Integrated Research as Key to the Development of a Sustainable Geothermal Energy Technology

Abstract

As estimated by the International Energy Agency, geothermal power can contribute to 3.5 % of worldwide power and 3.9 % to heat production by 2050. This includes the development of enhanced geothermal systems (EGSs) in low-enthalpy systems. EGS technology is still in an early stage of development. Pushing EGS technologies towards market maturity requires a long-term strategic approach and massive investments in research and development. Comprehensive multidisciplinary research programs that combine fundamental and applied concepts to tackle technological, economic, ecological, and safety challenges along the EGS process chain are needed. The Karlsruhe Institute of Technology (KIT) has defined a broad research program on EGS technology development following the necessity of a transdisciplinary approach. The research concept is embedded in the national research program of the Helmholtz Association and is structured in four clusters: reservoir characterization and engineering, thermal water circuit, materials and geoprocesses, and power plant operation. The proximity to industry, closely interlinked with fundamental research, forms the basis of a target-orientated concept. The present paper aims to give an overview of geothermal research at KIT and emphasizes the need for concerted research efforts at the international level to accelerate technological breakthrough of EGS as an essential part of a future sustainable energy system.

1 Introduction

1.1 Potential of geothermal energy

Geothermal energy offers an enormous potential for future power and heat provision. As a sustainable energy form, geothermal energy is renewable and low emission. It has a high availability and, as a domestic resource, it is decentralized and import independent. In contrast to other renewables, such as wind and solar power, geothermal energy is base-load capable and steerable. It is an ideal complement to fluctuating renewable energy sources within a renewable energy mix. Contributing to a secure future energy supply, geothermal energy is of major significance for the energy transition.

According to an estimation of the International Energy Agency (IEA), a contribution of deep geothermal energy of 3.5 % to the global electricity production and 3.9 % of projected final energy for heat by 2050 is realistic; thus avoiding 800 megatons of CO2, whereas half of the expected increase is made up by enhanced geothermal systems (EGSs).3 The IEA aims to install a minimum of 50 EGS research power plants and scaling up the EGS capacity by a factor of 3 until 2025. Eventually, 50 MWe power plants are planned to be realized in 2050 by the serial installation of EGS modules to achieve an EGS portion of 60 % of worldwide geothermal production. In Germany, geothermal energy is expected to provide 5 % of the power production and 10 % of the primary energy demand, providing that EGS technologies are utilized.

1.2 Requirements

EGS technologies have a key role for the establishment of geothermal technologies with a critical market share. However, the technology has not yet reached the state of maturity that is necessary for large-scale industrial application. The intended scaling up of power plant capacities from currently significantly below 10 MW to 50 MW in the future presents severe obstacles, including the assurance of efficiency, profitability, and safety of geothermal facilities. Among the most important challenges and milestones for EGS developments, as defined by the IEA,3 are 1) the reduction of drilling costs by advancing the development of cheaper drilling technologies; 2) arousing interest and confidence from investors in geothermal projects by defining medium- and long-term targets for geothermal energy technologies; 3) the economic harvesting of geothermal energy from different geological environments; and 4) improving social acceptability of the technology by controllability, that is, facing environmental impacts and safety.

Pushing EGS technologies towards market maturity presupposes a long-term strategic approach and requires massive investments in research and development. Comprehensive multidisciplinary research programs,1, 2 combining fundamental and applied research concepts, to tackle technological, economic, ecological, and safety challenges along the EGS process chain are required.

It is the task of fundamental research to create a sound basis for technological development by providing a profound understanding of the involved thermal, hydraulic, mechanical, and chemical (THMC) processes in the reservoir and underground and surface installations. To achieve this, there is an urgent need for an enhanced experimental benchmarking data set. This is also the necessary basis for the further development of numerical simulations, which enable model-based process predictions.

Generic test sites, and finally large-scale demonstration plants, have to be established for technological research and development based on objective criteria. Target-oriented research projects have to be defined in close cooperation with industrial partners.

It must be the distinct goal of all required research efforts to enhance—hand in hand with technological advancements for economic viability—the acceptability of EGS technologies for society in terms of ecological sustainability and risk mitigation. Indeed, this aspect has evolved to become a crucial issue, since public confidence in geothermal energy has weakened, particularly after incidents involving induced seismicity, as in Basel in 2006.4 In close collaboration with social sciences, communication and participation concepts on the basis of objective information and transparent research findings are necessary to accompany the envisaged technological breakthrough of EGS.

1.3 Transdisciplinary research concept

Objective and transparent research is of major significance for the technological development of EGS at the current state of technology advancement. Complying with the outlined complex requirements will be only successful with a systematic approach across disciplines and scales, incorporating new scientific concepts.

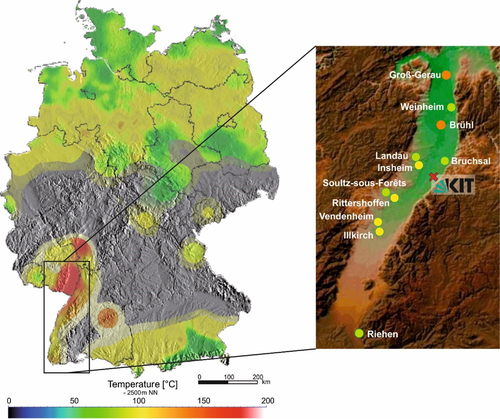

The Upper Rhine Graben (URG) offers remarkably favorable conditions for deep geothermal energy utilization (Figure 1). Hydrothermal convection cells in crystalline basement rocks and deep-seated sediments result in basal heat flow rates up to >150 mW m−2 and temperature gradients up to 110 °C km−1 in the URG. It is therefore not surprising that numerous geothermal projects have been developed, ranging from the well-established hydrothermal doublet system in Riehen to the newly installed EGS plant in Rittershoffen, France, used solely for the supply of industrial process heat. The European geothermal research project at Soultz-sous-Forêts became a milestone for the utilization of deep geothermal energy: The concept of EGS as a further advance of the hot dry rock approach was developed and made the URG a leading center of EGS technology development.

Underground temperatures in Germany at a depth of 2500 m. The enlarged part shows the URG, with the Karlsruhe Institute of Technology (KIT) close to geothermal projects. Green: project running, yellow: project under construction, orange: abandoned. Temperature map modified after Leibniz-Institut für Angewandte Geophysik (LIAG), Hannover.

The KIT, located within the URG, takes advantage of these framework conditions and has defined a comprehensive research program on EGS technology development, following the necessity of a transdisciplinary approach. Research activities cover the whole EGS process chain, including system integration and span from fundamental to applied research across scales. The geothermal research group at KIT has collaborated with various projects in both the German and French parts of the URG. The proximity to industry, closely interlinked with fundamental research, forms the basis of a target-orientated research concept. It incorporates not only the perspective of geoscientists, but combines the disciplines of geosciences, geophysics, materials science, engineering, geochemistry, and numerics.

The following overarching goals with respect to EGS technology development have been defined: 1) safe, predictable, and effective reservoir engineering; 2) enhanced productivity and economic feasibility; 3) minimal environmental impact; 4) systematic quality assurance; and 5) reliable and intelligent system integration.

These goals serve the final aim of sustainability and societal acceptability of EGS as a pillar of a future renewable energy portfolio.

The KIT research concept is embedded in the national research programs of the Helmholtz Association. The topic “geothermal energy systems” within the program “Renewable Energies” in the research fields “Energy” is tackled together with the partners GFZ (German Research Center for Geoscience) in Potsdam and UFZ (Helmholtz Center for Environmental Research) in Leipzig.

1.4 Necessity for large-scale infrastructures

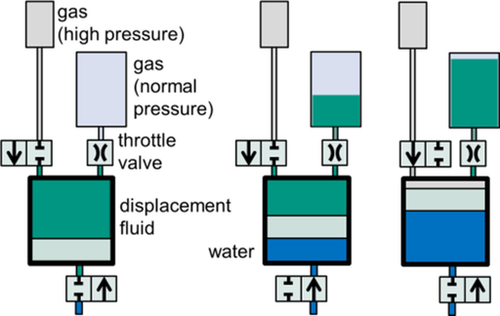

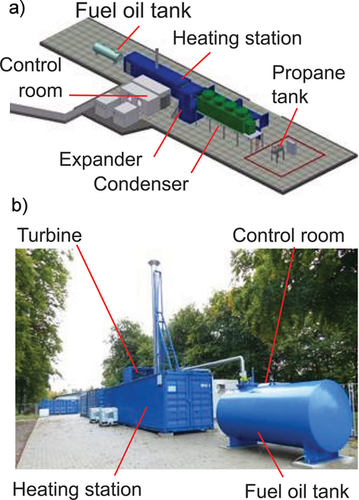

An early technical breakthrough is critical to success in developing EGS and requires—together with the discussed interdisciplinary system thinking and multiscale approaches—technology-specific research infrastructures. Integration into national research programs allows, in addition to strategic medium- to long-term planning with the incorporation of various research groups, the establishment and provision of infrastructure platforms as a unique opportunity for large-scale research. To give EGS research urgently needed impetus, two large-scale infrastructures comprising both ends of the EGS process chain, which allow research close to real scale, are currently being planned or established, respectively: the underground facility of the Geothermal Underground Laboratory (GeoLaB) and the modular low-temperature power plant cycle Modularer Niedertemperaturkreislauf Karlsruhe (MoNiKa). MoNiKa and GeoLaB have the potential to form core elements of geothermal research and serve as interdisciplinary platforms for various research groups at KIT and the research community; these are already at the stage of planning and establishment.

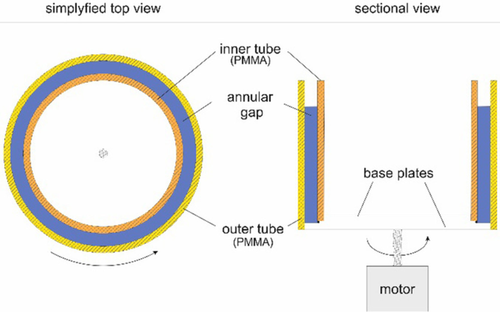

MoNiKa is a generic power plant circuit to investigate low-temperature geothermal electricity production. It is designed as a modular and mobile test stand, which offers unique opportunities to study geothermal power generation and low-temperature power generation in general. The goal is to characterize the exchangeable main components and their interdependencies and, finally, to optimize power plant cycle thermodynamically and economically to achieve highest possible efficiency. Currently, the test facility is under construction (see Section 4.1).

