingdom | West Midlands | Birmingham | Yes | Liberal | Operations Manager | |

| 9 | 50–249 | Engineering | Domestically-owned firm | Germany | Oberbayern | Ebersberg | Yes | Collective | CEO | |

| 10 | 250 or more | Biotech | Domestically-owned firm | Sweden | Stockholm | Stockholm | Yes | Statist | HR Manager | |

| 11 | 250 or more | Engineering | Domestically-owned firm | Germany | Düsseldorf | Mettmann | Yes | Collective | HR Manager | |

| 12 | 250 or more | Engineering | Subsidiary of partially foreign-owned company | Sweden | Stockholm | Stockholm | Yes | Statist | HR Manager | |

| 13 | 250 or more | Engineering | Domestically-owned firm | Sweden | Stockholm | Stockholm | Yes | Statist | Operations Manager | |

| 14 | 250 or more | Engineering | Subsidiary of wholly foreign-owned company | Sweden | Stockholm | Stockholm | Yes | Statist | HR Manager | |

| 15 | 250 or more | New Material | Domestically-owned firm | Sweden | Övre Norrland | Norrbottens län | Yes | Statist | Operations Manager | |

| 16 | 250 or more | Biotech | Subsidiary of wholly foreign-owned company | United Kingdom | Inner London - East | Haringey and Islington | Yes | Liberal | Operations Manager | |

| 17 | 250 or more | Engineering | Subsidiary of partially foreign-owned company | Germany | Berlin | Berlin | No | North America | Collective | Operations Manager |

| 18 | 250 or more | Engineering | Subsidiary of wholly foreign-owned company | United Kingdom | Inner London - West | Camden and City of London | Yes | Liberal | HR Manager | |

| 19 | 250 or more | New Material | Subsidiary of wholly foreign-owned company | Germany | Hamburg | Hamburg | No | Asia | Collective | Managing Director |

| 20 | 250 or more | Engineering | Domestically-owned firm | Spain | Región de Murcia | Región de Murcia | Yes | Mixed | Managing Director | |

| 21 | 250 or more | New Material | Subsidiary of wholly foreign-owned company | Germany | Stuttgart | Schwäbisch Hall | Yes | Collective | Operations Manager | |

| 22 | 50–249 | Engineering | Domestically-owned firm | Italy | Sicilia | Agrigento | Yes | Mixed | Operations Manager | |

| 23 | 250 or more | Engineering | Domestically-owned firm | Italy | Calabria | Reggio di Calabria | Yes | Mixed | HR Manager | |

| 24 | 50–249 | Engineering | Domestically-owned firm | Italy | Marche | Ancona | Yes | Mixed | CEO | |

| 25 | 250 or more | Engineering | Domestically-owned firm | Spain | Andalucía | Sevilla | Yes | Mixed | Managing Director | |

| 26 | 50–249 | Engineering | Domestically-owned firm | Italy | Sicilia | Catania | Yes | Mixed | HR Manager |

3.3 Variables

The outcome condition under investigation was a high level of educational match (MATCH), along with its absence/mismatch (match).11 In order to capture the level of educational match, I built on the self-assessment measure (Groeneveld, 1997; Verhaest & Omey, 2006) by asking respondents to subjectively assess whether they felt satisfied with the qualification levels of three different categories of employees: manual workers, technical workers and management. Four explanatory conditions (EDU, BREADTH, ITTRAIN & VOCCOLL) were used to capture shop-floor employees' educational attainment levels, and their companies' corporate training strategies, as described in the following subsections. Further details of the construction of the conditions are provided in the Appendix A.

3.3.1 Level of shop-floor employees' educational attainment

Because one of the goals of the research is to understand what stock of knowledge best fits companies in the context of I4.0, I considered one crucial factor of a firm's workforce: the educational level of shop-floor workers employed on the operational floor either directly and/or indirectly linked to the production process, excluding managers. I captured the level of shop-floor employees' educational attainment (EDU) by examining the proportion of shop-floor workers with either a vocational or general tertiary-level qualification.

3.3.2 Corporate training strategies

To capture the attitude of a company towards training its employees, I took into consideration: (i) the extent to which the company trained its employees; and, (ii) the company's engagement with local vocational training institutions in developing its employees' skills.

