Digital Capabilities and Supply Chain Resilience: Is Supply Chain Mapping the Missing Link?

Funding: This work was supported by Sunway University, GRTIN-KSGS(02)-DMNGT-07-2023.

ABSTRACT

Despite growing awareness of digital capabilities are crucial to supply chain resilience (SCR), but the understanding of how these capabilities enhance SCR remains limited. Prior research has provided the empirical evidence on the role of supply chain mapping (SCMAP) in enhancing SCR. However, the specific ways in which digital capabilities can aid firms in developing a thoroughly mapped supply chain across various levels remain unclear. This paper explores the interrelationships between digital capabilities, SCMAP, and their collective impact on SCR. The findings reveal that while digital capabilities do not have a direct impact on SCR, they significantly influence SCR indirectly via SCMAP. This research is pioneering in examining these connections, offering fresh perspectives on the interplay between digital capabilities, SCMAP, and SCR. In light of these insights, the study recommends that firms sequentially develop their digital capabilities, refine their SCMAP, and enhance their SCR to achieve optimal outcomes.

1 Introduction

Globalization has intensified supply chain complexity and amplified market uncertainties, creating significant operational challenges for firms worldwide (Piprani et al. 2024). The global business landscape has recently encountered extraordinary disruptions, most notably the COVID-19 pandemic, which starkly revealed the vulnerabilities of deeply interconnected supply chains (Ivanov and Das 2020; Kähkönen et al. 2023). Unlike previous localized events, the pandemic's worldwide impact triggered concurrent shutdowns across multiple tiers of the supply network, leading to cascading disruptions that exposed structural weaknesses even in highly advanced systems (Ivanov and Das 2020; van Hoek and Dobrzykowski 2021).

Compounding these disruptions, rapid technological advancement and increasingly shorter product life cycles have contributed to heightened supply chain instability and fragility (Singh and Vinodh 2017; Piprani et al. 2022). As a result, organizations have been compelled to reassess their operational strategies and adopt innovative practices to build greater resilience (Ivanov and Dolgui 2022). For example, Apple experienced a 20%–30% decline in production during China's COVID-19 lockdown due to halted manufacturing, component shortages, logistics bottlenecks, and labor constraints across its global supply ecosystem (Sharma et al. 2023, 2024). Likewise, the Ukraine conflict has caused widespread supply chain disruptions, particularly in energy and critical raw materials (Cui et al. 2023). In the year 2022, the sharp rise in natural gas prices across Europe compelled manufacturers to adopt energy rationing measures and adjust their production schedules (Di Bella et al. 2024). Likewise, chemical producers, particularly in Germany, were forced to scale down operations and shift production to alternative facilities in Asia (Selg and Farhod 2025). Simultaneously, Ukraine's critical role in supplying neon gas for semiconductor manufacturing emerged as a major vulnerability. The resulting surge in prices prompted companies to seek alternative sources in other Asian countries, leading to longer lead times and highlighting the fragility of global supply chain interdependencies (Singal 2022).

In response to such systemic shocks, firms are increasingly prioritizing supply chain improvements to maintain competitiveness in a volatile global environment (Khan et al. 2023; Piprani et al. 2024). While some organizations struggled to adapt, others, such as Expedia, Dell Technologies, and Nvidia, demonstrated remarkable resilience by leveraging agile operations and proactive risk management strategies (Datskevych 2022; Reeves et al. 2022). For instance, Expedia accelerated its digital transformation and significantly reduced operating costs by streamlining its workforce and consolidating brands. Similarly, Dell mitigated regional dependencies by diversifying its supplier network across multiple countries and leveraging predictive analytics to anticipate disruptions and optimize inventory. In contrast, Nvidia addressed semiconductor shortages by forming strategic partnerships with manufacturers and prioritizing the production of high-margin products to sustain profitability (Sharma et al. 2024). Collectively, these varied outcomes emphasize the urgent need to identify and understand the key enablers that empower firms to maintain continuity and achieve performance objectives amid severe supply chain disruptions.

Confronted with these mounting challenges, numerous firms have accelerated the integration of digital technologies to strengthen their supply chain resilience (SCR) (El Baz and Ruel 2024). SCR, characterized by the ability to withstand shocks, adapt to changes, and recover quickly from disruptions, has risen to prominence in academic and professional discussions (Pettit et al. 2019). Balakrishnan and Ramanathan (2021) contend that digital technologies have been crucial in strengthening supply chain resilience amid the pandemic crisis caused by various COVID strains. Companies like JD.com and Tata Steel have leveraged digital technologies to maintain operations during the pandemic, proving the efficacy of such technologies under difficult conditions (Dubey et al. 2023). Ivanov et al. (2022) highlight that a digitally driven supply chain features a dynamic and inherently self-adaptive structure and process. This agility enables it to react effectively to uncertainties in internal and external environments, thereby providing greater resilience in the face of disruptions.

The increasingly crucial role of emerging technologies in business operations and supply chain management is well documented (Venkatesh et al. 2024). Amidst this technological advancement, scholars are investigating how technological capabilities can improve different facets of supply chain management (Akbari and Hopkins 2022). For example, Mubarik et al. (2021) emphasize the importance of supply chain mapping in bolstering supply chain resilience, highlighting its role in providing a comprehensive view of the entire network, its elements, and their interconnections. Through detailed mapping across various levels, organizations can identify potential vulnerabilities, assess risks, and devise effective strategies to mitigate disruptions (Berger et al. 2023). By creating a detailed visualization of the supply network including suppliers, manufacturers, distributors, and logistics providers, companies can proactively identify bottleneck areas and sources of disruptions that might not be visible when focusing solely on immediate suppliers (Sodhi and Tang 2021). This increased visibility enables more precise risk assessments, allowing organizations to sense and assess the potential impact of disruptions at different levels in the network and to formulate targeted mitigation strategies, such as diversifying suppliers or establishing alternative transportation routes (Ivanov 2021). Digital capabilities are pivotal in transforming supply chain management across all segments: Upstream, midstream, and downstream. These capabilities encompass individual, managerial, and operational competencies, offering a holistic framework for enhancing supply chain mapping (Wei et al. 2024). At the upstream level, technical skills and critical thinking enable effective supplier management and performance evaluation through advanced digital tools. Managerial capabilities promote the adoption of these technologies, optimizing procurement with automated systems and real-time analytics to reduce disruptions (Shamout 2024). At the midstream level, digital tools enhance process efficiency and quality control, boosting manufacturing outputs with smart technologies and digital twins (Wanasinghe et al. 2020). At the downstream level, digital expertise in customer service and marketing drives online sales and customer satisfaction, supported by managers skilled in omnichannel strategies and logistics, ensuring seamless customer experiences and efficient inventory management (Ishfaq et al. 2022). By synchronizing individual technological capabilities with strategic managerial capabilities and operational advancements, companies are better equipped to handle the complexities of modern supply chains amidst disruptions. This approach not only strengthens resilience against disruptions but also positions organizations to capitalize on emerging opportunities in a swiftly evolving global market.

