Research progress in processing technology of rabbit meat

Abstract

Rabbit meat is tender, high in protein, low in fat and cholesterol, and offers several nutritional benefits. However, it has a stronger taste and can be challenging to cook. The global rabbit industry has been developing steadily, and China's total rabbit meat production has exceeded half of the world's total production in 2021. Along with the progress of the production process, the meat of the nutrition and taste at the same time, to improve smell also can get better control, solved the problems met in rabbit meat production. This article discusses the attributes of rabbit meat and outlines the deodorization, texture adjustment, and water retention techniques currently used in rabbit meat processing, aiming to offer a theoretical foundation for the advancement of rabbit meat processing technology.

Rabbit meat is characterized by high protein, high lysine, high phospholipids, low fat, low cholesterol, and low calories. It possesses a high nutritional content and favorable health index (Frunză et al., 2023), making it a high-quality source of nutritional meat. Rabbit meat contains higher levels of certain important amino acids compared to other meats from livestock and poultry. Therefore, it is often used in the research and development of infant complementary food, medicinal diet, low-temperature meat products, and other products. In the past 60 years, the global rabbit industry has been growing steadily. Since 2001, the average rabbit meat production has been stable at 30,000 tons, and in 2020, rabbit meat production has increased from 397,000 tons in 1961 to 893,000 tons. China is the world's largest producer of rabbit meat, the total production of rabbit meat in 2021 has accounted for 53.7% of the world's total, and has been on the rise for several consecutive years.

However, the processing technology of rabbit meat products also has some bottlenecks that are difficult to break through at present, such as different varieties, genders, weights, rabbit age, and so forth, the degree of odor is also different (Hao et al., 2023), improper thawing and processing methods have adverse effects on the flavor of rabbit meat products, as well as water loss and color changes caused by production, transportation, and storage. These problems have become the focus of current researchers. Therefore, to promote the continuous innovation, upgrading, and diversified development of the rabbit meat processing industry, and provide safer and high-quality rabbit meat products, this paper reviews the technologies that have been used in the processing of rabbit meat products and may be applicable in the future, hoping to provide a theoretical basis for the development of this industry.

1 CHARACTERISTICS OF RABBIT MEAT

1.1 Nutritional characteristics

Rabbit meat is nutrient-rich and high-quality meat, as shown in Table 1 (Liu & Chai, 2017; Yang et al., 2022). Compared with other meat, it contains more amino acids, protein, and water, and has lower fat and cholesterol content, a while having higher digestibility so it is easier for human body to digest (Dalle Zotte & Szendrő, 2011). According to the Chinese medicine book “Supplementary Records of Famous Physicians” records, rabbit meat has the effect of strengthening the spleen and stomach and removing toxins from the body. However, the processing temperature is too high, the processing method is improper, the storage conditions are poor, the transportation time is too long, and other reasons may cause the loss of nutrients.

| Nutrition composition | Rabbit | Pork | Beef | Goat | Chicken |

|---|---|---|---|---|---|

| Fat (%) | 1.51 | 21.6 | 4.4 | 11.1 | 2.7 |

| Protein (%) | 21.97 | 14.8 | 21.9 | 18.3 | 23.6 |

| Lysine (%) | 1.73 | 1.36 | 1.96 | 1.62 | 1.59 |

| Cholesterol (mm/100 g) | 60.0 | 126.0 | 106.0 | 90.0 | 75.0 |

| Moisture content (%) | 75.3 | 61.4 | 71.2 | 68.6 | 71.6 |

| Digestibility (%) | 85.0 | 75.0 | 55.0 | 68.0 | 50.0 |

1.2 Textural characteristics

The rabbit muscle fiber is relatively small. Generally, finer muscle fibers result in stronger water pressure and more tender meat, leading to a better chewing experience. However, rabbit meat also possesses a distinct fishy odor which can be masked or eliminated through various heat processing methods to enhance taste and quality while preserving its original nutritional advantages. As shown in Table 2 (Abdel-Naeem et al., 2021), the sensory attributes of rabbit meat are influenced differently by common thermal processing methods, including boiling, oven-roasting, grilling, pan-frying, and microwave. Boiled and roasted rabbit meat showed no significant differences in terms of elasticity, cohesion, and resilience. However, the hardness, viscosity, and chewability of roasted rabbit meat were significantly higher compared to boiled rabbit meat (Li, Rao, et al., 2022).

