Industry 4.0 Challenges and Implementation Strategies: Benchmarked Results From Food and Beverage Manufacturing Industries in Tanzania

ABSTRACT

The study assessed the challenges and strategies of Industry 4.0 (I4.0) in Tanzania's food and beverage manufacturing industries (FBMIs). Pertinent data were collected through a closed-ended questionnaire from 103 medium and large FBMIs. Data validity and reliability were tested using SPSS 23, where p-values < 0.05 for validity testing and Cronbach Alpha value of > 0.7 were determined for the reliability of the collected questionnaires. The normality of the data was tested using Kolmogorov–Smirnov and Shapiro–Wilk tests. The study found that employees were more informed about the benefits of adopting I4.0, with a mean score of 4.78. The prospect of I4.0 improving industry competitiveness on the international stage was ranked second in terms of awareness. Also, there was no significant difference in awareness levels for nine I4.0 technologies among the FBMIs. Most FBMIs had not fully established a roadmap for using I4.0 technologies. Findings showed that challenges have no significant differences, for example, for financial challenges (χ2 = 1.121, p = 0.571 > 0.05), return on investment and cost–benefit analysis for implementing I4.0 technologies with (χ2 = 0.027, p = 0.987 > 0.05), identifying and securing funds for implementing I4.0 technologies (with χ2 = 1.918, p = 0.383 > 0.05), among others. Implementing I4.0-related technologies is high; the findings showed that the overall mean score was 3.75, corresponding to “level 4” on the five-point Likert awareness scale. Also, some challenges should be tackled to implement I4.0-related technologies smoothly. Consequently, such challenges can be addressed by implementing the proposed strategies. The study suggests that stakeholders must implement relevant technologies fully despite FBMIs' high I4.0 awareness. Lastly, the study proposed strategies for implementing I4.0 in the FBMIs, including embracing data-driven decision-making and training leaders and top management regarding the benefits of I4.0 implementation. Strategies should be supported by top management commitment and adequate budget allocation.

1 Background

Each country's economy and society are impacted by the fourth industrial revolution's (IR) technological breakthroughs [1]. Using new technologies and going digital can significantly improve corporate productivity, corporate competitiveness, and social well-being across nations. The first IR (Industry 1.0) made mechanized production possible by using steam and reclaimed water [2]. Industry 2.0 relied on electricity to create mass production. The third IR introduced mechanized production by applying electronics and computer technologies. The fourth IR is presently replacing the third IR, or the digital revolution, which has been going on since the middle of the 20th century [3, 4].

Industry 4.0 (I4.0) can be split into three categories: vertical, horizontal, and end-to-end integration. Eleven key components of I4.0 include artificial intelligence (AI), machine learning (ML), Internet of Things (IoT), digital twin, big data analytics (BDA), cognitive computing, computer simulation, cyber security, additive manufacturing (3D printing), cloud computing, augmented reality (AR), quantum computing, mixed reality (MR), virtual reality (VR), and virtual factories (VF) [5-7]. Other components include vertical and horizontal systems integration, smart factories, dark factories, connected businesses, cognitive computing, and autonomous robots [8-10]. Manufacturing industries (MIs) are subjected to various working practices that will reduce operational costs and simplify production logistics. With the I4.0 agenda, these industries can benefit from a variety of applications in I4.0 that can assist with various tasks [6].

MIs include small, medium, and large industries. The categorization of these industries is appreciated for the liquidity and capacity to handle production needs in terms of manpower, material, and infrastructure. MIs, the cornerstone of most economies, are widely recognized for providing employment opportunities and taxes to the governments for development [11].

Wider issues that have been identified as impeding the growth of the manufacturing industry sector in many countries include restricted access to financing; an expensive labor force; a shortage of skilled labor; difficulties implementing new technology; difficulties implementing new organizational structures; difficulties with quality management; difficulties implementing administrative regulations; difficulties with infrastructure; and difficulties with consumer purchasing power [12]. Businesses increasingly adopt digital technologies to enhance their operations, culture, strategy, product delivery, customer experience, and decision-making [11]. These technologies offer speed, flexibility, connectivity, innovation, transparency, responsiveness, and real-time inventory management.

Digital supply chains offer speed, flexibility, transparency, and connectivity, enabling companies to adapt to fluctuating market environments and respond quickly to buyer demands through Industry 4.0 technology, enabling real-time monitoring and management [13, 14]. One example is the potential of additive manufacturing, a key component of I4.0, to create complicated geometries suited for tiny batches of just one item. By enabling decentralized, data-driven decision-making, I4.0 enables end-to-end integration of multiple industrial assets on the shop floor and elsewhere [15].

A cyber-physical system enhances interoperability, transparency, and real-time monitoring of production resources, allowing for advanced analytics applications and enhanced monitoring of product and process data [16]. I4.0 benefits extend beyond manufacturing, impacting entire supply chain operations like product development, smart processes, quality control, employee training, and business intelligence through technologies like IoT, cloud computing, and BDA [13, 17]. I4.0 enhances the enterprise ecosystem by integrating value chains, promoting transparency, and enhancing IT infrastructure. It promotes agility, customization, data accuracy, decision-making, and increased productivity, enhancing supplier collaboration and customer satisfaction.

Geissbauer et al. [18] and Çınar et al. [19] emphasized that AI is another essential element of I4.0, which focuses on the computational capacity to make judgments based on data and construct autonomous systems. Digital supply chains distinguish themselves from their rivals by innovating in their products and processes, enabling them to compete globally and establish themselves as world-class companies. It is obvious that in the current business climate, I4.0 disruptive technologies are the key to creating smart facilities that are highly efficient and digitally interconnected [15]. It is still concerning that MIs are unfamiliar with the key drivers behind I4.0's implementation despite firms realizing its potential [11]. No matter an industry's nation of origin, this has caused transformation to occur across sectors at a sluggish and unequal pace [1]. There are many different perspectives on how firms view I4.0, and there is much debate among experts on what the crucial elements, technologies, tools, and procedures could be that could completely transform their industry.

Moreover, in the literature by several studies, Maganga and Taifa [1], Ngowi [20], and Khin and Kee [15] have presented a set of related factors of I4.0 and associated terms manufacturing industry, including beverage and food industries. Results show that industries generally hesitated to use I4.0 to digitally transform their operations, despite its various advantages and its growing relevance [5]. However, many manufacturing industries are unfamiliar with the key drivers behind I4.0's implementation, leading to debate among experts on what elements, technologies, tools, and procedures could completely transform their industry. In Tanzania, there is a need to assess the challenges of implementing I4.0 and establish strategies for food and beverage manufacturing industries (FBMIs). Three specific objectives were identified: determining the I4.0 awareness level for FBMIs, assessing challenges toward I4.0 implementation by FBMIs, and proposing I4.0 implementation strategies for FBMIs.

Therefore, achieving the assessment of I4.0 challenges together with the awareness level can lead to achieving I4.0 benefits. IR has significantly impacted the economy and society, improving corporate productivity, competitiveness, and social well-being. I4.0 technologies include key components such as artificial intelligence, machine learning, Internet of Things, digital twin, big data analytics, cognitive computing, computer simulation, cyber security, additive manufacturing, cloud computing, augmented reality, quantum computing, mixed reality, virtual reality, and virtual factories. Major industries, including small, medium, and large ones, are increasingly adopting digital technologies to enhance their operations, culture, strategy, product delivery, customer experience, and decision-making. The I4.0 technologies offer speed, flexibility, connectivity, innovation, transparency, responsiveness, and real-time inventory management. Digital transformation for FBMIs can be positively impacted by speed, flexibility, transparency, and connectivity, enabling companies to adapt to fluctuating market environments and respond quickly to buyer demands.

2 Literature Review

2.1 I4.0 Adoption

Tanzania manufacturing industries (TMIs) structure, including assembling (4%), processing (43%), and MIs (53%), faces challenges like complex legal structures, lack of modern technology, skilled personnel shortage, and inadequate research and design centers [21]. Despite embracing Industry 1.0, 2.0, and 3.0 stages, opportunities exist for I4.0, as suggested by Ngowi [20], Ntamulyango [22], and Nhelekwa et al. [23]. The fourth IR is defined as the connection between autonomous, independent devices that can communicate in real-time and possibly cooperate in a smart environment to make decisions and take actions based on the data gathered, following the success of the third IR [24, 25]. There are 11 fundamental components of I4.0, according to Khin and Kee [15] and Haiston [26], including BDA, collaborative robots, machine-to-machine communication, cybersecurity, VR, cloud computing, cyber-physical security, the IoT, simulation, horizontal and vertical integration, and supply chain. The integration of humans and machines has significantly improved productivity, efficiency, and human life quality, enhancing product quality, time efficiency, and stakeholder cooperation, supported by scientific studies [27].

I4.0 is a relatively recent idea that has become a hot topic; there is not a single conception of its adoption in the literature [20]. Nonetheless, the term “I4.0”, which refers to the fusion of cutting-edge industrial technology and information and communication technologies (ICTs), is commonly used in academic contexts. The IoT, cloud computing, and cyber-physical systems are just a few of the technologies included in this area of I4.0. Also, one of I4.0's key characteristics is the capacity to integrate equipment with production systems in a smart and autonomous environment. This makes it possible for the components to communicate in real-time and for the manufacturing system to receive feedback [25].