Despite the recognized importance of digital capabilities in enhancing resilience, there remains a significant gap in understanding how holistic digital capabilities contribute to both supply chain mapping and resilience. While empirical studies have highlighted specific technologies like blockchain in improving supply chain mapping, existing research tends to isolate technological tools without fully examining the broader digital capabilities required for mapping and visibility across complex, multitier networks. Furthermore, the existing literature has established direct links between digital capabilities and supply chain resilience, yet the mediating role of supply chain mapping–spanning upstream, midstream, and downstream segments, remains largely unexplored. This gap is critical, as mapping practices serve as a key mechanism through which digital capabilities translate into resilience outcomes. Foundational studies have emphasized the supply chain mapping's role in risk identification and mitigation (Christopher et al. 2004; Sodhi and Tang 2021), but an organization's capacity to effectively utilize digital capabilities at individual, managerial, and operational levels to enhance real-time mapping functionality needs further investigation. As supply chains face increasing complexity and volatility, empirical evidence on how digital capabilities can be effectively employed to achieve well-mapped, dynamically responsive, and resilient supply chains becomes essential.

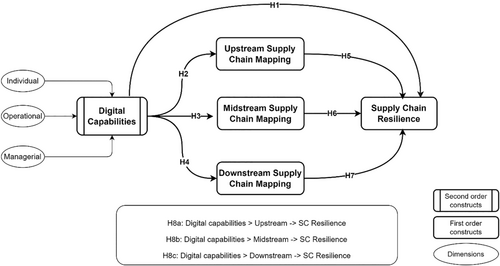

RQ1: How do multilevel dynamic digital capabilities (individual, managerial, and operational) influence supply chain resilience?

RQ2: How does supply chain mapping (upstream, midstream, and downstream) mediate the relationship between dynamic digital capabilities and supply chain resilience?

2 Literature Review and Hypothesis Development

2.1 Theoretical Underpinnings

This study investigates how firms' digital capabilities at the individual, operational, and managerial levels enhance supply chain resilience (SCR), and examines the mediating role of supply chain mapping in this relationship. Grounded in dynamic capabilities theory (DCT), which extends the resource-based view (RBV), the study explores how digital capabilities enable firms to sense, seize, and transform in response to disruptions (Teece 2017). DCT posits that competitive advantage arises not only from valuable and scarce resources but also from the firm's ability to adapt and reconfigure these resources in a dynamic environment.

Digital capabilities serve as dynamic resources, allowing real-time decision-making, proactive risk management, and strategic responsiveness (Piprani et al. 2022). In this context, supply chain mapping acts as a critical enabler by offering end-to-end visibility across upstream, midstream, and downstream operations. It facilitates the identification of vulnerabilities and supports agile responses to disruptions, thereby enhancing resilience (Belhadi et al. 2024; Mubarik et al. 2024).

While prior studies have explored factors influencing SCR, limited attention has been given to the integrative role of digital capabilities and supply chain mapping in driving resilience. Addressing this gap, the present study proposes a conceptual framework to clarify the mechanisms through which digital capabilities and mapping practices jointly strengthen supply chain resilience.

2.2 Supply Chain Resilience

The concept of supply chain resilience (SCR) initially emerged within the contexts of risk management and vulnerability assessment (Jüttner et al. 2003). Christopher and Peck (2004) later offered a clear definition, viewing SCR as a system's ability to recover or adapt to a more desirable state after disruption. Sheffi and Rice Jr (2005) expanded this view, highlighting resilience as a competitive advantage. Since then, SCR has gained prominence, especially after major disruptions like COVID-19. It is now seen as a supply chain's ability to anticipate, respond to, and recover from disruptions while maintaining continuity, cost efficiency, and productivity Piprani et al. 2022. Supply chain resilience (SCR) is the ability to anticipate, respond to, and recover from disruptions while maintaining continuity, controlling costs, and sustaining productivity (Piprani, Jaafar, et al. 2022). It involves both reactive and proactive strategies to ensure competitiveness and business continuity (Tukamuhabwa et al. 2017). A World Economic Forum survey (2013) found that over 80% of firms view SCR as a major concern (Scholten et al. 2020), underscoring its strategic importance. Beyond mitigating risks, SCR offers a competitive edge by enabling firms to adapt quickly and seize opportunities, making it vital for success in today's volatile and interconnected supply networks (Lin et al. 2023; Zhao et al. 2023).

2.3 Dynamic Digital Capabilities

The notion of dynamic capabilities was first proposed by Teece et al. (1997), who defined it as a firm's capacity to integrate, build, and reorganize internal and external skills to respond to swiftly evolving the environment. While the concept of Dynamic Digital Capabilities (DDCs) has arisen in reaction to the rapid advancement of digital transformation across several industries (Dubey et al. 2023). Dynamic digital capabilities encompass an organization's capacity to adapt, innovate, and restructure digital technologies to meet strategic goals in unpredictable business environments (Sousa-Zomer et al. 2020). These skills include technical expertise, organizational learning, leadership support, and cross-functional integration. Thus, the rise of digitalization has instigated a profound transformation in organizational capabilities, leading to the development of intelligent, interconnected, and decentralized interorganizational relationships within supply chains (Machado et al. 2019). This shift has facilitated the emergence of the “Industry 4.0” (I4.0) paradigm, which integrates advanced technologies with organizational skills, aiming to enhance agility, sustainability, and flexibility in supply chain dynamics. Additionally, I4.0 strives to optimize the use of resources and information while increasing adaptability to changing economic conditions and management practices (Mujahid Ghouri et al. 2021; Tortorella et al. 2020). At the heart of the dynamic digital capabilities' framework are three essential capabilities aimed at reducing uncertainties and enhancing process efficiency: Individual employee capabilities, operational capabilities, and managerial capabilities (Belhadi et al. 2022). Individual employee capabilities involve specific skills, knowledge, and competencies that employees use to improve efficiency, reduce errors, and enhance the performance and resilience of the supply chain ecosystem (Dubey et al. 2023). These capabilities are critical in cultivating a workforce that is not only technically skilled but also capable of adapting to the fast-evolving digital landscape of contemporary supply chains. Operational capabilities, on the other hand, pertain to the technological and infrastructural assets that enable the transformation of organizational processes. These capabilities facilitate improved communication, strengthen interorganizational ties, and support real-time data monitoring and information sharing (Lu et al. 2023). By capitalizing on advanced operational capabilities, organizations can foster a more responsive and cohesive supply chain network, adept at navigating market volatility and operational hurdles. Managerial capabilities form the third pillar of this framework, equipping leaders to implement and manage advanced technical processes that bring about continuous improvements across value chains (Luthra et al. 2020). These capabilities are essential for strategic decision-making, resource distribution, and guiding digital strategies that align with broad organizational goals. Effective managerial capabilities are vital to ensuring that the benefits of individual and operational capabilities are fully leveraged, leading to comprehensive optimization of the supply chain. As firms progress in their digital transformation journeys, the development and synchronization of these capabilities will become increasingly crucial in securing a competitive edge in the global market.