| Boiling | Oven-roasting | Grilling | Pan-frying | Microwave | |

|---|---|---|---|---|---|

| Appearance | 6.32 ± 0.33 | 8.88 ± 0.05 | 7.85 ± 0.20 | 8.92 ± 0.11 | 6.12 ± 0.27 |

| Flavor | 5.86 ± 0.17 | 8.79 ± 0.14 | 8.75 ± 0.08 | 8.69 ± 0.17 | 5.86 ± 0.25 |

| Tenderness | 6.85 ± 0.09 | 7.75 ± 0.19 | 8.65 ± 0.15 | 6.21 ± 0.25 | 8.55 ± 0.21 |

| Juiciness | 6.25 ± 0.24 | 7.85 ± 0.27 | 8.79 ± 0.13 | 6.25 ± 0.19 | 8.69 ± 0.12 |

1.3 Flavor characteristics

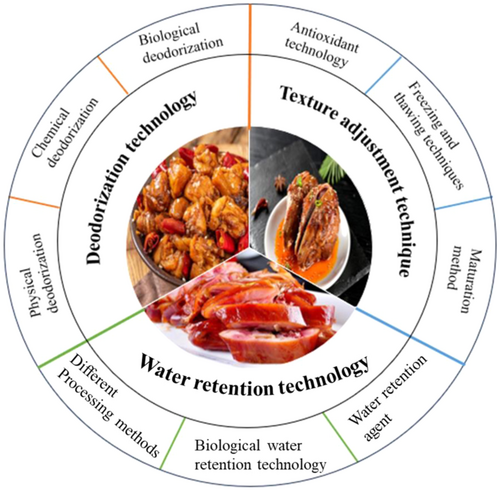

Rabbit meat contains a variety of alcohols, aldehydes, hydrocarbons, ketones, furans, and other flavor compounds. Meat's flavor components consist primarily of alcohols, including linalool with a convallaria scent and 1-octene-3-alcohol with a mushroom aroma. Meat primarily contains acids and aldehydes such as caproic acid and valeraldehyde. Furan and alcohol compounds found in rabbit meat, like 2-amyl-furan and amyl alcohol, can create undesirable fishy flavors such as earthy, liver, mutton, and bean smells when exposed to heat. This can negatively impact the taste of rabbit meat and diminish its flavor profile. The hot processing technology influences the primary volatile flavor compounds, leading to the distinct aroma and flavor of rabbit meat products. Insufficient removal of odor during processing can significantly impact the quality of the product. The production and processing of rabbit meat often involve the utilization of physical, chemical, or biological methods to mitigate or conceal its odor (Figure 1).