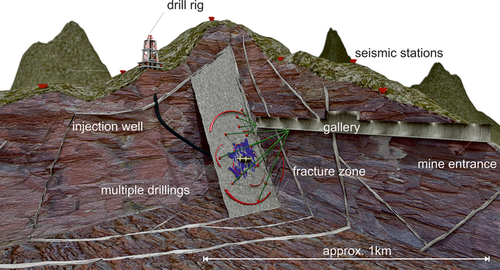

The planned underground laboratory, GeoLaB, is designed as a generic underground research laboratory in the Black Forest or the Odenwald. The target rock is representative of the world's most widespread geothermal reservoir rock, the crystalline basement. GeoLaB shall address fundamental challenges of reservoir technology and borehole safety. The target goals of research in GeoLaB are 1) to increase the efficiency of EGS with a unique geothermal underground laboratory for fundamental research; 2) to reduce induced seismicity by controlled, in situ, high-flow experiments (CHFE) in a reservoir simulator; 3) to reduce the prospecting risk by benchmarking for future geothermal projects in crystalline rock; and 4) to promote the social acceptance of geothermal projects by developing methods and technology for efficiency, safety, and ecological sustainability. As an interdisciplinary and international research platform, GeoLaB will cooperate with the German Research Foundation (DFG), universities, industrial partners, and professional organizations to foster synergies and technological and scientific innovations. Hence, GeoLaB will significantly contribute to our understanding of processes associated with increased flow rates in crystalline rock (see Section 4.2).

2 Scientific Priorities

Forecasting processes and interactions of materials and circulating fluids within geothermal reservoirs and EGS power plants represent a major scientific goal. The operational reliability and economic viability remain to be demonstrated to gain the necessary support and acceptance from industry and the population. This gives rise to the following technological and scientific focuses for EGS-related research.

Detailed knowledge of the subsurface reservoir characteristics, including its complex structure, is of major importance for the success of geothermal installations during planning and establishment, reservoir engineering, and operation. Present exploration and monitoring methods are not standardized and often not suited to clearly identify potential reservoirs. The goal is to develop and standardize novel geophysical exploration and monitoring techniques, including inversion methods of magnetotelluric (MT) and gravimetric data and electromagnetic and self-potential monitoring. Accordingly, the high drilling costs and high prospecting risk due to the unreliable identification of exploitable zones can be minimized, which increases the attractiveness for potential investors. During stimulation and operation, knowledge about the subsurface structures and evolving geochemical and geomechanical characteristics of fractures are a prerequisite to understand the dynamic behavior of the reservoir and to develop, based on this knowledge, smart stimulation techniques. Efficient observation networks for temporally and spatially high-resolution (HR) data have to be defined to detect potential environmental impacts already in the forefront. Developing reliable data analysis and modeling techniques to image the seismic cloud are evidently a basic prerequisite in managing the seismic hazard.

Borehole integrity is a precondition for the safe and long-term operation of geothermal power plants. Experimental and simulation studies with a focus on durable and thermal shock resistant cementations and safe abandonment measures are the goal of ongoing research towards a long-term reliable sealing. In situ experiments, as an extension to laboratory studies, will provide new insights into the drilling behavior of brittle magmatic or metamorphic rocks with possibly extended damage zones and into the behavior of the involved materials and the complex interactions among each other and the surrounding rocks and fluids. Thus, reliable access to subsurface structures can be guaranteed, while ensuring integrity.

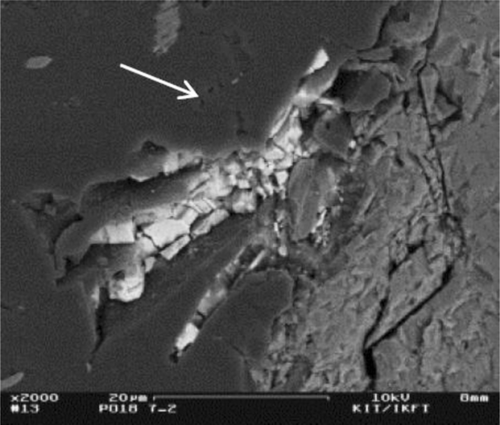

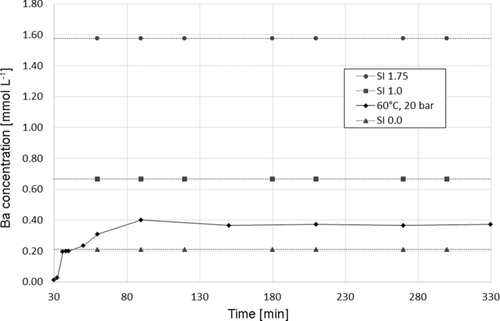

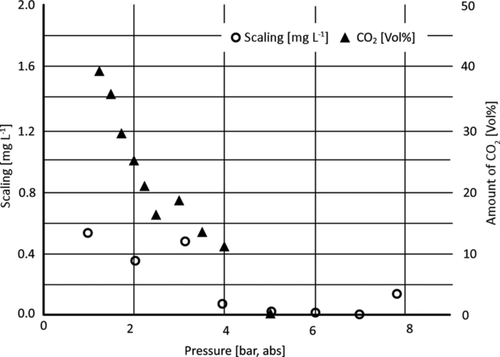

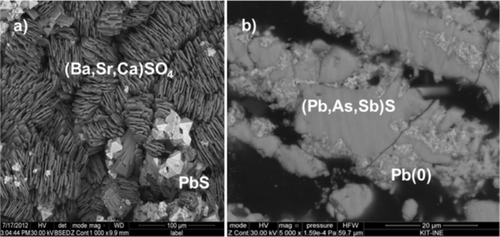

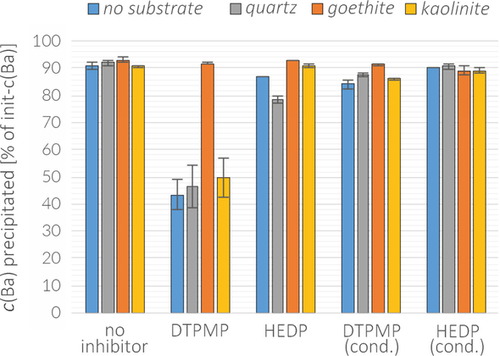

During operation of EGS power plants, a commonly observed phenomenon is the precipitation of minerals from geothermal fluids in surface installations. These mineral precipitations may incorporate naturally occurring radioactive minerals that are hazardous to human health and the environment. Current research focuses on the inhibition and avoidance of scaling; thus enhancing the safety and durability of EGS systems. Reduction of scaling will also enhance heat transfer and decrease pressure losses in the system.

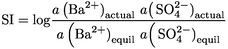

Scaling occurring within the reservoir after reinjection of the thermal brine (e.g., baryte) can strongly decrease injectivity, and hence, the long-term efficiency of a plant. Fundamental understanding of the related processes of scaling formation forms the basis for the development of scaling inhibitors.

The highly saline character of the fluids and the high load of mineral particles cause mechanical abrasion, as well as corrosion, on power plant components. Related enhanced microbial activity inducing corrosion, even at lower temperatures, or biofilm formation are the focus of corrosion research. New resistive materials have to be selected and developed based on results gained from in situ and laboratory experiments with artificial and real geothermal brines.

The basis for an adequate selection of durable materials is a profound understanding of the influence of the fluid properties on the precipitation and corrosion process by hydrothermal simulations and hydrochemical modeling. Both experimental and modeling approaches are necessary to understand the relationship between geological parameters and structures and observed THMC processes in fractures and the reservoir.

Despite site-specific framework conditions, geothermal plants are still constructed from off-the-shelf components. Multiscale process simulations, combined with experiments, are essential to provide important insight into the processes at different resolution levels and to serve as a basis for the subsequent design and adaption of technical components. Hence, the operational costs, as well as expenses for investment and maintenance, can be minimized and the efficiency of components, such as pumps and heat exchangers, can be increased.

EGS systems require a vast range of measuring instruments to control their reliable installation and operation and to satisfy increasing environmental concerns of the public. There is a need to develop high-temperature logging tools that are economically suitable for deployment under conditions typical for geothermal reservoirs.

Developing an efficient reservoir through stimulation and managing the high flow rates in the reservoir to harvest geothermal energy in an economically viable, predictable, and sustainable manner is a core task of geothermal research and development. Essential conceptual achievements have been made to establish EGS technology, especially through projects in the URG. Current research aims to transfer the previously followed learning curve in this regard, which was rather practically and economically oriented and case specific, to universally applicable scenarios. Another focus is on the transferability of geothermal experience in sedimentary rocks, in which flow mostly takes place in the pores, to projects in crystalline rocks, in which fractures are the main flow paths.

To give EGS technology the decisive momentum towards a more widespread and socially accepted usage, research and development will be closely tied to previous EGS experiences. It is also crucial to develop a fundamental understanding of the THMC interacting processes in the reservoir to provide generic solutions. As a precondition for this, fundamental scientific data have to be acquired and new research approaches followed. High-rate fluid flow in fractured media has to be addressed. The currently unknown constitutive flow laws for large-scale processes have to be derived. The dynamic processes in space and time that result in mechanical stress variations have to be qualitatively and quantitatively described. A 4D benchmark data set of THMC parameters is needed.

A highly topical issue is the transfer of results from experimental laboratory data to the reservoir scale. The identification and quantification of experimental uncertainties, model uncertainties, and process uncertainties are integral parts of scaling processes up and down. A major focus of geothermal research must therefore be on the scale dependence of THMC processes and the development of strategies for scaling up and down. This includes process-related investigations based on multiple data acquisitions, data description, and modeling over various scales. These considerable research challenges can be successfully tackled with a technology-specific underground laboratory as a generic reservoir simulator to bridge laboratory and field scales and serve as a research platform across disciplines.