2.2 Technology Adoption Theories

2.2.1 Technology Acceptance Model (TAM)

Davis [28] developed TAM, which was later found to be better at clarifying individual acceptance of some technologies. According to TAM, the individual would accept a specific technology if he or she believes certain things about the technology. These beliefs are “perceived ease of use (PEOU) and perceived usefulness (PU)”, which are used to describe the person's acceptance of the information system [29]. As a result, TAM is an essential model that can be integrated into some larger theories, such as the theory of planned behavior, which can investigate the intention to embrace I4.0 in FBMIs and consider relevant human and social elements.

2.2.2 Technological-Organizational-Environment (TOE) Framework

The TOE framework is a better choice among the theories given for studying the application of I4.0. The TOE framework covers the variables that affect technology acceptance and its likelihood [30]. The technology adoption and implementation process describes how a corporation adopts and uses technological innovation and how the organization, the environment, and the technological background affect this process [31].

2.3 I4.0 Models

The I4.0 Model builds on the outline of the I4.0 Reference Architecture Model (RAMI 4.0) model. The creation of the RAMI 4.0 was part of Germany's Platform I4.0 program (RAMI 4.0) [32]. As I4.0 became more well-known throughout Europe and beyond, the need for a clear and uniform nomenclature increased. The goal of RAMI 4.0 was to create a common framework for communications and ideas among nations. The structure of RAMI 4.0 is an idea map that depicts manufacturing processes and production products in a straightforward and organized manner to foster a shared knowledge of I4.0. RAMI 4.0 ensures that participants participating in I4.0 conversations can communicate effectively [33]. This model defines each production object and includes the data and functions that go with it. The output is a full virtual description of the object. A three-dimensional framework known as the value stream and life cycle, hierarchy levels, and layers serves as the foundation for RAMI 4.0.

2.4 Empirical Literature Review

2.4.1 Challenges for I4.0 Adoption in MIs

The adoption of I4.0 has been influenced by a number of criteria that determine whether MIs will adopt it or not. According to Nguyen and Luu [24], technology is advancing quickly and has an impact on practically every industry worldwide. A comprehensive restructure of government and income is necessary to accommodate the extent of these changes. Several factors can either hinder or help the Industry's 4.0 adoption process in MIs.

The elements that affect the adoption of I4.0 have been the subject of numerous studies, but little is known about the factors that encourage adoption. For businesses with better access to the resources essential to deploy I4.0 standards, facilitators like government backing may have an impact in favor of adopting I4.0. Among the outside elements cited concerning implementing new technologies are government support in funding, training, and technological direction. Internal organizational factors include infrastructure, skilled personnel, and technological know-how. Support in financing, training, and technological guidance is among the external elements listed when adopting new technologies. Internal organizational considerations include technological know-how, a capable workforce, and infrastructure.

Maganga and Taifa [1] proposed three enabler dimensions: “Human”, “Organization” and “Technology.” According to Khin and Kee [15], key aspects to consider for I4.0 are financial resources, staff skills, education and training support, and financial resources. Although neglecting the significance of financial support, other studies, on the other hand, have recognized technology resources and skills as facilitators of digital transformation. Due to this contradiction, it is necessary to look into both internal and external elements that could help manufacturing companies undergo a digital transition.

Firms must be aware of the impediments to I4.0 adoption, and a decision to travel must be made before leaving. The challenges may be viewed as impediments that ultimately resulted in the choice to forego new technology investments. Despite the fact that some researchers have identified issues connected to I4.0, few have shown how they affect I4.0 adoption. According to Khin and Kee [15], “lack of technology infrastructure” was the main issue preventing I4.0, while “lack of competencies” and “lack of financial resources” were the biggest roadblocks. However, their findings contradict those of others who claim that perceptions of MI managers' barriers do not affect the adoption of I4.0. Furthermore, other research has highlighted several I4.0 problems that need additional assurance. Nimawat and Das Gidwani [34] showed that competitive challenges are numerous for the future and could significantly affect the I4.0 adoption.

2.4.2 Strategies for I4.0 Adoption

According to existing literature on new technology adoption, as indicated in summary Table 1, numerous manufacturers are considering innovative manufacturing technology due to its advantages and opportunities [15, 24, 36]. The advantages of I4.0, such as increased productivity and efficiency, are key drivers for adoption. In addition to the operational advantages, manufacturers are considering implementing I4.0 due to market and commercial opportunities. Despite the strong economic cases for implementing I4.0, many organizations find it challenging to do so since the technology is still in its infancy and is beset by insufficient drivers and barriers.

| Strategies | Sources |

|---|---|

| Conduct a technology readiness assessment to establish the readiness level that guides the nature of I4.0 technologies required | [35] |

| Develop a clear digital transformation strategy | [36] |

| Foster an organizational culture of innovation and learning | |

| Collaborate with I4.0 technology providers (e.g., AI, IoT, RFID, etc.) | |

| Start with industrial pilot projects | [15] |

| Recruit the in-house expertise (or skilled workforce) or resources to navigate and utilize these technologies effectively | |

| Enhance policy and regulations that support technology transfer | |

| Seek government support for subsidizing the cost of importing I4.0-related technologies | [5] |

| Embrace data-driven decision-making | |

| Address security and privacy concerns | |

| Conduct training and skill development for all employees | [24] |

| Translating industrial business needs to IT requirements | |

| Plan how to identify and secure funds for implementing I4.0 | |

| Uniting new I4.0 technologies into existing infrastructure | [12] |

| Ensure reliable electricity supply to the industry | |

| Stabilize reliable internet connectivity to the industry | [15] |

| Procure advanced software to facilitate I4.0 implementation | |

| Facilitate the availability of additional resources for computational power and robust hardware to facilitate I4.0 implementation | |

| Foster enacting I4.0 standards and protocols, resulting in interoperability issues between different systems and technologies | [11] |

| Establish vision and strategy for I4.0 implementation | |

| Training leaders and top management regarding the economic benefits of I4.0 implementation |

2.5 Research Gap

MIs are baffled by the I4.0 concept. Khin and Kee [15] and Nimawat and Das Gidwani [34] investigated the adoption of important I4.0 technologies. These technologies include organizational learning, virtual reality, and radio-frequency identification (RFID). The authors examined the market structure, the supply chain, management leadership, and implementation challenges for implementing RFID as organizational, environmental, and organizational learning capacity for implementing additive manufacturing. Studies have been done to determine the essential elements of implementing I4.0 for the Manufacturing Industry, especially in emerging nations. However, studies conducted by academics in industrialized countries to assist the quick spread of the idea among MIs were highly accepted and judged significant [25]. Adoption of I4.0 in a developing economy is still difficult. I4.0 is necessary for Tanzania's MIs to compete in the international market. There have been few studies on the adoption of I4.0, which is primarily aimed at MIs in developing nations like Tanzania. Given this obvious information gap, the research aims to scrutinize the challenges and strategies influencing negatively and positively, respectively, I4.0 adoption in Tanzanian MIs, particularly in the FBMIs.

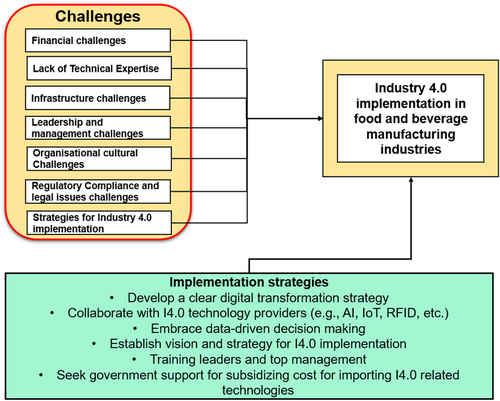

2.6 Conceptual Framework

A conceptual framework depicts the conceptual status and connections between the items under study (Figure 1). It is an interrelated system of assumptions, expectations, and beliefs [37]. It depicts the theoretical connection between the variables under investigation by connecting the study's notions of branding practices, identifying gaps in the state of knowledge regarding the phenomena or subject, and outlining the methodological underpinnings of the research project.

3 Research Methodology

3.1 Research Design and Study Area

This study deployed a cross-sectional research approach. A cross-sectional research design is an empirical study that examines a sensation within its real-life context using multiple sources of evidence and examining the boundaries between phenomena [38]. This form of study design is justified because it permits the use of various sources of evidence and, occasionally, triangulation techniques. This study was conducted in medium and large MIs producing food and beverages in Dar es Salaam and Pwani regions. This study was conducted in FBMIs in Dar es Salaam and Pwani, Tanzania's most industrialized region. Forty-two percent of Tanzania's manufacturing comprises food, tobacco, and beverages [39]. Therefore, there are many FBMIs in Tanzania, resulting in a focus on those industries. Micro and small FBMIs have low technology and digitalization, making assessing their awareness of I4.0 difficult, as most are not yet in Industry 3.0 [40, 41]. Compared to large industries, small and micro industries lack advanced manufacturing technologies [40]. They focus on standard processes and low technology levels and operate with standard machines [40]. The food industry encompasses many processes, including farming, harvesting, processing, packaging, transportation, and distribution. Each process involves different technologies, equipment, and production methods, making generalizing I4.0 adoption across the entire industry challenging.

