Insights on advanced g-C3N4 in energy storage: Applications, challenges, and future

Abstract

Graphitic carbon nitride (g-C3N4) is a highly recognized two-dimensional semiconductor material known for its exceptional chemical and physical stability, environmental friendliness, and pollution-free advantages. These remarkable properties have sparked extensive research in the field of energy storage. This review paper presents the latest advances in the utilization of g-C3N4 in various energy storage technologies, including lithium-ion batteries, lithium-sulfur batteries, sodium-ion batteries, potassium-ion batteries, and supercapacitors. One of the key strengths of g-C3N4 lies in its simple preparation process along with the ease of optimizing its material structure. It possesses abundant amino and Lewis basic groups, as well as a high density of nitrogen, enabling efficient charge transfer and electrolyte solution penetration. Moreover, the graphite-like layered structure and the presence of large π bonds in g-C3N4 contribute to its versatility in preparing multifunctional materials with different dimensions, element and group doping, and conjugated systems. These characteristics open up possibilities for expanding its application in energy storage devices. This article comprehensively reviews the research progress on g-C3N4 in energy storage and highlights its potential for future applications in this field. By exploring the advantages and unique features of g-C3N4, this paper provides valuable insights into harnessing the full potential of this material for energy storage applications.

1 INTRODUCTION

The energy crisis and environmental pollution have become important factors restricting human progress.1-3 At present, fossil fuels still dominate energy consumption, and the increasing demand for energy and the depletion of fossil fuels have led to a continuous deterioration of the supply–demand balance.4-6 The problems of atmospheric pollution, acid rain, climate change, glacier melting, and the greenhouse effect caused by fossil energy consumption have seriously affected human normal life.7-10 Therefore, it is urgent to develop clean and renewable secondary energy represented by solar and wind energy. Due to the uneven geographical distribution and unstable output of clean energy sources, however, the energy utilization rate of renewable energy is very low, resulting in resource waste. Therefore, it is urgent to develop large-scale energy storage systems and store clean energy in other forms.11, 12

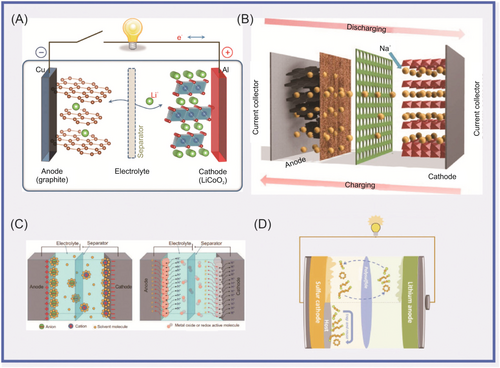

Lithium-ion batteries (LIBs), sodium-ion batteries (SIBs), and other representative secondary batteries are widely used in electrochemical energy storage systems.13-20 They have become an important means to solve energy, resource, and environmental problems due to their recyclability and environmental friendliness.21, 22 Secondary batteries, which have the advantages of high energy density, short response time, and good flexibility, are electrochemical energy storage/release devices that utilize redox reactions to achieve reversible conversion between electrical and chemical energy.23-28 Their working principle lies in the reversible deinsertion of electrolyte ions between positive and negative electrode materials to achieve energy storage. According to the different electrolyte ion/electrode materials, the secondary batteries can be divided into LIBs, lithium-sulfur batteries (LSBs), SIBs, potassium-ion batteries (PIBs), and so forth. Figure 1 is a schematic illustration of the working principle of energy storage devices.29-32

1.1 A brief introduction to graphitic carbon nitride (g-C3N4)

Battery materials encompass various components, notably electrodes, separators, and more.33, 34 They serve as essential elements in energy storage devices. For researchers, there is a growing interest in investigating batteries with high specific capacity, superior energy density (both bulk and quality), elevated power density, prolonged cycle life, and impeccable safety standards, leading to challenging yet promising research avenues.35-40 Among these materials, electrodes and diaphragms emerge as pivotal focuses for energy storage device advancements.41-43 Specifically, electrode materials are categorized into positive and negative types, each presenting its unique merits and drawbacks in the context of energy storage.44, 45 The primary issues concerning positive electrode materials include limited specific capacity, phase transition during charge–discharge cycles, cycle life, and interface reactions.46-48 These challenges call for dedicated research and development efforts to overcome these limitations and unlock the full potential of energy storage technologies. The primary challenges associated with anode materials encompass electrode material agglomeration, specific capacity, safety concerns, phase and volume changes during charge–discharge cycles, cycle life, and rate performance.49, 50 Researchers are actively exploring various strategies to address these issues, such as nanostructure design, lattice doping, grain boundaries, surface treatment, particle size reduction, carbon coating, element doping, and the development of composite materials.51-55 Furthermore, the separator plays a vital role in a battery, not only ensuring its fundamental functionalities but also significantly impacting its overall safety. Careful attention and research are devoted to enhancing the separator's properties to guarantee the reliable and secure operation of batteries.56-58 Simultaneously, the diaphragm serves as the carrier of the electrolyte, playing a pivotal role as it becomes infused with the electrolyte, thereby establishing an essential pathway for ion transport. Consequently, the diaphragm's characteristics significantly influence the electrolyte's wettability, pore structure, and overall electrochemical performance of the energy storage device. Researchers acknowledge the critical impact of the diaphragm's properties on optimizing the device's efficiency and functionality, leading to extensive investigations in this domain.59-63

There are four main kinds of synthesis methods for the preparation of g-C3N4, including thermal polymerization method, solvothermal method, template-assisted method, and photopolymerization method. Among these, g-C3N4 is easily fabricated by thermal polymerization of abundant nitrogen-rich precursors such as melamine,64-69 dicyandiamide,70-73 cyanamide,74, 75 urea,76, 77 thiourea,78 and ammonium thiocyanate.79 g-C3N4 exhibits two fundamental structural units: the triazine ring (C3N4) and the tris-triazine ring (C6N7).65, 80 The triazine ring comprises N atoms outside the ring connected to a single C3N4 unit, while the tris-triazine ring consists of N atoms outside the ring linked with three polymerized C6N7 units.77, 81-84 These structural units, composed of arranged C and N atoms, form a gap-like configuration, and each unit extends outward, connecting with N atoms as nodes, resulting in a planar layered structure with limitless expansion possibilities. To enhance the applicability of g-C3N4 in energy storage devices, incorporating functional groups into its molecular structure is advantageous. The introduction of such functional groups can improve the material's performance and properties, making it more suitable for energy storage applications.85-87 Researchers are exploring this avenue to design g-C3N4 molecules with tailored functional groups to optimize their performance in energy storage devices. This development holds great promise for advancing energy storage technologies.

The discovery of g-C3N4 as a metal-free conjugated semiconductor photocatalyst for H2 evolution was first reported by Wang et al. in 2009,88 which may also lead to research and exploration of the potential for application of inorganic conjugated semiconductor materials in energy storage.89-91 It was found that the basic tectonic units that establish allotropes of g-C3N4 are triazine (C3N3) and tri-s-triazine/heptazine (C6N7) rings.92, 93

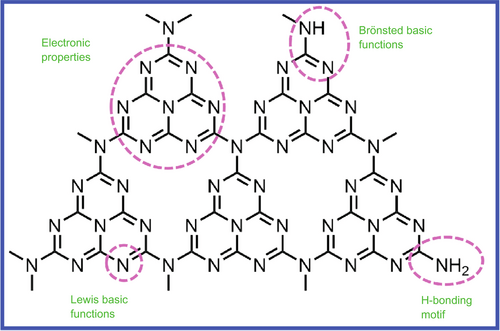

Since polymeric g-C3N4 consists of earth-abundant carbon and nitrogen elements, it is versatile in providing reactions to alter its surface activity without manifestly changing its theoretical structure and composition. Due to the polymeric feature of g-C3N4, its surface chemistry can be easily modulated by means of surface engineering at the molecular level. As shown in Figure 2, the surface of g-C3N4 is rich in amino groups (–NH2) and nitrogen, which is conducive to its functionalization.94, 95 Furthermore, it is the most stable among the five phases (α, β, cubic, pseudocubic, and graphitic) of C3N4, and establishes the π-conjugated electronic structures owing to the presence of sp2-hybridized carbon and nitrogen.96 g-C3N4 has a moderate band gap of 2.7–2.8 eV, resulting in the onset of visible light absorption at around 450–460 nm.81 g-C3N4 is thermally stable up to 600°C in air, which can be ascribed to the aromatic C–N heterocycles. g-C3N4 is a metal-free, earth-abundant, and nontoxic material with a polymeric two-dimensional (2D) structure.97 It has been widely used in pollutant degradation, water splitting, and solar energy transfer due to its outstanding photocatalytic and optoelectronic properties.91, 98-100 The lone pair of its nitrogen atoms and electron delocalization endows the tri-s-triazine derivatives, including g-C3N4, with a unique electronic structure,101-103 which was controllable due to their tunable band gap. Furthermore, the excellent thermal and chemical stability of g-C3N4 make it one of the most promising semiconductor materials in this exciting research field.

2D g-C3N4 materials possess outstanding physical and chemical properties, rendering them highly versatile in various applications. One significant advantage lies in their capability to act as carriers for loading diverse nanomaterials. This property enables them to serve as excellent platforms for hosting and supporting different nanoparticles (NPs), thus facilitating the development of advanced composite materials with enhanced functionalities. Additionally, g-C3N4 materials exhibit the ability to encapsulate and protect other materials. By acting as protective shields, they safeguard sensitive components from external factors, such as harsh environments or chemical reactions, thereby preserving the integrity and performance of the encapsulated materials. These remarkable attributes open up promising avenues for their utilization in numerous fields. As carriers and protective agents, 2D g-C3N4 materials hold great application prospects and significant value for further advancements in various industries and research areas.