2.4 Supply Chain Mapping

Supply chain mapping (SCM) originated in the late 1980s (Gardner and Cooper 2003) and has since evolved into a key organizational tool for improving supply chain efficiency and integration (MacCarthy et al. 2022; Mubarik et al. 2021). It visualizes the flow of materials, information, and funds across upstream, midstream, and downstream networks, enabling firms to identify vulnerabilities and interdependencies (Ali et al. 2021; Fabbe-Costes et al. 2020). Especially in the wake of global disruptions like COVID-19, SCM has proven essential for scenario planning and resilient supply chain design (Ali et al. 2023). Thus, supply chain mapping (SCM) is a critical tool that offers a visualization of the supply chain network, illustrating the movement of materials, information, and funds across all SC streams (i.e., upstream, midstream, and downstream supply chain) from suppliers to end customers (Fabbe-Costes et al. 2020). By improving supply chain visibility and transparency SC mapping facilitates more effective monitoring and control over supply chain activities (Khan et al. 2022) The origins of supply chain mapping can be tracked back to the end of the 1980s (Star and Griesemer 1989). Following then, it has been widely employed as a crucial organizational method to enhance the efficiency of supply chain (Mubarik et al. 2021) that specifically examines the connections and integration between various agencies within a supply chain (MacCarthy et al. 2022). According to Montoya-Torres (Montoya-Torres et al. 2021), the utilization of SC mapping is a highly effective tool that offers significant insights into the operations of a supply chain (Ivanov 2021). Furthermore, it serves to enhance visibility, support management of risks, and facilitate process improvement (Mubarik et al. 2021; Richert and Dudek 2023).

2.5 Dynamic Digital Capabilities and Supply Chain Resilience

Supply chain resilience is essential for the mitigation of risks and the rapid adaptation and recovery of businesses from a number of challenges, including economic downturns, natural disasters, political disputes, and technological advancements (Piprani et al. 2024). Consequently, digital capabilities enable real-time visibility into supply chain operations, sense and respond to long-term changes in their demand and supply situations (Shi et al. 2023). These innovations help supply networks adapt to changes while recovering from interruptions (Piprani et al. 2023). According to prior studies, organizations' that prioritize regular digital skills training are more equipped to navigate and embrace technological advancements and disruptions (Iftikhar et al. 2024; Papadopoulos et al. 2017). Likewise, operational capabilities to streamline and optimize supply chain processes (Ivanov and Dolgui 2020). While, managerial capability enables managers to strategic planning, decision-making, and other managerial tasks to enables better risk assessment promoting resilient supply chain operations (Essex et al. 2015). Collectively, these capabilities facilitate informed decision-making, proactive risk management, efficient operations, and improved visibility, thus ensuring that supply chains can effectively recover from disruptions. Hence, this leads to the formation of following hypothesis.

H1.Dynamic digital capabilities positively influence supply chain resilience.

2.6 Dynamic Digital Capabilities and Supply Chain Mapping

The integration of diverse digital capabilities, such as individual, operational, and managerial, within organizational processes can markedly enhance the effectiveness and precision of supply chain operations (Dubey et al. 2023). Individual capabilities, for instance, boost the digital proficiency of employees, leading to more accurate data collection and analysis, which, in turn, improves the integrity of supply chain mapping (Tortorella et al. 2020). Similarly, operational capabilities, which encompass technologies and infrastructure, can transform organizational processes by enhancing communication, commitment, and tracking of information and data (Belhadi et al. 2022). Additionally, the enhancement of managerial digital capabilities can significantly improve decision-making and strategic planning, thus optimizing efficiency and extending the scope of supply chain mapping (Kamble et al. 2020). Effective supply chain mapping is essential for identifying and addressing challenges that arise from misalignments and a lack of coordination in various organizational activities, from procurement to delivery to customers (Stavrulaki and Davis 2010). Prior research suggests that the utilization of digital capabilities leads to improved resource efficiency by fostering complete transparency across the value chain, resulting in a more coherent and visible supply chain process (Beier et al. 2020). Based on this discussion, the following hypotheses are proposed for further investigation.

H2.Dynamic digital capabilities positively influence the upstream supply chain mapping.

H3.Dynamic digital capabilities positively influence the midstream supply chain mapping.

H4.Dynamic digital capabilities positively influence the downstream supply chain mapping.

2.7 Supply Chain Mapping and Resilient Supply Chain

The absence of visibility within supply networks significantly hampers an organization's capacity to manage disruptions effectively (MacCarthy et al. 2022) Nonetheless, a well-designed supply chain map provides clear and easily comprehensible information across all three dimensions: Upstream, midstream, and downstream (Pimenta et al. 2022). Enhancing the visibility of complex supply chain networks is essential, as comprehensive visibility is fundamental to building resilience, enabling continuous monitoring and rapid response to disruptions (Dey 2023; Holgado and Niess 2023). Previous research indicates that organizations can pinpoint critical vulnerability points and potential failure sites by meticulously mapping every link in the supply chain (Sharma et al. 2023). Such detailed supply chain mapping facilitates effective monitoring of information, goods, and financial flows across the supply chain (Mubarik et al. 2023), allowing for a more precise risk assessment and improved prioritization of mitigation efforts (Richert and Dudek 2023), which ultimately enhances supply chain resilience. Hence, this leads to the formation of the following three hypotheses.

H5.Upstream supply chain mapping positively influences the resilience in supply chain.

H6.Midstream supply chain mapping positively influences the resilience in supply chain.

H7.Downstream supply chain mapping positively influences the resilience in supply chain.

