Relationships Between Mechanical Behavior and Structure/Properties for Macroscopically Homogeneous Porous Composites Containing Randomly Shaped Filler

Funding: This work was supported by the Brno University of Technology [Specific University Research Grant FCH-S-23-8208].

ABSTRACT

The work focuses on researching relationships between structure/properties and mechanical behavior of porous composites. The primary data comes from tensile testing. The observed properties include elastic modulus, ultimate strength, ultimate strain, and energy need for ultimate strength achievement. The studied materials include composites based on different polyurethane matrices and one rubber filler with various filler and porosity contents. Presented work expands the possibilities of an approach based on measured data fitting by a suitable function followed by obtained parameters interpolation. The utilization of new structural parameters leads to a spatial linear function shape instead of spatial exponential. The newly introduced equation is z c = z m + z m · (b · p 1 + c · p 2), where z c /z m is generally labeled mechanical property value for composite/nonporous matrix, p 1/p 2 are suitable structural parameters, and b/c are fitting parameters subjected to interpolations by logarithmic function containing values of properties typical for matrices. The work focuses on studying the case of different matrices and one kind of filler. The work includes all potentially valuable interpolations for earlier mentioned properties with the most interesting results in cases of pairs p 1/p 2 containing two from three parameters: n (porosity), 1 − v m (v f + porosity), and v f (filler volume fraction).

1 Introduction

Understanding the behavior of materials around us (including those porous) is important. The ability to predict material behavior can be the decisive parameter to its successful utilization. Materials can differ in their complexity in composition and structure. Except for the matrix, they can include fillers, reinforcement, and porosity. The term structure can also contain the shape of particles and voids, which can affect how the material will behave under loading. Description of the material behavior is usually more difficult as the material is more complex in composition and structure. This interested materials containing (except matrix) particles, voids, and mainly both of them.

First, it is necessary to mention the one-component porous materials. Many authors have endeavored to find some relationships between structure/composition and chosen mechanical properties. But the works were usually dedicated only to one material type with different degrees of porosity as porous metal [1-5], ceramics [1, 4, 6-14], polymers [1, 15], and natural materials [16]. The describing functions acquire different mathematical forms. The mathematical types of dependencies usually using some adjustable fitting parameter(s) are linear [1, 5-7, 9-13], exponential [1, 5, 6, 11, 12], power [1-4, 6, 9, 11, 12, 14, 15, 17-19], and logarithmic [5].

The more difficult situation is in the description dedicated to the more complex materials—composites. There are two approaches for describing or predicting the material behavior, which can be illustrated in the porous composites [20]. The first approach means different models [21-26] and simulations using various mathematical methods such as Fast Fourier Transform [27], finite element method [28, 29], or fractals [21]. These solutions depend on the exact physical knowledge and simplifying expectations about the composition and structure of the microscopic levels in studied materials. These expectations can vary a lot according to chosen research work. The expected limits can mean shapes of filler as granular particles [30], short fibers with cylindrical shapes [28], or circular cross-sections [27]. Forms of voids can be limited to spherical [25]. Expectations can include the exclusion of contact among pores and (short) fibers [28] or particles [21] or even the separation of one bulk phase and the open porosity by the surface phase [29]. Pores and filler are expected nano-sized in both cases [27] or only particles in the form of nanotubes or nanoparticles [23, 24]. Specific requests include the unidirectional orientation of nanofibers [27] and splitting the filler according to size distribution and location of different fractions in different domains [21]. The approach using various models and simulations predominates in the literature. It is used for the research of elastic region of loading [21, 26-28] and also for the nonlinear stress [22-24, 29, 30] with the comparisons between expected results and measured results from a provided measurement on materials.

The second approach observes the material from a macroscopic point of view concerning the properties of its components. The first part is the measurement when the measured data can be subjected to fitting by a suitable function with the following interpolation of obtained parameters to reach dependence between properties and structure/composition of the material. Work dedicated to tensile testing of porous composites containing nanofibers and describing their fracture probability according to fracture toughness and porosity by Weibull analysis [31] is an example of a macroscopic point of view.

To show the porous composites as recently studied topics, papers dedicated to porous composites differing by their compositions and potential applications instead of a general description of the connection between the structure and properties can be mentioned. The examples include regenerated cellulose/cross-linked poly(ethylene glycol) reaching up to 97% porosity for potential biomedical applications, packaging and sewage purification [36], properties of glass–ceramic/nanocopper [37], alloy composed of titanium, aluminum and vanadium/silver particles reaching up to 50% of porosity for biomedical applications [38], and even ceramics/epoxy resin or polycaprolactone with approximately 70% of porosity [39].

The main goal of this article is to contribute to a description of relationships between structure/composition and properties for porous-filled composites. It directly follows earlier works [32, 33] and uses the same primary data set. It should effort another insight by using complementary structural parameters to those (n p , v m , 1 − v f , etc.) used in previous articles [32, 33], because the complementary parameters introduced in this paper embody different mathematical behavior. They could then lead to new contributions in describing the behavior of porous materials. The mechanical behavior dependencies of porous composite materials are not fully known, and each contribution could stand significant.

2 Materials and Methods

2.1 Materials

This work uses the same primary dataset as previous works [32, 33], as mentioned in the introduction. The original data come from tensile testing of porous composites and the corresponding porous matrices (nonporous matrices and composites were unavailable due to the porous nature of used polyurethane matrices). All 10 used matrices were based on the same MDI (methylene-di-phenyl-di-isocyanate) pre-polymer Unixin 4223CS (Lear, Czech Republic, 6.9 wt% of isocyanate (NCO) groups, number average of molecular weight 690 g/mol, viscosity 2800 ± 500 mPa s), used the same accelerator (Lear, Czech Republic, di-butyl-tin-di-laureate, DBTL) and differed by used curing agents including castor oil (Fichema, Czech Republic), distilled water and glycerol (Penta Chemicals, Czech Republic). Some of the matrices included suitable modifying components such as linseed oil serving as a plasticizer (Fichema, Czech Republic) or inorganic fillers in powder forms of quartz (Millisil W12, Provodínské Písky, Czech Republic), calcite and iron (both of them from Pkchemie, Czech Republic, 14–16 wt% of silicon in iron) serving for the matrix stiffening to reach higher diversity in observed mechanical properties range of matrices without changes of rate or kind of curing agent. The composition of matrices in vol% is in Table 1 with the OH/NCO rate in polyurethane before curing labeled δ and designation used throughout the entire article. Particle size distributions of quartz, calcite, and iron are in Figure S1.

| Designation | PU4223 CS (vol%) | Curing agent (vol%) | Others (vol%) | δ a (−) | ρ t (g cm−3) | n m (%) |

|---|---|---|---|---|---|---|

| P99-W1 | 99 | 1 (W) | — | 0.68 b | 1.10 c | 57 ± 7 |

| 16 ± 2 | ||||||

| P95-G5 | 95 | 5 (G) | — | 1.22 | 1.12 d | 9.5 ± 0.7 |

| P80-G20 | 80 | 20 (G) | — | 5.79 | 1.15 d | 10 ± 1 |

| P85-G5-CO10 | 85 | 5 (G) +10 (CO) | — | 1.55 | 1.05 d | 2 ± 2 |

| P65-CO35 | 65 | 35 (CO) | — | 0.87 | 1.04 d | 4 ± 1 |

| P49-CO26-LO25 | 49 | 26 (CO) | 25 (LO) | 0.87 | 1.03 d | 1 ± 2 |

| P33-CO17-Si50 | 33 | 17 (CO) | 50 (Si) | 0.87 | 1.85 e | 16 ± 1 |

| P33-CO17-Ca50 | 33 | 17 (CO) | 50 (Ca) | 0.87 | 1.86 e | 32 ± 2 |

| P33-CO17-Fe50 | 33 | 17 (CO) | 50 (Fe) | 0.87 | 4.04 e | 22.6 ± 0.5 |

| P72-G18-Ca10 | 72 | 18 (G) | 10 (Ca) | 5.79 | 1.30 e | 16.3 ± 0.6 |

- Note: Pre-polymer: PU4223 CS (P); curing agents: Water (W), glycerol (G), castor oil (CO); plasticizer: Linseed oil (LO); fillers included in matrices: SiO2 (Si), CaCO3 (Ca), Fe (Fe) [32]. Reference [33] is Reprinted by permission from Springer Nature Customer Service Centre GmbH: Springer Nature, SN Applied Sciences.