1.2 Scope of this review

To date, numerous excellent review papers have focused on key materials for rechargeable batteries, emphasizing safety performance, energy density, and battery cost. To the best of our knowledge, however, there is a dearth of articles discussing multifunctional materials. This significant gap in the literature has motivated us to thoroughly review and elucidate the recent progress achieved by using g-C3N4 for the fabrication of high-performance rechargeable batteries and supercapacitors. In this comprehensive review, we primarily focus on the application of g-C3N4 as a multifunctional material in energy storage devices. Additionally, we explore potential future developments and research directions in the field of energy storage devices. With its unique atomic structure, electronic configuration, and chemical stability as a triazine framework material, g-C3N4 has found widespread use in energy storage applications. Its distinctive electronic structure facilitates structural regulation and the construction of conjugated systems, enabling multifunctionality and expanding its application in electrode materials and electrolytes for energy storage devices. This review serves as a comprehensive guide, shedding light on the promising advances and future prospects of utilizing g-C3N4 in energy storage devices. By examining the distinctive features and capabilities of g-C3N4, this paper not only provides valuable insights but also paves the way for further exploration and innovation in the realm of multifunctional materials for energy storage.

2 THE ROLES OF G-C3N4 IN ENERGY STORAGE DEVICES

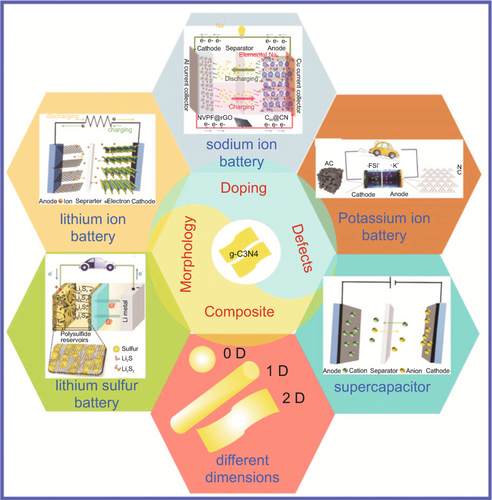

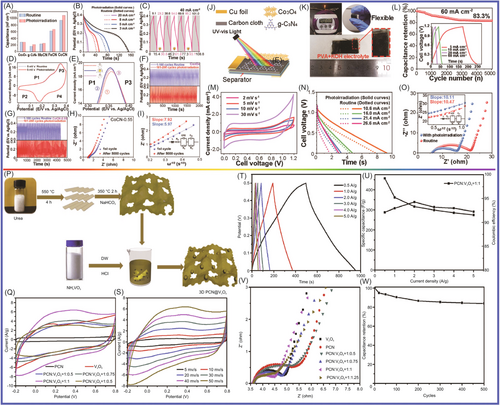

g-C3N4 has been the most widely reported member of the carbon nitride family, as its macropores serve as storage sites for alkali metal atoms. The adsorption of Li atoms at these triangular pore sites occurs at a high adsorption energy (Ead) of ~4.2 eV, exceeding the desorption energy (3 eV) of bulk Li, resulting in ineffective desorption. The modulation of vacancies has been an attractive strategy to improve the conductivities of semiconductor materials for high-performance electrodes in LIBs. g-C3N4 can be regarded as a special nitrogen-doped carbon material (C-NC), which has nitrogen-rich properties and good physical and chemical stability. It has great potential applications in electrochemical storage (SIBs, LIBs, LSBs, supercapacitors, etc.) and other fields in Figure 3. However, there are several challenges that researchers and engineers need to address for its successful application in these devices, including low conductivity, limited charge storage structural stability, scalability production cost, and electrolyte compatibility, which limits its application in electrochemistry. To improve the level of application, it is necessary to optimize and modify the material.

2.1 g-C3N4 applied in LIBs

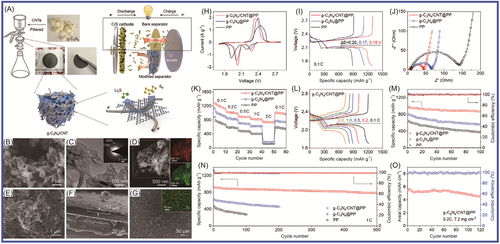

With the deepening of environmental pollution and the energy crisis, it is imperative to develop clean, efficient, and sustainable electrochemical energy storage devices.104, 105, 107-109 When graphite was used as the negative electrode material for commercial LIBs, it had a theoretical low specific capacity (372 mAh g−1) and slow lithium-ion diffusion, which made it unable to meet the capacity requirements of rapidly upgraded portable electronic devices and electric vehicles.110, 111 g-C3N4 as a negative electrode material for LIBs has a high theoretical specific capacity (1165.7 mAh g−1) and high stability, exhibiting high conductivity and low reversible capacity.112-114 The optimization modification of g-C3N4 could overcome the shortcomings of low conductivity and irreversible capacity of the material by removing some graphite N from the structure.115, 116

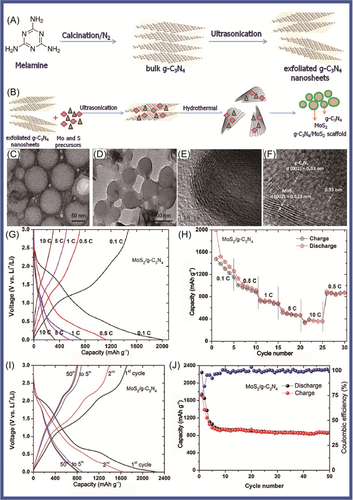

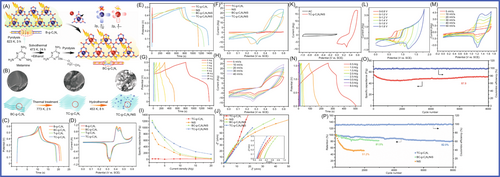

Chen and colleagues117 reported that N-doped graphene/porous g-C3N4 nanosheets supporting layered-MoS2 hybrid, which were applied in LIB anode, had been designed and prepared. To form a good 2D multilayered nanostructure, few-layer MoS2 nanosheets were highly dispersed on the N-doped graphene/porous g-C3N4 nanosheet matrix. Benefiting from this unique structure, the hybrid nanosheets exhibited superior electrochemical performance, which included excellent cycling stability (maintaining 91% capacity after 100 cycles), a high rate capability (retaining 83% capacity from 50 to 500 mA g−1), and a large capacity (achieving more than 800 mAh g−1 at 100 mA g−1). Wang and colleagues118 designed and prepared g-C3N4-rGO, where rGO is reduced graphene oxide via an in situ chemical synthetic approach, which considered differing g-C3N4/rGO ratios in LIBs. The g-C3N4-rGO exhibited stable and reversible capacity (1525 mAh g−1 at current density of 100 mA g−1 after 50 cycles). It delivered high performance (943 mAh g−1 at the large current density of 1000 mA g−1). The high electrochemical performance of g-C3N4-rGO was attributed to the specific characteristics of its unique nanostructure (covalent interactions between the two moieties, good conductivity, and high special surface area of the nanocomposite [NC]) of g-C3N4-rGO. Li et al.119 reported that Zn2GeO4 NPs and ultrathin g-C3N4 layers (Zn2GeO4/g-C3N4 hybrids) were synthetized by a facile solution approach. Zn2GeO4/g-C3N4 served as anode in LIBs, which delivered high performance (1370 mAh g−1 at 200 mA g−1 after 140 cycles and excellent rate capability of 950 mAh g−1 at 2000 mA g−1). This excellent performance was mainly attributable to Zn2GeO4 and g-C3N4, in which the Zn2GeO4 NPs contributed high capacity. The Zn2GeO4 NPs were loaded on g-C3N4 layers via in situ growth, in which the g-C3N4 layers acted as an effective substrate for nucleation. To improve the electrochemical performance of graphene-based materials in LIBs, a novel composite of active Fe2O3 NPs encapsulated in g-C3N4/graphene hybrid nanosheets (Fe2O3/CN-G) was developed by Gao and colleagues.120 The Fe2O3/CN-G was applied in LIBs as an anode, which showed excellent electrochemical behavior (large reversible capacity of 1023 mAh g−1, great Coulombic efficiency of 97.6%). The 2D sandwich-type hybrid nanosheets were constructed from porous g-C3N4 and highly conductive graphene, which offered readily accessible channels and sufficient conductive pathways for ionic diffusion and charge transport due to the shortcomings of pure g-C3N4 material, in which poor conductivity and serious irreversible capacity loss were pronounced, owing to its high nitrogen content. Mao and colleagues121 prepared nitrogen-deficient g-C3N4 (ND-g-C3N4), which exhibited a thinner and more porous structure composed of an abundance of relatively low-nitrogen-doped wrinkled graphene nanosheets and showed enhanced lithium storage properties as LIB anodes (storage capacity of 2753 mAh g−1 after 300 cycles), via magnesiothermic denitriding technology. Mao and colleagues122 fabricated highly N-doped graphene-like carbon (NGC) through the carbonization of a mixture containing polypyrrole (PPy) and g-C3N4 nanosheets. The NGC material, which integrated a range of excellent features, including high nitrogen content (17.54 at%), large specific surface area (635.73 m2 g−1), and abundant mesopores with high pore volume (1.9483 cm3 g−1), was used as anode material in LIBs. The NGC material exhibited a promising initial discharge capacity of 2749 mAh g−1 at current density of 50 mA g−1. It had a high specific capacity of 1143 mAh g−1 at current density of 50 mA g−1 after 200 cycles and excellent rate performance with 440 mAh g−1 at 2 A g−1. Chenrayan et al.123 reported the construction of N-rich C3N4/MoS2 nanosphere from 2D layered materials, which served as a potential anode material for LIBs, delivering a reversible capacity of 857 mAh g−1 at 0.1 C rate for 50 cycles in Figure 4. It has superior rate performance of 383 mAh g−1 at 10 C rate. The excellent performance was mainly attributed to its excellent structure through the rapid electron transfer of nitrogen-rich g-C3N4 and the large electrode/electrolyte contact area of MoS2. g-C3N4/MoS2, in which the nitrogen-rich carbon and interconnection properties of the g-C3N4/MoS2 structure contributed to good electronic conductivity and a shorter diffusion length and provided mechanical flexibility to adapt to volume changes and the formation of heterostructures. Sasidharan and colleagues124 reported anatase TiO2 nanosphere (TNS) wrapped in nitrogen-rich carbon nanosheets (TiO2@CNSs, TCNSs), which were a robust and facile self-assembly approach involving titanium alkoxide and CNS under hydrothermal conditions followed by heat treatment. The TCNS nanostructures (mass loading of TiO2/CNS = 1.2) displayed very high lithium-ion storage capacity, 303 mAh g−1 at 0.1 C after 125 cycles and 136 mAh g−1 at 5 C after 500 cycles with high Coulombic efficiency (99%). The excellent performance was mainly attributed to the synergistic effect promoting structural flexibility and mechanical stability, as well as the electronic and ionic conductivity of TCNS composites, which provided excellent lithium storage, cycle life, and rate performance.

