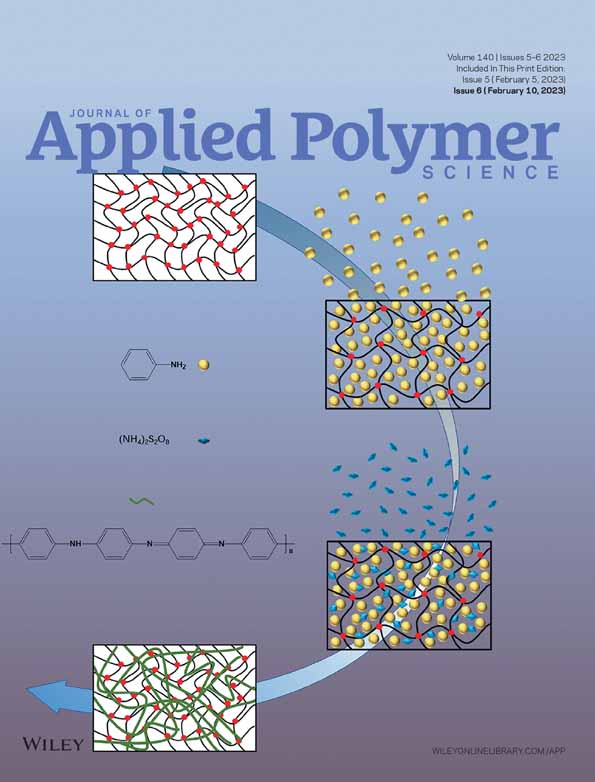

Evolution of electrical conductivity in semi-interpenetrating polymer network of shape memory polyvinyl chloride and polyaniline

Corresponding Author

Xuelian Wu

School of Mechanical Engineering, Jiangsu University, Zhenjiang, China

Correspondence

Xuelian Wu, School of Mechanical Engineering, Jiangsu University, 301 Xuefu Road, Zhenjiang, China.

Email: [email protected]

Weimin Huang, School of Mechanical and Aerospace Engineering, Nanyang Technological University, 50 Nanyang Avenue, Singapore.

Email: [email protected]

Contribution: Investigation (lead), Writing - original draft (lead), Writing - review & editing (lead)

Search for more papers by this authorJiaxing Zou

School of Mechanical Engineering, Jiangsu University, Zhenjiang, China

Contribution: Investigation (equal)

Search for more papers by this authorJian Yang

School of Mechanical Engineering, Jiangsu University, Zhenjiang, China

Contribution: Software (equal)

Search for more papers by this authorJiang Jiang

School of Mechanical Engineering, Jiangsu University, Zhenjiang, China

Contribution: Software (supporting)

Search for more papers by this authorQin Feng

School of Mechanical Engineering, Jiangsu University, Zhenjiang, China

Contribution: Investigation (equal)

Search for more papers by this authorZihao Ye

School of Mechanical Engineering, Jiangsu University, Zhenjiang, China

Contribution: Software (equal)

Search for more papers by this authorCorresponding Author

Weimin Huang

School of Mechanical and Aerospace Engineering, Nanyang Technological University, Singapore, Singapore

Correspondence

Xuelian Wu, School of Mechanical Engineering, Jiangsu University, 301 Xuefu Road, Zhenjiang, China.

Email: [email protected]

Weimin Huang, School of Mechanical and Aerospace Engineering, Nanyang Technological University, 50 Nanyang Avenue, Singapore.

Email: [email protected]

Contribution: Writing - review & editing (equal)

Search for more papers by this authorCorresponding Author

Xuelian Wu

School of Mechanical Engineering, Jiangsu University, Zhenjiang, China

Correspondence

Xuelian Wu, School of Mechanical Engineering, Jiangsu University, 301 Xuefu Road, Zhenjiang, China.

Email: [email protected]

Weimin Huang, School of Mechanical and Aerospace Engineering, Nanyang Technological University, 50 Nanyang Avenue, Singapore.