I gathered information on the first of these by identifying what training initiatives a company carried out starting with looking at the breadth of training (BREADTH), which measured the number of subjects in which a firm trained its employees. These included oral communication, team-working, foreign languages and problem-solving, which underpin skills - such as flexibility, creativity, intuition, situational adaptability, judgement, and communication–unlikely to be automated any time soon (Shestakofsky, 2017). Then, I looked at the extent of advanced IT training (ITTRAIN) which a firm provided to its employees in relation to the IT skills necessary for them to operate effectively in the context of I4.0 (such as analytics and modelling, machine learning, digital-to-physical conversion, and human–machine interaction).

With regard to the second aspect of corporate training strategies, that is, company engagement with local vocational training institutions, I collected information on how a company developed its training by asking about involvement in skills development in collaboration with technical schools (VOCCOLL) both at local and national levels.

Having calibrated the data, I listed all of the logically possible configurations of conditions and their respective outcomes.12 I chose to analyse all configurations with at least one case, setting the frequency threshold of the analysis to 1, as recommended by Ragin (2008). This meant that only those causal configurations that showed at least one empirically relevant case were taken into consideration. According to QCA standards, this is a common practise when using small samples (e.g., Aversa et al., 2015). The objective of a fs/QCA analysis is to identify the minimum number of configurations (‘minimised configurational solutions’) that lead to the occurrence of the outcome of interest, obtained by applying Boolean minimization algorithms.13

4 RESULTS AND DISCUSSION

4.1 Necessity analysis

Table 2 shows the results of the necessity analysis for the presence (Table 2A) and absence (Table 2B) of high levels of educational match in a firm. A condition is defined as necessary if it is always present when the outcome occurs. None of the four explanatory conditions in a firm (i.e., neither those associated with educational attainment nor with corporate training strategy) proved necessary for either high levels of educational match (MATCH), or educational mismatch (match), because the results did not exceed the threshold of 0.9 (Schneider et al., 2010). This result suggests that the new wave of technological transformation fosters firms' requirements for new skills and knowledge that must be acquired through a combination of education and training, since no condition on its own is necessary to achieve educational (mis)match. This finding seems to be aligned with the literature on I4.0, indicating the need for a combined response of education and training, via the ability and commitment of the educational sector, policymakers and businesses, to train, retrain or uptrain individuals (Pittarello et al., 2020). In the new manufacturing era, knowledge will play an even greater role in the understanding and use of new technologies, and it will date more quickly than was previously the case. Hence, ‘human capital development cannot stop with education, but must stretch into lifelong learning, training and retraining’ (Bailey & De Propris, 2020, p. 243).

| A. Match: Firms' educational match | |||

|---|---|---|---|

| Condition | Consistency | Coverage | RoN |

| EDU | 0.71 | 0.70 | 0.77 |

| edu | 0.57 | 0.75 | 0.71 |

| BREADTH | 0.72 | 0.65 | 0.67 |

| breadth | 0.56 | 0.63 | 0.77 |

| ITTRAIN | 0.44 | 0.65 | 0.85 |

| ittrain | 0.69 | 0.52 | 0.51 |

| VOCCOL | 0.51 | 0.60 | 0.78 |

| voccol | 0.49 | 0.42 | 0.56 |

| B. Match: Firms' educational mismatch | |||

|---|---|---|---|

| Condition | Consistency | Coverage | RoN |

| EDU | 0.58 | 0.57 | 0.69 |

| edu | 0.70 | 0.71 | 0.78 |

| BREADTH | 0.56 | 0.63 | 0.77 |

| breadth | 0.61 | 0.68 | 0.80 |

| ITTRAIN | 0.36 | 0.54 | 0.81 |

| ittrain | 0.77 | 0.57 | 0.54 |

| VOCCOL | 0.33 | 0.39 | 0.70 |

| voccol | 0.67 | 0.78 | 0.64 |

- Note: RoN is a parameter of fit called relevance of necessity. The lower the RoN score, the more trivial a condition is. The higher the score, the higher the relative importance of that condition as a necessary one (Dușa, 2017).