Vo et al.125 reported the preparation of an SnO2 nanosheet/g-C3N4 (SN/CN) composite, in which SnO2 nanosheets were agglomerated to form a cauliflower-like morphology with the assistance of mercaptoacetic acid in a hydrochloric acid medium. The SN/CN composite exhibited improved cycling performance, which was attributed to the presence of g-C3N4, compared to the stand-alone SnO2 nanosheets. Subsequently, Vo and colleagues126 reported that an SN/GO/g-C3N4 (SGC) composite had been prepared via the hydrothermal method, in which the SnO2 nanosheets were grown on GO/g-C3N4 support. In the first cycle, the discharge capacity of 1230.6 mAh g−1 at 0.1 C and the initial Coulombic efficiency of the SGC were obtained. The GO, which provided an electron- and ion-conductive medium, leading to good reaction kinetics, was introduced into SnO2 nanosheets/g-C3N4. The mesoporous g-C3N4 nanosheets were first introduced into the GO to form composite materials, which could support the formation of a stable solid-electrolyte interphase (SEI) layer, accommodating the volume changes during the lithiation/delithiation process and significantly improving the cycling performance of the electrode. To improve device performance, Vo and colleagues127 synthetized WS2/g-C3N4 composites via a facile one-step solid-state reaction. Their WS/CN-5 sample delivered a reversible capacity of 622.7 mAh g−1 after 400 cycles with a high current density of 1000 mA g−1, indicating excellent lithium storage performance.

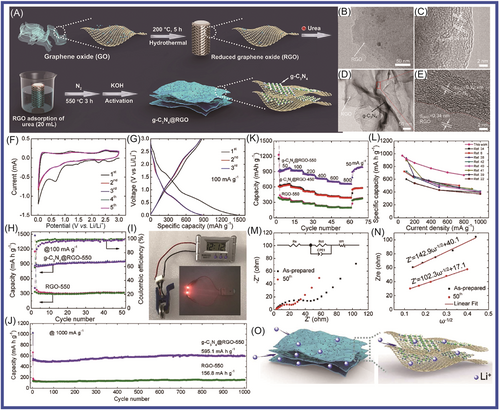

2D nanomaterials, which have high gravimetric capacity and rate capability, were a key strategy for the LIB anode, although they still posed a challenge for lithium-ion storage. Their limited conductivity and inability to alleviate the volume changes upon lithiation and delithiation limited their application in LIBs. Goodenough and colleagues128 prepared an anode with three-dimensional (3D) structure via the hydrothermal method, which consisted of layers of 2D layered g-C3N4 and rGO nanosheets (CN rGO). It exhibited a capacity of 970 mA h g−1 after 300 cycles, which was 15-fold higher than for the BCN. Yin et al.129 synthesized SnS2/g-C3N4 (SnS2/CN) nanosheets by a facile microwave hydrothermal method, which consisted of hierarchical nanoflower SnS2 anchored on g-C3N4 nanosheets. This sample delivered a high discharge capacity of 444.7 mAh g−1 (at current density of 100 mA g−1 after 100 cycles) with a Coulombic efficiency of over 99.9%. It had a high specific capacity of 383.8 and 350.8 mAh g−1 at current density of 800 and 1000 mA g−1, respectively. The performance of the SnS2/CN composite, which provided more active sites and accelerated the migration of electrons and lithium ions during charge/discharge cycles, was attributed to its large surface area. To solve the agglomeration problem of graphene in LIBs and improve its performance, Sun et al.130 prepared a layered g-C3N4@rGO composite (g-C3N4@rGO) via a scalable and easy strategy, as shown in Figure 5. This material showed excellent performance (cycling stability of 899.3 mAh g−1 after 350 cycles under 500 mA g−1 and remarkable rate performance of 595.1 mAh g−1 after 1000 cycles under 1000 mA g−1), which was mainly attributable to its large interlayer distances, rich N-active sites, and microporous structure. Interestingly, the g-C3N4@rGO-based electrode was enough to power two tandem red-light-emitting diodes and run a digital watch, which was able to work continuously for more than 20 days. Wang and colleagues131 reported that a composite with cubic Co3O4 nanocrystals anchored on chemically integrated g-C3N4-modified N-graphene (CN-NG), which was applied in LIBs, had been synthesized via a facile strategy. It delivered a high specific reversible capacity (capacity of 1096 mAh g−1 at current density of 100 mA g−1) with excellent cycling stability and rate capability. The Co3O4/CN-NG composite material provided paths for the insertion/extraction of Li+ and buffered volume changes during charging and discharging. Sasidharan and colleagues132 synthesized g-C3N4@rGO hybrid materials, in which 2D layered g-C3N4 and GO were formed by self-assembly via a single-step hydrothermal reaction. The g-C3N4@rGO hybrid material as an anode material for LIBs exhibited excellent electrochemical performance (capacity of 901 mAh g−1 at the 0.1 C rate and 302 mAh g−1 at the 5 C rate). Tang and colleagues133 reported that g-C3N4/MoS2/ZnS composites, in which MoS2/ZnS heterojunctions were tightly anchored onto the surfaces of the g-C3N4 nanosheets, had been synthesized by a one-step hydrothermal method. The g-C3N4/MoS2/ZnS ternary NCs exhibited high capacity and excellent cycling stability, 1310 and 805 mAh g−1 at current densities of 0.1 and 1 A g−1, respectively.

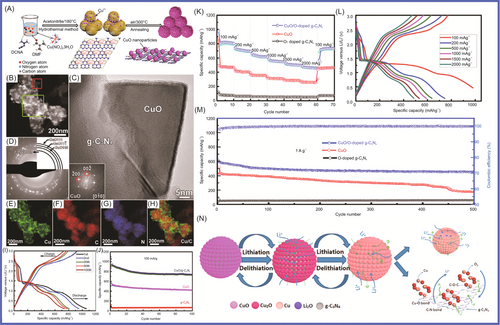

To improve the electrochemical performance of MnO-based anode materials, which were applied in high energy-density LIBs, Chen and colleagues134 reported that porous MnO/g-C3N4/carbon composite spheres had been synthesized through an aerosol–pyrolysis route. The porous MnO/g-C3N4/carbon composite spheres (with g-C3N4/carbon content of 8.6 wt%) displayed excellent electrochemical properties, with the first-cycle discharge capacity reaching 1096.8 mAh g−1 at 0.2 C. The discharge/charge capacities reached 918.9/605.8 mAh g−1 at 0.5 C. The highest reversible capacity was 781.9 mAh g−1, which was higher than the theoretical capacity of MnO (755 mAh g−1). This material showed good stability, and the reversible capacity retention reached 99% after 150 cycles at 0.5 C. Nitrogen atom doping has been widely recognized as a promising technique to improve the electrochemical performances of various carbonaceous materials applications for energy storage devices. NiCo2O4, which showed high performance due to its better electrochemical activity and higher capacity compared to traditional simple oxides, was regarded as a desirable electrode material in LIBs. Shao and colleagues135 coupled nanoparticulate NiCo2O4 with g-C3N4, which effectively reduced SEI formation and led to a high initial Coulombic efficiency. The NiCo2O4/g-C3N4 hybrid materials had excellent performance, with a capacity of 1252 and 476 mAh g−1 after 100 cycles at current density of 100 and 500 mA g−1, respectively. The Li4Ti5O12/g-C3N4 composite, in which g-C3N4 acted as a support to enhance the electronic conductivity of Li4Ti5O12, was prepared by the solvothermal method followed by heat treatment at 700°C for 5 h for the first time by Sun and colleagues.136 When the Li4Ti5O12/g-C3N4 was applied in LIBs as anode material, the Li4Ti5O12/g-C3N4 displayed a reversible capacity of 150.8 mAh g−1 with a capacity retention of 86.8% at 0.5 C after 502 cycles. Its excellent electrochemical performance was mainly attributed to the existence of the g-C3N4 support. As shown in Figure 6, Su and colleagues137 reported that copper oxide (CuO)/O-doped g-C3N4 nanospheres had been prepared by a two-step hydrothermal process at 180°C followed by annealing in air at 300°C. When the CuO/O-doped g-C3N4 was used as anode material, it exhibited high performance (specific capacity of 738 mAh g−1 at current density of 100 mA g−1 and specific capacity of 503 mAh g−1 at current density of 1 A g−1). The CuO/O-doped g-C3N4 nanospheres showed excellent performance, which was mainly attributed to the fact that O-doped g-C3N4 could effectively avoid agglomeration of CuO NPs during in situ growth, which is conducive to lithium-ion transfer and electrolyte penetration; the buffer volume of the porous structure accommodated the changes during the insertion/removal of Li+; and the O-doped g-C3N4 exhibited a reduced band gap and improved electrical conductivity. Mullins and colleagues138 synthesized C3N4-Cu and C3N4-Fe nitrogen-doped carbon. Compared with alloying Fe (carbon with a high degree of graphitization, low nitrogen content (<10%), and medium pore volume), the carbon formed by nonalloying Cu has high defects with high nitrogen content (32%–24%) and large pore volume. The C3N4-Cu (since Cu templating is beneficial to Li+ storage, with the carbon formed at 750°C) exhibited the highest specific capacity of 900 mAh g−1 at 0.1 A g−1 and 275 mAh g−1 at 20 A g−1. It retained 96% of its initial capacity after 2000 cycles at 2 A g−1. To improve the electrochemical performance of LIBs, composite electrode materials were designed and manufactured. Hierarchical nanoflower SnS2 anchored on g-C3N4 nanosheets (the SnS2/CN composite) was synthesized via a facile microwave hydrothermal method by Yin et al.139 The SnS2/CN composite material delivered excellent performance (cycling stability, high rate capacity, and structural integrity) at higher current density for LIBs. It exhibited a specific capacity of 444.7 mAh g−1 with a current density of 100 mA g−1 after 100 cycles with a Coulombic efficiency of over 99.9%. It exhibited a specific capacity of 383.8 and 350.8 mAh g−1 at current densities of 800 and 1000 mA g−1, respectively. The SnS2/CN composite materials, which provided more active sites and accelerated the migration of electrons and lithium ions during charge/discharge cycles, showed remarkable electrochemical performance.