2 RABBIT MEAT PROCESSING TECHNOLOGY

2.1 Deodorization technology

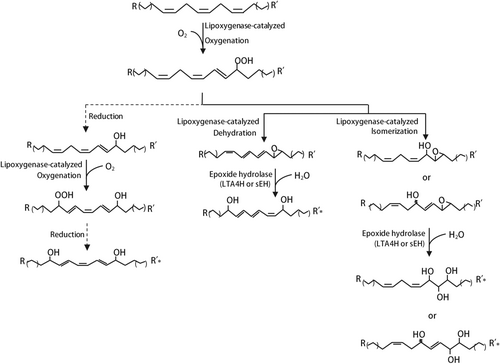

Studies have shown that lipoxygenase (LOX) catalyzes polyunsaturated fatty acids to produce dihydroxyl fatty acids, trihydroxyl fatty acids (Figure 2 [An et al., 2021] for the catalytic mechanism), and other polyunsaturated acid hydroperoxides with conjugated double bonds. It has been proved in fish products that under heating conditions, polyunsaturated fatty acids are easily oxidized to small molecular volatile compounds such as aldehydes, ketones, and alcohols, which play a decisive role in fish taste (Liu et al., 2024). The presence of over 10 types of unsaturated fatty acids in rabbit meat indicates a direct correlation between the final products, such as aldehydes, amines, furan derivatives, and other substances, with their aroma. Failure to undergo proper deodorization treatment will significantly impact the flavor profile of rabbit meat products. Currently, deodorization technology is categorized into physical, chemical, and biological techniques.

2.1.1 Physical deodorization

Physical deodorization utilizes methods like embedding, adsorption, and irradiation to remove fishy chemicals and enhance the sensory quality of rabbit meat products (Liu et al., 2023). The embedding method is a straightforward technique used to fix enzymes into a polymer microgel grid or polymer semipermeable membrane. Embedding agents such as β-Cyclodextrin and microcapsules have effectively minimized the fishy odor in meat, protected against external factors, maintained the stability of active ingredients, and demonstrated notable efficacy in eliminating fishy odors in fish (Pan et al., 2018; Serfert et al., 2010). The adsorption technique is straightforward and effective, utilizing the potent adsorption properties of chitosan (Liang et al., 2020), β-glucan (Zhang, Wu, et al., 2020), and other adsorbents to eliminate odor compounds. However, it primarily targets the meat's surface, has a restricted adsorption capacity, and requires precise control of operational parameters. Irradiation is also one of the methods to remove the fishy smell. For example, in the study of pork, electron beam irradiation could reduce the growth rate of bacteria and increase the content of fat oxidation and volatile compounds. The results showed that the irradiation treatment had a certain effect on eliminating the odor of meat. On the other hand, excessive radiation dose can make meat produce unpleasant radiation taste and reduce the acceptability of meat products (Chen et al., 2023; Yao et al., 2024). The physical deodorization approach is not fully effective in eliminating the fishy taste and has limitations on its application. It is mostly in the research phase and has not been used on rabbit meat.

2.1.2 Chemical deodorization

Chemical deodorization involves treating meat with certain chemicals or reagents to eliminate or greatly decrease the presence of fishy substances. Based on the principle of chemical deodorization and elimination, the commonly used spices transform the fishy flavor components of meat into new substances with no or small odor and use amino acids, peptides, and other substances in spices to improve the flavor of food. Studies showed that adding cloves could increase a variety of flavor compounds in the volatile components of chicken, including the inherent volatile components in cloves and the compounds that reacted with chicken components, thereby reducing or masking the original abnormal odor of chicken (Lu et al., 2011). Star anise could significantly increase the total volatile flavor compounds and reduce the fishy flavor compounds in pork ribs, and the main increase in volatile compounds came from star anise (Zhao et al., 2021). Herbs are natural deodorizers. Perilla has the ability to mask the odor of animal raw materials while simultaneously creating a distinct aroma, with safety being a significant benefit (Yang, Kong, et al., 2023; Yu et al., 2024). Spices contain volatile chemicals like selenium, alcohol, mercury, ketones, and esters, which provide distinctive flavors. As shown in Table 3, their color, smell, and taste properties and medicinal functions can cover up and eliminate the fishy taste of meat and add flavor. Research has demonstrated that utilizing plant extracts and spice mixes can effectively decrease the fishy taste in meat and improve its sensory characteristics (Djenane et al., 2023; Huang et al., 2022). Cooking wine is produced from various spices and is a frequently utilized condiment. The cooking wine contains alcohol and phenolic substances, which can be esterified with the carboxylic acid odor substance in rabbit meat to produce organic acid ester with an aromatic odor. It can also use the permeability of ethanol to dissolve the odor substance in the cell and react with acetic acid to produce ethyl acetate, which can achieve the effect of reducing odor, seasoning, and enhancing flavor (Wang, 2005; Xiao et al., 2023). Spices are commonly utilized in the preparation of hand-torn rabbit, dried rabbit meat, and spicy rabbit legs.