- a Reflecting OH/NCO molar ratio.

- b For this purpose, H2O represents two OH groups.

- c Measured by pycnometer method.

- d Obtained from knowledge about volume, mass, and porosity.

- e Calculated via simple mixing equation.

The composite materials contained except matrix also rubber filler. The rubber filler was supplied and used in three fractions labeled R0–R2 (RGP Recycling, Czech Republic, higher index number means larger particles). The knife milling served for R1 and R2 fractions manufacturing. The milling with a rolling machine led to R0 manufacturing. The origin of rubber filler was the same in all cases—waste car tires. The size distributions of R0 and R1 rubber (and also of inorganic fillers) are in Figure 1 and come from laser analysis (HELOS (H2568) & RODOS). The laser analysis was not appropriate for R2 distribution due to the large dimensions of particles, and it was obtained only partially by the sieve analysis. The particle shapes of all fillers are in Figure S2 and come from scanning electron microscopy (TESCAN MIRA 3 for inorganic fillers and Carl Zeiss EVO LS 10 for rubber). The densities of all fillers were measured by a pycnometer three times. The average values are 1.18 g/cm3 for all rubber fractions, 2.65 g/cm3 for quartz, 2.68 g/cm3 for limestone, and 7.03 g/cm3 for iron.

2.2 Preparation and Testing of Samples

The preparation of samples was manual. First, liquid components were mixed (pre-polymer, curing agent(s), accelerator, and plasticizer, if it was a part of the matrix). The addition of the rubber (only one fraction in all cases) or its mixture with inorganic filler to the liquid part followed. The curing of the final blend was carried out under ambient conditions. The stainless steel molds were equipped with low-density polyethylene foil for better separation and used for the curing.

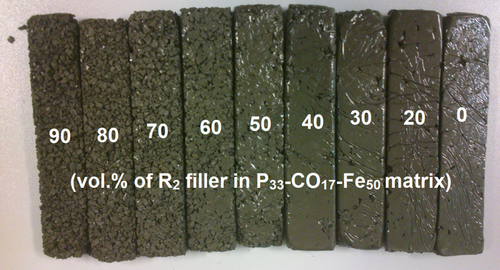

The range of filling with rubber was 20–90 vol% with a 10% increment for all matrices. Values are valid in case of porosity neglect. This concentration set was used independently for all three rubber fractions except for the high filling of mainly lower filler fractions with combinations of some matrices. The detailed scheme of prepared and tested samples is in Figure S5. The beams creating examples with different filler contents are in Figure 1. Figure 1 also indicates the porosity rate, which usually decreases with increasing filler volume fraction. The solid filler then replaces the porous matrix. When the filler content exceeds some value differing according to matrix porosity, the matrix cannot fulfill the space between filler particles, and the porosity increases. It is usually the highest when the filler content is also highest and reaches up to 50 vol% of closed and open pores together.

2.3 Base of Calculations

Plenty of symbols are in this work. The explanations of labels are in Table S1. Table S2 contains the significance, meaning, and source for chosen parameters if they are significant for calculations. The Supporting Information section contains some schemes for a better understanding of the basic principles of this work. The scheme generally shows the data processing from the measurement to the final equations in Figure S1. Figure S2 contains the scheme of the work from rough materials through a system of prepared samples to obtain data.

3 Results and Discussion

3.1 Observation of Used Materials

The compositions and porosity of matrices are in Table 1. Measured values of mechanical properties of prepared matrices are in tables including Tables 3–6. These tables enable the comparison of the values for real porous matrices and hypothetical nonporous matrices obtained by fitting. The observed values from Tables 3–6 are elastic modulus, ultimate strength, ultimate strain, and energy need for ultimate strength achievement. Particle size distributions (obtained by laser analysis) are in Figure S1, except for the R2 rubber particle size distribution obtained by sieve analysis due to large particles. 50 wt% of R2 particles exceeded the size of 2.5 mm. The randomness of the shapes of particles is in Figure S2. The following random microstructure of composites is in Figure S3.

Composites include 10 matrices and six fillers. The calculations are focused only on different matrices. The reason is that three fillers (all inorganic) are included in matrices. The fractions of rubber filler (R0, R1, and R2) embody only low differences in particle sizes—about one mathematical order. This difference seems insufficient for study on their influence on proposed relationships. Moreover, the weak differences enabled including all rubber fractions into one filler in calculations (in each prepared sample was only one from the mentioned fractions).

3.2 Data Fitting and Numerical Relationships Between Obtained Parameters

Complementary structural parameters can be derived easily from the basic structural parameters. A suitable example is Equation (9), showing the relationship (n n = 1 − n p ) between the interspace filling (n p ) and the interspace porosity (n n ) as its opposite. The same equation shape serves for the replacement of the basic parameters to complementary parameters in the direction shown by arrows: 1 − v f → v f , 1 − v m → v m , n pf → n fp , and 1 − n → n.

Like basic structural parameters, the complementary structural parameters are in the fitting equations used in pairs. There are similarly able to describe the composition of material from two chosen parameters [32, 33].

| Parameter | Suitability or reason for exclusion |

|---|---|

| n + n n | Nonporous composite: n + n n = 0 |

| n fp + v f | Porous matrix: n fp + v f = 0 |

| n fp + n; n fp + (1 − v m ) | First fitting: low R 2 |

| (1 − v m ) + n n ; n n + v f ; n fp + n n | Slopes values differing according to the used pair of structural parameters |

| (1 − v m ) + n; n + v f ; n + (1 − v m ) | Repetition of slope values |

- Note: Unsuitable pairs were excluded immediately after finding some insufficiency without the whole search for their complex behavior.

It is necessary to add that the b and c parameters can acquire positive or negative values in both cases of slope sign. It means that, for example, a combination of a negative slope with two positive parameter values, two negative parameter values, or one positive and one negative parameter value according to the chosen fitting example (property and matrix, explained below). When the slope changes its sign, the signs of parameter values also change. It is only a mathematical treatment shown by Equation (24).

The left-placed version of Equation (24) corresponds to Equation (17) which represents the only equation shape in this work. Equation (25) corresponds to Equation (24) after mathematical deriving by pointing the z m value out.

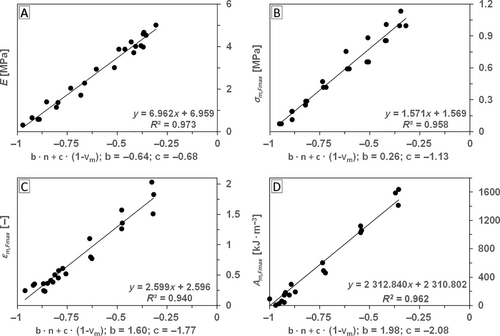

The data fitting used the form of an adjustment of the b and c values. It was provided separately for each chosen property, and a set of composites based on one from the used matrices. The filler was the same in all cases. Fitting was used for one property and one matrix in the composite as shown in Figure 2. The fitting was concerned with reaching the highest coefficient of determination (R 2) value. All combinations of b and c values embodying the highest R 2 value for separate fitting created a trend with a linear dependence of c on b. On that line, there were two combinations of b and c parameter values differing only by the b and c mathematical sign ensuring the same absolute value of slope and displacement. The resulting slope value then varies only in the mathematical positivity/negativity of its value and the result dependence, as depicted in Figure 2 and Equations (17-23) for the case of the positive slope. The results giving the positive slope were the only ones included in the following work. Figure 2 shows the typical difference between slope and displacement caused by the method used (usually the third valid numeral). The fitting results (for chosen structural pairs) in the form of displacements values are in Table 3 for E, Table 4 for σ m,Fmax , Table 5 for ε m,Fmax , and Table 6 for A m,Fmax . There are also the property values for real porous matrices and porosity to estimate obtained results (the accurate comparison is unsuitable due to the absence of real nonporous matrices).