An underground laboratory, as proposed with the GeoLaB concept, can provide a further essential function: to serve as an objective information platform. Recent seismic events within the framework of EGS projects and their public perception show the importance of scientific outreach. Hence, the geothermal research community has to enter into a continuous dialogue with the public and be a neutral information platform to communicate technological risks and opportunities. The formulation of regulatory guidelines and political decision-making processes requires the unbiased scientific input of large-scale geothermal research.

3 Research and Development

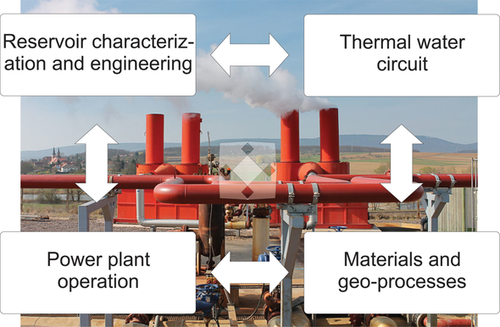

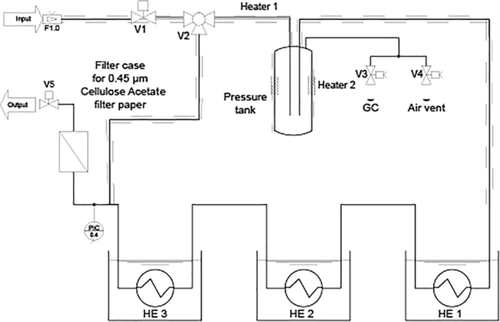

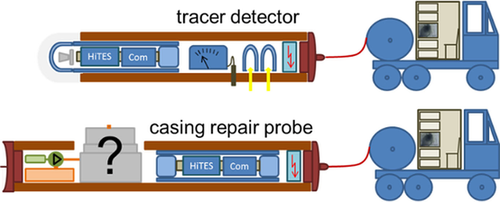

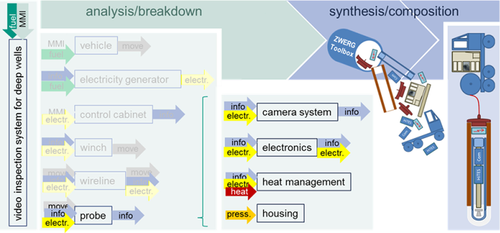

Structured in four clusters, KIT scientists contribute to all major parts of the development of a geothermal project from the prospection and exploration of potential reservoirs to the economic operation of an EGS power plant. The four clusters are (Figure 2): 1) reservoir characterization and engineering, 2) thermal water circuit, 3) materials and geoprocesses, and 4) power plant operation.

Overview of the four cross-cutting clusters of geothermal research at KIT.

These clusters comprise the EGS process chain and have numerous interfaces due to overlapping system processes, methodological cross-cutting issues, and increasingly due to future infrastructures as integrating research platforms (see Sections 4.1 and 4.2). This section provides a description of the clusters and gives an insight into ongoing work. It should also be considered an invitation to future collaborations.

3.1 Reservoir characterization and engineering

Central Europe hosts a number of important heat flux anomalies that are linked to upwelling fluids of enhanced temperature in a specific geological and tectonic setting. Major anomalies are located in the central URG to the east of the Black Forest5 and to the south of the Black Forest at the High Rhine,6 reaching heat flux densities up to 150 mW m−2. They are predestined for the development of EGS, since they are fault- and fracture-bound and susceptible to reservoir engineering measures.7 A reservoir characterization study is the basis for the development of a reservoir model.

For an optimization of the lifetime performance of a geothermal reservoir, a profound understanding of the reservoir rocks and fluids through accurate measurements and characterization is necessary.

Rock and fluid properties are characterized by formation evaluation based on downhole measurements, formation testing, and laboratory analyses. Petrophysical analysis is performed by using a wide variety of measurements to understand the reservoir and its detailed characteristics. Measurements at scales from pores to reservoirs are analyzed and interpreted to develop micro- and macrogeological models. Knowledge of local and field-wide structure and variability helps to achieve optimal reservoir performance and to avoid hazards.

Geophysical exploration methods provide a large image from the reservoir and its geological context, whereas wellbore-scale seismic and petrophysical data deliver detailed formation parameters. Large-scale sensing is used for the prospecting of geothermal reservoirs in all types of environments, providing the basis for a 3D reservoir model with its physical properties.

Reservoir engineering provides an understanding of fluid flow and phase behavior at all scales, for all kind of fluids and geological environments. A combination of downhole sampling and measuring techniques, as well as laboratory experiments, is used to estimate the reservoir potential and to model future performance. The integrative analysis of data acquired with various measurement techniques enables the development of sophisticated reservoir models to optimize reservoir performance, while mitigating seismic and environmental hazards.

In the following sections, specific research topics and results are presented.

3.1.1 Geophysical exploration of geothermally relevant faults

Geothermal exploration of EGS mostly targets the crystalline basement. The HR imaging of its structural setting from the surface is challenging. The nature of seismic reflectors within the crystalline basement remains the subject of inference, except where reflections have been traced directly to outcrop.8 Due to the lack of seismic reflectors, broadband MT surveys are crucial in geothermal exploration in volcanic areas to locate possible reservoirs. In particular, the detection of high-enthalpy reservoirs is performed indirectly through the detection of cap layers because their hydrothermal alteration products possess a high electrical conductivity.9 For the exploration of medium-enthalpy systems (<160 °C), the identification of fault zones is in the focus of recent research.10 Fractured reservoir zones may display a resistivity contrast to surrounding host rock when hydrothermal alteration products enhance electrical conductivity, and thus, can be resolved by audio-magnetotelluric (AMT) sounding by using adjusted interstation distances.11

Through an AMT approach, data are acquired in a period band of 10−3–512 s. A mean interstationing of 1–2 km is used on profiles of typically between 15 and 25 km. To respect geoelectric strikes, profiles are typically oriented perpendicular to the fault or fracture zones, on which convective heat transport is expected.12 Data are typically acquired over 1–3 days to allow for robust data processing. Measurements are performed by using Metronix MT stations with ADU-06 or ADU-07e data loggers, three MSF-06 or MSF-07e coil magnetometers, and four EFP-06 electrodes. In a project in the area of the Southern Black Forest, SPAM IV data loggers (from the Geophysical Instrument Pool (GIPP) at GFZ Potsdam) were used. Magnetometers and electrodes are oriented north (N)–south (S), east (E)–west (W), and vertically. Horizontal magnetic and electric sensors are installed at a depth of about 20 cm. Vertical magnetic sensors are buried completely. Cables are fixed to the surface and partly buried to reduce motion, for example, by wind. Remote stations are operated quasi-continuously at near (few 10 km) to intermediate (few 100 km) distances during the measurement campaigns. Time series data are processed to determine the impedance tensor by using mutual remote reference processing to reduce local electromagnetic noise.13

Typically, two different processing codes are applied. The WinGLink© code, including a 50 Hz and harmonics notch filter, yields good-quality transfer function data. If necessary, at long periods (T>1 s), robust data processing techniques are later applied.14

MTs in the granitic basement at the European EGS project in Soultz-sous-Forêts (France) imaged, for the first time, a naturally fractured reservoir.11 Three reservoir levels at depths of 2000, 3600, and 5000 m characterize the Soultz EGS project. Although comparably high natural hydraulic yields of 10−3 to 10−1 m3 MPa−1 s−1 and smectite and illite hydrothermal alteration products occur in the upper reservoir, the intermediate and lower reservoirs reveal a natural hydraulic yield in the order of 10−4 m3 MPa−1 s−1 and illite only in fractures.7 Given the low variation in salinity of the geothermal brine with depth, the successful visualization of the upper reservoir by very low electric resistivity (<4 Ω m) can be attributed to the high cation-exchange capacity (CEC) of smectite.

The presence of a comparably high volume of high saline fluid with a low amount of total dissolved solids (TDS=about 100 g L−1) may also contribute to this resistivity anomaly. Lower CEC and smaller fluid volume appear to prevent visualization of the intermediate and lower reservoirs.

Geothermally relevant faults have also been investigated in the volcanic crystalline basement by using MT.10 In the Villarrica volcano area in the Andean Cordillera of southern Chile, more than 20 thermal springs occur, mainly along the regional fault zones, the N–S striking Liquiñe-Ofqui fault systems (LOFS) and subperpendicularly the Villarrica-Quetrupillán-Lanín (VQL) volcanic chain. Fluid chemistry of the springs shows generally low TDS with a maximum of 850 mg L−1 for the fault-distant springs.

A HR broadband MT survey reveals two major geoelectric strike directions parallel to LOFS and VQL in phase tensors and induction arrows. The 2D inversion of the full impedance tensor shows intermediate resistivity zones (ρ>20 Ω m) along both fault systems down to a depth of >10 km, at which the brittle–ductile transition is expected.

To investigate the relatively high electric resistivity in these hydrothermally productive fault zones, clay mineralogy was investigated at Coñaripe, together with a hydrothermal alteration reference of the El Toro high-enthalpy geothermal field. A high fluid temperature at the Coñaripe spring (about 70 °C) and high reservoir temperature of about 130 °C determined from sulfate geothermometry, which is based on the temperature-dependent fractionation of oxygen in H2O and SO4,15 characterize this spring.

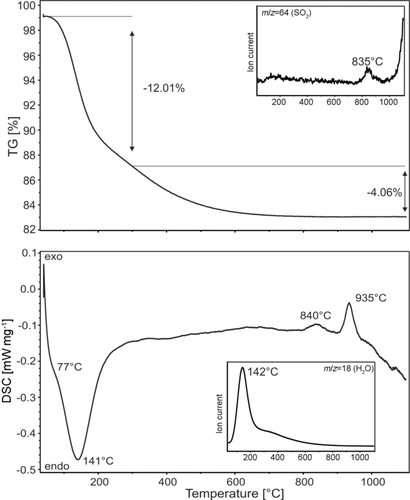

Clay mineralogy was determined from 50 mg powder with a grain size of 500 μm by means of simultaneous thermal analysis (STA) between 35 and 1100 °C at a heating rate of 10 K min−1. A Pt/Rh crucible was used under a nitrogen atmosphere with a STA 449 C Jupiter instrument connected to a quadrupole mass spectrometer QMS 403 C (Netzsch). Bulk powder and texture XRD was measured with a Siemens D5000 diffractometer with CuKα radiation for 2θ angles of 5–80° and 2–35°, respectively, in steps of 0.02° and 3 s. Oriented samples were prepared by mixing the sample material with deionized water and pipetting onto a glass slide after ultrasonic treatment. After drying, the textured samples were measured by starting with an untreated texture sample. Measurements were continued by adding ethylene glycol to the sample and first heating it to 375 °C and then to 550 °C.