3.2 Study Population and Sample Size

The targeted population was medium and large FBMIs that manufacture food and beverages based in Dar es Salaam and Pwani regions. From CTI and DI [42] and Lwesya et al. [43], medium and large industries have at least 50–99 employees and at least 100 employees, respectively. They should also have above $85,000–$340,000 and above $340,000 for medium and large enterprises, respectively. Likewise, the government of Tanzania categorizes the business sizes as shown in Figure 2. Thus, those criteria were used to determine the industry size. Automation and technological levels were also considered. The study population was 129; however, upon considering the selection criteria, such as the level of automation for some basic machinery, the capital invested for machinery, and the nature of products, 103 industries were included in the study. The sample size was obtained through the purposive sampling procedures.

Source: Ministry of Trade and Industry [44]

.3.3 Data Collection Methods

A closed-ended questionnaire was developed with four sections: Part A (Demographic information and industry information), Part B (Awareness level questions), Part C (Challenges for implementing I4.0) and Part D (Strategies for implementing I4.0). Some questions were adapted from previous studies, including the study by Maganga [37], Özavcı [45], Ntamulyango [22], and Nimawat and Gidwani [46].

3.4 Validity and Reliability

The validity of the questionnaire was tested, first, through face validation as suggested by Yusoff et al. [47] and Roebianto et al. [48], and second, by using Pearson Product Moment Correlations using SPSS 23 from the Pearson product–moment correlation. If the significance value < 0.05, then the questionnaire should be declared valid; otherwise, it is not [49]. Reliability is the degree to which research findings are valid across time and fairly represent the studied population. Internal consistency must be established to guarantee validity before a test is used for study or examination [48]. So, the reliability test was performed by determining Cronbach's Alpha to measure the internal consistency of the responses provided to the supplied questionnaires, as per Leung [50] and Taherdoost [51]. The test was carried out in SPSS 23.

3.5 Data Analysis

The awareness level of the I4.0 technologies and their applicability in FBMIs was compared with the awareness scale of the model developed by Paguigan and Jacinto [52]. The normality of the data was tested using Shapiro–Wilk and Kolmogorov–Smirnov tests, and then a Measure of Sampling Adequacy (MSA) was conducted in SPSS 23 through Kaiser-Meyer Olkin (KMO) and Bartlett's test of sphericity. In assessing the reliable sampling adequacy, the KMO value had to be over 0.5 and a significance level for Bartlett's test below 0.05, thus suggesting that there is a substantial correlation in the collected data [53].

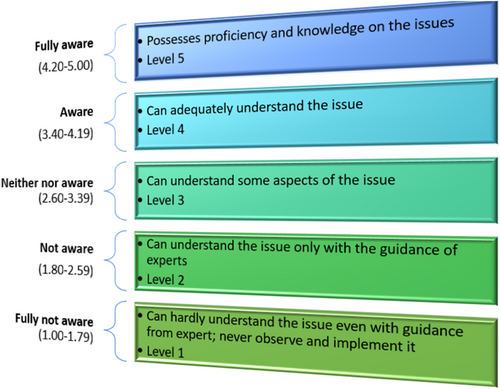

Both inferential and descriptive analyses were deployed to assess the gathered data regarding I4.0 awareness, challenges hindering I4.0 implementations, and strategies for implementing I4.0 in FBMIs. The awareness of I4.0 within the FBMIs was assessed by setting up a questionnaire regarding the operations or practices of I4.0 for the FBMIs. Figure 3 assisted in categorizing the awareness levels, as Paguigan and Jacinto [52] suggested.

Source: Paguigan and Jacinto [52]

.SPSS 23 software was used to analyze the suggested factors. Such factor analysis approaches included Exploratory Factor Analysis (EFA), which analyzed challenges based on their categories (financial, lack of technical expertise, infrastructure, leadership and management, organizational culture, and regulatory compliance issues). EFA is an approach used to determine the underlying structure of a relatively large set of variables [54]. In assessing I4.0 challenges in FBMIs, an EFA assisted in determining the fundamental associations between observed variables. The decisive factor was based on the loading, which is suggested to be at least 0.5 [55]. The Kruskal-Wallis Test was conducted to ascertain whether the challenges were rated differently by industry categories (food manufacturing, beverage manufacturing, and food-beverage manufacturing).

3.6 Strategy Development and Validation Process

The strategy development process involves reviewing or gathering opinions on deploying I4.0 technologies within Tanzania's FBMIs. Strategies were compiled and included in the closed-ended questionnaire based on the literature review. All 103 FBMIS ranked strategies based on relative importance to each other. Moreover, optimal strategies were rated early and top-rated. The validation was carried out by conducting focus group discussions (FGDs). FGDs consisted of different experts from FBMIs. Three FBMIs involved members who did not rank strategies during the data collection. Three experts came from the food industry, three from the beverage industry, and three from the industry that produces both food and beverages. They included engineers and production managers for particular industries. The working experience of experts who validated strategies revealed that three experts had 5 to 10 years of experience, four experts had experience between 11 and 20 years, and two experts had experience above 20 years. The focus group was carried out at each purposively selected industry.

4 Results and Discussion

4.1 Education and Experience Level of Respondents

The target sample for the study was 103, and all FBMIs participated fully. Obtaining the exact sample size is regarded as an accurate population representation, but obtaining more data than the sample size is regarded as good [56]. The analysis of the educational level of respondents revealed that a whopping number of respondents, 61, had a bachelor's degree, which is equivalent to 59.2%. Among these, 17 respondents (16.5%) had masters, and 11 respondents (10.7%) had other levels of education that were not specified in the questionnaire. The study also found that 10 respondents (9.7%) had a diploma level of education, and four respondents (3.9%) had a PhD. The general finding on the respondent's education is that 79.2% of respondents had at least a bachelor's degree, indicating a higher level of education for the respondents.

The experience of respondent results revealed that five respondents (4.85%) had experience of less than 1 year, 16 respondents (15.5%) had 1–5 years of experience, 39 respondents (37.86%) had experience between 6 and 10 years, 23 respondents (22.3%) had experience between 11 and 20 years, and 20 respondents (19.4%) had experience above 20 years. The general insight on the respondents' experience revealed that 82 respondents, which amounted to 79.6% of total respondents, had worked in the FBMIs for over 6 years.

4.2 FBMIs Details

This part analyzed the categories of industries in which data were collected. The categories were divided into three categories: food manufacturing industry, beverage industry, and food and beverage industry. The result of the analysis showed that 59 companies (57.3%) were beverage manufacturing companies, 27 industries (26.2%) were food manufacturing companies, and 17 (16.5%) companies produced both foods and beverages. The number of employees in the FBMIs was analyzed to understand how big each company was. The analysis revealed that only medium and large MIs were available in the sample. Twenty-two companies, equivalent to 21.4%, had employees between 50 and 99, which are medium-sized, while 81 industries (78.4%) had more than 100 employees, which fall under the large company category. The financial capacity of industries was assessed in this section, and the annual turnover categories were divided into four categories: less than 10 million, 10 to 50 million, 51 to 100 million, and above 100 million. After analyzing the responses, it was revealed that 22 industries (21.4%) had a turnover between 51 and 100 million, and 81 industries (78.6) had a turnover above 100 million.

The manufacturing process of the sampled industries was assessed to understand the level of automation in the manufacturing process. The categories included in the questionnaire were manufacturing production processes, manual production lines, semi-automated production lines, automated production lines, and job shop production. The analysis of responses revealed that only automated and semi-automated production lines were selected, with 57.3% and 42.7%, respectively. The level of digitalization in the sampled industries was assessed, and the questionnaire asked respondents to select the level to which their industries were digitalized. The selection scale included a purely physical production system, a low-digitalized production system, a medium-digitalized production system, a well-digitalized production system, and a fully digitalized production system. The analysis of responses showed that 66 industries (64.1%) had a medium digitalized production system, 27 industries (26.2%) had a well-digitalized production system, and 10 industries (9.7%) had a fully digitalized production system.

4.3 Validity Test

The validity of the questionnaire was tested, first, through face validation as suggested by Yusoff et al. [47] and Roebianto et al. [48], and second, by using Pearson Product Moment Correlations using SPSS 23. The face validation was conducted through a representative sample by sending sample questionnaires to the target population and letting them feed the questionnaires. The questionnaires' responses were checked to find if the questionnaires were filled out accordingly. The returned questionnaire showed it was well prepared, and respondents understood the wording, enabling them to collect the needed data. The questionnaire items were valid based on the Pearson product–moment correlation since the significance values were less than 0.05 [49]. For example, p-values for general I4.0 awareness questions were 0.03, while awareness for I4.0 technologies was 0.009. Likewise, the p-values for challenges were 0.001 and 0.004 for the questionnaire items. Hence, the questionnaire was declared valid to collect data.