| Matrix designation | Measured values (porous matrices) | E (MPa): fitted values of (nonporous matrices), if the structural parameters p 1 and p 2 are | ||||||

|---|---|---|---|---|---|---|---|---|

| n (%) | E (MPa) | n fp ; n n | 1 − v m ; n n | n n ; v f | 1 − v m ; v f | n; v f | n; 1 − v m | |

| P99-W1 | 57 ± 7 | 1.4 ± 0.3 | 6.65 | 4.69 | 5.98 | 8.85 | 8.78 | 8.80 |

| P99-W1 | 16 ± 2 | 4.1 ± 0.1 | ||||||

| P95-G5 | 9.5 ± 0.7 | 13 ± 2 | 11.38 | 16.10 | 12.52 | 14.94 | 15.13 | 14.99 |

| P80-G20 | 10 ± 1 | 4.8 ± 0.3 | 4.65 | 5.31 | 4.87 | 5.54 | 5.54 | 5.54 |

| P85-G5-CO10 | 2 ± 2 | 2.3 ± 0.3 | 2.15 | 1.69 | 1.97 | 2.49 | 2.50 | 2.49 |

| P65-CO35 | 4 ± 1 | 1.6 ± 0.4 | 2.22 | 1.63 | 2.00 | 2.58 | 2.60 | 2.61 |

| P49-CO26-LO25 | 1 ± 2 | 1.1 ± 0.03 | 1.07 | 0.81 | 0.96 | 1.22 | 1.25 | 1.24 |

| P33-CO17-Si50 | 16 ± 1 | 9 ± 1 | 12.39 | 13.12 | 12.47 | 15.15 | 15.14 | 15.17 |

| P33-CO17-Ca50 | 32 ± 2 | 4.9 ± 0.5 | 10.20 | 11.72 | 10.55 | 12.90 | 12.90 | 12.90 |

| P33-CO17-Fe50 | 22.6 ± 0.5 | 9.1 ± 0.6 | 14.96 | 16.66 | 15.46 | 18.41 | 18.41 | 18.44 |

| P72-G18-Ca10 | 16.3 ± 0.6 | 7.4 ± 0.8 | 5.83 | 6.51 | 6.03 | 6.96 | 6.94 | 6.96 a |

- a Depicted in Figure 2.

| Matrix designation | Measured values (porous matrices) | σ Fmax (MPa): fitted values of (nonporous matrices), if the structural parameters p 1 and p 2 are | ||||||

|---|---|---|---|---|---|---|---|---|

| n (%) | σ Fmax (MPa) | n fp ; n n | 1 − v m ; n n | n n ; v f | 1 − v m ; v f | n; v f | n; 1 − v m | |

| P99-W1 | 57 ± 7 | 0.56 ± 0.05 | 2.03 | 2.23 | 2.06 | 2.90 | 2.87 | 2.89 |

| P99-W1 | 16 ± 2 | 2.7 ± 0.3 | ||||||

| P95-G5 | 9.5 ± 0.7 | 4.7 ± 0.1 | 2.76 | 4.33 | 3.26 | 3.71 | 3.74 | 3.68 |

| P80-G20 | 10 ± 1 | 1.75 ± 0.08 | 1.25 | 1.46 | 1.32 | 1.45 | 1.45 | 1.45 |

| P85-G5-CO10 | 2 ± 2 | 1.24 ± 0.04 | 1.01 | 1.02 | 1.02 | 1.15 | 1.14 | 1.14 |

| P65-CO35 | 4 ± 1 | 0.42 ± 0.03 | 0.47 | 0.37 | 0.43 | 0.54 | 0.54 | 0.54 |

| P49-CO26-LO25 | 1 ± 2 | 0.4 ± 0.03 | 0.30 | 0.25 | 0.27 | 0.32 | 0.32 | 0.32 |

| P33-CO17-Si50 | 16 ± 1 | 2.2 ± 0.3 | 2.57 | 3.32 | 2.81 | 3.22 | 3.22 | 3.22 |

| P33-CO17-Ca50 | 32 ± 2 | 0.7 ± 0.04 | 1.14 | 1.21 | 1.16 | 1.41 | 1.41 | 1.41 |

| P33-CO17-Fe50 | 22.6 ± 0.5 | 1.09 ± 0.09 | 1.37 | 1.55 | 1.44 | 1.68 | 1.68 | 1.68 a |

| P72-G18-Ca10 | 16.3 ± 0.6 | 1.93 ± 0.06 | 1.33 | 1.61 | 1.43 | 1.57 | 1.57 | 1.57 a |

- a Depicted in Figure 2.

| Matrix designation | Measured values (porous matrices) | ε Fmax (%): fitted values of (nonporous matrices), if the structural parameters p 1 and p 2 are | ||||||

|---|---|---|---|---|---|---|---|---|

| n (%) | ε Fmax (%) | n fp ; n n | 1 − v m ; n n | n n ; v f | 1 − v m ; v f | n; v f | n; 1 − v m | |

| P99-W1 | 57 ± 7 | 94 ± 9 | 114 | 167 | 130 | 153 | 151 | 153 |

| P99-W1 | 16 ± 2 | 82 ± 12 | ||||||

| P95-G5 | 9.5 ± 0.7 | 140 ± 40 | 99 | 130 | 111 | 124 | 125 | 124 |

| P80-G20 | 10 ± 1 | 340 ± 20 | 328 | 462 | 374 | 367 | 367 | 367 |

| P85-G5-CO10 | 2 ± 2 | 100 ± 4 | 141 | 165 | 149 | 154 | 154 | 154 |

| P65-CO35 | 4 ± 1 | 39 ± 4 | 40 | 36 | 39 | 41 | 41 | 41 |

| P49-CO26-LO25 | 1 ± 2 | 68 ± 8 | 52 | 50 | 51 | 53 | 53 | 52 |

| P33-CO17-Si50 | 16 ± 1 | 22 ± 1 | 22 | 23 | 22 | 23 | 23 | 23 |

| P33-CO17-Ca50 | 32 ± 2 | 20 ± 1 | 19 | 18 | 18 | 19 | 19 | 19 |

| P33-CO17-Fe50 | 22.6 ± 0.5 | 13 ± 1 | 14 | 15 | 15 | 14 | 14 | 14 |

| P72-G18-Ca10 | 16.3 ± 0.6 | 260 ± 30 | 224 | 315 | 255 | 260 | 260 | 260 a |

- a Depicted in Figure 2.

| Matrix designation | Measured values (porous matrices) | A Fmax (kJ m−3): fitted values of (nonporous matrices), if the structural parameters p 1 and p 2 are | ||||||

|---|---|---|---|---|---|---|---|---|

| n (%) | A Fmax (kJ m−3) | n fp ; n n | 1 − v m ; n n | n n ; v f | 1 − v m ; v f | n; v f | n; 1 − v m | |

| P99-W1 | 57 ± 7 | 321 ± 14 | 881 | 1243 | 974 | 1315 | 1309 | 1318 |

| P99-W1 | 16 ± 2 | 1400 ± 400 | ||||||

| P95-G5 | 9.5 ± 0.7 | 4100 ± 700 | 1423 | 2478 | 1757 | 1965 | 1986 | 1946 |

| P80-G20 | 10 ± 1 | 3700 ± 300 | 2450 | 3593 | 2841 | 2749 | 2748 | 2748 |

| P85-G5-CO10 | 2 ± 2 | 700 ± 50 | 733 | 895 | 793 | 826 | 825 | 825 |

| P65-CO35 | 4 ± 1 | 69 ± 6 | 132 | 92 | 119 | 147 | 149 | 150 |

| P49-CO26-LO25 | 1 ± 2 | 90 ± 8 | 86 | 81 | 84 | 93 | 94 | 93 |

| P33-CO17-Si50 | 16 ± 1 | 210 ± 40 | 258 | 325 | 279 | 325 | 325 | 325 |

| P33-CO17-Ca50 | 32 ± 2 | 69 ± 9 | 114 | 128 | 116 | 147 | 146 | 147 |

| P33-CO17-Fe50 | 22.6 ± 0.5 | 70 ± 10 | 105 | 126 | 112 | 131 | 131 | 131 |

| P72-G18-Ca10 | 16.3 ± 0.6 | 3700 ± 300 | 1958 | 2942 | 2299 | 2311 | 2311 | 2311 a |