| Corresponds | Spice |

|---|---|

| Hot and spicy | Chili peppers, ginger, various types of bell peppers, peppercorns |

| Fragrance | Laurel, cinnamon, cloves, allspice |

| Spicy effect | Garlic, leeks, scallions, onions, peppers |

| Vanilla flavor | Fennel, basil, kudzu, sweet oregano, kukui, rosemary, sage, thyme |

| Food coloring | Turmeric, red pepper, saffron |

2.1.3 Biological deodorization

Biological deodorization technology utilizes microorganisms like Yeast, Lactobacillus, and enzymes to break down small molecules of unpleasant odors into larger, non-odorous molecules. Yeast deodorization involves the absorption of odorous compounds by the porous structure of Yeast, while enzymes produced by Yeast break down the odorous substances into less smelly compounds. Such as Yeast fermentation can improve the flavor of duck leg meat (Cai et al., 2020), and Saccharomyces cerevisiae can reduce the odor of seafood (Xu et al., 2022). Different studies have found that Lactobacillus can improve the flavor characteristics of dried mutton (Zhou et al., 2022), and although the mechanism of microbial deodorization remains unclear, the existing experiments show Cyberlindnera fabianii JGM9-1 and Lactobacillus plantarum RP26 fermentation can convert this tuna cooking liquid smell pleasant aroma (Ma et al., 2023). Introducing microbial enzymes simplifies and enhances the deodorization process, leading to a notable enhancement in the taste of meat products. Biological deodorization technology is not widely employed in the deodorization of rabbit meat but shows promising potential.

2.2 Texture adjustment technique

Rabbit meat is lean, tender, and flavorful, often referred to as “hundred-flavor meat.” Rabbit muscle contains less intermuscular fat, and incorrect processing can result in significant muscle fiber contraction, leading to a coarse texture when chewed. Various regions offer different types of rabbit meat with varying levels of moisture, fatty acids, and amino acids, resulting in distinct tastes. For instance, Shandong and Sichuan's Ira Rabbit, Goyal Rabbit, and Eplu Rabbit are compared to Shandong's I-Gol Rabbit, which is less tough, more elastic, easier to chew, and has the best taste (Fu, 2006). Improper processing can result in rabbit meat having an undesirable color, flavor, and reduced consumer acceptance.

2.2.1 Effect of antioxidant technology on texture

Meat oxidation during processing and storage diminishes tenderness, flavor, color, and juiciness by affecting myoglobin, myofibrillar proteins, and fat, resulting in a decline in quality and even endanger human health (Falowo et al., 2014; Huang & Ahn, 2019). Thus, the issue of antioxidants in meat products is a significant challenge in food manufacturing. Several experiments have shown that adding nutrients to the daily diet of rabbits during the breeding phase can enhance the self-oxidation stability of rabbit meat (Dos Santos et al., 2022; Zhang et al., 2023), increase crude protein content, improve fat deposition, and enhance nutritional value (Liu et al., 2022). This practice helps reduce browning reactions, slow down juiciness loss, and maintain sensory stability in terms of tenderness, color, and taste. Antioxidants can be added to rabbit meat processing to improve its sensory quality. Synthetic antioxidants are controversial due to health concerns, so researchers are focusing on natural antioxidants. These natural antioxidants are categorized based on their source and chemical structure. Plant-derived active compounds like green tea, garlic, sage, and thyme are commonly used in meat processing for their safety and effectiveness in inhibiting oxidation, reducing color changes, and improving sensory quality (Manessis et al., 2020; Zhang et al., 2022).

