A Stretchable, Attachable, and Transparent Polyionic Ecological Skin for Robust Self-Powered Interactive Sensing

Zhiqing Bai, Yunlong Xu, and Yuan Fan are joint first authors and contributed equally to this work.

ABSTRACT

Bioinspired energy-autonomous interactive electronics are prevalent. However, self-powered artificial skins are often challenging to be combined with excellent mechanical properties, optical transparency, autonomous attachability, and biocompatibility. Herein, a robust ecological polyionic skin (polyionic eco-skin) based on triboelectric mechanism consisting of ethyl cellulose/waterborne polyurethane/Cu nanoparticles (EWC) green electroactive sensitive material and polyethylene oxide/waterborne polyurethane/phytic acid (PWP) polyionic current collector is proposed. The polyionic eco-skin features sufficient stretchability (90%) and low Young's modulus (0.8 MPa) close to that of human soft tissue, high transparency (> 84% of transmission) in the visible light range, and broad static/dynamic adhesiveness, which endows it with strong adaptive implementation capacity in flexible curved electronics. More importantly, the self-powered polyionic eco-skin exhibits enhanced force-electric conversion performance by coordinating the effect of nanoparticle-polymer interfacial polarization and porous structure of sensitive material. Integrating multiple characteristics enables the polyionic eco-skin to effectively convert biomechanical energy into electrical energy, supporting self-powered functionality for itself and related circuits. Moreover, the eco-skin can be utilized to construct an interactive system and realize the remote noncontact manipulation of targets. The polyionic eco-skin holds tremendous application potential in self-powered security systems, human–machine interaction interfaces, and bionic robots, which is expected to inject new vitality into a human–cyber–physical intelligence integration.

1 Introduction

High demands for remote social interactions have accelerated the strong desire for flexible and portable energy-autonomous electronic devices [1-3]. Particularly, smart artificial skin that mimics the features and functionalities of human skin is attracting a great deal of attention because of promising diversified applications in human–machine interaction, smart identification, bionic robotics, and artificial intelligence systems [4-6]. Until now, artificial skins that rely on multiple operation mechanisms, including piezoelectricity [7, 8], triboelectricity [9], capacitance [10, 11], and piezoresistivity [12, 13], have been developed. In contrast, the multifunctional electronic skins based on triboelectric mechanism, coupled with the advantages of simple structure, wide options of materials, energy autonomy, and high mechanical-electrical conversion performance, open up more possibilities for high-quality self-powered interaction perception and long-distance communication [14-16].

Self-powered artificial skins require a balance of characteristics of high work efficiency, optical transparency, biocompatibility, and user-friendliness. In practice, artificial skins must withstand multiple and long-term stimuli from the external environment and be supposed to be autonomously attachable, enabling them to conformably and stably cover dynamic curved surfaces while supporting functionality under various deformations. Typical self-powered artificial skin consists of sensitive material and conductive electrode. Until now, most researchers have chosen traditional soft materials as sensitive materials, such as polyurethane [17], polyvinylchloride (PVC) [18], Ecoflex [19, 20], and polydimethylsiloxane [21]. These materials offer excellent mechanical flexibility, stretchability, and necessary deformation properties for self-powered artificial skin, while also allowing devices to remain optically transparent in the visible light range. However, their high force-electric conversion performance is often limited due to the lack of distinctive functional groups and the challenging regulation of triboelectrification. Moreover, their dependence on petroleum-based sources results in electronic waste after their service life ends, hindering sustainable applications and long-term feasibility. In recent years, available green materials, such as ethylcellulose ether (EC), derived from renewable biomass have attracted great attention owing to their environmental inclusiveness, carbon neutrality, and strong electron-donating nature [22-24]. It can also be easily mixed with many polymers to create sensitive materials that are mechanically stretchable. These advantages make EC highly suitable for self-powered artificial skin. On the other hand, existing hydrogel and ionogel electrodes, made from cross-linked polymer networks or ionic conductors, are essentially capable of integrating features required by artificial skin. However, they suffer from poor environmental stability and electrical conductivity degrades over time due to the dehydration of the hydrogel or evaporation of liquid solvents [25, 26]. Additionally, the potential leakage of ionic liquid from the gels diminishes the performance of the artificial skin and poses health risks. More importantly, the electrode layer and sensitive layer tend to delaminate owing to a lack of interfacial interaction, which greatly limits stable and reliable service. Consequently, developing robust ecological self-powered artificial skin with multiple integrated characteristics through the design of effective sensitive materials and stable electrode materials and their subtle configuration still faces significant challenges.