Results of STA-MS show significant differences between the clays sampled near the El Toro and Coñaripe hot springs. In contrast to the reference, in which a large amount of swelled three-layer clay is indicated by an endothermic peak in the differential scanning calorimetry (DSC) results between 123 and 157 °C, Coñaripe clays reveal no indication of hydrothermal alteration minerals (Figure 3). Endothermic peaks indicate crystal water. XRD texture analyses determined smectite as the major clay mineral fraction in the reference sample. In contrast, at Coñaripe, powder XRD analysis revealed silica and feldspar only.

STA-MS analyses of the altered crystalline basement at Conaripe thermal spring (Villarrica area, southern Chile). TG: thermogravimetry.

With respect to the development of exploration approaches for EGS in the central European crystalline basement, further MT studies were performed in the granitic basement in the Southern Black Forest,16 where the basement is outcropping at the surface. This area is also one of the possible sites for GeoLaB17 (see Section 4.2). Differences in 3H and 14C contents for Ca−Na−HCO3-type water in the springs in the Southern Black Forest, compared with Na−SO4−HCO3−Cl-type water in northern Switzerland, led to the interpretation that fluids in the crystalline basement of northern Switzerland were recharged in the Black Forest.18 A series of fault systems striking ESE–WNW to SE–NW is expected to provide related fluid pathways (Figure 4). After a period of inactivity during the Mesozoic Era, the Variscan Vorwald and related faults were reactivated. Recent displacements are seismically expressed, for example, in the Schopfheim earthquake (on May 5, 2009, with ML=4.5).

Geological map of the outcropping granitic basement of the southern Black Forest.

Regarding clay mineralogy in the Southern Black Forest, at Wilhelminenstollen, powder XRD analyses of fracture fillings indicate the presence of mica/illite together with an illite–smectite interstratification in the alteration products. No indication of free smectite is found.

In the Badenweiler-Lenzkirch zone, alteration with 60–90 wt % of illite, chlorite, and kaolinite19 resembles the clay mineral assemblage at the Soultz site. At the Lindau test site, only kaolinite occurs. Interestingly, clay minerals occur preferably in NW–SE striking fractures (Himmelsbach, personal communication).

In the framework of the geothermal power plant project,15 a 12 km long MT profile across the Vorwald fault, including 13 stations was investigated for low-resistivity anomalies. Analyses of ellipticity and dimensionality revealed a rather consistent mean geoelectric strike of N28°E that coincided with the strike of the Variscan faults and veins, including the Vorwald fault. It defines thus the rotation angle of the impedance tensors. Inversion was performed by using the regularization parameter τ=1. Because our inversion concept is based on 2D subsurface structures and transient electric (TE) mode is more sensitive to 3D effects, error levels for the apparent resistivity for TE and (transient magnetic (TM) modes of 100 and 10 %, respectively, and 1.5° for the phase shift of the modes are used.

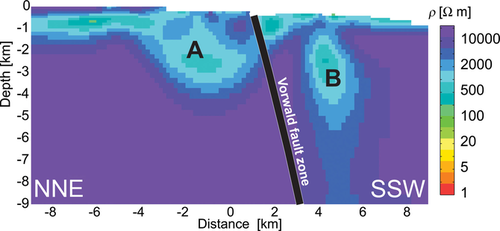

The 2D inversion results for a low overall RMS of 1.5 are displayed in comparison with major fault zones in Figure 5. Generally, the area reveals a very high electric background resistivity of ρ>10 kΩ m, in which two major anomalies, A and B, with 1 kΩ m<ρ<5 kΩ m are embedded. These anomalies are robust features; an overestimation of their extension to depth, however, is possible.

The 2D inversion of the MT profile across the Vorwald fault (Southern Black Forest).

In conclusion, it is observed that smectite fosters the occurrence of low-resistivity anomalies in conventional and EGS reservoirs. However, intermediate resistivities also characterize geothermally relevant structures. This is most likely to be due to porosity changes, as predicted by Archie's Law.

3.1.2 Multiscale fluid flow in fractures

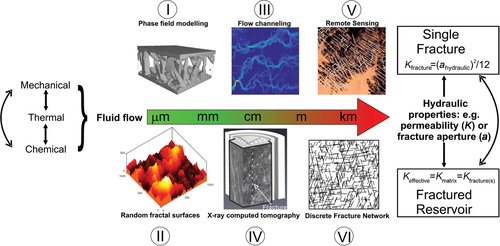

Apart from appropriate temperatures, permeability represents one of the most important subsurface parameters of geothermal reservoirs for an economic energy generation. In particular, fractures can play a crucial role by enhancing existing reservoir permeability (e.g., in porous media) or by creating new pathways in nearly impermeable rocks (e.g., EGS). However, under reservoir conditions, the presence of flow paths or flow channels (Figure 6 III) is not only a geometrical issue, but also depends on coupled boundary conditions, such as temperature, mechanics, and chemical processes that affect the actual permeability of fractures and associated discrete fracture networks (DFNs).

Multiscale fracture investigations from the micro- to kilometer scale. The color gradient of the scale bar indicates increasing uncertainty of hydraulic fracture properties with increasing fracture scale. Typically, hydraulic properties underlie coupled mechanical, chemical, temperature-dependent processes. Examples represent I) a phase field model (PFM) of fracture sealing;20 II) a synthetic model21 of a typical self-affine, rough fracture surface (fractal dimension=2.2[22]); III) a local cubic law visualization of typical flow channels based on aperture distributions;23 IV) a medical X-ray computed tomography (CT) scan of a fractured core sample;24 V) lineament interpretations based on remote sensing;25 and VI) a random stochastic DFN model.26 Fracture or DFN studies provide improved permeability predictions of single fractures (analytical,27 numerical24, 28) and fractured geothermal reservoirs (analytical,29 numerical24, 25, 30).

Typically, fracture permeability can be described by the well-known cubic law to simplify a fracture as a pair of parallel plates.27 However, due to their roughness, natural fractures are better represented by self-affine surfaces (Figure 6 II). Because, in most cases, fracture surfaces are mismatched to each other, the resulting mechanical and hydraulic apertures facilitate fluid flow and also fluid-induced reactive transport processes, which can affect hydraulic and mechanical fracture properties.31

In particular, fracture sealing plays an important role when considering time-dependent reservoir scaling and activation or utilization of (partly) sealed structures. Thermodynamically consistent PFMs provide a useful numerical tool that is able to reproduce polycrystalline sealing scenarios, such as tectonically unaffected crystal growth32 or syntectonic crack–seal processes.31, 33, 34 Wendler et al. showed that PFMs were able to reproduce hydrothermal quartz growth experiments (Figure 6 I).20 Hence, such models provide new insights into various sealing structures and corresponding flow paths. To fate, PFMs have only been used to simulate pure sealing processes on micro- to millimeter scales. However, under reservoir conditions, there should be an interaction of precipitation and dissolution processes, as shown in core-scale reactive percolation experiments under high pressure–temperature conditions with CO2-rich brines.28 Because reactive transport in fractures depends on available response surfaces, mechanically induced fracture geometries are crucial. However, hydraulic properties typically show a pronounced stress dependency. Applying stresses induces kinematical processes within the fracture, which typically close fractures and result in a permeability reduction, which is strongly linked to mechanical (e.g., stiffness) and geometrical properties of the fracture surfaces, such as roughness, matedness, or the distribution and shape of contact areas. Indeed, several studies have implemented such properties into the analytical cubic law since the pioneering work of Louis;27 however, these approaches cannot cover all fracture flow features and processes. Hence, numerical models based on more realistic fracture geometries provide an effective method to gain novel insights into fracture flow. Nevertheless, stress-dependent fracture geometries and fluid flow still represent a challenge. Typically, there are two approaches: 1) matching (scanned or synthetic) fracture surfaces by appropriate mechanical models, or 2) applying elaborate in situ fracture data (e.g., by X-ray CT). Accordingly, Schoenball et al.35 used synthetic fractal surfaces to show that shearing implicated a significant flow anisotropy within the fracture. Huber et al.36 used μCT scanning of an unaffected natural fracture to prove the significance of fracture heterogeneity on flow behavior. On the other hand, Kling et al.24 introduced a useful method to transfer in situ medical CT data of fracture flow under loading–unloading condition into flow simulations (Figure 6 IV).

Although the investigations mentioned above are not on the reservoir scale, at which fractures can form DFNs, DFN studies can reproduce fundamental fracture input parameters, such as fracture length and density, which are crucial for scaling up to reservoir models. One common approach to simulate fluid flow in multiple-fractured reservoirs is provided by stochastic DFN models (Figure 6 VI) based on statistical fracture network data.26, 30, 37 In this context, Zeeb et al.38 introduced the new toolbox called FraNEP to statistically analyze natural fracture data and to enable transformation into more consistent artificial DFNs by using customized fracture network generators.26 Whether these DFNs are representative of a reservoir or not depends strongly on the availability of outcrops and subsurface data; this is often provided, for example, by field measurements, terrestrial laser scanning,39 and remote sensing40 (Figure 6 V), as well as a applied sampling method, such as scanline or window sampling.38

In conclusion, the evaluation of fluid flow in fractured reservoirs is a matter of scales, ranging from single fracture scales (μm to cm scale, mechanically and chemically induced geometries) to the field scale (cm to km scale, transferability of DFN geometries), the interactions of which have to be better understood to provide more reliable geothermal reservoir models.