4.2 Sufficiency analysis

Table 3 presents the complex solution in relation to educational match, which means that only empirically observed combinations of causal conditions are incorporated into the minimization process. Configurations lacking empirical instances are excluded (Schneider et al., 2010). Each solution describes a sufficient combination of conditions (a configuration) leading to the outcome of interest. All configurations consist of combinations of conditions, because no condition is sufficient on its own to account for a high level of educational match in a firm.

| Conservative solution | Raw coverage | Unique coverage | Consistency | Cases |

|---|---|---|---|---|

| EDU*ITTRAIN*VOCCOL | 0.23 | 0.10 | 1 | 2, 7, 8 |

| edu*ittrain*BREADTH*voccol | 0.22 | 0.22 | 0.80 | 5, 24 |

| EDU*breadth*VOCCOL | 0.21 | 0.08 | 0.89 | 7, 25 |

| ITTRAIN*breadth*VOCCOL | 0.18 | 0.05 | 1 | 7, 11 |

Solution coverage: 0.57 Solution consistency: 0.88 |

- Note: Configurations: EDU*ITTRAIN*VOCCOL + EDU*ITTRAIN*BREADTH*VOCCOL + EDU*breadth*VOCCOL + ITTRAIN*breadth* VOCCOL = >MATCH. In Boolean algebra, * stands for the logical operator ‘and,’ while + represents the logical operator ‘or.’ Uppercase letters denote the presence of a condition, whereas lowercase letters denote the opposite.

Four configurations emerge as empirically relevant. The overall solution coverage score, which represents the joint importance of all configurations producing high levels of educational match, is 0.88. In other words, these four configurations together account for 88 per cent of the outcome.

The first configuration, displaying the greatest explanatory power, is EDU*ITTRAIN*VOCCOLL. This configuration shows that a company may have high levels of educational match where the following three conditions also apply: (i) a large proportion of shop-floor employees with vocational or general tertiary education (EDU); (ii) a training programme focused on advanced IT skills, such as analytics and modelling, machine learning, digital-to-physical conversion, and human–machine interaction (ITTRAIN); and, (iii) skills' development undertaken in collaboration with technical schools at local and/or national levels (VOCCOLL). This result suggests that, to train employees efficiently, such that they master a large spectrum of advanced IT activities, companies require a considerable stock of highly skilled workers. Thus, they should employ workers with vocational or general tertiary qualifications and should be actively involved in worker development by engaging with vocational institutions at a local or national level. This configuration seems to juxtapose SBTC theory, literature on I4.0 regional studies, and the economic geography debate on the importance of revitalising manufacturing in advanced economies. In particular, the presence of a large proportion of shop-floor employees with vocational or general tertiary education connected with high levels of educational match seems to be in alignment with SBTC theory, and the literature on labour economics, in terms of the task content of employment (Autor et al., 2003; Autor & Dorn, 2013; Goos & Manning, 2007). Recently, Frey and Osborne (2017) have reported how, in advanced countries, the poor performance of labour markets has intensified the debate amongst economists about technological unemployment. Such work supports the argument that the spread of computer technologies in recent decades has dramatically increased the demand for employees with high levels of education (EDU) when it comes to performing tasks oriented towards non-routine, analytical and interactive activities (Spitz-Oener, 2006). In accordance with SBTC research (Leigh et al., 2020) in manufacturing industries, the presence of computers (Falk & Koebel, 2004) and robots fosters the availability of work for high-skilled workers (which include those with at least a college degree) (Graetz & Michaels, 2018). The presence of the ITTRAIN and VOCCOLL conditions could be viewed in relation to the literature on manufacturing revitalization and I4.0. According to these streams of research, to counter the absence of a national VET system, and respond to the changing demands of local employers in the context of new manufacturing, innovative community- and business-led training initiatives should be implemented. Thus, Snell (2019) reports successful examples of workforce development in skill-formation ecosystems via flexible VET training that involves secondary schools, community colleges, key employers, industry associations and unions working with one another to meet the needs of local manufacturers. To summarise, this first configuration highlights how complementing a high level of educational attainment with skills' development ecosystems operating at local/national levels could resolve the needs for local industry skills of companies operating in modern manufacturing.