A biocompatible, user-friendly self-powered polyionic eco-skin is proposed, featuring a porous ethyl cellulose/waterborne polyurethane/Cu nanoparticles (EWC) electroactive membrane as the sensitive layer and a polyethylene oxide/waterborne polyurethane/phytic acid (PWP) composite as the current collector. This subtle combination provides the eco-skin with mechanical flexibility, high optical transparency, and versatile static/dynamic adhesion, achieving a comprehensive integration of multiple functionalities. Moreover, the EWC sensitive layer securely bonds with the bottom electrode layer due to the adhesive properties of the PWP composite, preventing delamination even under repeated mechanical deformations. Notably, the eco-skin exhibits excellent force-to-electric conversion owing to the positive synergistic effect of nanoparticle-polymer interfacial polarization and the abundant porous structure of sensitive material. With these attributes, the polyionic eco-skin easily adapts to complex irregular movements of the human body or bionic robots, making it an ideal platform for constructing self-powered user-friendly interaction systems.

2 Results and Discussion

2.1 Design and Fabrication of the Self-Powered Polyionic Eco-Skin

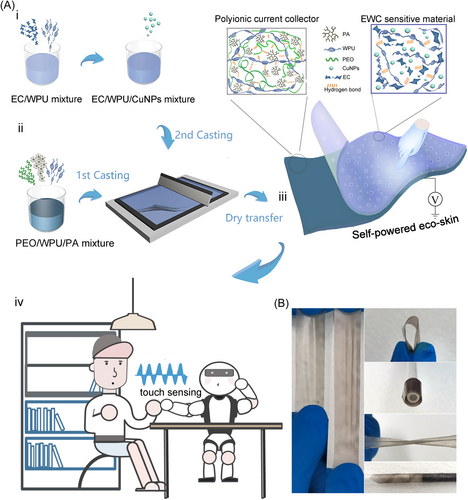

Figure 1A illustrates the structure of the self-powered polyionic eco-skin, comprising the top EWC electroactive layer and the bottom PWP polyionic electrode layer. The fabrication route is depicted in Figure 1A–i and Figure 1A–ii. In short, the homogeneous mixture of EC, water-borne polyurethane (WPU), and Cu nanoparticles (CuNPs) was blade-coated to form the porous EWC electroactive material. While EC offers strong triboelectric sensitivity and easy-adjustable charge storage capability, its poor tensile resilience and fracture toughness at room temperature. This deficiency inevitably leads to the performance degradation of electronics under complex human body movements and harsh environmental conditions. Fortunately, EC biopolymer can be well blended with biocompatible WPU and enhance the flexibility while reducing Young's modulus. Moreover, the CuNPs as functional fillers tend to provide EC-sensitive material with remarkable internal interface polarization and finally improve its positive triboelectroactivity. To integrate multiple features in the self-powered eco-skin, a novel PWP polyionic composite, created by cross-linking polyethylene oxide, WPU, and phytic acid materials via hydrogen bonding, is employed as the current collector due to its excellent stretchability, transparency, and autonomous adhesion. Subsequently, the PWP polyionic composite was laminated with the EWC-sensitive material using a simple dry transfer technology, forming a double-layered EWC/PWP self-powered eco-skin. More details on preparation can be found in the experimental section. As shown in Figure 1A–iii and Supporting Information: Figure S1, the EWC and PWP layers are seamlessly joined, achieving interface stability of eco-skin through physical adsorption and mechanical interlocking [27]. The as-prepared polyionic eco-skin can repeatedly withstand multiple deformations with little mechanical failure, including stretched, twisted, crumpled, folded, rolled, or tailored various shapes, as shown in Figure 1B and Supporting Information: Movie S1. Its high mechanical flexibility allows it to conform to irregular surfaces without delamination, ensuring reliable structural integrity. The polyionic eco-skin is expected to achieve self-powered touch sensing for humans or humanoid robots via scavenging biomechanical energies (Figure 1A–iv).