3.1.3 Particle deposition in granitic fractures

Little attention has been paid to the presence of colloids within the permeable fractures and their impact on porosity and permeability in geothermal reservoirs.41 In addition to negative economic issues, such as pore clogging (formation damage), during extraction of fluids from the subsurface or reinjection into the reservoir,42 in fractured reservoirs, the deposition of clay colloids enhances reactivation potential, and thus, permeability.11, 43

Investigations into the effects of mineralogy and surface roughness on controlling particle deposition/attachment can be found in the literature, including work from KIT.44, 45 We use the combination of fluorescence microscopy, laser scanning microscopy (LSM), and SEM as a methodological approach to obtain information on the colloid deposition/attachment behavior and spatial distribution as a function of, for example, mineralogy, surface roughness, and fracture orientation (horizontal/vertical). To prove the feasibility of this technique, postmortem analyses of the fracture surface are performed on continuous-flow experiments with horizontal fracture orientation on a cut Grimsel granodiorite core with a parallel-plate aperture of 0.75 mm by using synthetic monodisperse 1000 nm carboxylated fluorescence colloids. In these experiments, the flow velocity (1.66×10−5 and 5.47×10−5 m s−1) and colloid concentration (1 and 10 ppm) was varied. Further information on the experimental conditions, setup, and sample location can be found in Ref. 46.

After transport experiments, the flow cell is opened and the granodiorite disc is removed for postmortem analysis. After installation and adjustment of a pinhole aperture, the colloids are observed directly by using a fluorescence microscope (Axioplan 2 Imaging, fluorescence microscope, Zeiss, 10× magnification, image size 1401×1048 μm2). Focus stacking, also known as z stacking, is used in this case to obtain images with a greater depth of field (DOF) to compensate for surface roughness. To compare the results with LSM and SEM measurements, the same areas on the surface are investigated. By using ImageJ software,47 the z-stacking files are displayed on one plane. With the Particle and Pore tool implemented in the SPIP™ software package (Image Metrology), the colloids are quantified.

The colloid deposition (kinetics) are determined by calculating the dimensionless Sherwood number (Sh); for details, see Ref. 44.

Post mortem analysis was performed on 12 regions of interest (ROIs), covering 1.5 % surface area (17.63 mm2) of the total Grimsel granodiorite disc surface (1134.12 mm2). Under the prevailing geochemical conditions (pH 5, 1 mm NaCl), colloid retention values calculated on the basis of measured experimental breakthrough curves (BTCs) show an overall low colloid retention (maximum 5 %) and tend to increase with decreasing flow velocity (=increasing residence time). Retention on the granodiorite surface obtained by fluorescence microscopy is an extrapolated value based on the sum of the counted colloids in the abovementioned 12 ROIs. In the range of the error, the extrapolated percentage is, in all cases, comparable to or higher than the percentage obtained by BTC analysis. Colloid concentration variation revealed a limited site capacity for colloid retention under the experimental conditions. However, the use of fluorescence microscopy single-colloid analysis revealed no influence of flow velocity under the uncertainties of 2–3 % given.

(1)

(1)in which L is the characteristic length in m, D is mass diffusivity in m2 s−1, and K is the convective mass transfer film coefficient in m s−1.

(2)

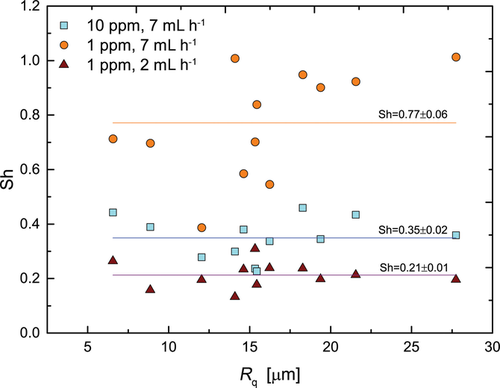

(2)By comparing the calculated Sh values under these unfavorable attachment conditions as a function of surface roughness (Figure 7), the highest values of colloid attachment could be observed for low colloid concentration and high flow velocity (1 ppm, 5.47×10−5 m s−1) with a tendency of Sh to increase with roughness most probably overcoming electrostatic repulsion. In contrast, lower Sh numbers are visible for experiments, including 10 ppm colloid concentration under the same flow velocity (7 mL h−1 or 5.47×10−5 m s−1), and lowest Sh values for low (1 ppm) colloid concentration at low flow velocity (2 mL h−1, 1.66×10−5 m s−1).

Sherwood number (Sh) as a function of surface roughness of continuous flow experiments with varying colloid concentration and flow velocity for 1000 nm colloids (lines with average Sh to guide the eye).

When comparing these findings to AFM measurements,46 it is reasonable to assume that there is no influence of surface roughness on colloid retention on 1000 nm colloids. The LS/LB ratio, which describes the dominating influence of either gravity (LS/LB>1) or Brownian diffusion (LS/LB<1) by comparing the ratio of the characteristic sedimentation length and diffusion length, is 1.19 for 1000 nm colloids at 1.66–5 m s−1. Based on this value, colloid deposition at 1.66×10−5 m s−1 is neither fully dominated by gravity nor by diffusion. Both forces act equally on the colloids. Under these conditions, a significant effect of colloid deposition by gravity, relative to the higher flow velocity (5.47×10−5 m s−1), is not expected.

In a further study, the specific role of fracture orientation and gravity on colloid retention is studied by simulating stagnant phases by stop–flow conditions (similar to geothermal power plant downtime periods), as partly documented in Stoll et al.46 Both experiments and hydrodynamic simulations by using COMSOL Multiphysics (Version 5.0) could univocally show that gravity plays a major role for colloids ≥1 μm.

To investigate colloid retention on granodiorite minerals, the self-fluorescent signal of the minerals obtained by changing the filter cubes of the microscope was compared with mineral deposition information. This additional procedure was performed exclusively for an experiment that involved a 1 ppm colloid suspension at 1.66×10−5 m s−1. Information from SEM/energy-dispersive X-ray spectroscopy (EDX) measurements of each ROI helps to identify the mineral phases. The combined image is shown in Figure 8 with marked mineral phases. The colloids are distributed evenly over the whole investigated ROI. No mineral-dependent increase or decrease of colloid deposition is detectable. This finding supports surface potential measurements and force volume measurements obtained by means of AFM, which show overall negative surface potentials and unfavorable repulsive conditions. Comparable observations are made for the other ROIs.

Colloid distribution (white spots) on granodiorite mineral phases of plagioclase (Plag), quartz (Qz), and micas muscovite (mu) and biotite (bi) in a continuous-flow experiment with a 1 ppm colloid concentration and 1.66×10−5 m s−1 flow velocity (ROI 90_2).

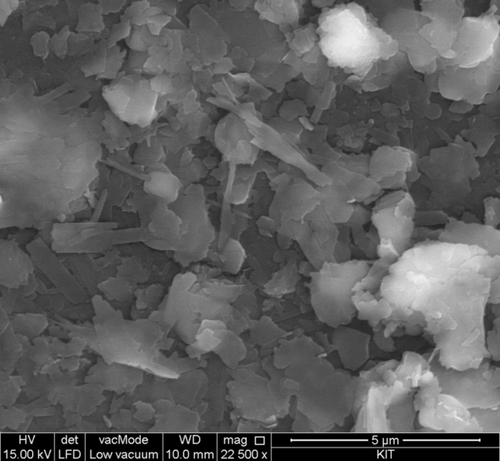

In summary, the results presented herein demonstrate that the multimethod approach of using macroscopic flow experiments and microscopic postmortem analysis provides an in-depth process understanding on the colloid–granite surface interactions under well-constrained laboratory conditions. By using this method, spatially resolved colloid deposition was quantified as a function of mineralogy and surface roughness. Current research is heading towards more realistic boundary conditions concerning hydro-geochemical parameters (higher ionic strength, higher flow velocity) and especially the use of natural clay colloids separated from the Soultz system (Figure 9).

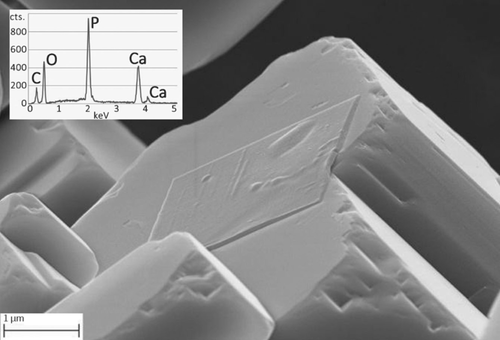

Natural illite-dominated colloids obtained from the fracture surface of drill core K117 at exploration well EPS-1 from the geothermal test site Soultz-sous-Forêts.

3.1.4 Mineral nucleation process for secondary-phase formation

The neoformation of secondary mineral phases can lead to colloid/particle formation or, through accumulation, to scaling, which changes the porosity of water-conducting features and potentially results in clogging phenomena. Furthermore, the sorption or incorporation of naturally occurring radioactive material (NORM) radionuclides into secondary mineral phases can strongly influence their migration within the thermal water circuit. The prediction of secondary-phase mineral formation requires knowledge of the kinetics of reactions involved in fluid–rock interactions.48 To predict such reactions by reactive transport codes, a prerequisite is a consistent thermodynamic database (TDB), including reaction kinetics (mineral dissolution/precipitation data).49 The kinetic data implemented in reactive transport codes to solve precipitation reactions frequently relies on mineral dissolution data that assume the same rate constant.50 Therefore, a potential reason for discrepancies observed between model and experiment might be an inappropriate TBD. KIT follows the objective to determine kinetic parameters for the nucleation and growth of mineral phases [herein, for example, celestite (SrSO4)] as a function of specific reaction variables (e.g., temperature, ionic strength, supersaturation ratio, addition of dissolved silicate) and the interaction of trace elements (radionuclides, heavy metals).

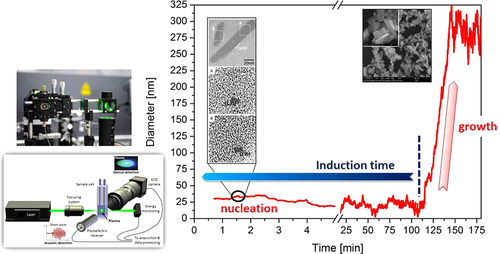

The nucleation of celestite is examined by means of laser-induced breakdown detection (LIBD),51 which allows a determination of the induction times (tind). The LIBD method has been applied here for the first time to study the kinetics of nucleation (Figure 10). The latter is defined as the time elapsed between the achievement of supersaturation and the detection of the first nuclei in solution. This is combined by crystal growth experiments that provide rates by using mixed-flow reactors (MFRs).52 The determined induction times allowed the calculation of rate constants, activation energies, and interfacial tensions. LIBD could show that the occurrence of quantitative nucleation is always preceded by the formation of early-stage nuclei (ESN). HR-TEM analysis confirmed that the ESN were already well crystalline in the case of celestite, which had a gyration radius of (29±10) nm, comparable to that of the radius estimated from LIBD data. The addition of dissolved silica to solutions supersaturated with respect to celestite caused a prolonged induction time.