Conversely, if the three explanatory conditions of this first configuration are not present simultaneously, companies may show equally high levels of educational match if they develop a broad training programme spanning, amongst other things, oral communication, team-working, foreign languages, technical-specific and problem-solving skills (BREADTH), as indicated by the second of the four identified configurations (edu*ittrain*BREADTH*voccoll). This result suggests alignment with the theory of human capital (e.g. Gibbons & Waldman, 2004), in which general (rather than company-idiosyncratic) human capital has a positive impact on the productivity of a firm itself, and those connected with it (Becker, 1962; Lazear, 2009).

The complementarity effect between EDU, ITTRAIN and VOCCOLL, and a broad training programme (BREADTH) providing workers with general human capital is also confirmed in the third and fourth configurations. Thus, to achieve high levels of educational match, companies specialising in a limited number of training activities (breadth) should not only invest in collaborating with technical schools at local and/or national level (VOCCOLL), but also employ a high proportion of workers with tertiary degrees (EDU), as described by the third configuration (EDU*breadth*VOCCOLL). Alternatively, as defined in the fourth configuration (ITTRAIN*breadth*VOCCOLL), companies specialising in a limited number of training activities (breadth) could invest in collaborating with technical schools (VOCCOLL) whilst also undertaking intensive training programmes focused on advanced IT to develop a wide range of IT skills relevant to the requirements of the I4.0 context (ITTRAIN).

In summary, the conditions EDU, ITTRAIN and VOCCOLL seem to have a reinforcing effect because their co-presence intensifies the achievement of high levels of educational match. Conversely, the presence of a broad training programme (BREADTH) counterbalances the absence of the other three conditions (EDU, ITTRAIN and VOCCOLL), whilst its absence is counterbalanced by their presence. Indeed, when EDU, ITTRAIN or VOCCOLL (or a combination of the three) are present, BREADTH is absent, and vice versa.

In the context of new manufacturing, operatives well-trained in skills and competences are crucial to manufacturing phases and processes (Bellandi et al., 2020). The different paths leading to high levels of educational match indicated by these four configurations suggest that new technologies and automation demand more analytical knowledge from shop-floor workers. Traditionally, these skilled workers were predominantly endowed with a synthetic knowledge base (more concrete know-how, craft and practical skills) (e.g., Asheim et al., 2011) usually acquired through on-the-job training, and/or professional or polytechnic schooling (Lund & Karlsen, 2020). However, the implementation of new manufacturing technologies has required shop-floor workers to gain further theoretical and abstract knowledge (Pfeiffer, 2015) as new production tasks demand a shift in workers' knowledge base (Lund & Karlsen, 2020). Drawing upon and combining SBTC and I4.0 literatures, it is clear that such new knowledge bases can be acquired via different educational journeys, which could encompass vocational training (in professional and polytechnic schools), and higher education (in universities). Indeed, as Snell (2019) states, the demarcation lines between vocational and non-vocational occupations are becoming increasingly blurred, rendering the bifurcated educational pathways which exist in traditional educational systems potentially problematic. The findings of the present analysis suggest the need for a more hybridised coexistence of tertiary education and training activities, which tends to emerge from the cooperation of local actors (both educational and training providers and businesses). The results indicate the balance needed between shop-floor workers' educational levels and corporate training strategies, contributing to the debate over the interplay between I4.0 and local economic development, in which scholars (Bellandi et al., 2020) claim that changes in the labour market due to digitalization and robotization have impacted on the labour–capital balance in productive processes, and call for new educational models and training structures that go beyond youth education to also include job retraining, and lifelong learning, so as to ensure constant upskilling.

Table 4 describes the complex solution for educational mismatch; that is, the set of factors associated with shop-floor employees' educational attainment and firms' training strategies with the greatest power to explain the absence of educational match (here defined as mismatch). The overall solution coverage score is 0.89. The first of the three configurations identified with educational mismatch is edu*ittrain*breadth*voccoll. Thus, firms experiencing the simultaneous absence of all four conditions reported educational mismatch. Although unsurprising in itself, this is a rather counterintuitive dynamic, because it might be expected that companies dissatisfied with their human capital would engage in at least some upskilling activities or seek to employ workers with higher educational attainments. This finding suggests the presence of a form of ‘low-skills equilibrium’ at company level, in which low skill levels in a firm's workforce are met by an equally low level of skills demand from the employer (OECD, 2014). One way for companies to escape this low-skills' equilibrium would be to expose workers to upskilling tools provided by a range of local actors, such as employer associations, universities, vocational training institutions and unions. If such companies were to adopt a coordinated approach, using a multi-stakeholder model, they could also share the associated risks and costs of these interventions (Desjardins & Rubenson, 2011). Evidence from Nordic countries suggests that this would encourage adult education/training, boosting the acquisition of both general and specific skills (Eide & Showalter, 2010).