2.2 Characteristics Characterization of the Self-Powered Polyionic Eco-Skin

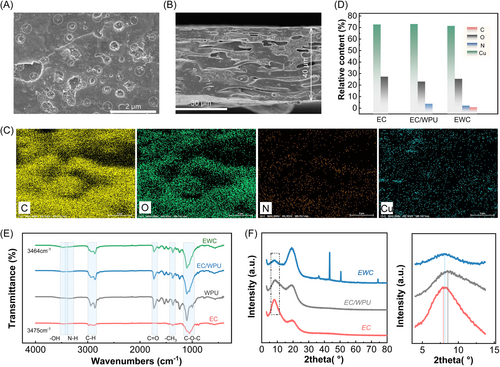

The surface morphology of polyionic eco-skin was observed in Figure 2A. The EWC sensitive material features a rough surface with many bumps and shallow pits, on which many CuNPs are randomly arranged, differing from the smooth EC membrane (Supporting Information: Figure S2). Moreover, the cross-sectional view reveals a gully-like porous structure with a thickness of approximately 40 μm (Figure 2B), attributed to the reconstruction of polymer chains and microphase separation in the homogeneous EWC/WPU/ethanol aqueous system [28, 29]. It is worth mentioning that abundant porous structure and dispersed CuNPs in EWC-sensitive material of polyionic eco-skin allow the larger relative capacitance and effective accumulation of additional charges, thus greatly contributing to the improvement in force-electric conversion performance [30]. To assess the distribution of CuNPs in the EWC porous networks, elemental mapping was performed using energy-dispersive X-ray spectroscopy (EDS) in Figure 2C. The analysis reveals a uniform distribution of C, O, N, and Cu elements across the EWC-sensitive material, which suggests that the EC chains, WPU chains, and CuNPs are well mixed, ensuring good interface compatibility. Meanwhile, the content of elements was examined by X-ray photoelectron spectroscopy in Figure 2D. In comparison to the EC membrane, the atomic percentage of C and O in the EWC-sensitive material decreases from their original levels of 72.63% and 27.37% to 71.39% and 25.47%, respectively, while the percentage of newly introduced N and Cu in the EWC sensitive material increase to 2.24% and 0.9%, separately. The surface chemical structure of polyionic eco-skin was analyzed using attenuated total reflectance-Fourier transform infrared (ART-FTIR) spectroscopy (in Figure 2E). The FTIR spectrum of EWC-sensitive material exhibits both EC and WPU characteristic absorption peaks centered at 3678–3327 cm−1, 2799–2980 cm−1, 1733 cm−1, 1051–1099 cm−1 and 1370 cm−1. These peaks are mainly attributed to the stretching vibration of both the N─H and ─OH, the symmetric and asymmetric stretching vibration modes of the C─H, the stretching vibration of C═O and C─O─C, bending vibration of ─CH3, respectively [31, 32]. Moreover, a slight rightward shift and increased intensity in the N─H and O─H broad peaks are observed, which illustrates the crosslinking interactions of hydrogen bonds between EC molecular chains and WPU molecular chains [33, 34]. Furthermore, the X-ray diffraction (XRD) measurement was conducted to reveal the internal crystal structure of polyionic eco-skin in Figure 2F. The pure EC membrane displays diffraction peaks at 2θ = 8.0° and 20.1°, showing its semicrystalline nature. Upon blending with biocompatible WPU polymer, these peaks become broader and less pronounced, signifying a reduction in crystallinity. This decrease in crystallinity contributes to the mechanical flexibility and extensibility of the composite material, making it more suitable for practical applications. Additionally, the XRD pattern of EWC-sensitive material presents new diffraction peaks at 2θ = 43.5°, 50.7° and 74.39°, which originates from the well-dispersed CuNPs (Supporting Information: Figure S3). It is also noted that the position of the characteristic peak at 2θ = 8° shifts to the right slightly, which may be attributed to the change of pore diameter lattice structure related to the interaction forces [35]. These results confirm the successful design of the EWC-sensitive material and self-powered polyionic eco-skin at the micro-scale.