Synopsis of the LIBD approach, showing the general optical setup of the system (left) and one example of evolution of the nanoparticle size with time. Nucleation and the growth state are shown; these determines the induction time.

In conclusion, by using the LIBD method, kinetic data on the onset of nucleation and growth can be determined; this provides a tool to obtain kinetic data to feed into TDBs.53 Ongoing studies focus on the effect of elevated temperatures, other mineral systems, and the influence of inhibitors.

3.1.5 Induced seismicity

The development of deep geothermal fields, in particular, EGSs, is often associated with induced seismicity. Induced seismicity is a unique phenomenon that helps to image geothermal reservoir properties. Without such information, a description of the underground structure away from the production and injection wells is very difficult. However, this seismicity can be felt by the population and many efforts are made to better understand the THMC processes at its origin and to mitigate it.54 Hence, from both points of view, induced seismicity has to be considered for the sustainable development of deep geothermal fields.

In this domain, research efforts at KIT are following three main directions: 1) the recording of induced seismicity, 2) the reliable processing of seismological data, and 3) the interpretation of the results. These working directions are often linked and can be found in the European H2020 DEEPEGS project, which started at the end of 2015.55 The general goal of the DEEPEGS project is to demonstrate the feasibility of EGS for delivering energy from renewable resources across Europe. Three different resource systems in three different locations and geological formations in Europe have been selected as demonstration sites.

Access to databases of seismicity induced in geothermal fields is of prime importance to understand this phenomenon, especially given that such databases are not numerous worldwide. In 2013 and 2014, KIT was involved in the seismic monitoring of the deep geothermal field of Rittershoffen (France) located 6 km from Soultz-sous-Forêts.56

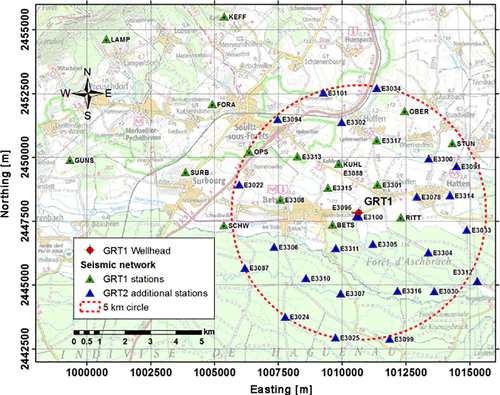

The power plant inaugurated in June 2016 delivers 24 MWth thermal energy to a biorefinery located 15 km away. In cooperation with the field operator ECOGI, the Électricité de Strasbourg-Géothermie Company, the LABEX G-EAU-THERMIE-PROFONDE of the University of Strasbourg, and support from the GIPP Potsdam, KIT deployed a temporary seismic network in addition to the permanent one to improve the monitoring of seismicity induced during the development phases of the geothermal reservoir (Figure 11). KIT also participated in the real-time data processing. Several hundreds of microearthquakes were recorded; none of them were felt by the local population. Doctoral work is currently ongoing to process and interpret the recorded events.

Map of the seismic network deployed at Rittershoffen in 2013 and 2014. The green triangles show the locations of the seismic stations that monitored the early operations in the GRT-1 well; for the monitoring of the GRT-2 well drilling and further operations, the blue triangle stations were added. The E3 stations belong to the KIT temporary network.

For meaningful interpretation of the induced seismicity, especially in terms of reservoir geometry, reliable catalogues listing the location, origin time, magnitude, and focal mechanisms of the earthquakes should be available. One of the means to achieve this is to provide each parameter with realistic errors. This requires errors introduced at different steps of seismological data processing to be better accounted for and/or modeled.

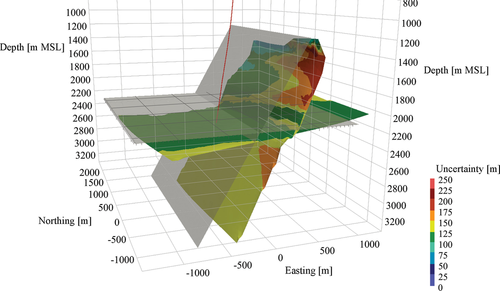

For example, for the Rittershoffen field, uncertainties of absolute earthquake locations, which are associated with the quality of the recorded data, vary spatially and are larger than ±150 m at the reservoir depth (≈2.5 km). Additionally, if the location is recorded without taking into account the normal fault that constitutes a major structure within the geothermal reservoir, the earthquake hypocenters can be shifted by 350 m57 (Figure 12). Such studies are of importance and may have economic consequences.

Rittershoffen case study: modeling location errors of earthquake hypocenters. The earthquakes initially located on the gray planes within a 3D velocity model are relocated on the colored surfaces if a 1D velocity model is applied. The color scale represents the location uncertainty.

Valuable information can also be gained by better constraining the earthquake hypocenters. This basic attribute is usually computed by using arrival times of seismic waves observed on monitoring networks. Time information is related to the distance between the seismometer and the earthquake. However, the widespread use of three-component sensors also gives access to additional information: the wave arrival direction. With support from the Landesforschungszentrum Geothermie and the Ministry of the Environment, Climate Protection, and the Energy Sector of Baden-Württemberg, a new Bayesian formulation has been developed that defines a probability density function of the earthquake hypocenter as a function of seismic body wave polarization.58 This probabilistic formulation, combined with usual ones, allows the accuracy of earthquake locations to be improved.

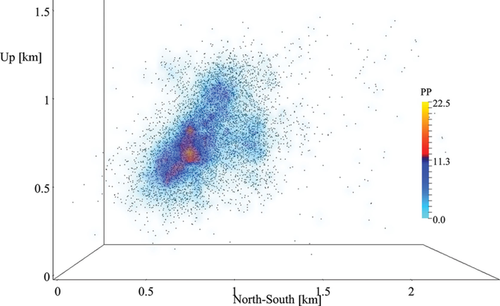

Earthquakes are associated with rock failures and highlight fracture or fault zones geomechanically perturbed in the subsurface. In deep geothermal fields, in which forced fluid injection can take place, such seismogenic zones may be representative of preferential fluid circulation pathways. Hence, induced seismicity, once correctly located, can be used to highlight DFNs in the geothermal reservoir. In recent work, the well-known three-point method is improved, which looks for preferred planar distribution of earthquakes in a seismic cloud of earthquakes by introducing weighting factors that depend on interevent distance and event magnitude. additionally, a novel statistical analysis of seismic clouds was developed to provide pseudospatial probability of an event-driven fracture network. This method also applies distance and magnitude weighting, but additionally allows the use of fault plane solution of the earthquakes. After testing and validating both approaches on synthetic data, they were applied to the seismicity induced in 2000 during the hydraulic stimulation of well GPK2 at the Soultz-sous-Forêts geothermal site. The results obtained at Soultz are comparable to those of previous works59 (Figure 13).

Soultz case study: seismicity induced in 2000 during the GPK2 stimulation. Pseudoprobability of earthquake connection as an indicator of the fracture network. PP=pore pressure, Up=vertical extension from defined origin.

3.1.6 Borehole Failure

Not only does a seismic survey of the reservoir allow monitoring of the principle mechanical response, but also important rheological parameters and the stress state before and/or during fluid injection can conventionally be inferred from observations made in boreholes. Such data are inevitable for forecasting the behavior of the subsurface at the scale of the entire reservoir. Thus, inducing fractures potentially leading to breakouts of the host rock wall surrounding a borehole is, at the same time, an undesired and welcome side effect while penetrating underground through drilling or fluid injection. Catastrophic failure can cause substantial additional costs, which may endanger the success of a geothermal project. However, creating fluid pathways and enhancing permeability through hydrofracturing the reservoir rock are considered to be prerequisites for the exploitation of deep geothermal systems.60 Furthermore, knowledge of the in situ stress field, its highly debated rotations, and mechanical properties of the reservoir obtained from borehole breakout patterns are essential for reservoir engineering in terms of the stability of the construction and the predictability of seismic hazards that result from production across the entire reservoir.61, 62

3.1.6.1 Insights from the Soultz-sous-Fôrets case study

On basis of field observations obtained from the Soultz-sous-Forêts geothermal field, a geomechanical model to simulate the dynamic response of the reservoir to drilling and fluid injection/production has been implemented. The Soultz project is arguably the most comprehensive research project in the field of EGS, which was developed more than 25 years ago, and thus, is well documented.63 Therefore, this case study is predestined for the development and testing of techniques applicable to characterize the mechanical properties of any crystalline reservoir.

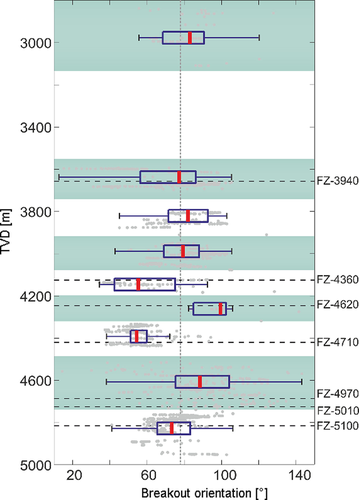

Studies of the wellbore stability during drilling are usually based on extensive observations from geophysical log data at the GPK4 well in the Soultz reservoir. Detailed analyses of failure patterns along this well have indicated a stress heterogeneity in the deep reservoir at a depth of around 5000 m (Figure 14).64 At such depths, slight variations in stress magnitude and orientation play a significant role. In addition, the deeply seated reservoir is highly fractured. Fractures are repeatedly accompanied by mineral alteration, acting as weak zones, which potentially promote failure along such heterogeneities. Combined with sonic logs65 and alteration logs,66 the impact of fractures and alteration on mechanical rock properties has been quantitatively estimated for the upper part of the crystalline section. For instance, the elastic moduli of fractured granites were 60 % lower than that for the intact granite.67 This result is in agreement with in situ laboratory measurements of the Soultz granite.68, 69 Furthermore, this finding suggests that integrated analyses of borehole log data, as shown by our study, could be used as an alternative to in situ laboratory measurements, and help to explain localized wellbore failure inside a highly stressed rock. Because the availability of core data is limited and in situ laboratory measurements are costly, this concept could play a significant role in the geomechanical modeling of deep EGS reservoirs.