- a Depicted in Figure 2.

| Property | p 1 + p 2 (in b · p 1 + c · p 2) a | Eq. | c = f(b) | c = f(b); R 2 |

|---|---|---|---|---|

| E | n fp + n n | (18) | c = − 0.864 · b − 1.101 | 0.994 |

| (1 − v m ) + n n | (19) | c = − 0.962 · b − 1.061 | 0.998 | |

| n n + v f | (20) | c = − 2.431 · b − 2.646 | 0.980 | |

| (1 − v m ) + v f | (21) | c = − 2.529 · b − 2.323 | 0.995 | |

| n + (1 − v m ) | (22) | c = − 0.574 · b − 1.097 | 0.997 | |

| n + v f | (23) | c = − 1.333 · b − 2.550 | 0.983 | |

| σ Fmax | n fp + n n | (18) | c = − 0.870 · b − 1.074 | 0.978 |

| (1 − v m ) + n n | (19) | c = − 0.991 · b − 1.047 | 0.993 | |

| n n + v f | (20) | c = − 2.301 · b − 2.483 | 0.939 | |

| (1 − v m ) + v f | (21) | c = − 2.295 · b − 2.410 | 0.961 | |

| n + (1 − v m ) | (22) | c = − 0.580 · b − 1.081 | 0.990 | |

| n + v f | (23) | c = − 1.314 · b − 2.483 | 0.940 | |

| ε Fmax | n fp + n n | (18) | c = − 0.603 · b − 0.282 | 0.872 |

| (1 − v m ) + n n | (19) | c = − 0.611 · b − 0.249 | 0.895 | |

| n n + v f | (20) | — | — | |

| (1 − v m ) + v f | (21) | — | — | |

| n + (1 − v m ) | (22) | c = − 0.819 · b − 0.414 | 0.876 | |

| n + vf | (23) | — | — | |

| A Fmax | n fp + n n | (18) | c = − 0.960 · b − 1.151 | 0.986 |

| (1 − v m ) + n n | (19) | c = − 1.020 · b − 1.091 | 0.995 | |

| n n + v f | (20) | c = − 1.908 · b − 2.201 | 0.946 | |

| (1 − v m ) + v f | (21) | c = − 2.057 · b − 2.223 | 0.978 | |

| n + (1 − v m ) | (22) | c = − 0.523 · b − 1.065 | 0.985 | |

| n + v f | (23) | c = − 1.062 · b − 2.199 | 0.936 |

- a There are also shown pairs of structural parameters in the Equations (18-23) generally shaped as z c = z m + z m · (b · p 1 + c · p 2).

| Porous composite (the examples of fitting results of Equations (21-23)) from up to down |

|---|

| σ c,Fmax (MPa) = 3.71 MPa + 3.69 MPa · (− 0.91 · (1 − v m ) − 0.42 · v f ) |

| σ c,Fmax (MPa) = 3.68 MPa + 3.68 MPa · (0.35 · n − 1.29 · (1 − v m )) |

| σ c,Fmax (MPa) = 3.74 MPa + 3.73 MPa · (−0.91 · n − 1.34 · v f ) |

| Multiplied parameters | Mathem. treatment | Multipliers behavior (Eq.) | Notice |

|---|---|---|---|

| Hypothetical nonporous composite | |||

| −0.91 · (1-v m ) − 0.42 · v f | −1.33 · v f | b + c (21) = c (22) = c (23) | 1 − v m = v f |

| 0.35 · n − 1.29 · (1 − v m ) | −1.29 · v f | c (22) = c (23) = b + c (21) | 1 − v m = v f , n = 0 |

| −0.91 · n − 1.34 · v f | −1.34 · v f | c (23) = b + c (21) = c (22) | n = 0 |

| Porous matrix | |||

| −0.91 · (1 − v m ) − 0.42 · v f | −0.91 · n | b (21) = b + c (22) = b (23) | 1 − v m = n, v f = 0 |

| 0.35 · n − 1.29 · (1 − v m ) | −0.94 · n | b + c (22) = b (23) = b (21) | 1 − v m = n |

| −0.91 · n − 1.34 · v f | −0.91 · n | b (23) = b (21) = b + c (22) | v f = 0 |

| Further relationships found between b and c multipliers | |||

| c (21) = −b (22) = b − c (23) | |||

- Note: The data fittings connecting the composites based on the P95-G5 matrix and corresponding ultimate strength values serve as an example.

3.3 Interpolation of b and c Parameters Obtained by Fitting

| Eq. | p 1 + p 2 | b = f(x); x = E m · δ | R 2 | c = f(x); x = E m · δ | R 2 |

|---|---|---|---|---|---|

| (18) | n fp + n n | b = −1.130 · ln x + 2.284 | 0.795 | c = 0.983 · ln x − 3.535 | 0.786 |

| (19) | (1 − v m ) + n n | b = − 1.359 · ln x + 3.346 | 0.879 | c = 1.311 · ln x − 4.287 | 0.881 |

| (20) | n n + v f | b = 0.451 · ln x − 2.203 | 0.822 | c = −1.112 · ln x + 2.742 | 0.829 |

| (21) | (1 − v m ) + v f | b = 0.638 · ln x − 3.315 | 0.741 | c = −1.505 · ln x + 5.224 | 0.760 |

| (22) | n + (1 − v m ) | b = 1.465 · ln x − 5.112 a | 0.763 | c = − 0.847 · ln x + 1.849 a | 0.772 |

| (23) | n + v f | b = 0.611 · ln x − 3.244 | 0.741 | c = − 0.839 · ln x + 1.827 | 0.772 |

| Eq. | p 1 + p 2 | b = f(x); x = E m | R 2 | c = f(x); x = E m | R 2 |

|---|---|---|---|---|---|

| (18) | n fp + n n | b = −1.388 · ln x + 2.912 | 0.711 | c = 1.144 · ln x − 3.523 | 0.642 |

| (19) | (1 − v m ) + n n | b = −1.679 · ln x + 3.457 | 0.840 | c = 1.588 · ln x − 4.342 | 0.810 |

| (20) | n n + v f | b = −0.516 · ln x − 2.173 | 0.647 | c = −1.378 · ln x + 2.845 | 0.767 |

| (21) | (1 − v m ) + v f | b = 0.761 · ln x − 3.350 | 0.658 | c = −1.847 · ln x + 5.404 | 0.715 |

| (22) | n + (1 − v m ) | b = 1.799 · ln x − 5.292 a | 0.718 | c = −1.063 · ln x + 1.996 a | 0.759 |

| (23) | n + v f | b = −0.727 · ln x − 3.274 | 0.653 | c = −1.053 · ln x + 1.972 | 0.757 |

- a Dependencies depicted in Figure 3.