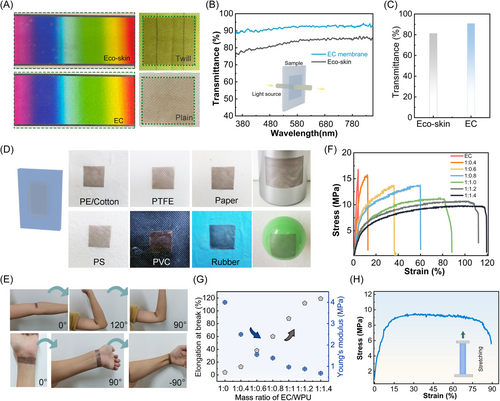

Despite the incorporation of CuNPs, the self-powered polyionic eco-skin maintains good optical transparency, as shown in Figure 3A. The colors of the bar covered by polyionic eco-skin are recognized and different interleaving structures (such as plain weave and the twill) of fabrics are easily identified. The transmission spectrum (Figure 3B,C and Supporting Information: Figure S4) reveals that the polyionic eco-skin has an average transmittance of over 84% in the visible range, slightly lower than the EC membrane (90%), yet still holds great potential to offer users the possibility of pursuing the esthetic requirements of electronics. More importantly, the polyionic eco-skin exhibits autonomously adhesive properties to different targets owing to the physical adsorption (hydrogen bonds, electrostatic attractions, and ion–polar interactions) and mechanical interlocking between PWP conductive electrode and the surface of targets [27], as demonstrated in Figure 3D,E. It can be found that the polyionic eco-skin can firmly attach to the surface of diverse materials (polyester-cotton fabric, PTFE fabric, wood, paper, rubber, and polyethylene glycol terephthalate plastic) without creeping down, showing extensive adhesion ability (Figure 3D). Supporting Information: Movie S2 demonstrated that the polyionic eco-skin undergoes adhesion failure during the peeling process and can be attached to the surface of these materials reversibly and repeatedly. Moreover, polyionic eco-skin can securely adhere to curved surfaces including spheres and cylinders (Figure 3D). The dynamic adhesion property of polyionic eco-skin was vividly demonstrated in Figure 3E. When the arm of the volunteer bends to the angle of 30°, 90°, and 120° in turn, the polyionic eco-skin attached to the elbow fossa deforms along with it, and always keeps the seamless interface adhesion with the surface of delicate skin in the whole process, showing no sign of detachment. The polyionic eco-skin adhered to the wrist showed similar stable dynamic adhesive properties, as shown in Supporting Information: Movie S3. This strong and stable adhesion property makes the eco-skin well-suited for interaction sensing applications for humanoid robotics or human bodies.