2.8 Dynamic Digital Capabilities, Supply Chain Mapping, and Resilient Supply Chain

With SCR, a firm can be able to proactively anticipate, prepare for, respond to, and recover from unexpected disruptions, maintaining uninterrupted operations and preserving performance (Ekren et al. 2023; Zamani et al. 2023). It plays a critical role in reducing vulnerability and helping organizations return to their prior operational state (Pettit et al. 2013). As the business environment becomes increasingly complex and dynamic, the management of risks assumes greater importance. In this context, researchers are exploring how supply chain mapping can help businesses enhance SCR, enabling them to recover performance levels after disruptions (Mubarik, Naghavi, et al. 2021). Incorporating digital capabilities, including individual, operational, and managerial skills, into organizational processes can significantly enhance the efficiency and accuracy of supply chain operations (Belhadi et al. 2022). Digital capabilities empower organizations to comprehensively map and understand their upstream supply network, encompassing suppliers along with their capabilities, limitations, and associated risk (Sodhi et al. 2023). Utilizing digital technologies to enhance visibility and integration with upstream partners (Rahman et al. 2025), firms can substantially enhance their capacity to foresee, mitigate, and address supply-side disruptions, thus bolstering overall supply chain resilience (Piprani et al. 2023). Additionally, digital capabilities enable more effective mapping and optimization of internal supply chain processes, which can lead to enhanced operational flexibility and responsiveness (Eckstein et al. 2015). Such improved midstream visibility and control can contribute to a more adaptable supply chain, capable of responding to both internal and external disruption (Brandon-Jones et al. 2014). Furthermore, dynamic digital capabilities allow for advanced mapping and analysis of downstream supply chain elements, potentially improving an organization's ability to detect and react to demand shifts and market disruptions (Belhadi et al. 2024). This enhanced downstream visibility and agility may bolster overall supply chain resilience by facilitating more effective demand management and maintaining customer service continuity during disruptive events (Hohenstein et al. 2015). Thus, this leads to the formation of the following hypothesis.

H8a.Upstream supply chain mapping mediates the relationship between dynamic digital capabilities and supply chain resilience.

H8b.Midstream supply chain mapping mediates the relationship between dynamic digital capabilities and supply chain resilience.

H8c.Downstream supply chain mapping mediates the relationship between dynamic digital capabilities and supply chain resilience.

Figure 1 illustrates the comprehensive study framework, developed based on the hypotheses presented.

3 Research Methodology

3.1 Instrument Development

The survey development process was grounded in a thorough review of the relevant literature to ensure that our instruments were both valid and reliable. Initially, academic experts reviewed the survey questions to confirm their face and content validity. This initial phase was followed by a pilot study where industry practitioners tested the survey, providing further validation through their practical insights. Based on the combined feedback from both academics and practitioners, we refined the questions, keeping only those that were agreed upon as accurately reflecting current practices and effectively measuring the intended constructs. This systematic approach, consistent with best practices in quantitative research (Belhadi et al. 2024; Piprani, Nazir, et al. 2025), guarantees accurate measurement of constructs and comprehensive analysis of the proposed relationships. Furthermore, we have secured approval from the ethics committee. For the section on digital capabilities, we included questions that assessed individual, managerial, and operational capabilities. All the measurement items from these dimensions of digital capabilities were adapted from Belhadi et al. (2022). The supply chain mapping, which was categorized from USC, MSC, and DSC, was adapted from Mubarik, Naghavi, et al. (2021), while supply chain resilience was adapted from Piprani et al. (2024) and Pu et al. (2023). The constructs used in our survey are detailed in Appendix 1.

3.2 Data Collection

This study focuses on manufacturing enterprises that have embraced a certain degree of digitalization in the Klang Valley, an area significantly impacted by supply chain disruptions. Relative to other regions in Malaysia, Klang Valley region is more economically advanced and has a higher concentration of manufacturing activities. As the region experiences rapid development, companies are increasingly adopting digital management practices to secure competitive advantages. The research centered on supply chain professionals from Malaysia's large-scale manufacturing industry, which is witnessing significant growth fueled by national digital transformation efforts. This study rigorously adhered to empirical research methodologies in the design, sampling, and distribution of the questionnaire. A stratified random sampling approach was employed, focusing on companies affiliated with the Federation of Malaysian Manufacturers (FMM), a pivotal entity in the industrial sector. The study specifically targeted large-scale manufacturers, defined as enterprises with over 200 full-time employees, to explore how Industry digital capabilities are reshaping essential capabilities like supply chain mapping in enhancing supply chain resilience. The questionnaires targeted managerial position holder within companies to ensure the data accurately reflected the operational conditions of the enterprises surveyed. Following Bartlett (2019) recommendation, the minimum sample size was determined using G*Power 3.1, which calculates optimal sample size based on the type of analysis and number of predictors. Based on Faul et al.'s (2009) guidelines, a minimum of 85 respondents was required, using a power level of 80%, an alpha of 0.05, and a medium effect size of 0.15.

Data collection spanned from November 2023 to February 2024 through an online survey. Out of 350 questionnaires distributed at the first stage yield 85 complete responses. A systematic follow-up strategy, involving monthly reminders and a final call, provided an additional 42 responses, thus a total 127 received. After rigorous scrutiny for quality, four responses were excluded due to inconsistencies or irrelevance to the study's scope, resulting in 123 valid questionnaires for analysis. The demographic details of the respondents, presented separately, provided wide representation across the sector, thereby enhancing the findings' applicability to the broader national context. This methodical data collection strategy ensures that the subsequent analysis yields insightful observations on the role of digital capabilities in enhancing supply chain resilience through supply chain mapping in Malaysia's evolving economic landscape.

3.3 Measurement Bias and Error

In our research, we took measures to mitigate potential common method bias (CMB) and nonresponse bias, which can compromise the integrity of survey-based studies. To counteract CMB, we incorporated procedural strategies including the use of subject matter experts as respondents, randomizing the sequence of questions, distinctly separating dependent and independent variables, and integrating attention-check questions within the survey. Additionally, we conducted three statistical tests to confirm the absence of CMB. The results of Harman's one-factor test indicated that a single factor accounted for only 35.68% of the total variance, well below the critical threshold of 50%. Furthermore, a full collinearity assessment using Smart PLS showed that all indicators had VIF values below 3, corroborating the nonexistence of CMB. We additionally examined this bias through the marker variable technique, as suggested by Simmering et al. (2015). We employed social desirability—a construct theoretically unrelated to our study—as a marker variable. By assessing the correlations among substantive variables before and after adjusting for the effects of the marker variable, we observed negligible changes (ΔR2 = 0.033). This indicates that common method variance had minimal impact on our key constructs and their interrelationships. To tackle nonresponse bias, we analyzed the early responses (first 85 participants) against the later ones (subsequent 42 participants) through a paired t-test, revealing no significant differences across any of the variables. These proactive steps and subsequent findings reinforce the reliability of our study, confirming it is free from significant influences of CMB and nonresponse bias.

4 Results and Analysis

4.1 Analysis and Interpretation of the PLS Model

Following a pilot study and preliminary assessments of reliability and validity, a large-scale data collection was conducted. The data were subsequently prepared, coded, and cleaned to ensure the robustness and accuracy of the results. Thereafter, SMART PLS 4.1 was employed to analyze the data. A two-step procedure was employed for the path model analysis. First, the measurement model was rigorously assessed for reliability and validity to ensure accuracy and precision. Subsequently, the structural model was evaluated to determine its relevance and explanatory strength.