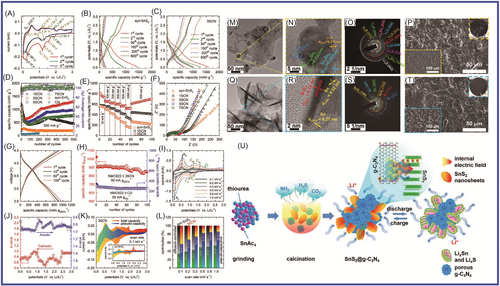

Nanostructure provided a way to solve the volume change for LIBs during charging and discharging. Fu and colleagues140 fabricated nanosized spinel ferrites, MFe2O4 (M = Mn, Ni, Cu, and Co) and g-C3N4 covalently functionalized nitrogen-doped graphene (CN-NG), which were formed in a 3D heteroarchitecture via a general approach, combining a self-assembly process, in situ substitution, and thermal annealing. The 3D MnFe2O4/CN-NG (0.4), 3D CuFe2O4/CN-NG (0.4), 3D CoFe2O4/CN-NG (0.4), and 3D NiFe2O4/CN-NG (0.4), which were applied in LIBs as anode materials, exhibited significantly high reversible capacities of 1032, 1105, 1008, and 919 mAh g−1 at current density of 0.1 A g−1, respectively. In particular, 3D MnFe2O4/CN-NG (0.4), as the anode material of LIBs, has maintained excellent magnification (capacity retention of 73%) and long-term stability after 800 cycles at the current density of 1 A g−1. The excellent electrochemical performance was mainly attributed to the unique 3D structure with some unique structural advantages. The layered structure was favorable for electrolyte penetration; N doping was beneficial to electron transmission by adjusting electronic structure. It had a large number of active sites and NPs were uniformly distributed; strong chemical bonds and metal carriers were conducive to improving lithium storage performance. Chen and colleagues141 used g-C3N4 nanosheets as the precursor and zinc powder as the template, from which the nitrogen-doped hollow carbon spheres (NHCS) were obtained. The NHCS delivered an acceptable initial discharge capacity of 1012.4 mAh g−1 at current density of 0.1 A g−1. It delivered promising cycling stability, which was 1064.5 mAh g−1 after 400 cycles as well as an excellent rate performance (360 mAh g−1 at 10 A g−1). Tin oxide and tin sulfide are widely studied by researchers for their characteristic conversion mechanism during the lithiating process, which endows them with high theoretical specific capacity. A simple approach promoting the performance of SnS2 was proposed here via strategically introducing the rGO/g-C3N4 hybrid to form a robust framework in the designed SnS2 composite. SnS2 was introduced in rGO/g-C3N4, which improved the conductivity of the SnS2 composite by Wen and colleagues.142 Excellent rate performance with a high recovered capacity of 864.9 mAh g−1 at current density of 800 mA g−1 was gained. The shuttle effect was efficiently suppressed by the N-rich host material. g-C3N4/carbon hybrid cages were rationally designed and fabricated as sulfur hosts. Chen and colleagues143 fabricated core-shell-structured S@g-C3N4/carbon cathode, which exhibited excellent cyclic stability. Ninety-one percent of the theoretical capacity of sulfur was achieved in the initial discharge at 0.2 C. The capacity of 636 mAh g−1, when S@g-C3N4/carbon served as the anode of LIBs, was obtained after 400 discharge/charge cycles at 1 C. Zuo et al.144 presented a one-pot solution-based strategy, in which SnS2 nanostructures were grown within a matrix of g-C3N4 and graphite plates (GPs). A series of SnS2-based LIB anodes had been researched and compared. When SnS2 nanoplates (SnS2-NPLs) were introduced in CN/GP, they provided the highest properties and displayed excellent rate capabilities (536.5 mAh g−1 at 2.0 A g−1), outstanding stability, and high pseudocapacitance contribution. The excellent electrochemical performance of SnS2/g-C3N4/GP composites materials is mainly attributed to the synergistic effects: porous g-C3N4 reduced the aggregation of SnS2 NPL, buffered the volume change of SnS2, and provided channels for Li ions; GP was conducive to charge transport; SnS2 NPL had a large comparative area for rapid Li ions intercalation and a proper geometry to stand volume expansions during lithiation/delithiation cycles. Cui and colleagues145 reported that a fluffy spherical Co1 − xS@g-C3N4 microcomposite, in which Co1 − xS NPs were uniformly anchored onto the cotton-like g-C3N4, was prepared via a facile one-step solvothermal method. The spherical-like Co1 − xS@g-C3N4 hybrid as anode material exhibited a higher reversible capacity of 789.59 mAh g−1 (at current density of 0.1 A g−1) than bare Co1 − xS (22.02 mAh g−1) after 210 cycles and delivered an ultralong cycle life of 1000 cycles with a capacity of 487.93 mAh g−1 (at current density of 0.1 A g−1). The excellent electrochemical performance of Co1 − xS@g-C3N4 was attributed to the following factors: (1) special fluffy structure; (2) the uniform adherence of Co1 − xS NPs to g-C3N4 matrix; and (3) buffer volume changes during charging and discharging processes. Transition metal dichalcogenides, particularly SnS2 with 2D layered structures analogous to that of graphite, had received special attention as innovative anode materials for practical applications. To improve low conductivity, the ND-g-C3N4 was fabricated via magnesiothermic denitriding method by Wang and colleagues.146 The high content of graphitic N will lead to serious irreversible capacity loss; the N content of g-C3N4 and successfully prepared ND-g-C3N4-n (ND-C3N4-n, n = heat treatment temperature) was reduced via magnesiothermic denitriding. ND-g-C3N4-675 presented excellent performance, which obtained 2264.9 mAh g−1 at current density of 1000 mA g−1 after 500 cycles. Amici and colleagues147 reported that g-C3N4 was directly used to synthesize SnO2@C3N4 for LIB anodes through a scalable solid-state reaction, in which anodes displayed high specific capacities of 1075 mAh g−1 at 156 mA g−1. SnO2@C3N4, as an anode in LIBs, achieved good rate capability and excellent stability upon prolonged cycling at high rates, which mainly attributed to regular and homogeneous distribution of SnO2 over g-C3N4 phase. The SnO2@C3N4 was easily obtained by a fast solid-state reaction by Amici and colleagues.147 The SnO2@C3N4 enabled the cell to achieve high rate capability (specific capacity of 1075 mAh g−1 at 156 mA g−1 with almost 50% of the initial specific capacity retained at current density of 3.9 A g−1) and excellent stability under prolonged cycling at high rates. As shown in Figure 7, Im and colleagues148 synthetized SnS2@g-C3N4 via a facile technique using a solid-state reaction. The obtained materials that demonstrated the specific capacity, rate performance, and cycling behavior were applied in LIBs. The excellent performance was mainly due to good dispersion of SnS2 nanosheets in the porous matrix of g-C3N4 and assigned to the buffering effect of the large surface area of the g-C3N4 matrix as well as the predominant contribution of the pseudocapacitive effect. g-C3N4, as a 2D functional material, has unique structural and electronic properties that are conducive to the storage of alkali metal ions and has attracted extensive research in the field of energy storage. It has a wide nitrogen-rich structure, a large triangular pore location, and a high theoretical LiB capacity of 524 mAh g−1. The lithium storage performance of g-C3N4, however, was greatly affected by its conductivity and structural performance. Hankel and colleagues149 successfully prepared Si-doped g-C3N4, which was an effective strategy to modulate its electronic properties and boost its reversible lithium storage capacity to solve the problem of ineffective lithium storage in monolayer 2D g-C3N4. The high performance included a lithium storage capacity of 557.7 mAh g−1. Mao and colleagues150 synthesized N-doped graphene as anode material for LIBs, for which g-C3N4 was used as a precursor with the assistance of polyvinylpyrrolidone (PVP). It had a promising specific capacity of 1236 mAh g−1 in LIBs at current density of 0.05 A g−1 and showed excellent cycling stability as well as acceptable rate capability.