4.4 Reliability Test

Reliability is the ability of the research method to produce consistent results on repeated measurements under similar conditions [51]. The most commonly used internal consistency measure is CA. The reliability test was conducted in SPSS 23 on items according to their categories, that is, awareness of I4.0 technologies, challenges for implementation of I4.0, and strategies for implementation of I4.0. The reliability results were excellent, with CA above 0.90 for all items (based on standardized items) [51]. Table 2 shows the reliability results.

| Items | CA | CA based on standardized items | Number of items |

|---|---|---|---|

| Awareness | 0.898 | 0.900 | 37 |

| Challenges | 0.866 | 0.909 | 34 |

| Strategies | 0.960 | 0.971 | 21 |

4.5 Awareness of the Applicability of I4.0 in FBMIs

The first part of this study's findings is intended to assess the awareness of I4.0 by the employees within the FBMIs through the practices of their companies, that is, the study asked questions regarding the operations or practices of I4.0 to the FBMIs. The purpose was to know whether employees understand the I4.0 technologies being used in their companies. The questionnaire asked respondents to rank each statement using the Likert scale of five points according to the level to which they agreed to a particular statement. The scale was (“1—strongly disagree, 2—disagree, 3—neither agree nor disagree, 4—agree and 5—strongly agree”). The mean score for each statement was calculated, and then the awareness level was determined from the awareness ranges developed by Eski et al. [57] and Paguigan and Jacinto [52].

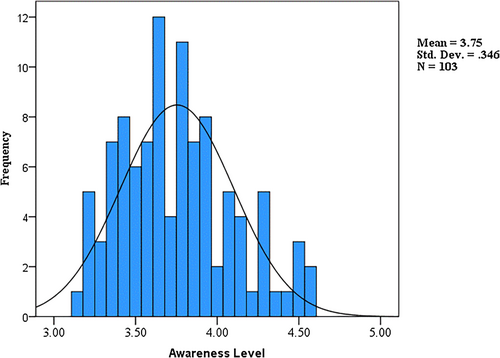

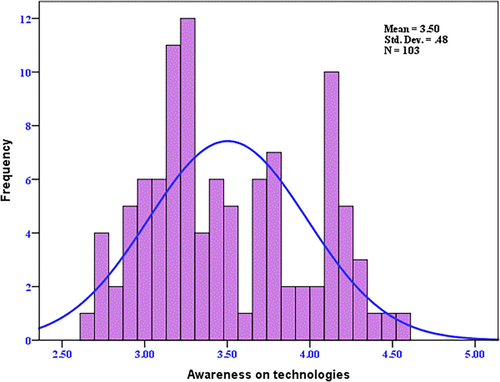

Paguigan and Jacinto [52] developed the scale for determining the awareness level of the tenants on campus policy on energy conservation and implementation using the mean scores, as Eski et al. [57] categorized their levels in 5-point; it was the same for Paguigan and Jacinto [52] as shown in Figure 3. The study adopted the approach used by Paguigan and Jacinto [52]; the mean scores for the ratings on the applicability of I4.0 were calculated, and the results were subjected to the ranking in the scale developed by Paguigan and Jacinto [52]. The findings showed that the overall mean score was 3.75, corresponding to awareness on the five-point Likert scale of awareness. Figure 4 shows the overall mean score.

The score for each factor revealed that employees were more informed about the benefits of adopting I4.0 (AW5), with a mean score of 4.78 ranked first. The prospect of I4.0 to improve industry's competitiveness on the international stage was ranked second in terms of awareness by employees, with a mean score of 4.65, corresponding to full awareness. The other aspect employees were fully aware of was the possibility of the company improving market share through implementing I4.0 technologies (AW14) with a mean score of 4.30. Respondents were unaware of only one aspect, that is, the framework or roadmap for planning the activities for implementing I4.0 (AW9), with a mean score of 2.44. This generalizes that most FBMIs have not fully established a clear roadmap to use I4.0 technologies. Table 3 shows the results for the awareness of the applicability of I4.0 in FBMIs.

| Items | Mean | t-value | SD | Level of awareness | Rank |

|---|---|---|---|---|---|

| AW1 | 3.45 | 0.190 | 1.297 | Aware | 9 |

| AW2 | 3.29 | 0.976 | 1.21 | Neither aware or not aware | 13 |

| AW3 | 3.32 | 2.079 | 1.222 | Neither aware or not aware | 12 |

| AW4 | 3.88 | 2.222 | 0.808 | Aware | 7 |

| AW5 | 4.78 | 0.368 | 0.418 | Fully aware | 1 |

| AW6 | 3.92 | 1.271 | 0.915 | Aware | 6 |

| AW7 | 3.69 | 5.446 | 0.96 | Aware | 8 |

| AW8 | 3.40 | 4.837 | 1.324 | Aware | 10 |

| AW9 | 2.44 | 5.729 | 1.446 | Not aware | 14 |

| AW10 | 3.36 | 2.913 | 1.11 | Neither aware or not aware | 11 |

| AW11 | 4.08 | 0.624 | 0.825 | Aware | 4 |

| AW12 | 4.00 | 0.894 | 0.886 | Aware | 5 |

| AW13 | 4.65 | 2.667 | 0.479 | Fully aware | 2 |

| AW14 | 4.30 | 1.688 | 0.725 | Fully aware | 3 |

The independent t-test was conducted to compare awareness level on the applicability of I4.0 in FBMIs for food and beverage, there were no significant difference on the awareness level between food and beverages for six items with t-values greater than 1.96 [58]; AW3—“Have you attended any workshop or training or seminar regarding to I4.0 or digital transformation technologies in the last 2 years?”, AW4—“Is your organisation aware of the current technologies associated with I4.0?”, AW7—“Are there any financial arrangements for the implementation of I4.0 technologies?”, AW8—“Has an I4.0 strategy been defined in your company for the next five years?”, AW9—“Is there a framework/roadmap for planning the activities for the implementation of I4.0 solutions in your company?”, AW10—“Is there any involvement, support, or experience of top management toward the implementation of I4.0?”, and AW13—“Are you aware that the digital transformation to I4.0 could improve your industry's competitiveness at the international stage?” The remaining items displayed a significant difference in the awareness level with a t-value of less than 1.96 [59]. Table 3 shows the results for the independent t-test and awareness level on the applicability of I4.0 in FBMIs. The t-values can be negative or positive in Table 3; they mean that they lie to the left of the mean [60]. The t-distribution, like the standard normal, has a mean of 0, and all values to the left are negative, while values to the right are positive [61].

4.6 I4.0 Technologies Awareness Level by FBMIs

The awareness of I4.0 technologies by FBMIs was assessed to determine how well I4.0 technologies were understood among the FBMIs. The approach used by Paguigan and Jacinto [52] was maintained in this section to assess the awareness of the applicability of I4.0 technologies in FBMIs. The analysis showed that the overall mean score was 3.50, corresponding to awareness on the awareness scale. This means that, in general, FBMIs were aware of I4.0 technologies. Figure 5 shows the overall mean score.

The individual technology assessment showed that artificial intelligence (TW1) was a very popular technology with a mean score of 4.8, which corresponds to fully aware on the five-point awareness scale. The analysis found that seven technologies were well known as respondents were fully aware of them, together with TW1, others including TW4 () autonomous robotics, TW5 () cyber security, (TW16, ) “smart sensors,” (TW15, ) “IoT,” (TW6, ) “simulation” and (TW23, ) “RFID chips (Radio Frequency Identification for object tracking).” On the other hand, the analysis revealed that FBMIs were not aware of five technologies namely; (TW22, ) (TW18, 2.22) “dark manufacturing,” (TW21, ) “virtual factory,” (TW13, 2.16) “block chain technology” and (TW14, ) “nanotechnology.” Table 4 depicts the awareness of I4.0 technologies by FBMIs.

| Items | Mean | t-values | SD | Level of awareness | Rank |

|---|---|---|---|---|---|

| TW1 | 4.80 | 3.257 | 0.405 | Fully aware | 1 |

| TW2 | 2.97 | 3.316 | 1.033 | Neither aware or not aware | 18 |

| TW3 | 3.68 | 2.490 | 1.04 | Aware | 11 |

| TW4 | 4.54 | 0.220 | 0.52 | Fully aware | 2 |

| TW5 | 4.50 | 2.613 | 0.592 | Fully aware | 3 |

| TW6 | 4.33 | 1.439 | 0.821 | Fully aware | 6 |

| TW7 | 3.21 | 3.028 | 1.296 | Neither aware or not aware | 16 |

| TW8 | 3.27 | 2.256 | 1.165 | Neither aware or not aware | 15 |

| TW9 | 3.46 | 1.217 | 1.243 | Aware | 13 |

| TW10 | 3.29 | 2.933 | 1.311 | Neither aware or not aware | 14 |

| TW11 | 3.71 | 2.738 | 1.25 | Aware | 10 |

| TW12 | 3.05 | 1.541 | 1.36 | Neither aware or not aware | 17 |

| TW13 | 2.16 | 1.562 | 0.872 | Not aware | 22 |

| TW14 | 2.07 | 1.579 | 0.832 | Not aware | 23 |

| TW15 | 4.34 | 1.702 | 0.619 | Fully aware | 5 |

| TW16 | 4.43 | 0.221 | 0.736 | Fully aware | 4 |

| TW17 | 3.49 | 3.807 | 1.313 | Aware | 12 |

| TW18 | 2.22 | 1.357 | 1.111 | Not aware | 20 |

| TW19 | 4.10 | 1.739 | 0.955 | Aware | 8 |

| TW20 | 4.04 | 1.312 | 1.066 | Aware | 9 |

| TW21 | 2.17 | 0.779 | 0.857 | Not aware | 21 |

| TW22 | 2.50 | 1.735 | 1.037 | Not aware | 19 |

| TW23 | 4.20 | 0.457 | 1.013 | Fully aware | 7 |

Also, an independent t-test (Table 4) was conducted to compare the I4.0 technologies awareness level between FBMIs. The result of independent t-test statistics showed that there was no significant difference on the awareness level on nine I4.0 technologies: TW1—“artificial intelligence (AI),” TW2—“cyber-physical systems,” TW3—“big data analytics,” TW5—“Cyber security,” TW7—“the industrial IoT,” TW8—“cloud computing,” TW10—“augmented reality,” TW11—“cyber manufacturing” and TW17—“cyber-physical systems.” These nine items had t-values greater than 1.96. The remaining items showed a significant difference in the level of awareness among FBMIs with t-values less than 1.96 [59].