4.2 Measurement Analysis

The study commenced with a confirmatory factor analysis (CFA) to assess the reflective orientation of the latent variables. According to Hair et al. [70], in PLS-based reflective models, constructs act as underlying reasons for their indicators, without affecting relationships among the constructs themselves. For evaluating construct reliability and validity, Hair et al. (2019) recommended employing Cronbach's alpha (Cα > 0.70), composite reliability (CR > 0.70), and average variance extracted (AVE > 0.50). The analysis confirmed that all measurement items for the variables exhibited strong factor loadings (above 0.70), as shown in Table 1. The study complied with Hair et al. (2019) criteria for construct reliability and validity by using Cronbach's alpha, composite reliability, and average variance extracted, each exceeding their respective benchmarks.

| Construct | Dimensions | Items | Outer loadings | Cronbach's alpha | Composite reliability | AVE |

|---|---|---|---|---|---|---|

| Dynamic digital capabilities (DDC) | Individual capabilities | ICP1 | 0.893 | 0.918 | 0.933 | 0.777 |

| ICP2 | 0.875 | |||||

| ICP3 | 0.881 | |||||

| ICP4 | 0.877 | |||||

| Managerial capabilities | MCP1 | 0.893 | 0.897 | 0.929 | 0.814 | |

| MCP2 | 0.915 | |||||

| MCP3 | 0.899 | |||||

| Operational capabilities | OC1 | 0.869 | 0.882 | 0.913 | 0.723 | |

| OC2 | 0.841 | |||||

| OC3 | 0.864 | |||||

| OC4 | 0.827 | |||||

| Supply Chain Mapping (SCMAP) | Upstream SC Mapping | USM1 | 0.703 | 0.934 | 0.941 | 0.638 |

| USM3 | 0.788 | |||||

| USM4 | 0.804 | |||||

| USM5 | 0.821 | |||||

| USM6 | 0.793 | |||||

| USM7 | 0.826 | |||||

| USM8 | 0.772 | |||||

| USM9 | 0.858 | |||||

| USM10 | 0.816 | |||||

| Midstream SC Mapping | MSM1 | 0.802 | 0.939 | 0.948 | 0.694 | |

| MSM2 | 0.827 | |||||

| MSM3 | 0.846 | |||||

| MSM4 | 0.805 | |||||

| MSM5 | 0.861 | |||||

| MSM6 | 0.833 | |||||

| MSM7 | 0.823 | |||||

| MSM8 | 0.864 | |||||

| Downstream SC Mapping | DSM1 | 0.863 | 0.921 | 0.934 | 0.669 | |

| DSM2 | 0.807 | |||||

| DSM3 | 0.811 | |||||

| DSM4 | 0.747 | |||||

| DSM5 | 0.822 | |||||

| DSM6 | 0.841 | |||||

| DSM7 | 0.828 | |||||

| SC Resilience | SCR1 | 0.782 | 0.866 | 0.904 | 0.653 | |

| SCR2 | 0.784 | |||||

| SCR3 | 0.873 | |||||

| SCR4 | 0.828 | |||||

| SCR5 | 0.768 |

Discriminant validity for all variables has been confirmed through various methods. This includes comparisons of the square root of the average variance extracted (AVE) with correlations, as detailed in Table 2, and adherence to the Heterotrait–Monotrait (HTMT) ratio criterion, shown in Table 3 (Henseler et al. 2015). The analysis of the reflective measurement model highlights its robustness in reliability, convergent validity, and discriminant validity, as summarized in Tables 1–3.

| DSM | ICP | MCP | MSM | OC | SCR | USM | |

|---|---|---|---|---|---|---|---|

| DSM | 0.818 | ||||||

| ICP | 0.594 | 0.881 | |||||

| MCP | 0.718 | 0.619 | 0.902 | ||||

| MSM | 0.811 | 0.660 | 0.624 | 0.833 | |||

| OC | 0.722 | 0.677 | 0.641 | 0.661 | 0.850 | ||

| SCR | 0.794 | 0.686 | 0.678 | 0.785 | 0.706 | 0.808 | |

| USM | 0.723 | 0.768 | 0.714 | 0.771 | 0.616 | 0.610 | 0.799 |

| DSM | ICP | MCP | MSM | OC | SCR | USM | |

|---|---|---|---|---|---|---|---|

| DSM | |||||||

| ICP | 0.646 | ||||||

| MCP | 0.782 | 0.681 | |||||

| MSM | 0.873 | 0.709 | 0.675 | ||||

| OC | 0.800 | 0.753 | 0.714 | 0.725 | |||

| SCR | 0.884 | 0.769 | 0.766 | 0.864 | 0.808 | ||

| USM | 0.819 | 0.823 | 0.766 | 0.820 | 0.896 | 0.899 |

- Note: Abbreviations: DSM = Downstream supply chain mapping; DSM = Midstream supply chain mapping; ICP = Individual capabilities; MCP = Managerial capabilities; OC = Operational capabilities; SCR = Supply chain resilience; USM = Upstream supply chain mapping.

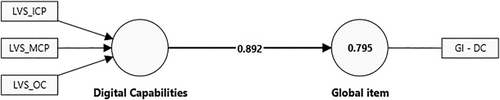

In this research, the formative construct of DDC was validated through redundancy analysis, assessing multicollinearity via VIF, and evaluating the significance of outer weights. The redundancy analysis results for DDC show the links between the global item (endogenous variable) and the dimensions of DDC (exogenous items), specifically individual, managerial, and operational capabilities. The path coefficient between the exogenous and endogenous variables was 0.892, surpassing the threshold of 0.7 as depicted in Figure 2. Additionally, the R2 value for the endogenous variable was 0.795, above the 0.5 standard, indicating strong convergent validity. The multicollinearity assessment with VIF found each DDC measurement item with a VIF below 3.3. Furthermore, the assessment of outer weights, presented in Table 4 and conducted through bootstrapping, confirmed the significance of all items at the 5% level, verifying that each dimension of DDC significantly influences its composition.

| Constructs | VIF | Outer weights (outer loadings) | T value | p |

|---|---|---|---|---|

| ICP | 2.071 | 0.790 (0.929) | 14.529 | 0.000 |

| MCP | 1.902 | 0.183 (0.610) | 1.993 | 0.066 |

| OC | 2.165 | 0.221 (0.771) | 2.833 | 0.005 |

4.3 Structural Model Assessment

Following the evaluation of both reflective and formative measurement models, the analysis advanced to the structural model. Path significance was determined using t-statistics obtained from bootstrapping with 10,000 subsamples. Variance inflation factor (VIF) values ranged from 1.582 to 2.497, all well below the commonly accepted threshold of 3.3, thus confirming no multicollinearity among the predictor constructs. The predictive relevance of the model was assessed through cross-validated redundancy employing a blindfolding technique, which indicated that the endogenous constructs—USM (0.274), MSM (0.521), DSM (0.754), and SCR (0.609)—all demonstrated Q2 values above zero, confirming their adequate predictive relevance.