| Conservative solution | Raw coverage | Unique coverage | Consistency | Cases |

|---|---|---|---|---|

| edu* ittrain*breadth*voccol | 0.28 | 0.26 | 0.94 | 15, 17, 23, 26 |

| ITTRAIN*BREADTH*voccol | 0.15 | 0.14 | 0.86 | 21, 22 |

| EDU*ittrain*BREADTH*VOCCOL | 0.11 | 0.11 | 0.82 | 12 |

Solution coverage: 0.53 Solution consistency: 0.89 |

- Note: Configurations: Edu*ITTRAIN*BREADTH*voccol+ITTRAIN*BREADTH*voccol + EDU*aditextent*BREADTH*VOCCOL = >match. In Boolean algebra, * stands for the logical operator ‘and,’ while + represents the logical operator ‘or.’ Uppercase letters denote the presence of a condition, whereas lowercase letters denote the opposite.

The second mismatch configuration (ITTRAIN*BREADTH*voccoll) indicates that a company will not achieve educational match if training activities closely focused on advanced IT skills (ITTRAIN) and a broad training programme (BREADTH) are not combined with collaborating with technical schools at a local or national level (voccoll). This result draws attention to the importance of building active relationships with local and national vocational training institutions if a firm's training activities are to be effective. It aligns with the evidence collected by Jürgens and Krzywdzinski (2015) on how long-term cooperation with vocational high schools enables firms to take an active role in defining the teaching curriculum, and also ties in with the experience of community-based, and local business-led approaches in new manufacturing which have been described by Snell (2019).

Finally, the third mismatch configuration (EDU*ittrain*BREADTH*VOCCOLL) yields the result that another situation sufficient to lead to educational mismatch is the presence of a low level of training activities focused on advanced IT skills (ittrain), this being the case even when it exists in combination with three other conditions: (i) a large proportion of shop-floor employees with vocational or general tertiary education (EDU); (ii) a broad training programme (BREADTH); and, (iii) involvement in skills' development in collaboration with technical schools at a local and/or national level (VOCCOLL). This finding indicates the importance, stressed by the emerging literature of I4.0, of undertaking advanced IT training in order to support and nourish a variety of upskilling activities (BREADTH) and contribute to there being a stock of educated workers (EDU).

4.3 Companies' skills awareness

I further explored whether companies with high levels of educational match showed a similar degree of awareness of their skills' needs as companies reporting an educational mismatch. I looked at three different aspects, these being: which skills companies found most difficult to recruit to, which skills were required to increase corporate competitiveness in the future, and which kinds of skills companies would most recruit to in 3 years' time.