2.2.2 Effect of freezing and thawing techniques on texture and structure

Rabbit meat that is frozen or refrigerated is now commonly used as raw materials for processing, mainly due to geographical variations in the source of rabbit meat and processing facilities. Refrigerated freezing technology is crucial in the food industry for storing fresh food materials, processed products, and semi-finished products. It plays a significant role in determining the texture of meat products. Research indicates that subjecting rabbit meat to prolonged exposure to low freezing temperatures and many freeze-thaw cycles can lead to increased loss of meat juices, heightened fat oxidation, and deeper rancidity, resulting in meat hardness, darkening, and a deterioration in quality (Wang et al., 2014, 2018).

The storage temperature at low temperatures is linked to the pace of defrost loss. The method used for thawing (such as natural, steamed, or microwave) has a direct impact on the sensory attributes of the meat, as well as its texture, nutritional content, and color. Natural thawing maintains the hardness, elasticity, and chewiness of rabbit meat, but it takes longer and can reduce freshness. Since the water state doesn't change much and the meat is more juicy after cooking thawing, there will still be some water loss because of the protein denaturation, decreased muscle fiber water retention, and other variables. Microwaving at high temperatures sterilizes the meat, preventing bacterial growth, but can result in uneven heating and partial “cooking” (Li et al., 2018). As demonstrated in Table 4, there has been increased development and application of physical field thawing technology in many types of meats in recent years. This technology offers improved control and uniformity to preserve meat quality and flavor, addressing the limits of traditional thawing approaches. Rabbit meat's high moisture and protein content make it appropriate for quick and efficient thawing, which could be crucial for future studies on rabbit meat processing technologies.

| Defrosting process | Meat species | Impact on texture |

|---|---|---|

| High-voltage electrostatic field thawing | Rabbit | Tender and juicy with a bright red color (Jia et al., 2017) |

| Pulsed electric field thawing | Pork | Bright red color, small hardness, good chewability (Yao et al., 2023) |

| RF defrosting | Goat | Juicy meat with little color variation (Sun et al., 2023) |

| Microwave defrosting | Duck | Higher hardness and chewiness, lower elasticity (Xu et al., 2023) |

2.2.3 Effect of maturation method on texture

Boiling, roasting, pickling, and braising are common methods of preparing rabbit meat. The adoption of rabbit cooking techniques by consumers differs substantially between nations (Szendrő et al., 2020). Boiled rabbit meat has a moderate taste, while high-pressure cooking results in a softer and more glutinous texture. Enzyme digestion after cooking increases chewiness and enhances nutrition and health indicators. However, the appearance, color, and flavor may not be easily accepted by consumers. Oven roasting leads to greater destruction of rabbit muscle fiber and connective tissue, resulting in a meat texture that is harder but with moderate elasticity, tenderness, and juiciness, which is more appealing to Chinese consumer preferences (Li, Rao, et al., 2022). Processes such as vacuum pickling and rolling pickling have been shown to enhance the tenderness of rabbit flesh, decrease juice loss, and minimize hardness (Wang et al., 2015; Wang, Yuan, et al., 2023).

2.3 Water retention technology for rabbit meat

Water retention technology is crucial in all aspects of rabbit meat production, processing, transportation, sales, and other related activities. The color, taste, and nutritional content of rabbit meat products are influenced by the amount of moisture lost during preparation. Excessive water loss can result in juice loss, reduced meat quality, surface discoloration, and ultimately impact product sales. Water retention technology is crucial for preparing rabbit meat.