Email: [email protected]

Contribution: Investigation (lead), Writing - original draft (lead), Writing - review & editing (lead)

Search for more papers by this authorJiaxing Zou

School of Mechanical Engineering, Jiangsu University, Zhenjiang, China

Contribution: Investigation (equal)

Search for more papers by this authorJian Yang

School of Mechanical Engineering, Jiangsu University, Zhenjiang, China

Contribution: Software (equal)

Search for more papers by this authorJiang Jiang

School of Mechanical Engineering, Jiangsu University, Zhenjiang, China

Contribution: Software (supporting)

Search for more papers by this authorQin Feng

School of Mechanical Engineering, Jiangsu University, Zhenjiang, China

Contribution: Investigation (equal)

Search for more papers by this authorZihao Ye

School of Mechanical Engineering, Jiangsu University, Zhenjiang, China

Contribution: Software (equal)

Search for more papers by this authorCorresponding Author

Weimin Huang

School of Mechanical and Aerospace Engineering, Nanyang Technological University, Singapore, Singapore

Correspondence

Xuelian Wu, School of Mechanical Engineering, Jiangsu University, 301 Xuefu Road, Zhenjiang, China.

Email: [email protected]

Weimin Huang, School of Mechanical and Aerospace Engineering, Nanyang Technological University, 50 Nanyang Avenue, Singapore.

Email: [email protected]

Contribution: Writing - review & editing (equal)

Search for more papers by this authorAbstract

Electrically conductive semi-interpenetrating polymer network (IPN) from shape memory polyvinyl chloride (PVC) and polyaniline (PANI) is realized. The mechanical properties and shape memory performance of semi-IPN are slightly different from the original PVC. The distribution of PANI within PVC is found to be non-uniform in the thickness direction. The electrical conductivity of the as-fabricated sample at room temperature is around 4.5 × 10−2 S/cm. However, after heating, thermal strain results in significant drop in electrical conductivity. Programming remarkably reduces the electrical conductivity as well. A higher programming temperature and higher programming strain result in more reduction. Subsequent heating for shape recovery causes further reduction in electrical conductivity, despite nearly full shape recovery is achieved. Doping (dedoping and redoping) is confirmed not the major player, but microgaps/fracture in PANI chains during stretching in programming and heating for shape recovery.

Open Research

DATA AVAILABILITY STATEMENT

The data that support the findings of this study are available from the corresponding author upon reasonable request.

REFERENCES

- 1J. Diani, E. Strauch-Hausser, Soft Matter 2021, 17, 7341.

- 2A. D. Rupali Gangopadhyay, Synth. Met. 2002, 132, 21.

- 3Y. H. Lin, T. C. Lee, Y. S. Hsiao, W. K. Lin, W. T. Whang, C. H. Chen, ACS Appl. Mater. Interfaces 2018, 10, 4946.

- 4S. Basu, R. Johl, S. Pacelli, S. Gehrke, A. Paul, ACS Macro Lett. 2020, 9, 1230.

- 5L. Zhou, T. Ma, T. Li, X. Ma, J. Yin, X. Jiang, ACS Appl. Mater. Interfaces 2019, 11, 15977.

- 6J. A. Claudio-Rizo, N. G. Hernandez-Hernandez, L. F. Cano-Salazar, T. E. Flores-Guía, F. N. Cruz-Durán, D. A. Cabrera-Munguía, J. J. Becerra-Rodríguez, J. Appl. Polym. Sci. 2020, 138, 49739.

- 7H. Wu, L. Zhao, S. Zhang, Y. Si, J. Yu, B. Ding, ACS Appl. Mater. Interfaces 2021, 13, 18165.

- 8M. Kamal, M. M. Jafri, D. K. Singh, T. C. Shami, H. B. Baskey, Adv. Polym. Technol. 2018, 37, 2663.

- 9R. Prabhakar, D. Kumar, J. Nanosci. Nanotechnol. 2017, 17, 5008.

- 10N. Sahiner, S. Demirci, J. Porous. Mater. 2018, 26, 481.

- 11M. A. Diab, A. Z. El-Sonbati, N. A. El-Ghamaz, S. M. Morgan, O. El-Shahat, Eur. Polym. J. 2019, 115, 268.

- 12J. Xie, X. Han, C. Zong, H. Ji, C. Lu, Macromolecules 2015, 48, 663.

- 13L. Li, Y. Zhang, H. Lu, Y. Wang, J. Xu, J. Zhu, C. Zhang, T. Liu, Nat. Commun. 2020, 11, 62.

- 14S. Bhadra, D. Khastgir, N. K. Singha, J. H. Lee, Prog. Polym. Sci. 2009, 34, 783.

- 15K. Otsuka, C. M. Wayman, Shape Memory Materials, Cambridge University Press, Cambridge 1998.

- 16W. M. Huang, Z. Ding, C. C. Wang, J. Wei, Y. Zhao, H. Purnawali, Mater. Today 2010, 13, 7.

- 17A. Lendlein, R. Langer, Science 2002, 296, 1673.