Table 5 encapsulates these findings, presenting path coefficients that mirror the estimated beta coefficients. The direct effect analysis revealed that except H1 (DDC → SCR) (β = 0.154, p > 0.1), all other direct effect effects are positive and significant. For mediation effect, the study employed (Hair Jr et al. 2014) reported methodology for testing mediation analysis. The analysis demonstrates that the indirect impact of USM (β = 0. 267, p < 0.01) and DSM (β = 0.200, p < 0.05) on the relationship between DDC and SCR are statistically significant, thereby supporting H8a and H8c. Conversely, the indirect effects of MSM on the DDC and SCR relationship is not significant, necessitating the rejection of H8b. The indirect effect results are presented in Table 6.

| Direct effect | t-statistics | p | Decision | |

|---|---|---|---|---|

| H1: DDC → SCR | 0.154 | 1.472 | 0.141 | No |

| H2: DDC → USM | 0.871 | 29.418 | 0.000 | Yes |

| H3: DDC → MSM | 0.739 | 11.821 | 0.000 | Yes |

| H4: DDC → DSM | 0.783 | 15.998 | 0.000 | Yes |

| H5: USM → SCR | 0.306 | 2.591 | 0.010 | Yes |

| H6: MSM → SCR | 0.228 | 1.911 | 0.056 | Yes |

| H7: DSM → SCR | 0.255 | 2.733 | 0.006 | Yes |

- Note: R2 → USM = 0.758; MSM = 0.547; DSM = 0. 613; SCR = 0.751; Q2 → USM = 0.274; MSM = 0.521; DSM = 0.754; SCR = 0.609.

| Structural paths | Indirect effect | T-value | p | 95% BC confidence interval | Results |

|---|---|---|---|---|---|

| H8a: DDC → USM → SCR | 0.267 | 2.575 | 0.010 | [0.060–0.464] | Yes |

| H8b: DDC → MSM → SCR | 0.169 | 1.802 | 0.072 | [−0.001–0.373] | No |

| H8c: DDC → DSM → SCR | 0.200 | 2.580 | 0.010 | [0.075–0.384] | Yes |

5 Discussion

The research rigorously evaluated the proposed hypotheses by employing partial least squares structural equation modelling (PLS-SEM). The analysis uncovers a complex interplay between dynamic digital capabilities, supply chain mapping, and supply chain resilience. This study builds upon the dynamic capability theory (Teece et al. 1997; 7), which has been extensively applied in supply chain management research. This study extends dynamic capabilities theory in several important ways. First, it reconceptualizes digital capabilities as a three-dimensional construct such as individual, managerial, and operational—shifting beyond the traditional technology-centric perspective to highlight the critical human and organizational enablers of digital transformation. Second, this study positions supply chain mapping as a key orchestrating mechanism that translates digital capabilities into resilience outcomes. By analyzing mapping across upstream, midstream, and downstream tiers, we offer a deeper understanding of how dynamic capabilities function across the supply chain. The analysis revealed that DDC significantly and positively influences the three dimensions of SCMAP at a 1% significance level. DDC were shown to significantly enhance upstream supply chain operations by improving visibility. The mapping enabled by DDC facilitates more effective handling of procurement, sourcing, supplier selection, and relationship management challenges. This increased transparency and better information flow fortify upstream operations, enhancing resilience and agility, and allowing firms to better manage risks and seize opportunities (Belhadi et al. 2022; Mishra et al. 2024). The study also demonstrated that midstream supply chain operations greatly benefit from the integration of DDC, underscoring their essential role in improving visibility across the organizational value chain. DDC enable more efficient management of manufacturing processes, technology adoption, product development, and quality assurance, providing real-time insights and supporting data-driven decisions that optimize midstream operations and boost organizational performance (Nguyen et al. 2020). While within downstream supply chain operations, DDC were found to significantly enhance visibility, playing a vital complementary role. This increase in transparency is crucial for effectively addressing challenges such as demand fluctuations, order fulfillment, inventory management, and customer relationship management. Through the strategic application of DDC, firms can adeptly manage customer-oriented aspects of their supply chain, thereby elevating operational efficiency and enhancing customer satisfaction (Belhadi et al. 2024). Collectively, the infusion of DDC into supply chain mapping markedly increases transparency and fosters comprehensive and sophisticated information sharing across all levels of the supply chain, ensuring a more cohesive and informed supply chain management framework.

The empirical investigation substantiated the proposed relationships between the three dimensions of supply chain mapping such as upstream, midstream, and downstream—and supply chain resilience, establishing these connections as both positive and statistically significant. This highlights the essential role of clarity, visibility, and transparency in supply chain information, achieved through thorough supply chain mapping, in cultivating a resilient supply chain ecosystem. The analysis revealed that the influence of these dimensions varies, with upstream mapping showing the most robust correlation to SCR, followed by downstream and midstream mappings. This tiered pattern of influence reflects the integral nature of upstream operations, which initiate the value addition process. Downstream operations further develop this process, and midstream operations serve as the pivotal link, fulfilling the expectations established by both upstream and downstream stakeholders.

Conversely, the direct impact of DDC on SCR was unexpectedly found to be statistically insignificant, challenging prevailing assumptions that such capabilities inherently drive resilience (Ivanov et al. 2022). Prompted by this anomaly, further analysis into the indirect effects was undertaken, exploring how DDC influence SCR through all dimensions of supply chain mapping. The analysis of indirect effects revealed significant and positive correlations between DDC and supply chain resilience, mediated through upstream and downstream supply chain mapping. This aligns with and expands upon the insights of Ivanov and Dolgui (2022), who highlighted the importance of visibility and transparency in creating resilient supply chains. Upstream supply chain mapping mediates the link between digital capabilities and resilience by enhancing visibility into suppliers, raw materials, and disruption points—enabling proactive risk mitigation (Ivanov and Dolgui 2020). Similarly, downstream mapping strengthens customer-side resilience through improved demand sensing and network reconfiguration, supporting adaptive responses to market volatility (Xu et al. 2024). The mediation indicates that while digital capabilities may not impact resilience directly, they are vital enablers that augment the efficacy of supply chain mapping, thereby strengthening resilience. This mediating mechanism aligns with Resource Orchestration Theory (Sirmon et al. 2011), which posits that digital capabilities, when strategically deployed through supply chain mapping, can strengthen the resilience of the supply network. However, the study found that midstream supply chain mapping does not significantly mediate the relationship between DDC and SCR. This absence of mediation suggests that, in midstream operations, digital capabilities may enhance resilience more directly through process optimization rather than through mapping. Given the standardized and internally visible nature of these operations, the additional value of mapping may be limited.