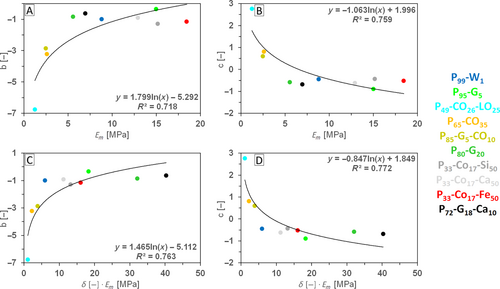

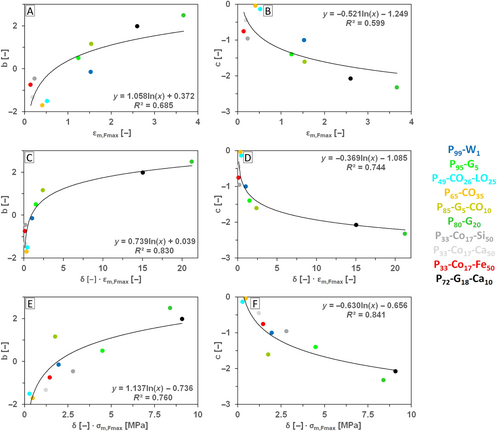

All interpolation possibilities of b and c parameters in the case of E are in Table 9 for all fitting Equations (18-23). The examples of interpolations coming from Equation (22) are in Figure 3. All interpolations lead to logarithmic functions.

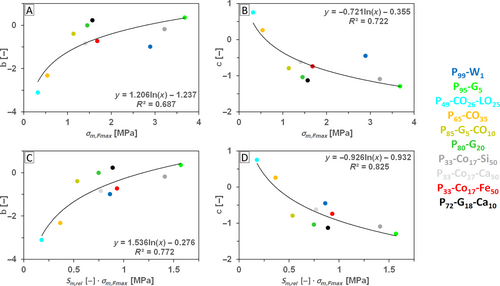

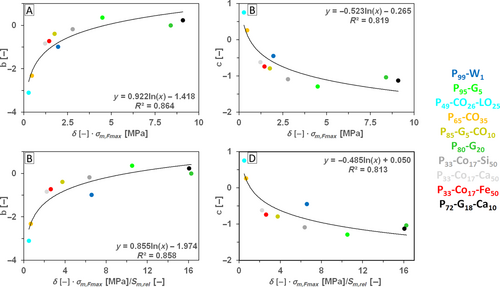

Equations (30-32) embody only a weak advantage against the interpolation presented by Equation (29). The interpolation possibilities overview if the observed property is the ultimate strength is in Table 10. The graphical overview for the case if the structural parameters are n and 1 − v m is in Figures 4 and 5.

| Eq. | p 1 + p 2 | b = f(x); x = σ m,Fmax | R 2 | c = f(x); x = σ m,Fmax | R 2 |

|---|---|---|---|---|---|

| (18) | n fp + n n | b = −0.949 · ln x − 0.225 | 0.668 | c = 0.763 · ln x − 0.868 | 0.559 |

| (19) | (1 − v m ) + n n | b = −1.088 · ln x − 0.026 | 0.817 | c = 1.080 · ln x − 1.022 | 0.816 |

| (20) | n n + v f | b = −0.361 · ln x − 1.004 | 0.603 | c = −0.976 · ln x + 0.145 | 0.781 |

| (21) | (1 − v m ) + v f | b = 0.526 · ln x − 1.592 | 0.673 | c = −1.246 · ln x + 1.258 | 0.689 |

| (22) | n + (1 − v m ) | b = 1.206 · ln x − 1.237 a | 0.687 | c = −0.721 · ln x − 0.355 a | 0.721 |

| (23) | n + v f | b = 0.514 · ln x − 1.579 | 0.664 | c = −0.774 · ln x − 0.372 | 0.820 |

| Eq. | p 1 + p 2 | b = f(x); x = σ m,Fmax · S m,rel | R 2 | c = f(x); x = σ m,Fmax · S m,rel | R 2 |

|---|---|---|---|---|---|

| (18) | n fp + n n | b = −1.145 · ln x − 0.902 | 0.778 | c = 0.938 · ln x − 0.316 | 0.675 |

| (19) | (1 − v m ) + n n | b = −1.350 · ln x − 0.840 | 0.860 | c = 1.344 · ln x − 0.213 | 0.863 |

| (20) | n n + v f | b = 0.457 · ln x − 0.736 | 0.698 | c = −1.207 · ln x − 0.858 | 0.864 |

| (21) | (1 − v m ) + v f | b = 0.635 · ln x − 1.182 | 0.694 | c = −1.571 · ln x + 0.264 | 0.775 |

| (22) | n + (1 − v m ) | b = 1.536 · ln x − 0.276 a | 0.772 | c = −0.926 · ln x − 0.932 a | 0.825 |

| (23) | n + v f | b = 0.620 · ln x − 1.181 | 0.681 | c = −0.946 · ln x − 0.976 | 0.862 |

| Eq. | p1 + p2 | b = f(x); x = σ m,Fmax · δ | R 2 | c = f(x); x = σ m,Fmax · δ | R 2 |

|---|---|---|---|---|---|

| (18) | n fp + n n | b = −0.680 · ln x − 0.062 | 0.848 | c = 0.607 · ln x − 1.027 | 0.872 |

| (19) | (1 − v m ) + n n | b = −0.772 · ln x + 0.129 | 0.834 | c = 0.784 · ln x − 1.185 | 0.870 |

| (20) | n n + v f | b = 0.296 · ln x − 1.081 | 0.915 | c = −0.676 · ln x + 0.003 | 0.848 |

| (21) | (1 − v m ) + v f | b = 0.411 · ln x − 1.677 | 0.885 | c = −0.951 · ln x + 1.433 | 0.862 |

| (22) | n + (1 − v m ) | b = 0.922 · ln x − 1.418 b | 0.864 | c = −0.523 · ln x − 0.265 b | 0.819 |

| (23) | n + v f | b = 0.406 · ln x − 1.655 | 0.892 | c = −0.529 · ln x − 0.298 | 0.824 |

| Eq. | p1 + p2 | b = f(x); x = σ m,Fmax · δ/S m,rel | R 2 | c = f(x); x = σ m,Fmax · δ/S m,rel | R 2 |

|---|---|---|---|---|---|

| (18) | n fp + n n | b = −0.682 · ln x + 0.362 | 0.867 | c = 0.602 · ln x − 1.399 | 0.873 |

| (19) | (1 − v m ) + n n | b = −0.729 · ln x + 0.580 | 0.870 | c = 0.737 · ln x + 1.640 | 0.901 |

| (20) | n n + v f | b = 0.283 · ln x − 1.253 | 0.917 | c = −0.660 · ln x + 0.410 | 0.884 |

| (21) | (1 − v m ) + v f | b = 0.391 · ln x − 1.940 | 0.914 | c = −0.885 · ln x + 2.026 | 0.856 |

| (22) | n + (1 − v m ) | b = 0.855 · ln x − 1.974 b | 0.858 | c = −0.485 · ln x + 0.050 b | 0.813 |

| (23) | n + v f | b = 0.385 · ln x − 1.922 | 0.922 | c = −0.505 · ln x + 0.041 | 0.861 |

| Eq. | p 1 + p 2 | b = f(x); x = ε m,Fmax | R 2 | c = f(x); x = ε m,Fmax | R 2 |

|---|---|---|---|---|---|

| (18) | n fp + n n | b = −0.822 · ln x − 1.102 | 0.860 | c = 0.424 · ln x + 0.353 | 0.550 |

| (19) | (1 − v m ) + n n | b = −0.676 · ln x + 0.908 | 0.889 | c = 0.372 · ln x + 0.294 | 0.647 |

| (20) | n n + v f | not found | — | c = −0.696 · ln x − 0.942 | 0.885 |

| (21) | (1 − v m ) + v f | not found | — | c = −0.647 · ln x − 0.647 | 0.667 |

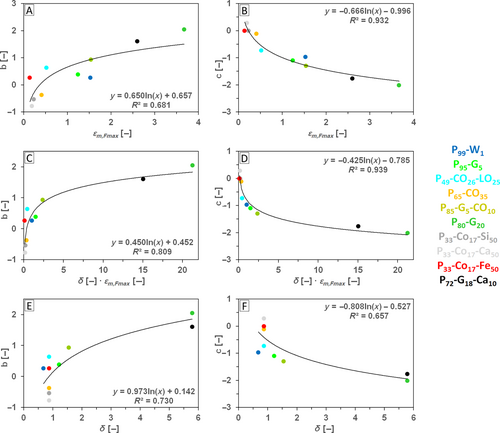

| (22) | n + (1 − v m ) | b = 0.650 · ln x + 0.657 b | 0.681 | c = −0.666 · ln x − 0.996 b | 0.932 |