The mechanical properties of polyionic eco-skin are crucial for interactive electronics. To maximize the extensibility and deformability of eco-skin, a group of EC/WPU sensitive materials with varying mass ratios were prepared and the stress-strain curves were measured in Figure 3F–H. The pure EC-sensitive material exhibits limited stretchability with breaking strain at only 4%, hindering its application potential. However, the introduction of WPU into EC dramatically improves the elongation at the break of the composite and reduces Young's modulus. As shown in Figure 3G, when the mass ratio of EC/WPU increases to 1:1.4, the breaking elongation increases to 120%, which is 29 times more than that of EC membrane. The considerable enhancement is ascribed to the synergistic effect between the hydrogen bonding crosslinking network and WPU soft chain segments in the EC/WPU sensitive material. Furthermore, the stretchable polyionic eco-skin with EC/WPU mass ratio of 1:1 exhibits a breaking elongation of 90% and a low Young's modulus of 0.8 MPa, closely matching human soft tissue (Figure 3H) [36]. These characterizations suggest that the proposed polyionic eco-skin is easily capable of forming conformal contact with epidermal skin or other curved surfaces, making it suitable for complex body movements or robotic applications.

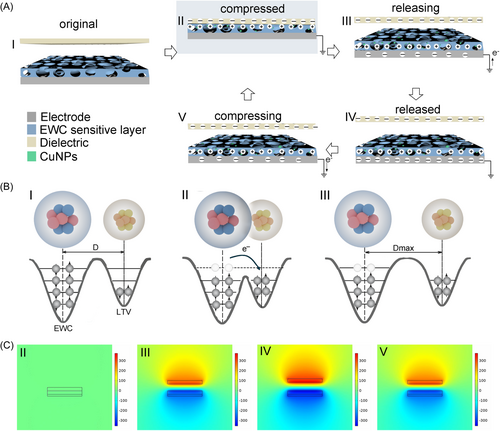

2.3 Operation Mechanism of Self-Powered Polyionic Eco-Skin

The working principle of self-powered polyionic eco-skin was described, as illustrated in Figure 4. The force-electric conversion mechanism can be explained by the coupling effect of contact electrification and electrostatic induction [37]. Initially, the polyionic eco-skin is separated from the other dielectric, with no charge transfer occurring (Figure 4A–I). With the external pressure, two dielectric materials contact each other, resulting in the triboelectrification between EWC sensitive layer and the negative dielectric layer, which is further analyzed and expounded by the electron-cloud potential-well model in Figure 4B. The surface electron potential wells of EWC sensitive layer and negative dielectric layer overlap each other so that electrons can hop between the atoms of the two dielectric materials, that is, from a higher energy level to a lower energy level. With the separation of two dielectrics, due to the existence of the energy barrier, equal charges with opposite electrical properties are kept on the surfaces of the EWC and negative dielectric material, respectively. As a result, the EWC-sensitive material is positively charged, while the negative dielectric material is negatively charged, as shown in Figure 4A–II. As they separate gradually, unshielded positive charges on the EWC sensitive layer will cause negative ions to gather at the EWC/PWP interface and then an electrical double-layer is formed at the interface of the PWP/conductive wire. To maintain electrostatic balance, free electrons flow from the ground to the PWP conductive electrode, leading to the pressure signal being converted into an electrical signal (Figure 4A–III,IV). When they are close to each other again, free electrons flow back in the opposite direction, as depicted in Figure 4A–V. With periodic contact-separation operation, external stimuli are continuously converted into alternative electrical signals by the self-powered eco-skin. It is emphasized that the effective generation and accumulation of tribocharges are closely related to the CuNPs and rich porous structure in the EWC sensitive layer. On one hand, massive CuNPs induce the internal interface polarization of the EWC sensitive layer and an enhancement of the dielectric constant, which further leads to an increase in the charge storage capacity and contributes to the improvement of force-electric conversion performance [38, 39]. On the other hand, positive tribocharges accumulate not only on the surface of the EWC sensitive layer but also within the pores during contact triboelectrification, which also greatly supports the formation of larger potential differences [30]. For a more straightforward understanding of force-electric conversion, the corresponding potential change in contact and separation states was also verified by finite element simulation in Figure 4C.