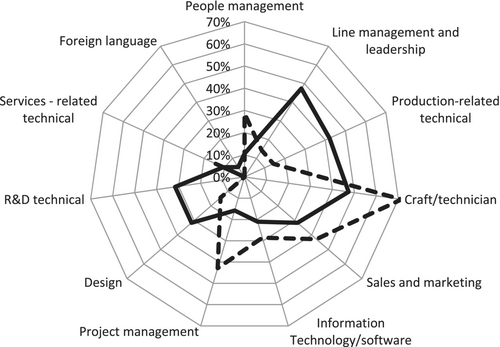

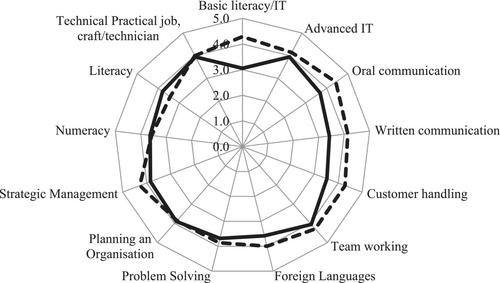

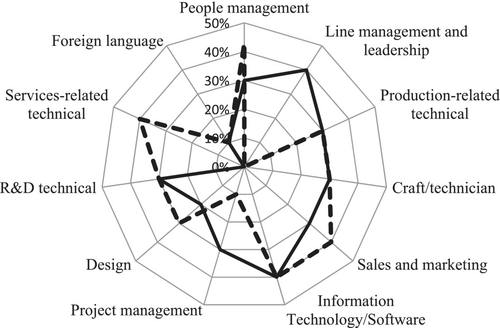

Figure 2 shows which skills are the most difficult to recruit to according to companies' levels of educational match. Thus, on average, companies showing the highest match faced the most significant difficulties in recruiting craft/technician skills, followed by project management skills, people management and sales skills, and IT/software skills, whereas companies reporting educational mismatch were dealing mainly with a shortage of line management, leadership, and R&D technical skills. These results reinforce the importance of skilling, reskilling and upskilling (Autor, 2015) workers in collaboration with knowledge institutions (Lund & Karlsen, 2020; Wu & Li, 2020), to provide them with digitally aware skills' sets, as well as preparing them to undertake cognitive non-routine tasks more effectively, particularly interpersonal/interactive ones (Autor et al., 2003).

Figure 3 highlights the importance14 companies attach to different levels of educational match to skills sets that will allow them to increase their competitiveness in the future. With the exception of skills relating to literacy, companies with higher educational matches attached greater importance to the overall spectrum of skills than companies showing a mismatch. Companies with a higher match focused their recruitment15 on those with people management, design and service-related technical skills (Figure 4). This result seems to be in line with the trend towards servitization16 (e.g. Neely, 2008; Parry et al., 2012; Vandermerwe & Rada, 1988), according to which creating value in a product draws not only on the innovation of the product itself, but increasingly also on the provision of digitalized services built around that product. This result is also in line with the World Economic Forum (2016) and Cedefop17 projection on the increasing need for workers undertaking cognitive tasks to have technical knowledge, problem-solving skills (e.g., service-related technical skills), analytical capabilities, intuition, and creativity (e.g., people management, design).

5 CONCLUSION

The manufacturing sector, which still accounts for a significant share of employment and innovation in advanced economies (Rueda-Cantuche, Sousa, Andreoni, & Arto, 2013), has been subject to substantial changes due to technological disruptions. Such disruptions have accelerated the computerization of manufacturing by rendering factories ‘smarter,’ more adaptable and resource-efficient (Holtgrewe, 2014 pp. 13–14), and thus contributed to the maintenance of sector competitiveness despite high-wage labour markets. Sustaining and fostering this sector appears to be ever more crucial in the face of rising nationalistic agendas and 2020s Covid-19 pandemic, which have encouraged a reshoring of manufacturing activities back to advanced countries.

In light of these trends, this study aimed to obtain evidence as to the mix of shop-floor employees' educational attainment, and what corporate training strategies an advanced factory should put in place to match the skills' sets needed to adopt the new I4.0 model of manufacturing most effectively. The results reveal several equifinal paths through which advanced manufacturing companies can achieve high levels of educational match in their workforces. Thus, companies may attain such an outcome in the co-presence of: (i) a large proportion of shop-floor employees with tertiary education; (ii) a training programme focused on advanced IT skills; and, (iii) involvement in skills' development in collaboration with technical schools at local and/or national level. Conversely, if these three explanatory conditions are not present simultaneously, a company may still show equally high levels of educational match if it develops a broad training programme that spans a range of skills from the technically specific to those underpinning communication, team-working and creativity/problem-solving, which do not lend themselves to automation. Alternatively, if a firm focuses its training activities on a limited number of subjects, it can still achieve a high level of educational match by combining investment in collaborations with technical schools with a large proportion of workers with a tertiary degree or, instead, with intensive training programmes focused on advanced IT.