| (23) | n + v f | not found | — | c = −0.666 · ln x − 0.996 | 0.933 |

| Eq. | p 1 + p 2 | b = f(x); x = εm,Fmax · δ | R 2 | c = f(x); x = ε m,Fmax · δ | R 2 |

|---|---|---|---|---|---|

| (18) | n fp + n n | b = −0.525 · ln x − 0.815 | 0.928 | c = 0.297 · ln x + 0.207 | 0.714 |

| (19) | (1 − v m ) + n n | b = −0.441 · ln x − 0.706 | 0.903 | c = 0.262 · ln x + 0.182 | 0.765 |

| (20) | n n + v f | b = 0.072 · ln x − 0.294 a | 0.446 | c = −0.447 · ln x − 0.712 | 0.931 |

| (21) | (1 − v m ) + v f | b = 0.104 · ln x − 0.478 a | 0.514 | c = −0.448 · ln x − 0.444 | 0.793 |

| (22) | n + (1 − v m ) | b = 0.450 · ln x + 0.452 b | 0.809 | c = −0.425 · ln x − 0.786 b | 0.939 |

| (23) | n + v f | b = 0.102 · ln x − 0.470 a | 0.550 | c = −0.424 · ln x − 0.786 | 0.936 |

| Eq. | p 1 + p 2 | b = f(x); x = δ | R 2 | c = f(x); x = δ | R 2 |

|---|---|---|---|---|---|

| (18) | n fp + n n | b = −1.050 · ln x − 0.431 | 0.758 | c = 0.671 · ln x − 0.034 | 0.741 |

| (19) | (1 − v m ) + n n | b = −0.900 · ln x − 0.440 | 0.657 | c = 0.604 · ln x + 0.003 | 0.713 |

| (20) | n n + v f | b = −0.197 · ln x − 0.356 a | 0.711 | c = −0.902 · ln x − 0.406 | 0.730 |

| (21) | (1 − v m ) + v f | b = 0.270 · ln x − 0.557 a | 0.770 | c = −0.970 · ln x − 0.137 | 0.717 |

| (22) | n + (1 − v m ) | b = 0.973 · ln x + 0.142 b | 0.730 | c = −0.805 · ln x − 0.529 b | 0.652 |

| (23) | n + v f | b = 0.264 · ln x − 0.547 a | 0.805 | c = −0.805 · ln x − 0.529 | 0.652 |

- a Excision of two devious points belonging to composites based on P33-CO17-Fe50 and P49-CO26-LO25 matrices.

- b Dependencies depicted in Figure 6.

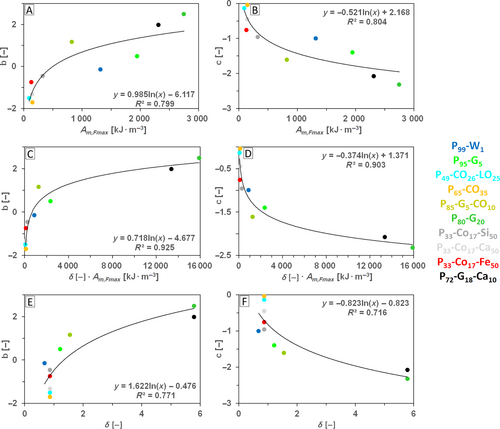

Functions coming from interpolation are in Table 12, which serves as an interpolation overview for interpolations related to A Fmax . The possibilities of interpolation if the pair of structural parameters is n + 1 − v m are in Figures 7 and 8.

| Eq. | p 1 + p 2 | b = f(x); x = A m,Fmax | R 2 | c = f(x); x = A m,Fmax | R 2 |

|---|---|---|---|---|---|

| (18) | n fp + n n | b = −0.750 · ln x + 3.558 | 0.780 | c = 0.720 · ln x − 4.565 | 0.769 |

| (19) | (1 − v m ) + n n | b = −0.692 · ln x + 3.397 | 0.708 | c = 0.723 · ln x − 4.662 | 0.738 |

| (20) | n n + v f | b = 0.325 · ln x − 2.681 | 0.772 | c = −0.643 · ln x + 3.052 | 0.784 |

| (21) | (1 − v m ) + v f | b = 0.477 · ln x − 4.027 | 0.782 | c = −1.029 · ln x + 6.353 | 0.840 |

| (22) | n + (1 − v m ) | b = 0.985 · ln x − 6.117 a | 0.800 | c = −0.521 · ln x + 2.168 a | 0.804 |

| (23) | n + v f | b = 0.468 · ln x − 3.965 | 0.778 | c = −0.525 · ln x + 2.186 | 0.813 |

| Eq. | p 1 + p 2 | b = f(x); x = Am,Fmax · δ | R 2 | c = f(x); x = A m,Fmax · δ | R 2 |

|---|---|---|---|---|---|

| (18) | n fp + n n | b = −0.538 · ln x + 2.448 | 0.904 | c = 0.521 · ln x − 3.529 | 0.907 |

| (19) | (1 − v m ) + n n | b = −0.480 · ln x + 2.219 | 0.683 | c = 0.505 · ln x − 3.457 | 0.723 |

| (20) | n n + v f | b = 0.238 · ln x − 2.219 | 0.887 | c = −0.457 · ln x + 2.057 | 0.854 |

| (21) | (1 − v m ) + v f | b = 0.351 · ln x − 3.351 | 0.921 | c = −0.735 · ln x + 4.750 | 0.931 |

| (22) | n + (1 − v m ) | b = 0.719 · ln x − 4.677 a | 0.925 | c = −0.374 · ln x + 1.371 a | 0.903 |

| (23) | n + v f | b = 0.346 · ln x − 3.307 | 0.920 | c = −0.376 · ln x + 1.370 | 0.903 |

| Eq. | p 1 + p 2 | b = f(x); x = δ | R 2 | c = f(x); x = δ | R 2 |

|---|---|---|---|---|---|

| (18) | n fp + n n | b = −1.257 · ln x − 0.578 | 0.804 | c = 1.234 · ln x − 0.606 | 0.830 |

| (19) | (1 − v m ) + n n | b = −0.992 · ln x − 0.612 | 0.398 | c = 1.064 · ln x − 0.486 | 0.438 |

| (20) | n n + v f | b = 0.570 · ln x − 0.871 | 0.777 | c = −1.045 · ln x − 0.553 | 0.678 |

| (21) | (1 − v m ) + v f | b = 0.806 · ln x − 1.300 | 0.790 | c = −1.599 · ln x + 0.434 | 0.719 |

| (22) | n + (1 − v m ) | b = 1.622 · ln x − 0.477 a | 0.771 | c = −0.823 · ln x − 0.823 a | 0.716 |

| (23) | n + v f | b = 0.795 · ln x − 1.291 | 0.796 | c = −0.823 · ln x − 0.823 | 0.716 |

| Eq. | p 1 + p 2 | b = f(x); x = ε m,Fmax | R 2 | c = f(x); x = ε m,Fmax | R 2 |

|---|---|---|---|---|---|

| (18) | n fp + n n | b = −0.836 · ln x − 1.318 | 0.659 | c = 0.855 · ln x + 0.137 | 0.738 |

| (19) | (1 − v m ) + n n | b = −0.627 · ln x − 1.094 | 0.380 | c = 0.687 · ln x + 0.036 | 0.437 |

| (20) | n n + v f | b = 0.385 · ln x − 0.553 | 0.723 | c = −0.667 · ln x − 1.121 | 0.564 |

| (21) | (1 − v m ) + v f | b = 0.546 · ln x − 0.873 | 0.757 | c = −0.521 · ln x − 1.249 | 0.599 |

| (22) | n + (1 − v m ) | b = 1.058 · ln x + 0.372 b | 0.685 | c = −1.092 · ln x − 0.417 b | 0.700 |