2D materials can provide a layered structure for transition metal oxides. CuO nanorods were grown on Cu/g-C3N4 nanosheets (where the 2D Cu nanosheets were grown on porous g-C3N4 nanosheets [Cu/g-C3N4]) (CuO@Cu/g-C3N4) by Su and colleagues.151 The CuO@Cu/g-C3N4 delivered a discharge-specific capacity of 726 mAh g−1 after 200 cycles at 0.1 C and a discharge-specific capacity of 457 mAh g−1 after 625 cycles at 1 C. Its outstanding stability and cycling performance were attributed to the unique 2D Cu nanostructure, which provided a large area and enhanced electronic transmission for Li+ insertion. The ordered CuO nanorods changed in volume for buffering during charging and discharging, providing more paths for charge and Li+ transfer, while the porous g-C3N4 nanosheets endow the prepared structure with more active sites. Pan and colleagues152 synthesized g-C3N4/Mo2CTx hybrid materials via a facile in situ strategy, which exhibited much improved Coulombic efficiency and cycling stability. The g-C3N4/Mo2CTx delivered excellent performance, including a reversible capacity of 229.6 mAh g−1 at 2 A g−1 after 1800 cycles, 528.5 mAh g−1 at 0.1 A g−1 after 100 cycles, and high initial Coulombic efficiency of 70.8%. Pan and colleagues153 reported that MoOx-UCN, where UCN is urea, in which MoO@MoO2 heterojunctions were anchored on 2D g-C3N4, had been synthesized, and the MoOx-UCN applied in LIBs showed excellent lithium-ion storage and rate performance (with a high capacity of 992 mAh g−1 under 0.5 A g−1 after 100 cycles and stable capacity of 716 mAh g−1 under 2 A g−1 after 500 cycles). Wang and colleagues154 prepared novel NGC nanosheet- (CN) and carbon nanotube (CNT)-encapsulated Co3O4 NPs (N-doped CN@Co-Co3O4/CNTs) via a simple self-template method, which exhibited high discharge capacity (460 mAh g−1 at 5000 mA g−1). Zhu and colleagues155 reported that N-doped multicavity Sn/C composite was prepared by a template-assisted structural design as an anode for LIBs, which displayed high specific capacity (512 mAh g−1 at 1.0 A g−1), good capacity retention (82% after 1000 cycles), and excellent rate performance. Vo et al.148 reported that the SnS2@g-C3N4 composite materials were produced by a facile one-pot synthesis method, in which the SnS2@g-C3N4 composite materials had different proportions of mixed precursors (different thiourea/SnAc4 mass ratios of 1, 3, 5, and 7) to identify the best proportion. The obtained SnS2@g-C3N4 samples were denoted as xSCN (x = 1, 3, 5, and 7). The 3SCN showed high performance (specific capacity of 1720.7 mAh g−1 at current density of 100 mA g−1), which was attributed to the buffering effect of the large-surface-area g-C3N4 matrix as well as the predominant contribution of the pseudocapacitive effect and the formation of heterointerfaces between the semiconductors SnS2 and g-C3N4. Pan and colleagues152 synthesized a g-C3N4/Mo2CTx hybrid, in which Mo2CTx was further exfoliated and the g-C3N4 protection layer was constructed by a facile in situ strategy. The g-C3N4/Mo2CTx delivered excellent Coulombic efficiency (70.8%) and good cycling performance (reversible capacity of 528.5 mAh g−1 at 0.1 A g−1 after 100 cycles) and cycling stability (229.6 mAh g−1 at 2 A g−1 after 1800 cycles). The high performance was mainly attributed to the unique structure of the g-C3N4/Mo2CTx hybrid, which increased the lithium storage performance, reduced the diffusion lengths of electrons and ions, and accelerated charge transfer. Lin and colleagues156 prepared hierarchical g-C3N4@WS2 composite material, which was intended for LiBs. It displayed outstanding lithium storage performance, with a specific capacity of 1136.1 mAh g−1 at 0.1 C, a high reversible specific capacity of 454.4 mAh g−1 after 200 cycles at 0.2 C, and superior cycling stability of 433.8 mAh g−1 after 1000 cycles. Chen and colleagues157 reported that the nitrogen vacancies in g-C3N4 were increased via energetic ion bombardment. The obtained ND-g-C3N4 (g-C3N4-x) delivered a high reversible capacity (high capacity of 647 mAh g−1 after 400 cycles at 0.1 A g−1) and stable cycling (ultrastable cycling performance of 232.8 mAh g−1 after 5000 cycles at 1 A g−1). The superior electrochemical performance was attributed to the increased specific surface, the reduced band gap, enhanced lithium absorption energy, different charge density due to the vacancy modulation, and active sites caused by the plasma bombardment. Sn/g-C3N4 (S/CN) composite, for which the capacity recovery of the S/CN composite was similar to that of Sn (437.8 mAh g−1) as current density was reversed to 100 mA g−1, was prepared using a simple chemical reduction method by Vo and colleagues.158

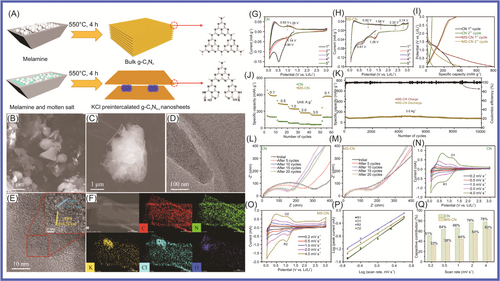

To improve the electrochemical properties of g-C3N4, Deng and colleagues159 prepared well-designed KCl preintercalated C3N4 nanosheets with abundant pyridinic-N, which showed a high specific discharge capacity and long cycle life (66% capacity retention after 10,000 cycles at 3.0 A g−1), via an one-step molten salt method, as shown in Figure 8. The KCl-preintercalated carbon nitride nanosheets applied in LIBs showed excellent electrochemical performance (high specific capacity and excellent cycle life), in which KCl as a prop enhanced the interlayer spacing and the structural stability, and the pyridinic-N and N vacancy increased the conductivity, as well as the reversibility of Li+ storage and the active sites. Dutta and colleagues160 studied the effect of g-C3N4 on the electrochemical performance of ZnS. ZnS/g-C3N4 composite anodes were obtained. One sample (0.7ZnS:0.3g-C3N4) delivered long-term reversible capacity (596.9 mAh g−1 after 1150 cycles in the Li+ half-cell configuration and 432.6 mAh g−1 after 750 cycles in the Na+ half-cell configuration, at a high current density of 1 A g−1). Dutta and colleagues161 prepared In2S3/g-C3N4 NC materials, which successfully enhanced performance. The best ratio was 0.8In2S3:0.2 g-C3N4, which delivered a reversible capacity of 358 mAh g−1/1000 cycles versus Li metal. Jin and colleagues162 synthesized spinel CuCo2O4 nanowire arrays and supported them on g-C3N4 nanosheets via facile hydrothermal methods, which formed a unique sandwich-like interconnected 3D mesoporous structure containing a high amount of void spaces. Tang and colleagues163 successfully prepared porous Si/nitrogen-doped CNS composites via in situ growth of nanosilicon on a graphene-like carbon. This material showed excellent electrochemical performance, 1106.7 mAh g−1 after 200 cycles with capacity retention of 93.6% and the Coulombic efficiency remaining above 99.5%. The fascinating surface chemistry of MXene allows the rational design of 2D heterostructures. Alshareef and colleagues164 designed a hybrid heterostructure (MXene@CN) comprising g-C3N4 and Ti3C2Tx. It was applied in LIBs, which showed excellent performance. This was mainly because MXene and g-C3N4 formed reinforcing bonds, and what is more, its chemical-bonding-induced charge redistribution ensured fast Li+ intercalation kinetics. Liu and colleagues165 synthesized a novel graphitic anode (Ni-g-C3N4) by using nickel (Ni) as the catalyst and g-C3N4 as the precursor. Ni-g-C3N4 demonstrated good performance (high capacity of 487.1 mAh g−1, with high capacity retention of 99.3% after 600 cycles and satisfactory average Coulombic efficiency of 99.4%).

2.2 g-C3N4 applied in LSBs

LSBs have attracted great attention as one of the most promising power sources due to their higher energy density, lower cost, and better environmental friendliness.166-169 LSBs have become one of the most promising electrochemical energy storage systems due to their high theoretical specific capacity (1673 mAh g−1) and high energy density (2600 Wh kg−1),170, 171 although there are issues with the polysulfide shuttle in LSBs.172 The problem of the polysulfide shuttle in LSBs leads to low Coulombic efficiency and cycle life, which has limited the practical application of LSBs.173, 174 Researchers have used hard carbon materials to combine with sulfur to promote electron transfer and inhibit the diffusion of polysulfides, thereby improving the stability of the electrode materials.175-178 The anchoring of polysulfides by nonpolar carbon interactions was weak, however, and could not inhibit the shuttling of polysulfides.179-182 g-C3N4, on the other hand, has abundant N content (pyridine nitrogen) and polar carbon and can utilize chemical adsorption to anchor polysulfides.