Overall, these findings indicate the importance of the vocational or general tertiary system to today's manufacturing companies and the need to foster its expansion in advanced economies. In line with economic SBTC theory, in order to adapt cyber-physical systems to physical production processes most efficiently, advanced factories require a large proportion of highly educated shop-floor workers. In particular, the role played by vocational schools emerges as pivotal in the context of I4.0. Indeed, direct involvement in skills' development through collaboration with vocational training institutions is a condition present in three of the four configurations that lead to high levels of educational match, whereas its absence leads to educational mismatch in two out of three configurations. This result suggests that it is important for companies approaching I4.0 to engage in vocational training programmes by collaborating with local and/or national institutions. As described in the first and fourth configurations associated with high educational match, the co-presence of intense IT training (ITTRAIN) and engagement with vocational schools (VOCCOLL), alongside other conditions such as a high proportion of workers with a tertiary degree (EDU) or more specialised training (breadth), is one possible way by which companies can improve their performance, because skills' demand then seems to meet skills' supply. These results advance the research by Shibata (2001) and address his call to further investigate the importance of integrated skills' formation in manufacturing, which seems to be closely linked to the call for policymakers to promote support packages enabling business and vocational training institutions to co-create industrial learning, and knowledge transfer schemes, aimed at fostering educational matches. The findings are also in line with the work of Lund and Karlsen (2020), who argue that new technologies and expectations of future technologies: (i) prompt an upgrading of skilled workers' knowledge bases and the development of new educational programmes; and, (ii) sustain the relevance of skilled workers in current and future manufacturing. The need to upgrade educational programmes and improve the competence and knowledge of these workers is particularly critical for high-cost countries (Lund & Karlsen, 2020). Such pressure derives in part from the new challenges advanced countries now face due to the Covid-19 pandemic. These countries need to reorganise their supply chains to be less dependent on manufacturing in emerging countries and, in turn, increase their self-sustainability in case of further global supply chain disruptions in the future. However, reshoring manufacturing activities in advanced economies requires a reversal of the erosion of skills traditionally associated with their manufacturing heritage as a result of the wholesale offshoring of manufacturing to emerging countries (Pisano & Shih, 2012), as well as the development of skills to match companies' new demands. New technologies of communication allow for more tailored instructions in workplace-specific topics and provide significant competition for education institutions (Ingram & Neumann, 2006). Nevertheless, VET represents a critical source of knowledge in adapting to new technologies (Lund & Karlsen, 2020). If companies want to procure this knowledge, in the present and in the future, they should work alongside local educational institutions to co-develop new and upgrade existing educational programmes to meet the required demands. However, collaborations such as these favour large manufacturers as they are more likely to be endowed with the resources necessary to set up collaborations with local knowledge providers (Snell, 2019). Thus, policymakers should put in place tools that allow more inclusive access to these types of collaboration so as to involve smaller manufacturers. An inclusive co-development of skills' sets would help to rebuild local manufacturing bases with digitally-aware skills' sets, contributing to local occupational mobility and, in turn, to the ongoing development of local economies.

Although this study has some limitations, the results offer promising opportunities for further research. Thus, for example, future research might further explore the mix of tertiary degree attainments present in the operational activities of advanced manufacturing companies, in order to establish which combinations of vocational and general tertiary degrees a company should seek in its shop-floor recruits to maximise its economic performance. Similarly, because gender differentiation within the educational system (in particular in ICT subjects) is mirrored in labour market segregation (Lindley, 2012; Støren & Arnesen, 2007; Vuorinen-Lampila, 2016), future research could investigate working opportunities for women in the high-tech context (e.g., Khilji & Pumroy, 2019) of I4.0 and, at the same time, identify opportunities for more gender-inclusive working environments.

ACKNOWLEDGEMENTS

This work was supported by the European Commission's Marie-Curie Actions (Project nr. H2020-MSCA-IF-2014 Proposal No. 660022, Project Acronym: SkillUP). I kindly thank Professor Lisa De Propris for all her valuable comments and insights. An earlier version of this article was accepted to the Academy of Management Conference.

CONFLICT OF INTEREST

There is no conflict of interest.

Endnotes

APPENDIX A

A.1 Firms' educational match (MATCH)

Companies were asked to declare how satisfied they were with the qualification levels of three categories of employees (manual workers, technical workers and management). Possible answers were: extremely inadequate, slightly inadequate, neither adequate nor inadequate, slightly adequate, and extremely adequate. In order to build the MATCH condition, I computed the following steps. Firstly, for each category of worker, I attached a value of 1 to the ‘extremely adequate’ option, 0.5 to the ‘slightly adequate’ option, and 0 otherwise. Secondly, I summed the values of the three categories. Thirdly, I coded the outcome condition according to a four-value fuzzy set: ‘fully in’ (fuzzy-set score 1) if a company scored a maximum value above 2.5; ‘more in than out’ (fuzzy-set score 0.67) if a company scored a maximum value between 2.5 and 1.5 (excluded); ‘more out than in’ (fuzzy-set score 0.33) if a company scored a maximum value between 1.5 and 0 (excluded); ‘fully out’ (fuzzy-set score 0) if a company scored a maximum value of 0.