2.4 Optimization of Force-Electric Conversion Performance of Polyionic Eco-Skin

To enhance the force-electric conversion performance of polyionic eco-skin, the effects of CuNPs contents and thickness of EWC-sensitive material on electrical signals were systematically discussed in Figure 5. A group of eco-skins composed of EWC-sensitive materials with different mass ratios of CuNPs (5, 10, 20, 40, and 60 wt%) is paired with low-temperature vulcanized silicone rubber-negative sensitive materials for subsequent measurement. As depicted in Figure 5A–C, although the polyionic eco-skin without CuNPs has delivered considerable electrical signals with a voltage of 100 V, current of 13 μA, and transferred charge of 28 nC, the positive effect of CuNPs on the force-electric conversion performance of devices is still remarkable. The response electrical signals show a nearly linear increase with the mass ratio of CuNPs from 3 wt% to 5 wt% (Figure 5G). This enhancement occurs because increasing the mass ratio of CuNPs significantly boosts the charge storage capacity of the sensitive material. As shown in Supporting Information: Figure S5, the even-distributed CuNPs in EWC-sensitive material tend to induce the formation of nanoparticle-polymer interfaces, in which the interfacial polarization occurs owing to the diverse relaxation times between the CuNPs and polymer phases, leading to the accumulation of more charges at these interfaces. This will lead to an enhancement in the dielectric constant of EWC-sensitive materials, which increases the capacitance and surface charge density for obtaining high force-electric conversion performance of polyionic eco-skin [40, 41].

Furthermore, a group of EWC-sensitive materials with diverse thicknesses ranging from 10 to 60 μm was prepared for constructing self-powered eco-skins. The measured voltage, current, and transferred charge were recorded in Figure 5D–F. The polyionic eco-skin containing the 10 μm EWC sensitive layer delivers a voltage of 150 V, a current of 21 μA, and a transferred charge of 41 nC. As the thickness of EWC-sensitive material increases to 40 μm, the voltage, current, and transferred charge of the device rise to 209 V, 29 μA, and 55 nC, respectively, which is attributed to the increase in accumulated charges in the EWC-sensitive material. More tribopositive charges will be produced and accumulated in a thicker EWC-sensitive layer, thereby enhancing the force-electric conversion performance of eco-skin. However, as the thickness of the EWC-sensitive material exceeds 40 μm, the polyionic eco-skin exhibits decreased electrical signals rather than a continued increase (Figure 5G). This change is because the excessive thickness enlarges the distance between the PWP polyionic electrode and tribocharges, limiting the effective implementation of electrostatic induction. According to the above discussion, the EWC-sensitive material with a mass ratio of 5 wt% CuNPs and 40 μm thickness is chosen for constructing optimal self-powered polyionic eco-skin.