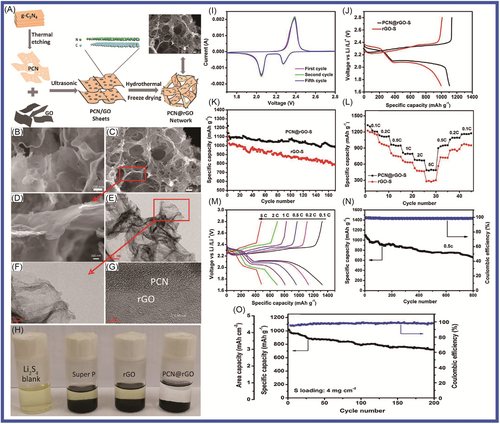

Meng et al.183 prepared g-C3N4 nanosheets, in which the nitrogen content was 56 wt% and the specific surface area was 209.8 m2 g−1, and sulfur was loaded onto them. The composite material, which had a sulfur content of 70.4 wt%, exhibited excellent specific capacity of 1250 mAh g−1 at 0.5 C and specific capacity of 578.0 mAh g−1 at 0.05 C during charge/discharge. The g-C3N4 contained abundant N atoms, which was beneficial for lithium sulfide loading and prevented the aggregation of sulfur, Li2S2, and Li2S. Gong et al.184 designed and prepared 3D lightweight and porous C3N4 nanosheets@rGO (PCN@rGO) materials, as shown in Figure 9. The specific capacities of PCN@rGO were 1205, 1150, 986, 800, 685, and 483 mAh g−1 at rates of 0.1, 0.2, 0.5, 1, 2, and 5 C, respectively. Li and colleagues185 synthesized porous g-C3N4 composed of graphite-like 2D corrugated sheets and high content of pyridinic nitrogen, which improved the performance of LSBs. The porous g-C3N4/S exhibited a specific capacity of 1050 mAh g−1 due to its unique porous structure and high charge polarity. The shuttle effect caused by the diffusion of polysulfides has limited the development of LSBs. g-C3N4 contains abundant pyridinic N, which is beneficial for the adsorption of polysulfides. Huangfu et al.186 covered a commercial polypropylene membrane with the ultrathin g-C3N4 membrane through vacuum filtration technology. The prepared material could effectively inhibit the shuttling of polysulfides. The prepared material exhibited an excellent reversible specific capacity of 829 mAh g−1 at 0.2 C after 200 cycles.

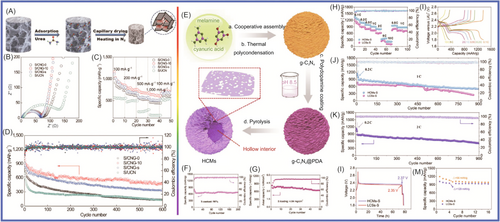

As shown in Figure 10A–D, the g-C3N4 was introduced into 3D graded porous graphene through molecular design to achieve polysulfide confinement and catalytic synergy by Wang et al.187 The hybrid material showed excellent specific capacities of 700 mAh g−1 (at current density of 0.5 C) and 600 mAh g−1 (at current density of 2 C), respectively. The hybrid material showed better sulfur utilization and cycle stability. The graphene network formed porous g-C3N4 nanosheets in situ, providing a surface to catalyze the conversion of polysulfides, and the porous carbon via assembly to provide channels for charge carriers. To solve the problem of the low conductivity of sulfur and sulfide shuttles, Chen et al.188 designed a functional diaphragm, which was coated with g-C3N4 and crystalline carbon (M-C3N4/C) on the surface of the commercial diaphragm. Transition metals were uniformly distributed on g-C3N4/C as active centers, which were chemically adsorbed on g-C3N4 to regulate polysulfide catalysis, facilitate rapid carrier transfer, and achieve efficient utilization of active sulfur species. The membrane-modified as-prepared Ni-C3N4/C hybrid material was applied in LSBs and showed a specific capacity of 999 mAh g−1 at 0.5 A g−1 and 724.6 mAh g−1 at 1.0 A g−1, respectively. It showed excellent cycling stability (with a high capacity retention rate of 89.4% after 300 cycles). As shown in Figure 10E–M, Zhou et al.189 prepared O/N co-doped hollow carbon microspheres (HCMs) using a sacrificial template method, which was obtained by carbonizing polydopamine. The as-prepared HCMs were constructed from porous nanosheets, with high specific area (873 m2 g−1), high pore volume (4.84 cm3 g−1), and high O/N doping (6.99 and 5.36 at%). The HCM-S hybrid material exhibited a specific capacity of 900 mAh g−1 at 1–2 C and excellent cycling stability (maintaining 530 mAh g−1 after 900 cycles). Deng et al.190 used SiO2 NPs as hard templates to synthesize graded porous g-C3N4/rGO through polycondensation and applied it in LSBs. The as-synthesized g-C3N4/rGO material had a sulfur content of 75% and a moderate macroporous density. The specific capacity was 958.5 mAh g−1 at 0.2 C. The g-C3N4/rGO hybrid material showed good cycling stability (specific capacity of 589.6 mAh g−1 at 2 C after 100 cycles). Its excellent electrochemical performance was attributed to the combination of its conductive rGO layer, polar g-C3N4, and graded porous structure with medium to large pore density in the main material. Fang and colleagues191 uniformly dispersed g-C3N4 on the electrode through a spraying method, which was a simple, time-saving, and universal method. Their sulfur graphene aerogel foam treated with g-C3N4 showed a specific capacity of 927 mAh g−1 at 0.2 C. After 280 cycles, it exhibited excellent cycling stability (with a specific capacity of 720 mAh g−1) after 280 cycles. The g-C3N4 nanosheet film slightly increased the quality of the electrode, thus inhibiting the “shuttle effect” of self-discharge and polysulfides. Jia et al.192 synthesized g-C3N4 through a simple method, which was used to synthesize active points anchoring polysulfides from trithiocyanuric acid to inhibit the shuttle effect. The synthesized g-C3N4 delivered a specific capacity of 1200 mAh g−1 at 0.2 C in LSBs. It could still maintain a specific capacity of 800 mAh g−1 with a Coulombic efficiency of 99.5% after 100 cycles. The synthesized g-C3N4 had high N doping, which was beneficial for improving the cycling stability of LSBs.

The separator was one of the research focuses of LSBs. Deng et al.193 prepared multifunctional molecular sieves, which were composed of g-C3N4, boron nitride, and graphene. The prepared molecular sieve crystal structure contains g-C3N4 with a channel size of 3 Å, which can effectively prevent the passage of polysulfides and facilitate the passage of Li+. BN served as a catalyst, and graphene facilitated charge collection and transport. The device exhibited a specific capacity of 600 mAh g−1 at 1 C after 500 cycles. With a sulfur loading of 6 mg cm−2, the specific capacity attenuation per cycle was less than 0.01%. Wu et al.194 prepared graphite-phase carbon nitride/CNT (g-C3N4/CNT) hybrid membranes through a vacuum filtration process. The as-prepared g-C3N4/CNTs could effectively adsorb and inhibit the shuttling of polysulfides. The prepared device exhibited a first discharge-specific capacity of 876 mAh g−1 at 0.5 C. The specific capacity remained 633 mAh g−1 after 300 cycles. The prepared hybrid material was conducive to adsorbing polysulfide and inhibiting self-discharge behavior. Sun et al.195 designed and synthesized mesoporous boron carbon nitride/graphene as a multifunctional modifier. The LSBs exhibited excellent cycling and high magnification capabilities. When the active material load was 4.6 mg cm−2, the device exhibited a specific capacity of 774.0 mAh g−1 at 200 mA g−1 after 80 cycles. When the active material load was 6.11 mg cm−2, the device exhibited a specific capacity of 573.6 mAh g−1 at 200 mA g−1 after 80 cycles. Guo et al.196 designed a layered structure to load sulfur. MnO2 nanosheets were grown on one side of carbon paper and g-C3N4/CNTs were loaded on the other side. The introduction of CNTs facilitated the infiltration of sulfur and electron transport. A g-C3N4@CNT-MnO2 hybrid material was obtained. When the sulfur content was 70.3 wt%, the device displayed an ultrahigh specific capacity of 1182.7 mAh g−1 at 0.2 C.

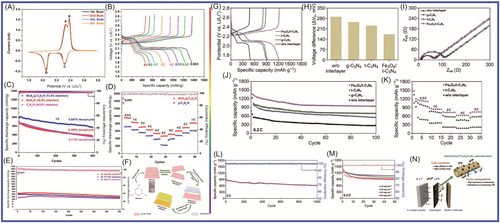

As shown in Figure 11A–F, Majumder et al.197 synthesized molybdenum disulfide/graphite-phase carbon nitride porous nanosheets (MoS2/g-C3N4) for application in LSBs. The as-prepared MoS2/g-C3N4 exhibited excellent cycling and rate performance (at the rate of 8 C, after 400 cycles, the specific capacity was 430 mAh g−1, with a decay rate of 0.028% per cycle). The excellent performance was attributed to the synergistic effects of lithium polysulfide with MoS2 and g-C3N4, which effectively inhibited the shuttling of polysulfides. Bai et al.198 prepared porous honeycomb-like C3N4 (PHCN) through the hard template method. PHCN-loaded S, as an electrode material applied in LSBs, exhibited an excellent high initial specific capacity of 1061.1 mAh g−1. The PHCN showed excellent rate performance, with a discharge-specific capacity of 495.1 mAh g−1 at 5 C. The specific capacity remained at 519 mAh g−1 at 1 C after 400 cycles. Under high load, the attenuation rate of each cycle was only 0.16% after 200 cycles. Ma et al.199 proposed a multiple lithium sulfide capture strategy, in which g-C3N4-x and CNTs were combined to form a hybrid material. The application of the g-C3N4-x/CNT modified separator in LSBs showed a discharge capacity of 1128 mAh g−1 at 0.2 C. The reversible capacity was 774 mAh g−1 after 100 cycles. Not only can the defect-rich g-C3N4-x catalyze polysulfide reactions with an affinity for polysulfides but also the g-C3N4-x/CNT hybrid material was conducive to electron transfer. Kim et al.200 designed an LSB interlayer with graded Fe3O4/C3N4 nanostructures to regulate the shuttle effect and improve sulfur utilization, as shown in Figure 11G–N. The synthesized Fe3O4/tubular (t)-C3N4 was beneficial for polysulfide anchoring to improve electron transport. t-C3N4 exhibited high surface area and anchoring ability to lithium polysulfide. The prepared Fe3O4/t-C3N4 was applied in LSBs, exhibiting an initial discharge capacity of 828 mAh g−1 at 2 C. The Fe3O4/t-C3N4 exhibited excellent cycling stability, with a specific capacity of 658 mAh g−1 after 1000 cycles (with a capacity decay of 0.02% per cycle). Wu et al.201 designed and synthesized a 3D-network-structured N-doped carbon material (C-NC) using biomass chitin as raw material. C-NC and GN were introduced into g-C3N4 to form C-NC/GN/g-C3N4 hybrid material. The as-synthesized S@C-NC/GN/g-C3N4 hybrid material in supercapacitors showed excellent cycling stability (with a specific capacity of 1130 mAh g−1 after 500 cycles). Tong et al.202 reported an additive, defective graphite-phase carbon nitride, which has a buffering effect on lithium polysulfide. The defect-rich g-C3N4-x combined with commercial polypropylene exhibited excellent performance.