2.3.1 Water retention agent

The phosphorus-containing water-retaining agent is commonly utilized in meat preparation. Phosphate in the right quantity can regulate the pH of meat, enhance the space and ion strength of myofibrillar proteins, bind to metal ions like Ca2+, Mg2+, and Fe2+, exhibit emulsifying and antioxidant properties (Zhen et al., 2023), and enhance water retention while forming a protein gel in rabbit meatballs (Xue & Xie, 2021). The high levels of phosphate pose risks to human health and environmental safety, such as reduced human kidney function (Rubio-Aliaga & Krapf, 2022) and uncontrolled growth of algae and large plants in the water (Ahmad et al., 2023), leading to a growing focus on researching non-phosphorus water holding agents. Phosphorus-free water retention agents applied to meat products in various forms, such as chitosan, alginate, potassium alginate, and so forth, through a certain chemical reaction to form a dense and stable network structure, to protect the water in the meat is not easy to lose (Qiao et al., 2024). Sodium bicarbonate increases water-holding capacity by changing the pH in muscle tissue, causing electrostatic rejection of peptide chains and myofibril, resulting in swelling of protein structures (Li, Luo, et al., 2022). The composite phosphorus-free water-retaining agent has been well-developed in studies on pork (Cho & Jeong, 2018) and sea bass (Li et al., 2023), but there is less study on its application in rabbit meat, making it a potential area for further investigation.

2.3.2 Biological water retention technology

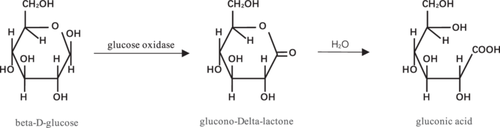

Biological water retention technology, including enzyme preparations, basic amino acids, and modified starch, is commonly employed in meat processing due to its environmentally friendly, safe, and effective characteristics. Enzyme preparations are highly specific, safe, and nontoxic. They can enhance water retention and stability in rabbit meat products, extending their shelf life. For example, glucose oxidase catalyzes the conversion of β-d-glucose into gluconic acid and hydrogen peroxide under specific aerobic conditions (reaction Figure 3 [Meyer et al., 1998] represents the water conservation mechanism). Lysozyme breaks glycosidic bonds in the cell wall, promoting bacterial death, and its heat and acid resistance further improves preservation (Zhao et al., 2023). The research discovered that l-lysine in alkaline amino acids enhances the water retention capacity, quality attributes, and sensory properties of meat (Fan et al., 2024; Lu et al., 2023; Zhang, Zhang, et al., 2020). Additionally, phosphate starch powder enhances the water retention, elasticity, and chewiness of chicken tablets, resulting in superior sensory qualities compared to the addition of cornstarch powder. Hence, the prospective utilization of biological water retention technology in rabbit meat holds greater potential.

2.3.3 Water retention effect of different processing methods

Enhancing and utilizing processing technology efficiently helps decrease moisture loss in meat products and preserve high quality, as demonstrated in poultry meat processing trials. A popular method for preparing cured meat is rolling and kneading, which uses physical force to break down the meat's cell structure and alter the internal tissue architecture to retain water and minimize cooking loss (Yang & Yang, 2023). Modern industry demands have led to the development of novel rolling technologies, such as pulsing vacuum rolling and pneumatic variable pressure rolling, which preserve meat's freshness and tenderness while enhancing its ability to retain water and accelerate the rate at which pickling liquid is absorbed. Vacuum processing technology, including vacuum critical low temperature drying and enriched vacuum immersion techniques, is beneficial due to its lack of chemical additives, short processing time, minimal meat color changes, increased nutrient and moisture retention, extended storage time, and applicability to rabbit products. Electric field processing technology, specifically pulsed electric field and ultrasound, has significant applications. The pulsed electric field can enhance water absorption in animal cell membranes, while ultrasound can disrupt protein bonds, altering their spatial conformation. It has been experimentally proven that ultrasound can boost the water retention capacity of meat and improve its sensory characteristics (Wang et al., 2022; Zhou et al., 2020).