- 18W. M. Huang, Y. Zhao, C. C. Wang, Z. Ding, H. Purnawali, C. Tang, J. L. Zhang, J. Polym. Res. 2012, 19, 9952.

- 19X. L. Wu, S. F. Kang, X. J. Xu, F. Xiao, X. L. Ge, J. Appl. Polym. Sci. 2014, 131, 338.

- 20J. S. Leng, X. L. Wu, Y. J. Liu, Smart Mater. Struct. 2009, 18, 7566.

- 21X. L. Wu, W. M. Huang, Y. Zhao, Z. Ding, C. Tang, J. L. Zhang, Polymers 2013, 5, 1169.

- 22P. Zhang, M. Behl, M. Balk, X. Peng, A. Lendlein, Macromol. Rapid Commun. 2020, 41, e1900658.

- 23E. Su, C. Bilici, G. Bayazit, S. Ide, O. Okay, ACS Appl. Mater. Interfaces 2021, 13, 21786.

- 24S. Xue, Y. Wu, G. Liu, M. Guo, Y. Liu, T. Zhang, Z. Wang, J. Mater. Chem. A 2021, 9, 5730.

- 25L. N. Woodard, V. M. Page, K. T. Kmetz, M. A. Grunlan, Macromol. Rapid Commun. 2016, 37, 1972.

- 26X. Kuang, K. Chen, C. K. Dunn, J. Wu, V. C. F. Li, H. J. Qi, ACS Appl. Mater. Interfaces 2018, 10, 7381.

- 27S. Jagtap, V. Dalvi, K. Sankar, D. Ratna, Polym. Int. 2019, 68, 812.

- 28M. R. Pfau, K. G. McKinzey, A. A. Roth, M. A. Grunlan, Biomacromolecules 2020, 21, 2493.

- 29H. Gao, J. Li, Y. Liu, J. Leng, Adv. Compos. Hybrid Mater. 2021, 4, 957.

- 30M. Sobczyk, S. Wiesenhütter, J. R. Noennig, T. Wallmersperger, J. Intell. Mater. Syst. Struct. 2021, 33, 379.

- 31V. B. Ozdemir, K. Kwok, J. Intell. Mater. Syst. Struct. 2017, 20, 2.

- 32X. Huang, M. Panahi-Sarmad, K. Dong, R. Li, T. Chen, X. Xiao, Compos. Part A: Appl. Sci. Manuf. 2021, 147, 147.

- 33S. Zhu, Q. Zhou, M. Wang, J. Dale, Z. Qiang, Y. Fan, M. Zhu, C. Ye, Compos. Part B: Eng. 2021, 204, 108497.

- 34T. X. Wang, H. M. Chen, A. V. Salvekar, J. Lim, Y. Chen, R. Xiao, W. M. Huang, Polymers 2020, 12, 13.

- 35J. S. Leng, W. M. Huang, X. Lan, Y. J. Liu, S. Y. Du, Appl. Phys. Lett. 2008, 92, 204101.

- 36F. F. Li, J. S. Leng, Y. J. Liu, C. Remillat, F. Scarpa, Mech. Mater. 2020, 148, 103518.

- 37X. Y. Wang, J. Y. Lan, P. P. Wu, J. Y. Zhang, Polymer 2021, 212, 1123174.

- 38X. Z. Huang, F. H. Zhang, Y. J. Liu, J. S. Leng, ACS Appl. Mater. Interfaces 2020, 12, 23236.

- 39X. L. Wu, W. M. Huang, Z. G. Seow, W. S. Chin, W. G. Yang, K. Y. Sun, Smart Mater. Struct. 2013, 22, 125023.

- 40J. C. Wang, H. Wang, L. L. Huang, C. Q. Wang, Waste Manag. 2017, 67, 20.

- 41S. Yang, W. Wu, Y. Jiao, H. Fan, Z. Cai, Polym. Int. 2016, 65, 1172.

- 42C. Luo, H. Pen, L. Zhang, G. L. Lu, Y. Wang, J. Travas-Sejdic, Macromolecules 2011, 44, 6899.

- 43B. E. T. Thornton, A. Harrison, A. L. Pham, C. E. Castano, C. Tang, ACS Omega 2018, 3, 3587.

- 44H. Yoshikawa, T. Hino, N. Kuramoto, Synth. Met. 2006, 156, 1187.

- 45V. Ugraskan, O. Yazici, F. Karaman, J. Electron. Mater. 2020, 49, 5460.