4.7 Challenges for Implementation of I4.0 Technologies in FBMIs

The study assessed challenges hindering the implementation of I4.0 in FBMIs in Dar es Salaam and Pwani regions. The implementation challenges were categorized into six groups (financial, lack of technical expertise, infrastructure, leadership and management, organizational culture, regulatory compliance, and legal issues). The first part of the analysis on the challenges of I4.0 technologies implementation included descriptive analysis followed by a normality test to check data distribution using the Kolmogorov–Smirnov test and Shapiro–Wilk.

The second part of the analysis of the challenges involved the use of EFA to assess the theoretical construct of the variables. Before factor analysis, MSA was conducted through KMO to ensure the possibility of conducting factor analysis [55]. Then, the Kruskal Wallis test was used to assess the responses based on categories of FBMIs, followed by developing strategies for implementing I4.0 in FBMIs.

4.7.1 Descriptive Analysis for Challenges Hindering the Implementation of I4.0 in FBMIs

The results of descriptive analysis for the mean scores of challenges for the implementation of I4.0 technologies in FBMIs revealed that the top 10 highest-rated challenges included infrastructure and leadership-related challenges as follows; “(IC4, ) Inadequate advanced software to facilitate I4.0 implementation,” “(IC5, ) Absence/inadequate of additional resources for computational power and robust hardware to facilitate I4.0 implementation,” “(IC1, ),” “(IC3, ) Unreliable internet connectivity to the industry,” “(IC6, ) Upgrading or replacing existing systems can be disruptive and time-consuming, requiring careful planning and investment,” “(IC7, ) Limited resources to invest in robust cybersecurity measures, making them more vulnerable to potential breaches and data theft,” “(MC4, ) Having organization's leadership/top management who have no vision and strategy for I4.0 implementations,” “(MC5, ) Having organization which has not roadmap or implementation framework for I4.0,” “(IC2, ) Unreliable electricity supply to the industry,” “(MC1, ) Having top management which does not support I4.0 implementation.” The lowest mean score was for “(RC5, ) Lack of governmental support and policies.” Descriptive results are shown in Table 5.

| Challenges | N | Mean | SD |

|---|---|---|---|

| FC1 | 103 | 3.91 | 1.139 |

| FC2 | 103 | 4.05 | 1.115 |

| FC3 | 103 | 4.23 | 1.012 |

| FC4 | 103 | 4.43 | 0.914 |

| FC5 | 103 | 4.24 | 0.965 |

| FC6 | 103 | 4.38 | 1.001 |

| FC7 | 103 | 4.42 | 0.880 |

| TC1 | 103 | 4.34 | 1.217 |

| TC2 | 103 | 4.33 | 1.004 |

| TC3 | 103 | 3.00 | 1.528 |

| TC4 | 103 | 3.91 | 1.366 |

| IC1 | 103 | 4.78 | 0.484 |

| IC2 | 103 | 4.54 | 0.802 |

| IC3 | 103 | 4.74 | 0.484 |

| IC4 | 103 | 4.94 | 0.235 |

| IC5 | 103 | 4.81 | 0.421 |

| IC6 | 103 | 4.69 | 0.524 |

| IC7 | 103 | 4.68 | 0.528 |

| MC1 | 103 | 4.51 | 0.895 |

| MC2 | 103 | 4.49 | 0.850 |

| MC3 | 103 | 4.38 | 1.077 |

| MC4 | 103 | 4.63 | 0.700 |

| MC5 | 103 | 4.60 | 0.705 |

| OC1 | 103 | 4.09 | 1.086 |

| OC2 | 103 | 3.96 | 1.188 |

| OC3 | 103 | 3.46 | 1.334 |

| OC4 | 103 | 4.00 | 1.111 |

| OC5 | 103 | 4.04 | 1.111 |

| OC6 | 103 | 4.07 | 1.207 |

| RC1 | 103 | 4.44 | 0.605 |

| RC2 | 103 | 4.34 | 0.722 |

| RC3 | 103 | 4.36 | 0.765 |

| RC4 | 103 | 4.49 | 0.640 |

| RC5 | 103 | 2.21 | 1.557 |

4.7.2 Normality Test for Challenges

The normality assumption of the data was conducted using SPSS 23 in this section, and the normal distribution test for the data was performed using the Shapiro–Wilk and Kolmogorov–Smirnov tests. The results of the Shapiro–Wilk and Kolmogorov–Smirnov tests, presented in Table 6 for the FBMIs, indicate that the difficulties in implementing I4.0 technologies in these two scenarios deviate from normality. Since principal component analysis does not depend on data normality [62], it was the best choice for factor analysis in exploratory factor analysis. Additionally, the survey was examined using a non-parametric method (the Kruskal-Wallis test).

| Kolmogorov-Smirnov | Shapiro–Wilk | |||

|---|---|---|---|---|

| Challenges | Statistic | Sig. | Statistic | Sig. |

| FC1 | 0.267 | 0.000 | 0.804 | 0.000 |

| FC2 | 0.279 | 0.000 | 0.739 | 0.000 |

| FC3 | 0.378 | 0.000 | 0.704 | 0.000 |

| FC4 | 0.404 | 0.000 | 0.658 | 0.000 |

| FC5 | 0.347 | 0.000 | 0.741 | 0.000 |

| FC6 | 0.402 | 0.000 | 0.652 | 0.000 |

| FC7 | 0.426 | 0.000 | 0.609 | 0.000 |

| TC1 | 0.386 | 0.000 | 0.589 | 0.000 |

| TC2 | 0.418 | 0.000 | 0.651 | 0.000 |

| TC3 | 0.249 | 0.000 | 0.840 | 0.000 |

| TC4 | 0.302 | 0.000 | 0.764 | 0.000 |

| IC1 | 0.484 | 0.000 | 0.504 | 0.000 |

| IC2 | 0.434 | 0.000 | 0.612 | 0.000 |

| IC3 | 0.463 | 0.000 | 0.560 | 0.000 |

| IC4 | 0.539 | 0.000 | 0.248 | 0.000 |

| IC5 | 0.493 | 0.000 | 0.488 | 0.000 |

| IC6 | 0.442 | 0.000 | 0.600 | 0.000 |

| IC7 | 0.437 | 0.000 | 0.608 | 0.000 |

| MC1 | 0.415 | 0.000 | 0.606 | 0.000 |

| MC2 | 0.417 | 0.000 | 0.641 | 0.000 |

| MC3 | 0.417 | 0.000 | 0.623 | 0.000 |

| MC4 | 0.458 | 0.000 | 0.557 | 0.000 |

| MC5 | 0.432 | 0.000 | 0.611 | 0.000 |

| OC1 | 0.285 | 0.000 | 0.768 | 0.000 |

| OC2 | 0.275 | 0.000 | 0.805 | 0.000 |

| OC3 | 0.250 | 0.000 | 0.865 | 0.000 |

| OC4 | 0.272 | 0.000 | 0.790 | 0.000 |

| OC5 | 0.292 | 0.000 | 0.795 | 0.000 |

| OC6 | 0.343 | 0.000 | 0.751 | 0.000 |

| RC1 | 0.319 | 0.000 | 0.733 | 0.000 |

| RC2 | 0.305 | 0.000 | 0.763 | 0.000 |

| RC3 | 0.333 | 0.000 | 0.740 | 0.000 |

| RC4 | 0.353 | 0.000 | 0.718 | 0.000 |

| RC5 | 0.374 | 0.000 | 0.721 | 0.000 |

4.7.3 EFA on the Challenges Hindering the Implementation of I4.0 in FBMIs

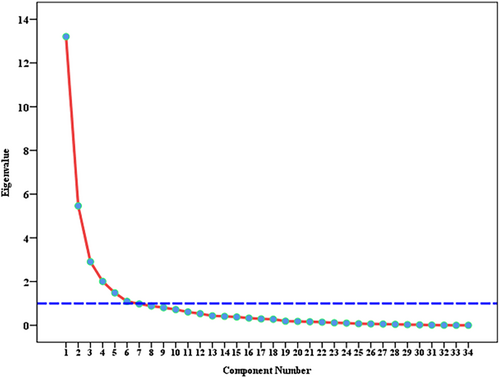

The MSA results showed that the collected data were suitable for conducting factor analysis as the value of KMO was 0.785. For conducting factor analysis, the KMO value must be greater than 0.5, as suggested by several studies (Abdol [54, 63]). EFA results supported the six-dimension structure of the study through the extraction of components with Eigen values greater than one [64], as shown in Figure 6 and Table 7.