A.2 Level of shop-floor employees' educational attainment (EDU)

- Below upper secondary: below high-school programmes or equivalent level.

- Upper secondary or post-secondary non-tertiary vocational: high-school programmes, technical diplomas, and primary professional education providing job-specific technical training for trades. These programmes generally focus on providing students with hands-on instruction.

- Upper secondary or post-secondary non-tertiary general: general programmes usually designed for students planning to continue to academic or professional studies at tertiary level.

- Tertiary vocational: higher technical education, community college education, technician or advanced/higher vocational training, associate degree, or bac + 2 offering job-specific technical training.

- Tertiary general: bachelor's, masters or doctorate degrees or equivalent.

In order to build the EDU condition, I took the sum of the proportion of shop-floor workers with a tertiary degree (tertiary vocational and tertiary general). I used a direct method of calibration (Ragin, 2008) with thresholds of 0.15 for the full set exclusion, 0.20 for the set crossover, and 0.25 for the full set inclusion. The calibration thresholds were justified by and located in the middle of notable gaps in the raw data (e.g., Freitag & Schlicht, 2009). I tried to use labour force survey data collected by EUROSTAT and set the thresholds according to the average educational attainment level for these five countries, but the values obtained were incompatible with those available in the sample under consideration.

A.3 Breadth of training (BREADTH)

Company managers were asked to declare in which subjects they trained their employees. The following options were presented to them: (1) basic computer literacy/using IT; (2) advanced IT or software skills; (3) oral and written communication skills; (4) customer-handling skills; (5) team-working skills; (6) foreign language skills; (7) problem-solving skills; (8) planning and organisation skills and strategic management skills; (9) numeracy and literacy skills; (10) technical, practical or job-specific skills (craft/technician skills); and, (11) any other skills. They could tick all that applied.

To build the BREADTH condition, I added up the number of subjects in which the firm trained its employees. To translate the breadth of training activities carried out by the companies into a fuzzy-set membership score, I used a four-value fuzzy-set scheme: fully in (1.00) if the sum was equal to 5 or above (which represented at least half of the training activities, because no firm ticked option number 11); more in than out (0.67) if the sum was equal to 4; more out than in (0.33) if the sum was equal to 3; and fully out (0) if the sum was equal to 2 or below.

A.4 Extent of advanced IT training (ITTRAIN)

Company managers were asked to declare whether they trained their employees in advanced IT or software skills. If managers declared that they did so, they were asked to state in which subjects they trained their employees to improve their ICT literacy: (1) analytics and modelling (such as digitization and automation of knowledge work, advanced analytics); (2) mathematics and optimization; (3) data architecture and engineering (such as big data/open data, the Internet of Things/M2M, and cloud technology); (4) machine learning; (5) digital media; (6) coding and programming; (7) digital-to-physical conversion (such as additive manufacturing/3D printing, advanced robotics, energy storage and harvesting); (8) human–machine interaction (such as touch interfaces, virtual and augmented reality); and, (9) other. They could tick all that applied.

As per the BREADTH condition, I added up the number of subjects relating to IT skills in which a firm trained its employees. To translate the extent of advanced IT training carried out by the companies into fuzzy-set membership scores, I used a four-value fuzzy-set scheme: fully in (1.00) if the sum was equal to 4 or above (which represented at least half of the possible training activities because no firm ticked option number 9); more in than out (0.67) if the sum was equal to 3; more out than in (0.33) if the sum was equal to 2; and, fully out (0) if the sum was equal to 1 or 0.

A.5 Involvement in skills' development in collaboration with technical schools (VOCCOLL)

Company managers were asked to declare whether their companies were involved in collaborating with technical schools (at local or national level) to develop skills that they would need in 3 years' time. I attached a value of 1 to denote ‘fully in’ membership if the response was ‘Yes,’ and a value of 0 to denote ‘fully out’ otherwise.

Open Research

DATA AVAILABILITY STATEMENT

Due to ethical consideration, research data cannot be shared.