The comprehensive nature of this mediation across all supply chain dimensions underlines the holistic approach required to harness digital capabilities for enhancing resilience. This observation is consistent with Dubey et al. (2021), who advocate for an integrated digital transformation strategy within supply chains. Notably, the crucial role of upstream and downstream mapping is paramount as it addresses potential risks across the entire network. This aligns with the findings of Piprani, Jaafar, et al. (2025), who identify supply chain mapping as a key driver in building resilience and enhancing supply chain performance. By uncovering vulnerabilities from sourcing to end-user delivery, mapping supports continuity and promotes long-term sustainability in the face of disruptions.

6 Implications

6.1 Theoretical Implications

This study makes several significant contributions to theory. First, we extend dynamic capabilities theory by providing empirical evidence for the hierarchical nature of digital capabilities across individual, managerial, and operational levels. The theoretical implications of integrating dynamic digital capabilities within supply chain mapping and resilience are complex and significant, especially considering the scant empirical research in this domain. Our findings demonstrate that digital capabilities operate through distinct but interconnected dimensions. This multilevel conceptualization enhances our understanding of how dynamic capabilities emerge and function within organizational contexts. At an individual level, improved digital capabilities can enhance decision-making and streamline information processing across the supply chain. This may lead to more precise and timely mapping of upstream, midstream, and downstream activities, bolstering overall supply chain resilience. Employees proficient in advanced digital technologies are likely better prepared to identify potential disruptions, analyze intricate data patterns, and take pre-emptive actions to mitigate risks. From a managerial standpoint, digital capabilities can redefine how supply chain leaders manage and coordinate mapping activities. Managers proficient in digital tools may more effectively utilize advanced analytics, artificial intelligence, and machine learning algorithms to create detailed supply chain maps. Such increased visibility can lead to strategic decision-making, optimized resource deployment, and improved risk management throughout the supply network. Moreover, managers who are adept in digital technologies may promote an innovative, continuous improvement culture in supply chain mapping practices, potentially making supply chains more resilient and adaptable. On the operational front, digital technologies have the potential to transform supply chain mapping processes. Advanced tracking systems, Internet of Things (IoT) devices, and blockchain technology can offer real-time insights into the flow of goods and information across different supply chain segments. This heightened transparency and traceability can greatly enhance the accuracy and completeness of supply chain maps, allowing organizations to pinpoint vulnerabilities, streamline processes, and react more promptly to disruptions. The integration of these technologies can also encourage more collaborative and interconnected supply chain networks, further increasing resilience.

Second, this study advances dynamic capabilities theory by empirically validating supply chain mapping (SCMAP) as a pivotal mediating mechanism linking digital capabilities to supply chain resilience (SCR). The findings reveal that SCMAP, as a specific expression of sensing capabilities, plays a vital role in converting digital capabilities into actionable resilience outcomes during disruptions. Theoretically, the research enriches understanding of the nuanced relationship between digital capabilities and SCR, contributing to the digital supply chain management literature (Dubey et al. 2023; Ivanov 2021; Lin et al. 2023; Mubarik, Naghavi, et al. 2021). It highlights the indirect pathways through which digital capabilities enhance resilience, highlighting the importance of applying these capabilities in mapping processes rather than focusing solely on technological investments. The identification of SCMAP as a mediator challenges conventional supply chain models and calls for the development of new theoretical frameworks that account for the dynamic, real-time nature of digitally enabled mapping. These frameworks must integrate accelerated information flows, the potential of predictive and prescriptive analytics, and the evolving decision-making roles of humans within digitalized supply chain ecosystems. By establishing this causal link, the study opens new directions for exploring how firms can strategically deploy digital capabilities to strengthen supply chain mapping and, ultimately, build resilience in uncertain and turbulent environments.

6.2 Practical Implications

This study outlines several crucial practical implications for organizations aiming to enhance their SCR through digital capabilities and comprehensive SCMAP. The findings emphasize the necessity of a holistic approach to digital transformation within supply chain management. Organizations must understand that mere investment in digital capabilities at individual, managerial, or operational levels does not directly ensure enhanced SCR. Instead, these capabilities should be perceived as facilitators that, when adeptly integrated with thorough SCMAP, can markedly improve resilience.

First, it is imperative for organizations to prioritize developing and implementing extensive SCMAP across all three dimensions, that is, upstream, midstream, and downstream. Such an expansive approach establishes a vital connection between digital capabilities and resilience outcomes. Managers should strive for detailed visibility throughout the entire supply network, including suppliers, internal processes, and distribution channels. This might entail adopting advanced tracking systems, real-time data sharing platforms, and collaborative planning tools that encompass the full extent of the supply chain. Second, in the development of digital capabilities, firms should ensure these efforts are synchronized with their SCMAP initiatives. This alignment maximizes the impact of digital technologies in augmenting supply chain visibility and subsequently, resilience. For example, investments in data analytics should go hand-in-hand with strategies to gather and integrate data from diverse points within the SCMAP.

Third, organizations should maintain a balanced focus on developing capabilities across individual, managerial, and operational levels. Although our study did not establish a direct correlation between these capabilities and resilience, their indirect influence through supply chain mapping highlights the importance of a comprehensive digital capability portfolio. This might include training initiatives to boost digital literacy at the individual level, leadership development programs emphasizing digital transformation, and investments in operational technologies that enable seamless information exchange across the supply chain. Fourth, considering the mediating role of SCMAP, organizations would benefit from assigning dedicated roles or teams tasked with the ongoing maintenance and enhancement of their supply chain maps. These teams should collaborate closely with groups responsible for digital capability development to ensure that new technologies and skills are efficiently leveraged to boost supply chain visibility and responsiveness. Lastly, organizations should develop metrics and key performance indicators (KPIs) that reflect the sophistication of their digital capabilities and the extent of their SCMAP. These metrics, linked to resilience outcomes, would allow firms to monitor the efficacy of their investments and initiatives over time, facilitating data-driven resource allocation decisions between digital capability enhancement and SCMAP activities.