Profile of breakout orientations in the GPK4 well. Box plots are used to summarize the distribution of depth intervals. TVD is the true vertical depth below the wellhead. The lower and upper fences, the first and third quartiles (rectangles), as well as the median value, are plotted. As the median values of the breakout orientation scatter and deviate from the principle (far-field) stress field along the borehole, we are able to detect local stress rotations due to material heterogeneities. The depths of the intersected major fractures were taken from Ref. 70 and are indicated by dashed lines.

Such geomechanical modeling may provide a solid basis for understanding the dynamic behavior of the reservoir during hydraulic stimulation. In our study, injection is targeted inside the deep reservoir that consists of two different granites with different petrographic characteristics. The impact of rock characteristics on seismicity has long been observed in the engineering of mines and tunnels,71 but has not been analyzed for geothermal problems, to date. Herein, we are able to link the sharp mechanical contrast between different granites in the reservoir to the occurrence of microseismic events, that is, 85 % of events are located within highly fractured two-mica granite (Figure 15). Microseismicity in the two-mica granite occurred much earlier, when the increase of borehole pressure was still around 3 MPa, whereas fractures in the less-fractured porphyritic granite were reactivated 15 h later, when the borehole pressure stabilized at around 15 MPa (Figure 15). Furthermore, the pattern of microseismicity in each zone could also be matched with different injection schemes used in the field; this suggests that an adapted injection strategy can be developed based on the reservoir model proposed in this study. Because a majority of EGS projects target crystalline rocks, the understanding of lithological controls on seismicity achieved in this study is crucial for future developments. For further details of the geomechanical results, please see Refs. 62, 66, 67, 72, 73.

Fracture reactivation in the vicinity of the borehole. Microseismic events within 100 m radius from the borehole are selected to represent the reactivation of fractures in the vicinity of the borehole. Wellhead (thick line) and hole bottom (dashed line) pressures are also plotted. Fractures are reactivated at different borehole pressures and times, that is, the reactivation of deep fractures occurs before shallower ones. (M=magnitude).

3.1.6.2 Failure mechanisms and material behavior

The failure mechanisms and associated structures of borehole breakouts have long been regarded as a purely brittle time-independent response, for example, microfracturing of a Mohr–Coulomb material. For such solid mechanical materials, material parameters (internal friction angle, failure angle) can be inferred from deformation experiments under controlled laboratory conditions, and they have conventionally been extrapolated to reservoir rocks at shallow crustal levels under low-temperature conditions. However, recent observations made in deep boreholes (see previous sections) indicate complex coupled and time-dependent damage or mechanisms (Figure 14),72 as-yet undetected transient microphysical processes,74 and the severe influence of local material or structural instabilities.64 For these microprocesses, naturally encountered at elevated temperatures at which EGSs are located (depth>5 km), lower deviatoric stresses and/or longer geological timescales are required to induce localization instabilities.75 At this point, even unconventional brittle material assumptions fail to correctly predict the rock strength because the material reveals a severe temperature and rate sensitivity. This observation, next to often overlooked scaling effects, leads to significant gaps in knowledge of processes operating in deep geothermal systems and drilling technologies. Among other issues, these obstacles challenge the standard assumption that well costs linearly increase with depth in EGSs.60 Therefore, from both an academic and economic perspective, it becomes necessary to approach borehole failure with alternative concepts.

3.1.6.3 Recent advances in THMC modeling

At this point, continuum mechanics formulations, including nonequilibrium thermodynamics, have been applied to geothermal issues.75 In such a framework, the dynamic evolution of damage, permeability, and coupling effects between THMC processes are incorporated into the constitutive relationship of a creeping material.76 Although there are powerful numerical tools that are able to link the mechanics to the hydraulic effects at the reservoir scale,77 they do not implement the multiphysics and multiscale processes that operate at the scale of single grains at the borehole wall up to the entire reservoir. For such highly nonlinear applications that implicitly consider the effects of dissipative strain softening on chemical reactions and reactive transport, a parallel high-performance computing infrastructure is needed. To this end, recently developed tightly coupled THMC codes,78, 79 based on the multiphysics object-oriented simulation environment (MOOSE) finite element framework,80 have been adapted for geothermal applications. For example, the richness of borehole failure modes, such as the formation of compaction bands, shear bands, and shear fractures,74 can be captured by means of self-consistent THMC simulations that stem from ductile instabilities if both volumetric and deviatoric contributions to rate-dependent deformation are incorporated.78

3.1.6.4 Future perspectives

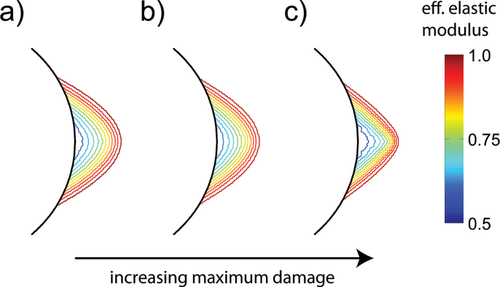

In light of engineering purposes, further steps have to be undertaken to retrieve fundamental material parameters directly out of borehole observations, as attempted in Figure 16, following first promising simulations that treat deformation structures as fundamental material instabilities.81 Next, great attention has to be paid here to realistically scale up microphysical damage processes to predict the behavior of an EGS. It is suggested to embark on the multiapplication features the MOOSE framework offers80 and to deal with critical sets of material parameters and boundary conditions. The numerical techniques presented herein do not rely on oversimplified material characteristics, obtained by costly laboratory experiments, and they are able to account for the multiscale and multiphysics of an entire EGS embedded in a complex tectonic setting. Such techniques can be readily adapted for related scientific disciplines, for example, for the disposal of radioactive waste.

Shape of borehole breakouts (colored contour lines) computed for differences in the effective elastic modulus, Eeff (see legend), ranging from convex (a) to linear (b) and concave (c) patterns with increasing maximum damage parameters. A comparison between simulated and natural failure patterns allows mechanical rock properties to be derived, that is, the elastic properties of the reservoir rock, directly from boreholes. The black curves represent a section of the borehole wall. Figure taken and modified from Ref. 72.

3.1.7 Effects of hydrothermal alteration on mechanical reservoir properties

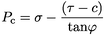

In the granitic reservoir of the geothermal site in Soultz-sous-Forêts, many fractures are affected by hydrothermal alteration involving the precipitation of clay minerals on the fracture surfaces. The mechanical weakness of clay-filled fractures has been demonstrated in several studies.82 Laboratory experiments suggest that even small amounts of clay on fracture surfaces determine the mechanical properties of the fault zone when an external stress is applied.83 It is assumed that the critical pressure, which is the pressure required to rupture, depends significantly on the clay inside the fault. Hence, the characteristics of induced seismicity should reflect the mechanical properties of the fractures. This study aimed to create probabilistic models of the critical pressure of fractures, which is the pressure required to induce shear movements on this fracture, in and around GPK1 by taking into consideration the clay content of the fractures. These models are compared with induced seismicity recorded during the 1993 stimulation of GPK1.

(3)

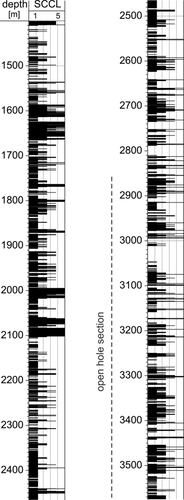

(3)in which Pc is the critical pressure, σ is the effective normal stress acting on the fracture, τ is the effective shear stress acting on the fracture, c is its cohesion, and ϕ the friction angle. The value of Pc is controlled by the orientation of the fracture in the prevailing stress field, the mechanical properties of the rock represented by its internal friction and cohesion, and by the pore pressure. The orientation of fractures in Soultz is known from borehole logging and the clay content can be derived from synthetic clay content logs (SCCLs), as developed by Meller et al.,66 which are semiquantitative models of the clay content of fractures along the Soultz boreholes. Friction and cohesion parameters can be chosen according to the clay content of a fracture. The SCCLs represent the density of clay-filled fractures in five groups. SCCL group 1 represents low-density intervals, whereas SCCL group 5 applies to the highest density. The synthetic log for well GPK1 is presented in Figure 17.

SCCL log for well GPK1. SCCL group 1 represents the fractures without clay filling, whereas SCCL group 5 contains fractures with the highest amount of clay. The open-hole section of the well between 2847 and 3590 m is marked by the dashed line.

Fractures identified on UBI logs of the open-hole section of well GPK1 were used to create a probability distribution of fracture orientations. The orientation and magnitude of the principal stress components, which are required to calculate the critical pressure for a fracture, are taken from reports by Valley68 and Cornet et al.,84 who provided the most recent solutions for the stress field magnitude and orientation at Soultz.

The overpressure in a reservoir corresponds to the wellhead pressure corrected for a frictional term related to friction of the stimulation fluid along the borehole. If the overpressure in the reservoir equals the critical pressure of fractures, shear is induced on each fracture with a Pc smaller than that of the applied overpressure. If each shearing fracture induces exactly one seismic event, the calculated distribution of Pc can be directly transferred to a seismic event curve versus stimulation pressure.

Well GPK1 is 3580 m deep with an open-hole section spanning the lowermost 730 m of the borehole. In September 1993, hydraulic stimulation of the open-hole section was performed in eight steps to approach a maximum injection rate of 37.8 L s−1. During and shortly after the stimulation operations downhole, which continued 15 days from September 2, the downhole seismic network recorded about 12 000–13 000 seismic events. Shut-in was on September 17, but the record of pressure and induced seismicity continued for another 13 days until the wellhead pressure reached zero.