The interaction between graphite nitride carbon and Li2S plays a role in capturing polysulfides, as reported by Versaci et al.203 Their prepared device exhibited excellent performance, with a 25% increase in specific capacity and improved service life. Li et al.204 developed a porous structure with N-defect g-C3N4 (NDCN) for application in LSBs. The synthesized NDCN delivered an outstanding specific capacity of 620 mAh g−1 at 1 C after 300 cycles. After 300 cycles, each cycle was attenuated by 0.045% at 1 C. The prepared NDCN hybrid material had a unique 3D structure, with macropores and mesopores facilitating storage and carrier transport, as well as providing active sites. Pan et al.205 introduced sulfur into the interlayer between a TixOy-Ti3C2 layer and a C3N4 layer. A sandwich-structured oxytetraclycline/S/C3N4 material was formed. The prepared material was applied in LSBs, achieving a specific capacity of 749.5 mAh g−1 after 2000 cycles at 0.5 C. When the sulfur load was 4.2 mg cm−2, the LSB still maintained 70.5% of its initial specific capacity after 200 cycles. The interlayer structure of the material was conducive to LiPS anchoring, and the synergistic effect of the bidirectional interlayer enhanced the reduction kinetics of LiPS and Li2S. Wu et al.206 prepared porous g-C3N4 nanotubes (PCNNTs) using a template method as S carriers. The PCNNTs/S hybrid material was applied in LSBs, and the initial specific capacity was 704.8 mAh g−1. This excellent performance was attributed to the high specific surface area and abundant macropores/mesopores of PCNNTs, achieving high sulfur loading and buffering the volume changes during charging/discharging processes of PCNNTs with a tubular structure. To improve the performance of LSBs, Li et al.207 designed and prepared bimetal -doped Fe/Co C3N4/C materials to reduce the shuttling of polysulfides and improve their electrochemical performance. In LSBs, when the sulfur load was 1.8 mg cm−2, an initial specific capacity of 949 mAh g−1 was delivered at 0.2 C. After 135 cycles, the reversible specific capacity remained at 749 mAh g−1, with a decay rate of 0.156% per cycle. The Fe/Co-C3N4/C material had high specific surface area, high conductivity, and rich active sites, which improved the adsorption and conversion of lithium polysulfide. Zhang et al.208 prepared 3D porous-structured graphene-like C3N4 nanoflakes/carbon cloth/sulfur (g-C3N4/CC/S) composite material through simple thermal polymerization. The application of porous binderless g-C3N4/CC/S material in LSBs showed good electrochemical performance (with a specific capacity of 892 mAh g−1 at 0.2 C after 250 cycles). This excellent performance was attributed to the high porosity and favorable skeleton of g-C3N4/CC/S composite material for charge transfer. Carbon fiber was introduced to enhance conductivity. Wang et al.209 developed a g-C3N4/CNT hybrid material to enhance the multifunctional polysulfide barrier, inhibiting the shuttle effect and improving device performance, as shown in Figure 12. The obtained g-C3N4 had a unique sponge shape and a large specific surface area, providing carrier transport channels as well as an interface and active sites for polysulfide anchoring. The g-C3N4/CNT achieved excellent cyclability with a minimum decay rate of 0.03% per cycle (after 500 cycles). When the sulfur load was 10.1 mg cm−2, there was a high areal capacity of 7.69 mAh cm−2. Liu et al.210 prepared hollow tubular graphite-phase carbon nitride and applied it as a functional interlayer in LSBs to achieve the goal of suppressing the shuttle effect. It showed excellent performance (with a reversible specific capacity of 494 mAh g−1 at 1 C after 500 cycles). Each cycle had a specific capacity attenuation of 0.085%. N-doped tubular graphene-like (Tg)-C3N4 enhanced electron transfer and improved chemical adsorption and active sulfur catalysis. As a unique hollow tubular structure, Tg-C3N4 provided paths and active sites for ion migration. Jia et al.211 grafted carbon nitride onto waste-derived carbon. Sulfur grafted with C3N4-derived carbon was applied to LSBs, exhibiting a specific capacity of 1269.8 mAh g−1 at 0.05 C. The performance improvement was mainly attributed to the material's micropores, C3N4 as a sulfur carrier, and active sites on the surface. Xu et al.212 designed and prepared MoSe2@g-C3N4 composite material, MoSe2 loaded on the surface of g-C3N4 facilitated the migration of lithium polysulfide. When the MoSe2@g-C3N4 was applied in LSBs, it exhibited a specific capacity of 564.2 mAh g−1 at 3 C. At 0.5 C, the specific capacity decreased by 0.09% after 500 cycles at 0.5 C.

To improve the binding between nanosulfur and the main material, nanosulfur co-polymerization was achieved through a solution pathway under the action of 1,3-distyrene monomer. The loading of sulfur NPs on carbon-rich GCN was found to be beneficial for charge transfer by Tiwari et al.213 The sulfur content of the prepared composite material was 76%, indicating an initial specific capacity of 1380 mAh g−1 at 0.1 C. The discharge capacity was 700 mAh g−1 at 1 C after 1000 cycles. Each cycle had a specific capacity attenuation of 0.016%. Liu et al.214 uniformly dispersed and anchored CoS onto g-C3N4 nanosheets, forming CoS@g-C3N4 hybrid material. The as-synthetized CoS@g-C3N4 was loaded on polypropylene film. The device exhibited excellent performance with a specific capacity of 1290 mAh g−1 at 0.2 C. It delivered excellent cycling stability (with a specific capacity of 600 mAh g−1 at 0.1 C after 250 cycles). Wang et al.215 prepared protonated g-C3N4 (pCN)/CNTs by dissolution precipitation method. pCN was dispersed in H2SO4 and electrostatically self-assembled with CNTs. The optimal ratio of pCN to CNT was 1:1 (CC 1:1), exhibiting a specific capacity of 711.9 mAh g−1 at 1 C after 500 cycles. Sulfur was loaded on g-C3N4 and rGO, and PPy was polymerized and coated on the composite material. Moon et al.216 prepared g-C3N4/rGO/S@PPy hybrid material for application in LSBs. It showed a specific capacity of 1189 mAh g−1 after 200 cycles. When the sulfur content was 5 mg cm−2, the displayed g-C3N4/rGO/S@PPy areal capacity was 5.5 mAh cm−2. He et al.217 prepared graphite-phase carbon nitride and functionalized CNTs (g-C3N4/CNTs) through calcination and self-assembly methods, forming a 3D hybrid sulfur host. g-C3N4 nanosheets were grown in situ on the surface of CNTs and bonded with C–N bonds to form a large π-conjugated system. The hybrid material had a high sulfur utilization rate and polysulfide interaction, which effectively inhibited the polysulfide shuttle. The sulfur content was 80 wt%, and the device delivered a high specific capacity of 1351.2 mAh g−1. When the sulfur load was 5 mg cm−2, the initial specific capacity was 758.9 mAh g−1. After 200 cycles, the specific capacity retention rate was 77.1% at 1 C.

2.3 g-C3N4 applied in SIBs

SIBs are considered promising candidates to partially replace LIBs due to their abundant sodium resources and similar ion storage mechanisms.218-220 Their lower energy/power density and poor cycling stability have hindered their practical application, however.221-223 Increasing the surface load of active substances could effectively improve the energy/power density of SIBs.47, 224-226 The development of high-performance, inexpensive, and easily available negative electrode materials is of great significance for the industrialization of SIBs.227, 228