2.4 Other technologies

With the improvement of people's material living standards, safe and healthy diet has been widely concerned. Although traditional thermal sterilization technology can effectively inactivate microorganisms and extend shelf life, it will cause adverse physical and chemical reactions of food and reduce the content of heat-sensitive substances, thus affecting the nutritional value and sensory quality of rabbit meat products. Therefore, to improve the shortcomings of traditional thermal sterilization technology, many nonthermal processing technologies have been applied to the production and processing of meat products. Methods like ultra-high pressure sterilization inhibit enzyme activity to enhance softness, water retention, and preservation (Gokul Nath et al., 2023). Ultrasound sterilization enhances bacterial coagulation, leading to reduced toxicity or complete bacterial death, achieving water conservation (Li et al., 2024). Additionally, microwave and irradiation sterilization methods can increase moisture content in rabbit meat products while ensuring safety (Wang & Zhou, 2023).

Packaging plays a crucial role in the food sector by ensuring economic efficiency, food safety, health standards, and prolonging shelf life. Vacuum packaging is more effective than polyethylene-based plastic film in delaying microbial growth, reducing lipid oxidation, protein degradation, and color change (Redondo-Solano et al., 2022). As shown in Table 5 (Sun, 2004), the different gas mixture compositions of modified atmosphere packaging is determined by the different characteristics of food, which can effectively inhibit the growth of microorganisms and extend the shelf life of rabbit meat more effectively than vacuum packaging (Racewicz et al., 2023). New technologies, including coated packaging and sterile packing help preserve the sensory and quality of rabbit meat products and are commonly utilized for meat preservation.

| Kind | Oxygen content/% | Carbon dioxide content/% | Nitrogen content/% |

|---|---|---|---|

| Lean meat | 70 | 30 | - |

| Joint meat | 80 | 20 | - |

| Fresh fish | 30 | 40 | 30 |

| Poultry meat | - | 70 | 30 |

3 CONCLUSION

The processing of rabbit meat should be chosen and refined based on the specific qualities of rabbit meat and market needs. Various approaches, such as physical, chemical, and biological techniques, can successfully diminish the fishy taste of rabbit meat when preparing it. Meats prepared in various ways—boiling, roasting, pickling, braising, and freezing—have varying affects on flavor. It is important to choose the proper processing techniques based on production requirements. Various parameters such as processing time, temperature, and others will impact the moisture, color, nutrition, and quality of rabbit meat. To decrease water loss in meat, one can utilize water retention chemicals, modify processing techniques, and opt for biological water retention technology to maintain freshness and tenderness. Advancements in sterilization technology, packing, and preservation techniques are continuously progressing to further minimize the deterioration of rabbit meat quality and nutritional value in the future.

Although the global production and sales of rabbit meat products have increased year by year, there are still many problems in the rabbit breeding environment and sustainable development of processing technology, and product information transparency and consumer acceptance need to be improved. With the increasing demand of consumers for food, whether the advanced technology of green safety can be widely applied, improve product quality, efficient storage, transportation, and sales of products are all problems faced by rabbit meat enterprises. The government needs to give more support and supervision to the rabbit meat industry, rabbit meat farms, food companies, sellers need to work together to achieve the standardization of the rabbit meat products industry chain, science and technology, environmental protection, to have a larger market.

AUTHOR CONTRIBUTIONS

Yunjia Deng: Conceptualization; validation; writing—original draft. Qing Nie: Conceptualization; data curation; writing—review and editing. Yanan Zhou: Data curation; validation; writing—review and editing. Wei Wang: Resources; supervision; validation; writing—review and editing. Zhoulin Wu: Data curation; software; writing—review and editing. Lili Ji: Funding acquisition; project administration; supervision; validation; writing—review and editing. Jiamin Zhang: Supervision; validation; writing—review and editing. Decai Zhou: Supervision; writing—review and editing.

ACKNOWLEDGMENTS

This study was supported by the special funds for the construction of the National Modern Agricultural Industry Technology System fund for CARS-43.

CONFLICT OF INTEREST STATEMENT

The authors declare no conflict of interest.

ETHICS STATEMENT

None declared.