Comparison between recorded seismicity and the probabilistic curves of Pc may deliver an insight into the frictional properties of the reservoir, yet several assumptions have to be made for such a comparison. One of the strongest is that time variation of the pressure is not taken into account here. Indeed, to do so, a correct model of pressure propagation would be necessary, which is not a simple task, as identified by Cornet.85

The stimulation phase for wellhead pressures between 0 and 9.3 MPa is selected for this analysis. Figure 18 a shows the evolution of seismicity during stimulation between 0 and 9.3 MPa. It is compared with five probabilistic curves obtained by using different friction and cohesion parameters (Figure 18 b–f).

Semilogarithmic cumulative curves of the events during the September 1993 stimulation of GPK1 (a) and fractures versus Pc values calculated with the probabilistic fracture model (b–f) between 0 and 9 MPa. In b), the friction coefficient decreases with increasing clay content. In e), cohesion decreases with increasing clay content and in f) cohesion and friction coefficients decrease with increasing clay content.

The cumulative curve of seismic events during the September 1993 stimulation reveals an onset of seismicity at a downhole pressure of around 6 MPa. Between 6 and 8.3 MPa, the number of events approximately exponentially increases, resulting in a sublinear curve in the semi-logarithmic plot. The five steps in the curve are attributed to large structures inside the reservoir, which affect the propagation of fluid and seismicity. These structures could be either large fracture zones focusing fluid flow and microseismicity, as postulated by Evans,43 or very clay-rich zones, which hamper spreading of the seismic cloud.62

In Figure 18 b, constant friction coefficients and cohesion are used for the calculation of Pc. The evolution of seismicity illustrated by Figure 18 a and b is very different. Whereas the number of seismic events exponentially increase in Figure 18 a, the uniform friction and cohesion curve of Figure 18 b shows a rapid increase in the number of sheared fractures with increasing pressure. In this curve, 40 % of all fractures have a critical pressure between 6.5 and 7.5 MPa; this implies that 40 % of all fractures would shear within a pressure increase of 1 MPa at the beginning of the stimulation.

In Figure 18 c, the friction coefficient decreases linearly between 0.98 for SCCL group 1 and 0.58 for SCCL group 5. With these parameters, 1 % of the fractures would shear within a pressure increase from 3.5 to 4 MPa, followed by an exponential increase in the number of shear events. The gradient of the linear section in the semilogarithmic plot is smaller than that of the real seismic event curve of Figure 18 a. A steeper gradient is obtained when the range of friction coefficients between SCCL1 and SCCL5 is smaller. In Figure 18 d, the friction coefficient was linearly interpolated between 0.98 for SCCL group 1 and 0.68 for SCCL group 5. A similar result is obtained when the friction coefficient is kept constant, but the cohesion decreases with increasing clay content (Figure 18 e). The gradient of the linear section in this curve depends on the range between maximum and minimum cohesion. If both cohesion and friction coefficient decrease with increasing clay content, the gradient of the linear section is even smaller.

From these curves, it is clear that the evolution of seismicity cannot be explained by a uniform friction and cohesion throughout the reservoir. With uniform cohesion and friction, above a certain pressure level, all seismic events would happen within a small pressure range in the order of 1 MPa; this is not observed during the September 1993 stimulation. The exponential increase in the number of seismic events can only be reconstructed by discriminating fractures with different cohesion and friction. This highlights the importance of weak zones for the evolution of seismicity, especially at low stimulation pressures.

A common feature of the probabilistic curves created with distinct friction and cohesion parameters is the step at the onset of the curve, at which the number of fractures quickly increases to about 1 % within a small pressure increase of 0.3–0.5 MPa, which is not observed in the real seismic event curve. When comparing the probabilistic curves to the evolution of seismicity during GPK1 stimulation, it is assumed that all fractures inside the reservoir shear and produce a seismic event. This is not necessarily the case. Fractures with high clay contents, for example, might shear without producing microseismicity. The existence of such movements has been constrained for GPK1 stimulation by Cornet et al.86 on the basis of borehole image logs run before and after stimulation.

Despite modeling uncertainties and simplifications, the results show that there have to be several fractures with a friction coefficient below 0.98 to explain the evolution of seismic events. Even a low number of such weak fractures significantly affects the observed pattern. Considering that only 8 % of all fractures are SCCL groups 4 to 5, the effect of this small proportion of clay-rich fractures has a huge effect, especially for low overpressures. The results have shown that most of the fractures with low critical pressure are fractures with high amounts of clay inside. Without these weak fractures, the minimum Pc would be about 3–5 MPa higher and the evolution of induced seismicity would most likely be different from what was observed during the 1993 stimulation of GPK1. The onset of induced seismicity at low overpressures and the slow increase in the seismic rate until 8.5 MPa clearly indicate that weak fractures dominate the evolution of induced seismicity in the initial stage of hydraulic stimulation.

The study shows that 1) clay-filled fractures are most likely a weak link inside the reservoir, exhibiting much lower frictional and/or cohesive parameters than unaltered rock, and 2) the presence of such clay-rich fractures significantly affects the pressure-dependent evolution of induced seismicity. This indicates that the role of clay and lowering of the mechanical friction cannot be neglected in models of induced seismicity. Specifying the frictional properties of fractures according to their clay content is a new approach to explain the characteristics of induced seismicity. In future, this approach could be integrated into more complex structural and hydraulic models to develop stimulation strategies for geothermal wells. In particular, for soft stimulation, in which the goal is to mitigate large seismic events, the Pc distribution in time and space is a necessary input to adapt the stimulation pressure.

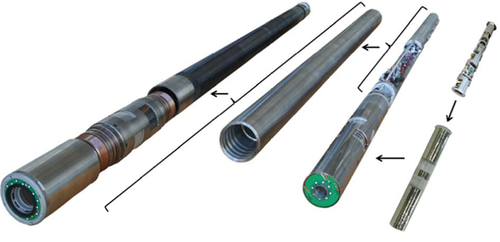

3.1.8 Well integrity

Deep geothermal boreholes are drilled into the ground to utilize its heat. To reach the target formation, drinking-water horizon(s) need to be penetrated. In addition, aquifers with different pore pressures may become connected through the drilling operation, leading to differential subsidence or elevation; this lead to undesired side effects with enormous damage in the past.

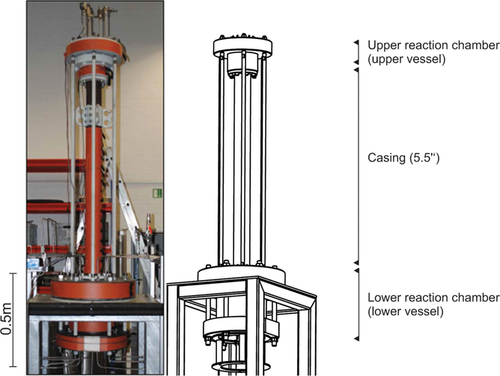

To avoid drinking-water contamination and the interconnection of different aquifers, the drilled holes need to be properly completed. Usually, a series of cemented steel casings are used 1) to ensure long-term stability of the well, 2) to avoid contamination of drinking water, and 3) to keep different pressurized aquifers separated. The functionality needs to be ensured beyond the time of utilization of the well. To ensure long-term integrity, even after abandonment, cement plugs are usually used. Well abandonment was the focus of a special series of full-scale in situ experiments at KIT (Figure 19), for which the system integrity of cemented casings at elevated temperatures (80 °C) and pressures (up to 8 MPa) were investigated.87

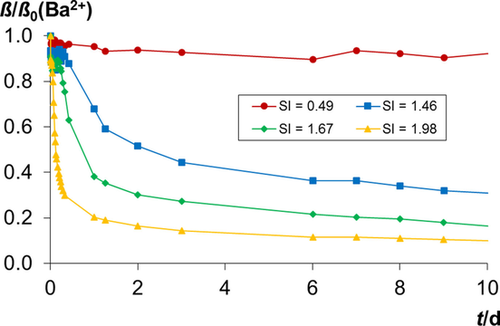

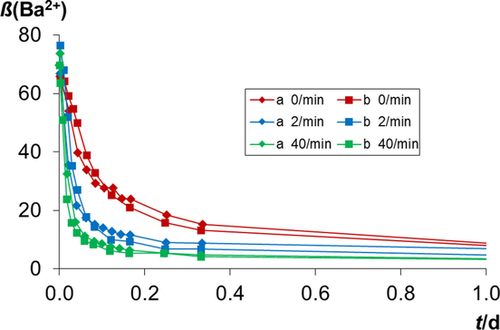

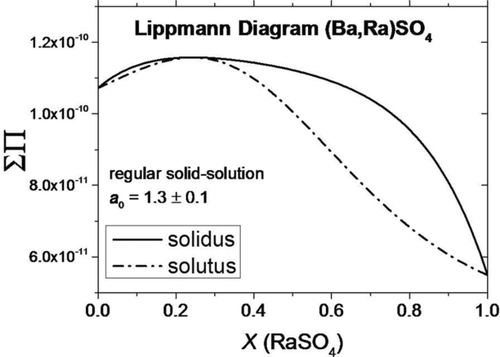

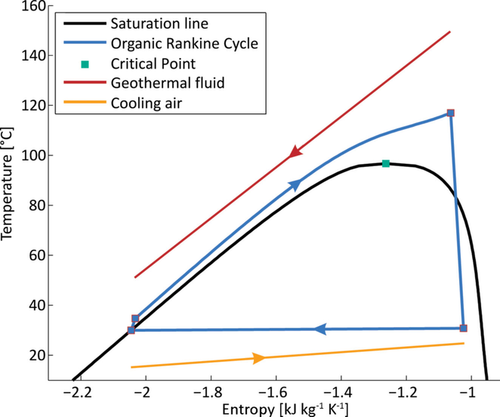

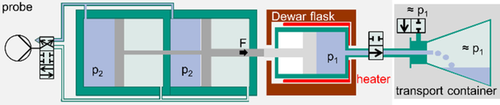

Photograph (left) and schematic (right) illustration of the full-scale autoclave COBRA for in situ tests of well integrity. Maximum 100 bar (1 bar=105 Pa) and 100 °C. Construction by Dustec Hochdrucktechnik GmbH.