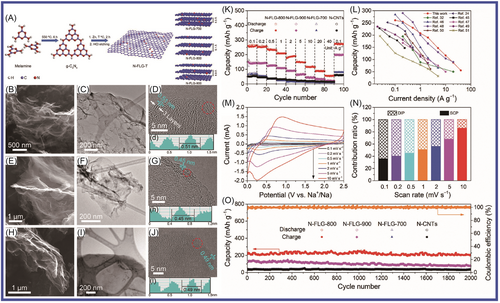

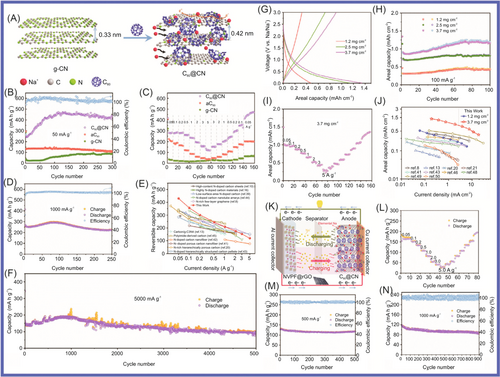

Lu and colleagues229 prepared antimony/graphitic carbon composite via a facile, high-throughput ball-milling method. The antimony/graphitic carbon composite materials were tested as anode for SIBs, which delivered an excellent overall performance in terms of packing density (200 mAh g−1 at 20 C), fast charge/discharge capability, and cyclability. The graphite matrix, which was tough and dense, provided an electron transport channel for the active materials, and the buffered antimony anode collapsed during charging and discharging. The optimization of graphite properties further improved the performance by increasing the cycle reversibility. Ultrathin N, P dual-doped hollow carbon fibers/g-C3N4 (huCP/g-C3N4) was synthetized by a simple and scalable approach, using common filter paper as a precursor, by Yang and colleagues230 As anode for SIBs, the huCP/g-C3N4 provided high reversible capacity of 345 mAh g−1 after 380 cycles at current density of 0.1 A g−1 and high capacity of 110 mAh g−1 after 4000 cycles at current density of 1 A g−1. The huCP/g-C3N4 and g-C3N4 networks had high contents of doped N and P, which not only had more defects and active sites but also expanded the plane surface area and provided conductive networks. Finally, the huCP/g-C3N4 as electrode material in SIBs showed excellent electrochemical performance. Camean and colleagues231 reported that graphitic carbon foam was prepared from bituminous coal via a simple procedure to construct suitable anode materials for SIBs in glyme-based electrolytes. The graphitic carbon foam was applied in SIBs, which exhibited excellent electrochemical performance (up to 90 mAh g−1 after 300 cycles at high electrical current density of 1.9 A g−1 with a Coulombic efficiency of 100%). Na+ ions underwent different combined intercalation processes through pseudocapacitance intercalation and diffusion control. The increased graphene layer spacing and the presence of boron promoted pseudocapacitance intercalation, and the increase in controlled intercalation capacity was mainly related to the increased boron content. Cao and colleagues232 reported that the N/S-co-doped hierarchically PCSs (denoted as S-N-HPCS), which had a large specific surface area (904.63 m2 g−1) and a high heteroatom-doping level (N: 10.51 wt%; S: 1.71 wt%), were synthesized by a novel and simple self-sacrificing dual-template strategy. g-C3N4 formed in situ and amorphous ZnO were used as sacrificial templates for preparing HPCS via high-temperature pyrolysis. The S-N-HPCS exhibited excellent reversible capacity of 270.1 mAh g−1 at current density of 100 mA g−1 and high stability (160.1 mAh g−1 after 2000 cycles at 1 A g−1 with a capacity retention of 82.3%). The spacing of g-C3N4 layers was limited, which limited the storage of sodium ions in the lattice. Highly ordered sulfur-doped MCN (S-MCN) was synthetized through a hard template approach by employing dithiooxamide as a single molecular precursor containing carbon, nitrogen, and sulfur elements by Vinu and colleagues.233 The larger S ions were introduced into the MCN lattice, and the interlayer spacing of carbon nitride was significantly expanded. This endowed the lattice with high capability for Na ion accommodation. Vinu and colleagues demonstrated via the first-principles density functional theory (DFT) calculations that the present S-MCN was highly optimized not only in terms of its chemical structure but also for taking up abundant Na ions with high adsorption energy. The optimized samples delivered a high reversible capacity of 304.2 mAh g−1 at current density of 100 mA g−1 after 100 cycles with nearly 100% Coulombic efficiency as an anode material for SIBs, which was far superior compared to the performances of nonporous S-CN and g-C3N4. Compared to the nonporous S-CN (167.9 mAh g−1) and g-C3N4 (5.4 mAh g−1), the specific discharge capacity of the SIBs was 304.2 mA h g−1. This excellent electrochemical performance was mainly attributable to the increased interlayer spacing, highly ordered structure, large surface area, uniform pore size distribution, and significant surface-induced capacitive contribution. Expanding the layer spacing revealed the influence of atomic doping on the structure of carbon materials, which became more effective anode materials for SIBs. Qiao and colleagues234 reported that a series of N-rich few-layer graphene (N-FLG) samples had been successfully synthesized with tunable interlayer spacing ranging from 0.45 to 0.51 nm via annealing g-C3N4 with zinc catalysis at selected temperatures (T = 700°C, 800°C, and 900°C), as shown in Figure 13. Due to the stronger electrostatic repulsion of pyrrole N, the interlayer spacing of graphene was increased. The N-FLG-800, which was used in SIBs as anodes, exhibited the optimal properties in terms of interlayer spacing, nitrogen configuration, and electronic conductivity. It showed excellent long-term stability (211.3 mAh g−1 at 0.5 A g−1 after 2000 cycles) and ultrahigh rate capability (56.6 mAh g−1 at 40 A g−1).

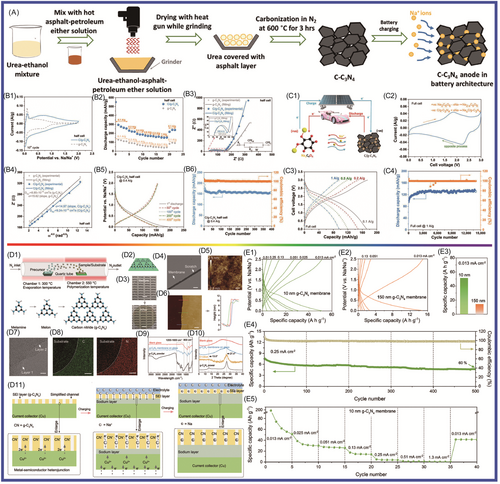

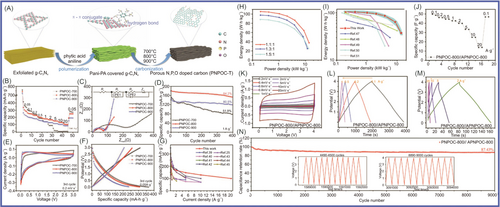

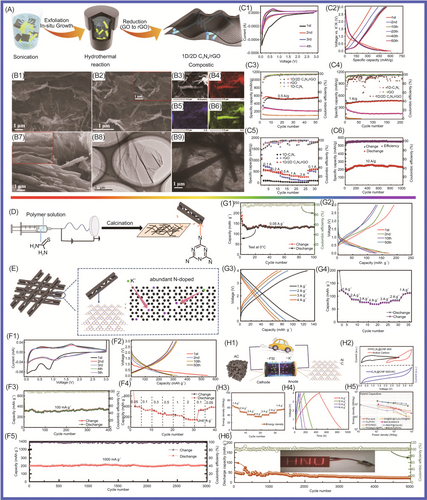

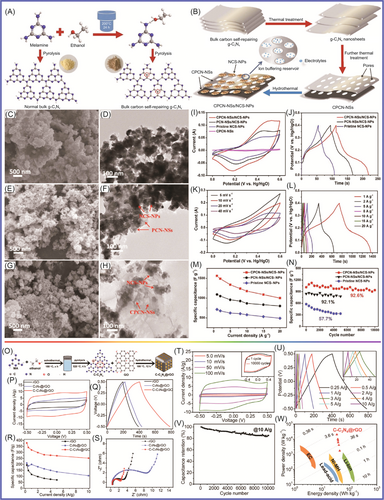

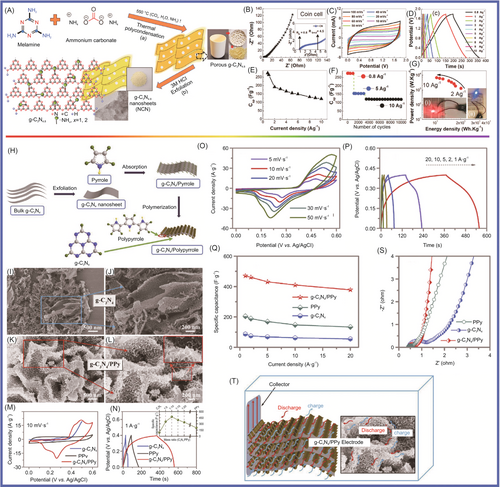

To improve g-C3N4 performance in SIBs, Taylor and colleagues235 prepared multilayer C/g-C3N4 composites via a facile one-pot heating of a mixture of low-cost urea and asphalt for application in SIBs, as shown in Figure 14A,B1–B6,C1–C4. The C/g-C3N4 demonstrated a specific capacity of 254 mAh g−1 (about two times higher than that of g-C3N4), and high Coulombic efficiency (~99.8%), rate capability, and cyclability. The discharge capacity remained at about 120 mAh g−1 after 14,000 cycles at 1 A g−1. Molaei et al.236 studied the application of P-doped g-C3N4 in SIBs using DFT. The results showed that P-doping narrowed the band gap of g-C3N4. The adsorption of Na on P-doped g-C3N4 was studied by investigating the density of states. The pyridinic N atom in g-C3N4 played a major role in the adsorption of Na. The calculations showed that when more P was doped, the lower voltage (below 2.2 V) was favorable for Na diffusion (with a barrier of 1.2 eV). The results showed that P-doped g-C3N4 was more suitable as an anode material for SIBs. As shown in Figure 14D1–D11,E1–E6, Xiao and colleagues237 deposited ultrathin g-C3N4 on Cu metal electrode and studied its effects on Na storage. The g-C3N4 film, which was prepared via a facile, efficient, and general chemical vapor deposition (CVD) method, was as thin as 10 nm. It delivered high reversible capacity up to 510,00 mAh g−1. This indicated that sodium was stored in g-C3N4, which was favorable for activating metal and sodium deposition. At the same time, an SEI layer was formed to avoid metal contact with the liquid electrolyte. Na2Ti3O7, which has the two disadvantages of low conductivity and sluggish Na+ diffusion in interfacial reactions as electrode material for SIBs, has stood out among many materials because of its low discharge voltage platform at about 0.3 V (relative to Na/Na+) and low cost. He and colleagues238 reported that Na2Ti3O7 nanotube species had been anchored to composites composed of graphite-phase carbon nitride (g-C3N4) and ultrafine graphene via a facile strategy (alkaline hydrothermal), forming 3D network structures. One Na2Ti3O7NT/g-C3N4/rGO sample retained a capacity of 210.8 mAh g−1 (after 300 cycles at 0.1 A g−1) and good rate capability (104.7 mAh g−1 at 2 A g−1) as a sodium storage material. The excellent electrochemical performance of Na2Ti3O7 nanotube/g-C3N4/graphene was mainly attributed to the following factors: the Na2Ti3O7 nanotubes in these carbon matrices could effectively shorten the Na+ transport paths, and g-C3N4/rGO support caused more active sites for Na+ insertion/extraction and accommodated the volume expansion of Na2Ti3O7.