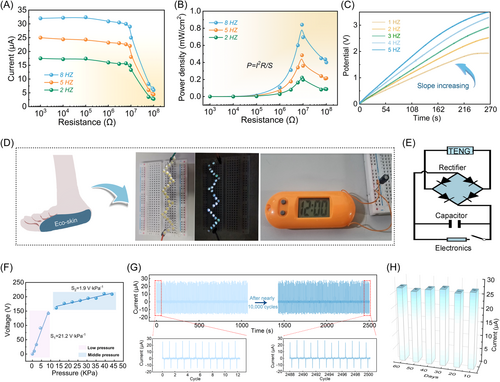

2.5 Force-Electric Conversion Characteristics of Self-Powered Polyionic Eco-Skin

The force-electric conversion performance of the polyionic eco-skin is typically reflected in two key aspects: one being its self-powered characteristics, meaning its capability to power itself or other devices; the other being its pressure responsiveness, which refers to the electrical signal output characteristics under different external stimulus conditions, including the amplitude and frequency of pressure, etc. Firstly, the polyionic eco-skin requires connection to an external circuit system in practical applications. These circuit systems, composed of multiple electronic components, typically exhibit varying circuit resistances. Quantifying the electrical outputs of the eco-skin under different impedance circuit conditions is essential for evaluating its self-powered characteristics in real-world applications. As shown in Figure 6A, the eco-skin exhibits outstanding electrical signal output across a broad range of system circuit resistance values from 103 to 108 Ω, reflecting its versatility and effectiveness in diverse circuit environments. Figure 6B and Supporting Information: Figure S6 illustrate the strong power supply capacity of the eco-skin and the optimal range of circuit resistance values to which it is suited. Additionally, the polyionic eco-skin also exhibits favorable self-powered characteristics when subjected to external forces at various frequencies. As depicted in Figure 6C, even under low-frequency force conditions of 1 Hz, the electrical output of the eco-skin can sustainably power itself, while excess power being able to charge a commercial capacitor to 0.5 V within 1 min. As the frequency of the force increases from 1 to 5 Hz, the power supply capability of eco-skin presents a gradual upward trend. This implies that the polyionic eco-skin's electrical output is not only capable of efficiently powering itself but can also supply surplus energy to power other components within the circuit. Further, the power supply behavior of eco-skin in the real application circuit is examined. As shown in Supporting Information: Figure S7, the capacitor of 1 µF can be charged to 5 V in about 7.6 s and a commercial capacitor of 22 μF can be continuously charged and discharged by the eco-skin, demonstrating fast charging capability and stable cyclic operation. Figure 6D demonstrated that a 6 × 8 cm² polyionic eco-skin integrated into a cotton sock effectively powers the LED array and successfully drives the digital watch under continuous walking movements (Supporting Information: Movie S4 and Movie S5). The simplified equivalent circuit is shown in Figure 6E.

On the other hand, the correlation evaluation between the compressive force and the output voltage was performed in Figure 6F. This result shows comparable sensitivities (21.2 and 1.9 V kPa−1 under low- and middle-pressure regions) with those of the previously developed ecological skin based on triboelectric mechanism. As depicted in Supporting Information: Figure S8, the voltage signal amplitude of the eco-skin increases with the touch pressure applied by the index finger, and the output frequency mirrors the touch pressure, demonstrating real-time pressure responsiveness. And Supporting Information: Figure S9 demonstrated that the electrical output of eco-skin increased with the strain increasing from 0% to 60%, which may be related to the coupling effect between the thickness of sensitive material and effective contact area. Supporting Information: Figure S10 indicated that the response time was about approximately 100 ms and the recovery time was approximately 160 ms. In addition, the work stability of force-electric conversion in the polyionic eco-skin was further assessed through 10 000 cycles of contact-separation movements or 2 months of exposure in atmospheric conditions. As illustrated in Figure 6G,H, the resultant electrical outputs remain nearly unchanged compared to the pristine sample, illustrating the polyionic eco-skin's robust reliability in long-term service. Furthermore, the polyionic eco-skin maintains stable electrical signals, without significant degradation even after 500 cycles of bending, stretching, and twisting (Supporting Information: Figure S11). Compared with previous artificial skins based on hydrogels, ionic gels, and liquid electrolytes, the proposed all-solid polyionic eco-skin offers strong robustness and is free from issues such as water evaporation and ionic liquid leakage.