| (23) | n + v f | b = −0.523 · ln x − 1.260 | 0.596 | c = −0.523 · ln x − 1.260 | 0.596 |

| Eq. | p 1 + p 2 | b = f(x); x = εm,Fmax · δ | R 2 | c = f(x); x = ε m,Fmax · δ | R 2 |

|---|---|---|---|---|---|

| (18) | n fp + n n | b = −0.572 · ln x − 1.031 | 0.817 | c = 0.575 · ln x − 0.159 | 0.883 |

| (19) | (1 − v m ) + n n | b = −0.437 · ln x − 0.906 | 0.440 | c = 0.475 · ln x − 0.170 | 0.497 |

| (20) | n n + v f | b = 0.261 · ln x − 0.679 | 0.846 | c = −0.463 · ln x − 0.903 | 0.692 |

| (21) | (1 − v m ) + v f | b = −0.376 · ln x + 1.044 | 0.889 | c = −0.749 · ln x − 0.074 | 0.817 |

| (22) | n + (1 − v m ) | b = 0.739 · ln x + 0.039 b | 0.830 | c = −0.369 · ln x + 0.745 b | 0.745 |

| (23) | n + v f | b = −0370. · ln x − 1.038 | 0.895 | c = −0.369 · ln x − 1.096 | 0.737 |

| Eq. | p 1 + p 2 | b = f(x); x = σm,Fmax · δ | R 2 | c = f(x); x = σ m,Fmax · δ | R 2 |

|---|---|---|---|---|---|

| (18) | n fp + n n | b = −0.887 · ln x − 0.543 | 0.765 | c = 0.806 · ln x − 0.609 | 0.677 |

| (19) | (1 − v m ) + n n | b = −0.887 · ln x − 0.414 | 0.798 | c = 0.900 · ln x − 0.669 | 0.785 |

| (20) | n n + v f | b = 0.362 · ln x − 0.878 | 0.670 | c = −0.786 · ln x − 0.478 | 0.823 |

| (21) | (1 − v m ) + v f | b = 0.523 · ln x − 1.402 | 0.669 | c = −1.172 · ln x + 0.726 | 0.776 |

| (22) | n + (1 − v m ) | b = 1.137 · ln x − 0.736 b | 0.760 | c = −0.630 · ln x − 0.656 b | 0.841 |

| (23) | n + v f | b = 0.511 · ln x − 1.388 | 0.660 | c = −0.634 · ln x − 0.664 | 0.845 |

There are many d, e, f, and g parameters in the equations shown in Tables 9–12. What is their function or meaning? The assumption is that parameters d, e, f, and g in the equations should vary according to the pair of filler and matrix in composites. These parameters are the last members in equations without proven meaning and description. On the other hand, the properties and behavior of fillers, their influence on material porosity, and other material properties are the undescribed parts of the composite material description in this work. Therefore, there is an assumption to join parameters d, e, f, and g and fillers properties together, but without accurate description, due to data focusing on different matrices and not focusing on different fillers with their properties and influence on material porosity in this work.

Therefore, there is also an assumption (or idea) of the extra d and e parameter values in the case of a porous matrix without filler if there is an assumption of dependence of d, e, f, and g on filler properties in composites. The potential interpolation is easy because only the b parameter is present in Equation (40), which leads to two interpolation parameters—d and e. Values of these parameters should exist as interpolation results of b parameters of porous matrices if filler absence is as filler type. The reduction of interpolation parameters then should lead to universal interpolation parameters in the case of Equation (40). Parameters d and e should become numbers in that case. However, there are possible influences of different void shapes on material behavior in the case of filler absence. It is indicated in the literature [40, 42, 43]. On the other hand, there is a question about its relevancy from a macroscopic point of view to the properties of material containing voids negligible in comparison with the dimensions of the material body as is suggested in this work. However, only a limited data set was available, but it was trying to find universal d and e parameters for Equation (40). The attempt is later. In contrast with Equation (40), the interpolation joined with nonporous composites (Equation 39) was not tried because they were not available.

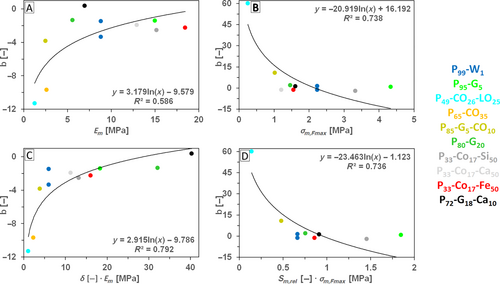

It is no fitting possibility for porous matrices as in the case of the porous composites because each matrix has only one porosity value (except the P99-W1 prepared with two porosity values). The process has to be different, and the results should be less accurate. The members of Equation (40) are from various sources. The measured z mn values for porous matrices and fitted z m values for nonporous matrices from the fitting of data belonging to porous composites are in tables including Tables 3–6 according to chosen property. The porosity value has the origin in Equation (6). The member b is the only remaining unknown calculated by known members. Equation (40) can have more versions because this equation can have the source of z m in different Equations (18-23) adapted to the chosen property, so the z m values are various due to the origin of the equation. It leads to several similar variants of Equation (40) b parameters presented for E and σ Fmax . The b interpolations possibilities are in Table 13. The example based on the 1 − v m and n parameters (also Equation (22)) is in Figure 9. The interpolations of ε Fmax and A Fmax were not successful. There are only hints of dependencies. The possible explanation is the absence of fitting and its replacement by calculations. It is necessary to perceive, that each b parameter arose from the fitted z m value of composites and measured values of n and z mn representing the low amount of samples (1 set = 5 identical samples). The assumption is its relevancy is lower when compared with the parameter b obtained by fitting several sets of identical samples (different sets = different porosity and sample properties). Therefore, inaccurate results are in Table 13.

| Elastic modulus | |||||

|---|---|---|---|---|---|

| Eq. | p 1 + p 2 → p | b = f(x); x = E m | R 2 | b = f(x); x = E m · δ | R 2 |

| (18) → (40) a | n fp + n n → n | b = −1.882 · ln x + 3.461 | 0.533 | Not found | — |

| (19) → (40) a | (1 − v m ) + n n → n | b = −11.24 · ln x + 24.14 | 0.777 | b = −7.49 · ln x + 19.66 | 0.562 |

| (20) → (40) a | n n + v f → n | b = −5.68 · ln x − 11.68 | 0.816 | b = −3.302 · ln x + 8.396 | 0.458 |

| (21) → (40) | (1 − v m ) + v f → n | b = 2.861 · ln x − 8.887 | 0.598 | b = 2.566 · ln x − 8.937 | 0.783 |

| (22) → (40) | n + (1 − v m ) → n | b = −3.179 · ln x − 9.579 b | 0.586 | b = 2.915 · ln x − 9.786 b | 0.792 |

| (23) → (40) | n + v f → n | b = 3.348 · ln x − 9.985 | 0.600 | b = 3.040 · ln x − 10.14 | 0.795 |

| Ultimate Strength | |||||

|---|---|---|---|---|---|

| Eq. | p 1 + p 2 → p | b = f(x); x = σ m,Fmax | R 2 | b = f(x); x = σ m,Fmax · S m,rel | R 2 |

| (18) → (40) a | n fp + n n → n | b = −13.56 · ln x + 9.92 | 0.664 | b = −14.69 · ln x + 0.26 | 0.658 |

| (19) → (40) a | (1 − v m ) + n n → n | b = −20.92 · ln x + 16.19 | 0.739 | b = −24.95 · ln x − 0.41 | 0.730 |

| (20) → (40) a | n n + v f → n | b = −18.50 · ln x − 13.11 | 0.727 | b = −21.25 · ln x − 0.71 | 0.724 |

| (21) → (40) a | (1 − v m ) + v f → n | b = −9.451 · ln x + 7.829 | 0.701 | b = −11.56 · ln x − 0.16 | 0.749 |

| (22) → (40) a | n + (1 − v m ) → n | b = −20.92 · ln x + 16.19 b | 0.738 | b = −23.48 · ln x − 1.11 b | 0.736 |

| (23) → (40) a | n + v f → n | b = −9.493 · ln x − 7.874 | 0.706 | b = −11.63 · ln x − 0.13 | 0.756 |

3.4 Discussion With Comparison to Earlier Published Results

Equation (17) has three versions based on three structural parameters pairs created by three parameters (n, v f , 1 − v m instead of n p , 1 − v f , and v m from Equation (16)) and leading to the nearly same z m values if they are compared (see Tables 3–6). The exact connection between the results from Equations (16 and 17) does not exist. The exception is only the Equation (9) dedicated to structural parameters. Further research should solve this problem after using nonporous matrices with the following direct comparison to measured and fitted values. There are also simple dependencies between b and c across different equations differing by structural parameters (n, v f , 1 − v m as example) in both relationships represented by Equations (17 and 16) (see Table 8 for Equation (17)). The possibility of simplified equations for nonporous composite (theoretically) and porous matrix (tested) is also valid for both approaches.