6.3 Implications on Malaysian Economy

From a policy-making viewpoint, the Malaysian government could benefit significantly from implementing a thorough supply chain mapping initiative to enhance manufacturing firm's resilience. The Ministry of International Trade and Industry (MITI) could spearhead a country-wide SCMAP project, amalgamating data from diverse sectors to construct a comprehensive overview of Malaysia's industrial ecosystem. This overview would enable precise, targeted interventions, such as pinpointing essential supply chain nodes that require bolstering through additional support or infrastructural enhancements. The Malaysian Digital Economy Corporation (MDEC) could assume a crucial role by establishing a national digital platform dedicated to supply chain mapping. This platform would function as a centralized hub for companies to both contribute and access supply chain information, thereby promoting collaboration and empowering smaller firms to leverage insights from larger corporations. To facilitate this endeavor, the government might introduce policy requirements for substantial supply chain transparency within critical industries. This could entail mandating larger companies to sustain and disseminate digital maps of their supply chains, thereby enhancing the resilience of the national economy. By prioritizing supply chain mapping in its digital transformation strategies, Malaysia could significantly advance its industrial competitiveness. This initiative would not only elevate the performance of individual companies but also strengthen the overall resilience of the Malaysian economy, preparing it more effectively for future global market disruptions and opportunities. This shift towards digitally enabled supply chain mapping marks a fundamental change in the strategies of Malaysian businesses and policymakers regarding supply chain management. It lays the groundwork for more informed decision-making, quicker disruption response, and strategic planning for sustained growth and resilience.

7 Conclusion

In conclusion, this study elucidates the complex interplay between DDC, SCMAP, and SCR. Although DDC does not exert a direct effect on SCR, it significantly enhances all dimensions of SCMAP such as upstream, midstream, and downstream. These SCMAP dimensions, in turn, positively influence SCR and fully mediate the relationship between DDC and SCR. This finding highlights the essential role of comprehensive supply chain mapping in converting digital capabilities into measurable resilience outcomes. Organizations aiming to enhance their supply chain resilience should concentrate on utilizing digital capabilities to augment visibility and coordination across all supply chain phases. This study contributes to a deeper understanding of the mechanisms for building resilience in supply chains, underscoring the importance of an integrated approach to digital transformation and supply chain management in today's erratic business environment.

7.1 Limitations and Avenues for Further Research

While this study has made significant contributions to both theory and practice, it also presents some limitations. Firstly, the use of a single-informant cross-sectional design constrains our understanding of how these relationships evolve over time. Future studies could employ longitudinal methods to explore the long-term impacts of digital capabilities on SCR via SCMAP, offering deeper insights as organizations progress in their digital transformation. Secondly, our study explored the indirect effects of DDC on SCR via SCMAP but did not explore the impact of specific technologies. Future research could examine how digital capabilities build on various applications and tools directly translate into improved mapping capabilities and resilience. Next, given that our data come from the large-scale Malaysian manufacturing sector, the generalizability of the findings may be limited. Future studies should consider cultural, environmental, and policy differences across various international contexts and extend the research to SMEs sectors to broaden the applicability of the insights. Lastly, while cross-sectional data were utilized with statistical methods to minimize biases, future research could enhance these findings through mixed-method approaches, incorporating qualitative analyses to enrich the understanding of the studied relationships.

Acknowledgments

The authors gratefully acknowledge the financial support provided by Sunway University under the Kickstart Grant [GRTIN-KSGS(02)-DMNGT-07-2023]. The institutional support and research environment were instrumental in the successful completion of this study. Open access publishing facilitated by LUT University, as part of the Wiley - FinELib agreement.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix 1 Scales/Measurement Items

| Construct | Dimensions | Items | Source |

|---|---|---|---|

| Digital capabilities | Individual capabilities | ICP1: Our employees are capable in terms of programming and data management. | Belhadi et al. (2022). |

| ICP2: Our employees show a superior understanding of technological trends. | |||

| ICP3: Our employees show superior ability to learn new technologies. | |||

| ICP4: Our employees are capable of decision support systems (e.g., expert systems, artificial intelligence, data warehousing, mining, etc.). | |||

| Operational capabilities | OC1: Our organization systematically collects and extracts insights from data. | ||

| OC2: Our organization uses real-time capability. | |||

| OC3: Our organization uses distributed systems to system interoperability. | |||

| OC4: Our organization uses virtualization and decentralization of decision-making. | |||

| Managerial capabilities | MCP1: We enforce adequate plans for the utilization of I4.0 technologies. | ||

| MCP2: We constantly monitor the performance of the I4.0 function. | |||

| MCP3: We frequently adjust I4.0 plans to better adapt to changing conditions. | |||

| Supply chain Mapping | Upstream | USM1: We are able to visualize our upstream SC processes, and activities. | Mubarik, Naghavi, et al. (2021); Khan et al. (2022) |

| USM3: Our firm is able to capture the real-time information about the products and materials sourced, their quantities, and replenishment lead time. | |||

| USM4: SC mapping provides real-time information sharing of suppliers. | |||

| USM5: We are aware of the tier-2 suppliers of the critical components and raw material. | |||

| USM6: We have documented processes for dealing with suppliers. | |||

| USM7: We are able to visualize the real-time flow of material from the suppliers. | |||

| USM8: We have a system for real-time sharing of information with suppliers. | |||

| USM9: Our SC mapping provides us a simplified representation of our upstream SC by capturing the essence of the environment in which the SC operates. | |||

| USM10: We have mapped the flow of products, and information in the upstream SC. | |||

| Mid-stream | MSM1: We have mapped processes showing the flow of material within the company. | ||

| MSM2: We can track the flow of goods within our company in real time from one department to other. | |||

| MSM3: We have a system of real-time sharing of information within the company, across several departments. | |||

| MSM4: We can identify the SC processes inefficiencies in real time. | |||

| MSM5: Due to the mapping of midstream processes, we can monitor the effectiveness of our SC strategy. | |||

| MSM6: The mapping of our SC helps to catalog and distribute key information for survival in a dynamic environment. | |||

| MSM7: Our SC mapping alerts our concerned managers to possible constraints in the system. | |||

| MSM8: We have mapped the flow of products and information in the midstream SC. | |||

| Downstream | DSM1: We have mapped the geographical dispersion of our customers. | ||

| DSM2: We have mapped the geographical dispersion of our tier-2 customers. | |||

| DSM3: We have a system of real-time sharing of information with customers. | |||

| DSM4: We can visualize the flow of goods from our company to customers' customers. | |||

| DSM5: The mapping of our downstream processes plays an essential role in providing guidance in the quantum changes in the downstream SC. | |||

| DSM6: We have mapped the flow of products and information in the downstream SC. | |||

| DSM7: The mapping of our downstream SC processes permits our company to identify areas for further analysis. | |||

| Supply chain Resilience | SCR1: Our company can use resources to prepare for disruption prevention. | Piprani et al. (2024); Pu et al. (2023) | |

| SCR2: Our company can predict possible demand disruptions. | |||

| SCR3: Our company can respond quickly to disruptions. | |||

| SCR4: Our company has a response team to alleviate the crisis. | |||

| SCR5: Our company can recover from a disruption in a short time. |

Open Research

Data Availability Statement

Data available on request from the authors.