| Component | |||||||

|---|---|---|---|---|---|---|---|

| Codes | Statement | 1 | 2 | 3 | 4 | 5 | 6 |

| FC1 | The investment costs associated with implementing I4.0 technologies | 0.776 | |||||

| FC2 | The return on investment (ROI) and cost–benefit analysis for implementing I4.0 technologies | 0.693 | |||||

| FC3 | Identifying and securing funds for implementing I4.0 technologies | 0.635 | |||||

| FC4 | Investing in new equipment, sensors, and data analytics systems can be financially burdensome | 0.848 | |||||

| FC5 | Cost for maintenance and repair of I4.0-related technologies | 0.726 | |||||

| FC6 | Costs to hire/recruit technical personnel on advanced technologies | 0.759 | |||||

| FC7 | Costs associated with training employees, consultancy services and integrating these technologies | 0.706 | |||||

| TC1 | Adopting and implementing I4.0 technologies requires specialized technical knowledge | 0.661 | |||||

| TC2 | The industry may lack the in-house expertise (or skilled workforce) or resources to navigate and utilize these technologies effectively | 0.810 | |||||

| TC3 | Difficult to understand which technologies are most relevant to specific operations and how to integrate them into their existing systems | 0.863 | |||||

| TC4 | Poor research and development on I4.0 implementation | 0.697 | |||||

| IC1 | Incorporating new I4.0 technologies into existing infrastructure | 0.738 | |||||

| IC2 | Unreliable electricity supply to the industry | 0.792 | |||||

| IC3 | Unreliable internet connectivity to the industry | 0.515 | |||||

| IC4 | Inadequate advanced software to facilitate I4.0 implementation | 0.767 | |||||

| IC5 | Absence/inadequate of additional resources for computational power and robust hardware to facilitate I4.0 implementation | 0.649 | |||||

| IC6 | Upgrading or replacing existing systems can be disruptive and time-consuming, requiring careful planning and investment | 0.690 | |||||

| IC7 | Limited resources to invest in robust cybersecurity measures, making them more vulnerable to potential breaches and data theft | 0.829 | |||||

| MC1 | Having top management which does not support I4.0 implementation | 0.787 | |||||

| MC2 | Having leaders and top management who are not committed enough to put I4.0 into practice | 0.914 | |||||

| MC3 | Having the organizationorganisation's leadership/top management who have less awareness/knowledge about I4.0 | 0.801 | |||||

| MC4 | The organizationorganisation's leadership/top management who have no vision and strategy for I4.0 implementations | 0.831 | |||||

| MC5 | Having organization which has no roadmap or implementation framework for I4.0 | 0.855 | |||||

| OC1 | Resistance to change within organizations can hinder the adoption of I4.0 technologies | 0.855 | |||||

| OC2 | Challenges in terms of employee mindset and willingness to embrace new technologies and adapt to new ways of working | 0.876 | |||||

| OC3 | Collaboration and communication challenges between various departments and teams within a company | 0.756 | |||||

| OC4 | Building a culture of innovation is a cultural challenge that companies need to overcome when implementing I4.0 | 0.859 | |||||

| OC5 | Fear of job displacement due to I4.0 implementation | 0.839 | |||||

| OC6 | The integration of connected devices and increased data collection in I4.0 raises concerns about data security and privacy | 0.874 | |||||

| RC1 | Legal issues and complications of your industry | 0.866 | |||||

| RC2 | Adopting I4.0 technologies may require industry to ensure that these technologies comply with industry-specific regulations | 0.830 | |||||

| RC3 | Meeting compliance requirements and ensuring traceability throughout the supply chain can be complex and resource-intensive | 0.813 | |||||

| RC4 | I4.0 lacks global standards and protocols, resulting in interoperability issues between different systems and technologies. This hinders the seamless integration needed for a truly connected industry. | 0.907 | |||||

| RC5 | Lack of governmental support and policies | 0.763 | |||||

The criteria for approving study constructs was through factor loading above 0.5 of each factor on their respective variables [55]. All factors presenting the challenges for implementing I4.0 technologies in FBMIs were retained in the study as they had loadings above the minimum value of 0.5, as Razali et al. [55] explained. One factor of RC5 ‘lack of governmental support and policies was dropped as it did not load in any of the six extracted components. The extracted components had a cumulative variance explanation of 76.92%.

4.7.4 Kruskal Wallis Test for Challenges of Implementing I4.0 in FBMIs

In order to investigate the variations in the difficulties associated with implementing I4.0 for FBMIs, null hypothesis testing was required. The test was conducted to ascertain whether the challenges were rated differently by industry categories (food manufacturing, beverage manufacturing, and food-beverage manufacturing). As a result, the following are the null hypothesis and alternative hypothesis based on FBMI categories:

Ho.There have been no statistical differences in the challenges of implementing I4.0 for FBMIs.

Ha.There have been statistical differences in implementing I4.0 for FBMIs.

Using the Kruskal Wallis test for grouping variables, Table 8 shows no significant differences for most challenges of implementing I4.0 in FBMIs between food manufacturing, beverage manufacturing and those that produce both food and beverage. There is a significant difference between FBMIs on TC1 to TC3 and MC5. However, there is a significant difference on FC1 to FC7, TC4, IC1 to IC7, MC1 to MC4, OC1 to OC6, RC1 to RC5.

| Challenges | Chi-square | df | Asymp. sig. | Decision |

|---|---|---|---|---|

| FC1 | 1.121 | 2 | 0.571 | Ho retained |

| FC2 | 0.027 | 2 | 0.987 | Ho retained |

| FC3 | 1.918 | 2 | 0.383 | Ho retained |

| FC4 | 3.291 | 2 | 0.193 | Ho retained |

| FC5 | 0.654 | 2 | 0.721 | Ho retained |

| FC6 | 1.473 | 2 | 0.479 | Ho retained |

| FC7 | 1.645 | 2 | 0.439 | Ho retained |

| TC1 | 7.978 | 2 | 0.019 | Ho rejected |

| TC2 | 5.994 | 2 | 0.05 | Ho rejected |

| TC3 | 9.543 | 2 | 0.008 | Ho rejected |

| TC4 | 4.723 | 2 | 0.094 | Ho retained |

| IC1 | 3.834 | 2 | 0.147 | Ho retained |

| IC2 | 2.843 | 2 | 0.241 | Ho retained |

| IC3 | 0.126 | 2 | 0.939 | Ho retained |

| IC4 | 0.316 | 2 | 0.854 | Ho retained |

| IC5 | 1.185 | 2 | 0.553 | Ho retained |

| IC6 | 2.26 | 2 | 0.323 | Ho retained |

| IC7 | 0.534 | 2 | 0.766 | Ho retained |

| MC1 | 3.252 | 2 | 0.197 | Ho retained |

| MC2 | 3.914 | 2 | 0.141 | Ho retained |

| MC3 | 3.254 | 2 | 0.197 | Ho retained |

| MC4 | 1.047 | 2 | 0.593 | Ho retained |

| MC5 | 6.974 | 2 | 0.031 | Ho rejected |

| OC1 | 3.262 | 2 | 0.196 | Ho retained |

| OC2 | 0.476 | 2 | 0.788 | Ho retained |

| OC3 | 1.147 | 2 | 0.564 | Ho retained |

| OC4 | 0.615 | 2 | 0.735 | Ho retained |

| OC5 | 1.271 | 2 | 0.53 | Ho retained |

| OC6 | 2.667 | 2 | 0.263 | Ho retained |

| RC1 | 0.218 | 2 | 0.897 | Ho retained |

| RC2 | 1.283 | 2 | 0.527 | Ho retained |

| RC3 | 0.21 | 2 | 0.9 | Ho retained |

| RC4 | 0.65 | 2 | 0.722 | Ho retained |

| RC5 | 0.024 | 2 | 0.988 | Ho retained |

The statistical result are showed that challenges having no significant differences, for financial challenges “(FC1) The investment costs associated with implementing I4.0 technologies” with χ2 (2, N = 103) = 1.121, p = 0.571 > 0.05 probability, “(FC2) The return on investment (ROI) and cost-benefit analysis for implementing I4.0 technologies” with χ2 (2, N = 103) = 0.027, p = 0.987 > 0.05 probability, “(FC3) Identifying and securing funds for implementing I4.0 technologies” with χ2 (2, N = 103) = 1.918, p = 0.383 > 0.05 probability, “(FC4) Investing in new equipment, sensors, and data analytics systems can be financially burdensome” with χ2 (2, N = 103) = 3.291, p = 0.193 > 0.05 probability, “(FC5) Cost for maintenance and repair I4.0-related technologies” with χ2 (2, N = 103) = 0.654, p = 0.721 > 0.05 probability, “(FC6) Costs to hire/recruit technical personnel on advanced technologies” with χ2 (2, N = 103) = 1.473, p = 0.479 > 0.05 probability, “(FC7) Costs associated with training employees, consultancy services and integrating these technologies” with χ2 (2, N = 103) = 1.645, p = 0.439 > 0.05 probability.