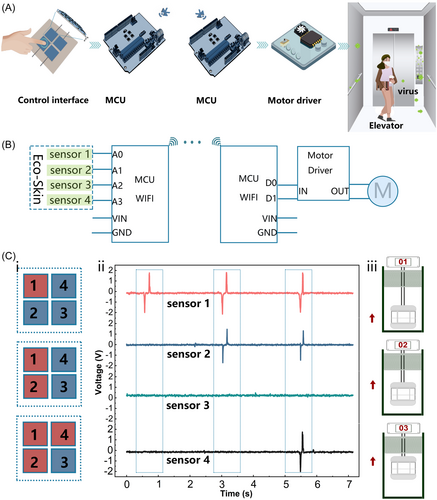

2.6 Polyionic Eco-Skin for Self-Powered Haptic Interaction

Being stretchable, transparent, conformable and excellent force-electric conversion, the polyionic eco-skin has promising potential in diversified sensing scenarios. To demonstrate its potential for self-powered sensing capabilities, polyionic eco-skin was used as a tactile sensor array to develop an intelligent wireless interactive system for remote and noncontact manipulation control of the public elevator for volunteers or robots. As shown in Figure 7A, the designed wireless smart interaction system consists of three components, where the eco-skin array (2 × 2 matrices) serves as the flexible touchpad, microcontroller unit hardware and motor driver are used for processing and transmitting electrical signals, and the elevator model is employed as the controlling terminal. Figure 7B demonstrates the detailed electronic circuit design of a wireless haptic interaction system. As shown in Figure 7C–i and Supporting Information: Figure S12, once the No.1 sensor in the 2 × 2 arrays is triggered, the corresponding trigger signal is generated by the eco-skin and transmitted to the microcontroller unit for judgment and processing. And the wireless signal receiver obtains the corresponding command and sends it to the motor driver. Finally, the elevator is raised to the first floor to realize contactless controllability. The patterns of triboelectric touch signal from the polyionic eco-skin array were recorded in Figure 7C–ii. Moreover, touching two sensors at the same time by the index and middle fingertip allows the No. 1 and No. 2 sensors to be triggered simultaneously, which drives the elevator up from the zero floor to the second floor. If no one uses the public elevator, it will automatically descend to the ground floor without any triggers. Supporting Information: Movie S6 intuitively demonstrated contactless interactive control for the elevator by the self-powered eco-skin array. Similarly, the elevator can be moved to the third floor, fourth floor or even higher floors by triggering the corresponding sensors. The proposed self-powered eco-skin exhibits attractive prospects in the era of digital information.

3 Conclusion

In summary, a stretchable, transparent, and attachable self-powered polyionic eco-skin was successfully developed for the first time. This innovative eco-skin is composed of an EWC electroactive layer and a PWP polyionic electrode layer and demonstrates versatile dynamic and static adhesion properties across materials with different textures and objects with diverse curved surfaces. The incorporation of biocompatible WPU polymer endows the EWC-sensitive material with a 29-fold increase in breaking elongation compared to the pure EC-sensitive material, resulting in the prepared eco-skin with high elongation at break (90%) and Young's modulus (0.8 MPa) approaching to that of human soft tissue. Moreover, the nanoparticle-polymer interfacial polarization and appropriate porous structure formation synergistically enhance the force-electric conversion performance of polyionic eco-skin without significantly compromising its optical transparency (>84% average transmittance). The polyionic eco-skin can adapt well to the curved surface movements of the human body and transform biomechanical energy into sustainable electricity to enable self-powered characteristics of microelectronics. Additionally, the polyionic eco-skin can serve as a flexible touch sensor for constructing an intelligent wireless interactive system. Its effectiveness was demonstrated by successfully achieving remote and noncontact manipulation of a public elevator. This proposed polyionic eco-skin holds extensive potential in fields such as medical protection, security systems, artificial intelligence, and bionic robotics.

Author Contributions

Zhiqing Bai conceived the idea, collected and analyzed data, and drafted the manuscript. Yunlong Xu performed experiments and contributed to data analysis and interpretation. Yunlong Xu and Yuan Fan reviewed and edited the manuscript. Zhiqing Bai and Qichong Zhang supervised the conduct of the experiment and provided experimental funding.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (52403284, 52473270 and T2422028), the Natural Science Foundation of Jiangsu Province (BK20240481), the China National Postdoctoral Program for Innovative Talents (BX20240408), the National Key R&D Program of China (2022YFA1203304), the Suzhou Institute of Nano-Tech and Nano-Bionics, Chinese Academy of Sciences (start-up grant E1552102). Z. Bai also thanks the China Postdoctoral Science Foundation and Jiangsu Funding Program for Excellent Postdoctoral Talent. We are grateful for the technical support of XRD for Nano-X Suzhou Institute of Nano-Tech and Nano-Bionics, Chinese Academy of Sciences. This work has been approved by the ethics committee. Informed written consent of all participants were obtained.

Conflicts of Interest

The authors declare no conflicts of interest.