The primary data included materials with different matrices, various porosity rates (up to 50 vol% without the possibility of influence of its value during the preparation in a more significant way), and only one type of filler (but including various filler contents). The filler behavior then cannot be accented in the shapes of relationships now. It could be included in the interpolation parameters d, e, f, and g with unclear behavior after research of composites based on different matrices but no fillers. Further research should focus on filler size distributions, surface values, surface properties, and their interaction with matrices. The surface properties of material components related to their adhesion should replace the δ value used as a simplification.

This work does not differ in the porosity type (open or closed pores) by visible means. There is an expectation that the porosity type (and its content in material) is a result of several factors such as matrix type, filler type, their rates, and ambient conditions affecting the porosity of the sample during its preparation—the pressing, for example. All these factors are directly or indirectly present in equation members, respectively, and their influence on them is expected (filler properties). There is also the question of the influence of void shapes and distribution to d and e parameters in simplified equations valid for porous matrices if the work focuses on the macroscopic point of view concerning the properties of components. Parameters d and e could be universal numbers for each one-component porous material, but it is necessary to prove it first. This work includes some effort to solve it. The limited data lead to only indication of results (low R 2), and this work should be repeated in another way in the future (more matrices with controlled porosity values for fitting, different shapes of voids if possible). Nevertheless, it is the first important step indicating future possibilities.

The proposed relationships for composites can process the data from materials on both sides of the percolation threshold in porosity/filler concentrations. It suggests an idea of utilization of similar equations in many different cases of not only the mechanical properties of materials.

The adjusted data processing approach could lead after discovering all relevant influences to relationships containing parameters adjustable according to types and rates of materials components. This approach could compose the composite behavior from the values of members in equations determined by the behavior of present components and their rates influenced by porosity if it would be present.

The base of our approach is relationships containing members determined accurately or approximately by their positions in equations and mathematical relations. First, materials with different compositions based on different matrices, fillers, and porosity can be prepared and tested. The work method is based on fitting measurement results to get an equation followed by equation members interpolation according to some properties and relations of components to find their mathematical behavior joined or comparable with the observed properties of components or the whole material.

It differs from most published works dedicated to physical models, where there is an accurate physical assumption at the beginning. This physical assumption is then compared with the behavior of existing material with some extent of accordance. The reason is simplification at the beginning—in material structure. In the model, it is hard to describe random structures containing randomly shaped particles and then randomly shaped pores. The expectations include granular particles [30], short fibers with cylindrical shapes [28], nanotubes or nanoparticles [23, 24] or unidirectionally oriented nanofibers [27] for example. Forms of voids can be limited to spherical [25]. The models are often limited to some properties. Examples include the elastic region of loading [21, 26-28] or the study of nonlinear stress [22-24, 29, 30]. The models can use different mathematical methods [21, 27-29].

The advantage of models is their awareness of physical rules, but there is often a problem with materials embodying random structures. Our proposed approach can work with randomly structured material due to its macroscopic point of view, and then it can describe also some stochastic properties, but not as well as elastic modulus. However, it does not work directly with an accurate physical description of the material on its microscopic level. Therefore, its understanding of phenomena occurring at a microscopic level is limited. It only connects the measured data with known properties of material components and structural parameters such as filler volume fraction, etc. These two approaches do not have to stand against each other. If our system were more complex (including also different filler types and maybe void types if it they are relevant), both approaches could meet in cases of material with a structure corresponding to limits of models such as spherical particles and voids, cylindrical particles, and so forth. This potential meeting or connection could contribute to understanding materials with different types of composition and structure complexity.

Our system of fitting and interpolating in presented forms comes from limited data set and needs continuation to solve a lot of question coming from proposed equations as filler and voids influence on material behavior.

4 Conclusions

This work introduces new forms of description for relationships between structure/properties and chosen mechanical properties from tensile testing of porous materials (mainly filled composites, not reinforced). It uses the mean when the measurement is the beginning, the data fitting follows, and further interpolation of obtained parameters is the finish. The proposed relationships used structural parameters leading to a new shape of fitting functions (spatial linear with displacement). The fitting is newly based not only on the value of the R 2 coefficient but also on the similarity of slope and displacement values (they should be ideally the same) in the linear fitting function. The following interpolation gives real meaning to obtained parameters.

The proposed function shape is z c = z m + z m · (b · p 1 + c · p 2), where z c /z m is generally labeled mechanical property value for composite/nonporous matrix, p 1 /p 2 are suitable structural parameters, and b/c are fitting parameters subjected to interpolations by logarithmic function containing values of properties typical for matrices. The interpolations were done by as many means as possible to obtain many interpolation results. It serves as an indication of the potential research directions. The logarithmic functions interpolating the b and c parameters contain d, e, f, and g members without clear description. On the other hand, the work is not focused on different matrices and porosity types. Therefore, these interpolation members could be related to these material components and their behavior. The members p 1 and p 2 represent structural parameters including v f (filer volume fraction), 1 − v m (volume fraction of filler and porosity together), n (porosity), n fp (filler volume fraction, if porosity neglect), and n n (interspace porosity) used in pairs. Combinations of the trinity of parameters—1 − v m , v f , and n make the connection of proposed equations that include them. There is a connection of b and c parameters across equations and the retaining of slope and displacement values across different equations (if the property is the same). It is not valid for pairs p 1 and p 2 created by another combination of structural parameters. Another interesting result is the linear dependence of c on b in each proposed equation unconnected with the choice of structural parameters.

The proposed equations enable mathematical simplification if the corresponding material is simpler (without pores or filler) to only one structural parameter, one fitting parameter (b), and two interpolation parameters (d, e). The version valid for porous matrices was proven and the results were interesting but not sufficiently suitable due to the low amount of available data. The results are important because they indicate potential future research directions. The nonporous composites were not available and practically studied except for mathematically deriving their equation.

This work introduces new means of data processing that are non-exclusive to those earlier published and mentioned in this work as references or for comparisons. The results are rough, but they are shown in numerical forms (equations, values in tables) to enable easier looking for utilizable ways in further research. The most significant output of this work is the general shape of equations and mean of work (fitting, interpolation). The general output is more significant than individual results of fitting and interpolation, which are only its support.

Section 3 discusses the potential relationship of our work to physical models as another approach for investigating composite materials. Currently, there is no connection, but this could change in the future.

Author Contributions

Miroslav Černý: conceptualization (lead), data curation (equal), formal analysis (lead), investigation (lead), methodology (equal), writing – original draft (lead). Přemysl Menčík: conceptualization (supporting), data curation (equal), funding acquisition (lead), investigation (supporting), methodology (equal), writing – review and editing (lead).

Acknowledgments

This work was supported by the Brno University of Technology [Specific University Research Grant FCH-S-23-8208]. Open access publishing facilitated by Vysoke uceni technicke v Brne, as part of the Wiley - CzechELib agreement.

Conflicts of Interest

The authors declare no conflicts of interest.

Open Research

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.