For technical expertise “(TC4) Poor research and development on I4.0 implementation” with χ2 (2, N = 103) = 4.723, p = 0.094 > 0.05 probability. For infrastructure challenges “(IC1) Incorporating new I4.0 technologies into existing infrastructure” with χ2 (2, N = 103) = 3.834, p = 0.056 > 0.05 probability, “(IC2) Unreliable electricity supply to the industry” with χ2 (2, N = 103) = 2.843, p = 0.241 > 0.05 probability, “(IC3) Unreliable internet connectivity to the industry” with χ2 (2, N = 103) = 0.126, p = 0.939 > 0.05 probability, “(IC4) Inadequate advanced software to facilitate I4.0 implementation” with χ2 (2, N = 103) = 0.316, p = 0.056 > 0.05 probability, “(IC5) Absence/inadequate of additional resources for computational power and robust hardware to facilitate I4.0 implementation” with χ2 (2, N = 103) = 3.834, p = 0.056 < 0.05 probability, “(IC6) Upgrading or replacing existing systems can be disruptive and time-consuming” with χ2 (2, N = 103) = 2.26, p = 0.323 > 0.05 probability, “(IC7) Limited resources to invest in robust cybersecurity measures, making them more vulnerable to potential breaches and data theft” with χ2 (2, N = 103) = 0.534, p = 0.766 > 0.05 probability.

For leadership and management challenges “(MC1) Having top management which does not support I4.0 implementation” with χ2 (2, N = 103) = 3.252, p = 0.197 > 0.05 probability, “(MC2) Having leaders and top management who are not committed enough to put I4.0 into practice” with χ2 (2, N = 103) = 3.914, p = 0.141 > 0.05 probability, “(MC3) Having organisation's leadership/top management who have less awareness/knowledge about I4.0” with χ2 (2, N = 103) = 3.254, p = 0.197 > 0.05 probability, “(MC4) Having organisation's leadership/top management who have no vision and strategy for I4.0 implementations” with χ2 (2, N = 103) = 1.047, p = 0.593 > 0.05 probability.

For organizational cultural challenges “(OC1) Resistance to change within organisations can hinder the adoption of I4.0 technologies” with χ2 (2, N = 103) = 3.262, p = 0.196 > 0.05 probability, “(OC2) Challenges in terms of uemployee mind set and willingness to embrace new technologies and adapt to new ways of working” with χ2 (2, N = 103) = 0.476, p = 0.788 > 0.05 probability, “(OC3) Collaboration and communication challenge between various departments and teams within a company” with χ2 (2, N = 103) = 1.147, p = 0.564 > 0.05 probability, “(OC4) Building a culture of innovation is a cultural challenge that companies need to overcome when implementing I4.0” with χ2 (2, N = 103) = 0.615, p = 0.735 > 0.05 probability, “(OC5) Fear of job displacement due to I4.0 implementation” with χ2 (2, N = 103) = 1.271, p = 0.530 > 0.05 probability, “(OC6) The integration of connected devices and increased data collection in I4.0 raises concerns about data security and privacy” with χ2 (2, N = 103) = 2.667, p = 0.263 > 0.05 probability.

For regulatory compliance and legal issues challenges “(RC1) Legal issues complication of your industry” with χ2 (2, N = 103) = 0.218, p = 0.897 > 0.05 probability, “(RC2) Adopting I4.0 technologies may require industry to ensure that these technologies comply with industry-specific regulations” with χ2 (2, N = 103) = 1.283, p = 0.527 > 0.05 probability, “(RC3) Meeting compliance requirements and ensuring traceability throughout the supply chain can be complex and resource-intensive” with χ2 (2, N = 103) = 0.210, p = 0.900 > 0.05 probability, “(RC4) I4.0 lacks global standards and protocols, resulting in interoperability issues between different systems and technologies” with χ2 (2, N = 103) = 0.650, p = 0.722 > 0.05 probability, “(RC5) Lack of governmental support and policies” with χ2 (2, N = 103) = 0.024, p = 0.988 > 0.05 probability.

The result of p < 0.05 denotes that there is a considerable variation in the challenges hindering the implementation of I4.0 among the FBMIs, as was observed in TC1 (p = 0.019), TC2 (p = 0.05), TC3 (p = 0.008) and MC5 (p = 0.031).

4.8 Strategies for Implementation of I4.0 Technologies in FBMIs

The responses to the proposed strategies (Table 9) for implementing I4.0 in FBMIs were analyzed in this section. The mean score and RII for each strategy were calculated. The scores showed that ST9 “Embrace data-driven decision making” was the strategy with the highest mean score of 4.8 and RII = 0.959, which indicates that respondents consider this strategy to be most important toward the implementation of I4.0 technologies in FBMIs, the lowest ranked strategy was ST21 “Training leaders and top management regarding the economic benefits of I4.0 implementation” with a mean score of 2.98 and RII = 0.596. all strategies were retained due to EFA since their extraction values were above 0.5.

| Descriptive statistics | EFA | |||

|---|---|---|---|---|

| Code | Strategies | Mean | RII | Extraction |

| ST1 | Conduct a technology readiness assessment to establish the readiness level that guides the nature of I4.0 technologies required | 4.48 | 0.895 | 0.711 |

| ST2 | Develop a clear digital transformation strategy | 4.69 | 0.938 | 0.742 |

| ST3 | Foster an organizational culture of innovation and learning | 4.58 | 0.917 | 0.848 |

| ST4 | Collaborate with I4.0 technology providers (e.g., AI, IoT, RFID, etc.) | 4.52 | 0.905 | 0.841 |

| ST5 | Start with industrial pilot projects | 4.55 | 0.911 | 0.889 |

| ST6 | Recruit the in-house expertise (or skilled workforce) or resources to navigate and utilize these technologies effectively | 4.5 | 0.901 | 0.894 |

| ST7 | Enhance policy and regulations that support technology transfer and incubation | 4.44 | 0.887 | 0.754 |

| ST8 | Seek government support for subsidizing the cost of importing I4.0-related technologies | 4.45 | 0.889 | 0.884 |

| ST9 | Embrace data-driven decision-making | 4.8 | 0.959 | 0.538 |

| ST10 | Address security and privacy concerns | 4.41 | 0.882 | 0.859 |

| ST11 | Conduct training and skill development for all employees | 4.59 | 0.918 | 0.897 |

| ST12 | Translating industrial business needs to IT requirements | 4.6 | 0.920 | 0.891 |

| ST13 | Plan how to identify and secure funds for implementing I4.0 technologies | 4.49 | 0.897 | 0.952 |

| ST14 | Incorporating new I4.0 technologies into existing infrastructure | 4.52 | 0.905 | 0.932 |

| ST15 | Ensure reliable electricity supply to the industry | 4.64 | 0.928 | 0.635 |

| ST16 | Stabilize reliable internet connectivity to the industry | 4.38 | 0.876 | 0.892 |

| ST17 | Procure advanced software to facilitate I4.0 implementation | 4.4 | 0.880 | 0.923 |

| ST18 | Facilitate the availability of additional resources for computational power and robust hardware to facilitate I4.0 implementation | 4.64 | 0.928 | 0.966 |

| ST19 | Foster enacting I4.0 global or regional standards and protocols, resulting in interoperability issues between different systems and technologies | 4.37 | 0.874 | 0.956 |

| ST20 | Establish vision and strategy for I4.0 implementation | 4.63 | 0.926 | 0.798 |

| ST21 | Training leaders and top management regarding the economic benefits of I4.0 implementation | 2.98 | 0.596 | 0.501 |

Therefore, all strategies had mean scores above 4.0, corresponding to “agree” in the Likert scale measurement, which implies that respondents agree to the proposed strategies except ST21 “Training leaders and top management regarding the economic benefits of I4.0 implementation” which had a mean score of 2.98.

Focus group discussions consisted of a different group of experts from FBMIs. Three FBMIs involved members who did not rank strategies during the data collection. Three experts came from the food industry, three from the beverage industry, and three from the industry that produces both food and beverages. They included engineers and production managers for particular industries. The focus group was carried out at each purposively selected industry.

4.9 Discussion

The study's main objective is to assess challenges and propose strategies for implementing I4.0 in FBMIs. Proposing strategies and assessing challenges were first preceded by assessing I4.0 awareness levels for FBMIs in Dar es Salaam and Pwani Regions. The results indicate a high level of awareness from 103 FBMIs. Also, the findings demonstrated no significant differences in the awareness level among categories of FBMIs. Such results were also observed by Ntamulyango [22], who assessed awareness among beverage industries in Dar es Salaam. However, there is a difference between the results of the current study and Ntamulyango's [22] study. Ntamulyango [22] only involved beverage industries, while the current study involved food and beverages. Therefore, the awareness level of implementing I4.0 in FBMIs can be generalized. Likewise, when Maganga [37] developed the transition framework for the selected MIs in Dar es Salaam and Pwani regions, his study concluded that the awareness level for the manufacturing mainly on I4.0 for the quality issues was found to be high.

The awareness level was also confirmed through the performed t-test. For example, the independent t-test was conducted to compare awareness levels on the applicability of I4.0 in FBMIs for food and beverage. Results concluded that there were no significant differences in the awareness level between food and beverages for six items with t-values greater than 1.96 [58]; AW3—“Have you attended any workshop/training or seminar regarding I4.0 or digital transformation technologies in the last 2 years?”, AW4—“Is your organisation aware of the current technologies associated with I4.0?”, AW7—“Are there any financial arrangements for the implementation of I4.0 technologies?”, AW8—“Has an I4.0 strategy been defined in your company for the next five years?”, AW9—“Is there a framework/roadmap for planning the activities for the implementation of I4.0 solutions in your company?”, AW10—“Is there any involvement, support, or experience of top management toward the implementation of I4.0?” and AW13—“Are you aware that the digital transformation to I4.0 could improve your industry's competitiveness at the international stage?” The remaining items displayed a significant difference in the awareness level with a t-value of less than 1.96 [59]. Table 3 shows the results for the independent t-test and awareness level on the applicability of I4.0 in FBMIs. The t-values can be negative or positive in Table 3; they mean that they lie to the left of the mean [60].

The next stage was to investigate the variations in the difficulties associated with implementing I4.0 for FBMIs; null hypothesis testing was required, as suggested by Tay et al. [65]. The test was conducted to ascertain whether the challenges were rated differently by industry categories (food manufacturing, beverage manufacturing, and food-beverage manufacturing). So, the following are the null hypothesis and alternative hypothesis based on FBMI categories: Ho: There have been no statistical differences in the challenges of implementing I4.0 for FBMIs and Ha: There have been statistical differences in implementing I4.0 for FBMIs.

Thus, the study adopted the Kruskal Wallis test for grouping variables as per Nimawat and Das Gidwani [34]. Results concluded that there were no significant differences for most challenges of implementing I4.0 in FBMIs between food manufacturing, beverage manufacturing and those that produce both food and beverage. There is a significant difference between FBMIs on TC1, TC2, TC3 and MC5. When comparing these challenges with other studies, the majority are similar, except for some that seem unique for the FBMIs, specifically in Tanzania. For example, even though I4.0 concepts emerged in Germany in 2011, scant studies in Tanzania focus on assessing challenges and conclude that “Poor research and development on I4.0 implementation” was one of them. Existing studies, including Ntamulyango [22] and Maganga [37], did not conclude that the absence of research and development focusing on I4.0 is one of them.

Having assessed challenges affecting the implementation of I4.0 in FBMIs, the next stage was looking for the potential solution toward those challenges. For example, Santos and Martinho [66] emphasized the need for implementable strategies to address challenges. Thus, the study proposed strategies for implementing I4.0 in the FBMIs. Each strategy's mean score and RII were calculated. The scores showed that ST9 “Embrace data-driven decision making” was the strategy with the highest mean score of 4.8 and RII = 0.959, which indicates that respondents consider this strategy to be most important toward the implementation of I4.0 technologies in FBMIs, the lowest ranked strategy was ST21 “Training leaders and top management regarding the economic benefits of I4.0 implementation” with mean score 0f 2.98 and RII = 0.596. all strategies were retained due to EFA since their extraction values were above 0.5. The obtained strategies align with various I4.0 strategies proposed by previous studies, including Vidanagamachchi and Lanka [35], Mpangule [36], Maganga and Taifa [27], Khin and Kee [15], Nguyen and Luu [24], Bettiol et al. [12], Khin and Kee [15] and Oria et al. [11].

4.10 Significance of the Study

This research has academic and practical implications. Since the research focused on understanding the level of I4.0 adoption in FBMIs, it is evident that the literature contributes to the existing one. Moreover, practitioners must realize the potential of I4.0, particularly how digital processes are going. Various challenges and strategies for I4.0 adoption by FBMIs are addressed, which can also serve as a yardstick for FBMIs, policymakers, and the government in Tanzania to establish foundations for I4.0 logistics to be employed in FBMIs to maintain the production of goods sustainably. Consequently, implementing the strategies is anticipated to improve the FBMIs in adopting I4.0, thus accruing associated benefits. The benefits would generally lead to optimized costs, quality, flexibility, dependability, speed, connectivity, innovation, transparency, responsiveness, and real-time inventory management [67, 68].

5 Conclusion and Recommendations

The study mainly assessed challenges and established I4.0 implementation strategies for FBMIs. The main objective was ascertained by three specific objectives: determining I4.0 awareness level, assessing challenges toward implementing I4.0 by FBMIs, and proposing I4.0 implementation strategies for FBMIs. Primary data were gathered through a closed-ended questionnaire from 103 medium and large FBMIs in Dar es Salaam and Pwani regions. Data validity and reliability were tested using SPSS 23, where p-values were obtained for validity testing while Cronbachs Alpha values were determined for the reliability of the collected questionnaires. All p-values were less than 0.05 while Cronbach's Alpha values were above 0.7, thus implying that both the questionnaires to collect data and the collected data were valid and reliable, respectively. Cronbach's Alpha values for the awareness was 0.900, challenges (0.909) and strategies (0.971). The normality of the data was tested using Shapiro–Wilk and Kolmogorov–Smirnov tests, and then the MSA was conducted in SPSS 23 through KMO and Bartlett's sphericity test. In assessing the reliability of the sampling adequacy, the KMO value had to be over 0.5, and the significance level for Bartlett's test was below 0.05, thus suggesting that there is a substantial correlation in the collected data.

Assessing the awareness level, determining challenges, and establishing strategies were all accomplished by establishing t-values for the awareness level, exploratory factor analysis, and Kruskal Wallis test for testing hypothetical challenges of implementing I4.0 in FBMIs. Likewise, descriptive analysis (i.e., mean scores), RII, and exploratory factor analysis were performed to propose strategies. Strategies were validated through a focus group discussion involving three FBMIs.

The independent t-test was conducted to compare awareness levels on the applicability of I4.0 in FBMIs. There was no significant difference in the awareness level between food and beverages for six items with t-values greater than 1.96. The score for each component that assessed the I4.0 awareness level revealed that employees were more informed about the benefits of adopting I4.0, with a mean score of 4.78, thus ranking first. The prospect of I4.0 to improve the industry's competitiveness on the international stage was ranked second in terms of awareness by employees, with a mean score of 4.65, corresponding to full awareness. The other aspect employees were fully aware of was the possibility of the company improving market share through implementing I4.0 technologies, with a mean score of 4.30. Respondents were not aware of only one aspect, that is, the framework or roadmap for planning the activities for implementing I4.0, with a mean score of 2.44. This generalizes that most FBMIs have not fully established a roadmap for using I4.0 technologies.

The study found no significant difference in awareness levels for nine I4.0 technologies among the FBMIs, with most items having t-values greater than 1.96. However, the remaining items showed a significant difference with t-values less than 1.96. Likewise, the study also investigated the challenges of implementing I4.0 in FBMIs using null hypothesis testing. The results showed no significant differences in the challenges for financial aspects, such as investment costs, ROI, identifying and securing funds, the financial burden of investing in new equipment, sensors, and data analytics systems, maintenance and repair costs, hiring/recruiting technical personnel, and costs associated with training employees and integrating these technologies. The study also found no significant differences in the costs associated with training employees and consulting services.

Lastly, the study proposed strategies for implementing I4.0 in the FBMIs. Each strategy's mean score and RII were calculated. The scores showed that “embracing data-driven decision making” was the strategy with the highest mean score of 4.8 and RII = 0.959, which indicates that respondents consider this strategy to be most important toward the implementation of I4.0 technologies in FBMIs, the lowest ranked strategy was ST21 “Training leaders and top management regarding the economic benefits of I4.0 implementation” with mean score 0f 2.98 and RII = 0.596. all strategies were retained due to EFA since their extraction values were above 0.5. In summary, the implementation of the majority of I4.0-related technologies is at a high level; the findings showed that the overall mean score was 3.75, corresponding to “level 4” on the five-point Likert scale of awareness. Also, some challenges should be tackled to implement I4.0-related technologies smoothly. Consequently, such challenges can be addressed by implementing the proposed strategies.

5.1 Recommendation

Although the FBMIs have demonstrated a high level of I4.0 awareness of technologies and the general I4.0 conceptualization, it is recommended that stakeholders keep fostering the emphasis on implementing all pertinent technologies fully. This would enable industries to accrue benefits from the full implementation of I4.0 in such industries. The study recommends implementing the proposed strategies, which should be fostered by the top management commitment and fully supported by allocating a sufficient budget. Since the research focused on understanding the level of I4.0 awareness in FBMIs, practitioners must realize the potential of I4.0, particularly how I4.0-leveraged technologies can impact industries. Various strategies for I4.0 adoption by FBMIs are addressed, which can also serve as a yardstick for FBMIs and other pertinent stakeholders to establish foundations for I4.0 logistics to be employed in FBMIs to produce goods sustainably.

5.2 Recommendations for Future Studies

The study explored awareness, challenges, and proposed strategies by engaging FBMIs within the Dar es Salaam and Pwani regions. Thus, other studies can be conducted in the rest of the regions. Also, only the FBMIs were the focused industries; other manufacturing industries, including tobacco, metal, plastic, textiles, leather, and mining, should be investigated to establish awareness levels and propose vital strategies. Moreover, only large and medium industries were involved, even for food and beverages; there is room for investigating challenges that hinder micro and small enterprises in implementing some I4.0-related technologies. It might not be easy for micro and small enterprises to implement all I4.0 technologies, but some technologies should assist such industries in accruing the benefits of deploying I4.0.

Author Contributions

Ismail W. R. Taifa: resources, data curation, project administration, formal analysis, writing – review and editing, methodology, investigation, software, conceptualization, writing – original draft, validation. Ikupa Mwakagamba: conceptualization, investigation, funding acquisition, writing – original draft, methodology, visualization, software, formal analysis, resources.

Conflicts of Interest

The authors declare no conflicts of interest.

Open Research

Data Availability Statement

Research data are not shared.