Surface functionalized nanocellulose as a veritable inclusionary material in contemporary bioinspired applications: A review

ABSTRACT

The past few decades have seen extraordinary gain in interest for bio-based products, driven by the intensifying call of the society for petrochemical material replacement and developing materials with next-to-no environmental impact. Cellulose, which is an abundantly available “green” material, can be derived from plant fibers and tailored for a plethora of possible uses where it can be used as a substrate or as a filler material. However, emerging technologies and product advancements necessitate the search for materials that are small, biodegradable, lightweight, and strong. Nanocellulose, which can be obtained through as mechanical and chemical production methods with tensile strength and Young's modulus of up to 0.5 and 130 GPa, respectively, proves to be the answer that they were looking for. However, the inherent hydrophilic nature of nanocellulose limited its potential widespread application. Surface modifications of nanocellulose to alter and diminish its hydrophilicity were done to address the aforementioned issues. In this article, we had reviewed on different types of surface modifications and their resulting impact on the properties of nanocellulose and their effect on polymer composites. The importance of nanocellulose in emerging applications such as biosensor, nanoremediation, papermaking, and automotive as well as the current state of the industry and the commercialization progress of nanocellulose were also discussed. © 2017 Wiley Periodicals, Inc. J. Appl. Polym. Sci. 2018, 135, 46065.

INTRODUCTION

Common interest in biomaterials to reduce dependency on fossil fuel, provide friendly end-of-life disposal and product enhancement is dictating the direction of research in this modern era. Cellulose, which is one of the illimitable naturally occurring polymers produced on Earth is arguably the “wonder” material most of the researchers are looking for. It was found that the average annual production was estimated to reach over 100 billion tons.1, 2 For the past hundreds of years, cellulose, an engineering material in macroscopic form, had played a major role in our lives especially in paper and textile industry. Although this traditional material possess admirable properties and quality, it has reached its “bottleneck” point where the current development of products are mostly targeted towards utilizing nanoscopic materials that are lightweight, modification-friendly and can provide higher strength/weight performance.

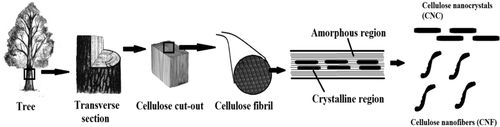

In order to meet the current standard of engineering applications, researchers have turned their eyes on extracting the fundamental basic unit of cellulose, nanocellulose to address the defects and discrepancies of cellulose.3-5 Nanocellulose is a fascinating material that has captured the interest of many and it can be extracted from fibrous structure of cellulose to the form of rod-like crystal or flexible spaghetti-like fibers depending on the treatment process as illustrated in Figure 1. Both types of nanocellulose carry hydroxyl groups on their surfaces which makes them hydrophilic in nature.6, 7 Acid hydrolysis is the most popular method employed to yield cellulose nanocrystals (CNC), where strong acids are used to attack the amorphous regions present in the cellulose, leaving the desired crystalline regions behind.8-12 Mechanical disintegration and enzymatic pretreatments have been reported to yield cellulose nanofibers (CNF).13-16 There is a plethora of source for nanocellulose production as listed in Table 1, ranging from agricultural residues of food crop, fiber crop, energy crop, grass crop to readily available raw materials. From an economic standpoint, the current use of these waste materials which involves conversion into livestock feed and soil compost are lackluster. Considering the supply chain for nanocellulose can be practically inexhaustible, this can be a golden opportunity to convert these agricultural wastes into wealth.17, 18 However, drawbacks such as some agricultural residues that have distinctive harvesting seasons may affect the continuous supply for nanocellulose production.6

Top down approach to extract CNC (from acid hydrolysis) and CNF (from mechanical disintegration).

| Composition (%) | ||||

|---|---|---|---|---|

| Agronomic classification | Source | Cellulose | Hemicellulose | Lignin |

| Food crop | Barley hull | 34 | 36 | 19 |

| Barley straw | 36–43 | 24–33 | 6.3–9.8 | |

| Banana shell | 13 | 15 | 14 | |

| Corn cob | 32–45 | 35–40 | 6.7–15 | |

| Coconut coir | 32–43 | 10–20 | 43–49 | |

| Corn stalk | 35 | 25 | 35 | |

| Corn stover | 35–40 | 21–25 | 11–19 | |

| Coffee pulp | 34–37 | 44–48 | 16–19 | |

| Rice straw | 29–35 | 23–26 | 17–19 | |

| Rice husk | 29–36 | 12–29 | 15–20 | |

| Wheat straw | 30 | 50 | 15 | |

| Sugarcane bagasse | 40 | 30 | 20 | |

| Oat straw | 31–35 | 20–26 | 10–15 | |

| Sorghum straw | 32–35 | 24–27 | 15–21 | |

| Fiber crop | Bamboo | 49–50 | 18–20 | 23 |

| Cotton | 85–95 | 5–15 | 0–1 | |

| Cotton stalk | 31 | 11 | 30 | |

| Flax | 63–71 | 12–21 | 2–3 | |

| Jute | 71 | 14 | 13 | |

| Kenaf | 36 | 21 | 18 | |

| Ramie | 76 | 17 | 1 | |

| Energy crop | Empty fruit bunch (EFB) | 50 | 30 | 17 |

| Elephant grass | 60 | 24 | 8 | |

| Grass crop | Switchgrass | 35–40 | 25–30 | 15–20 |

| Raw materials | Eucalyptus | 45–51 | 11–18 | 29 |

| Softwood | 40–44 | 25–29 | 25–31 | |

| Hardwood | 43–47 | 25–35 | 16–24 | |

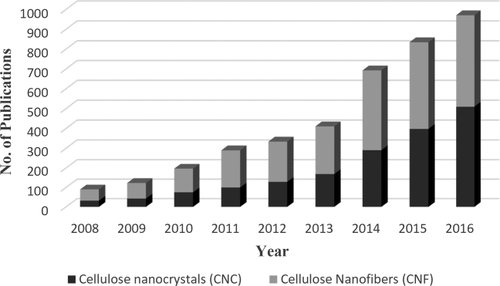

Judging from the steady increase in nanocellulose-related publications compiled from Scopus as shown in Figure 2, it is clearly evident that this particular research area is of great importance to the burgeoning science and economy.19 Research works had been observed to shift from nanocellulose characterization and production to nanocellulose functionalization in view of expanding its field of application. Therefore, this particular review will only be targeted towards discussion on the recent development and findings on nanocellulose surface functionalization and the potential applications of nanocellulose in emerging bioinspired technologies.

Number of publications per year from 2008 to 2016 (Scopus database).

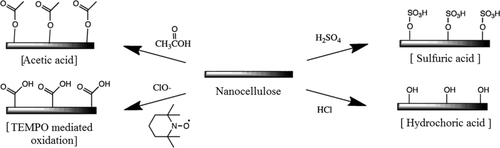

Surface Functionalization of Nanocellulose

It has been well known that dispersivity and filler–matrix interaction of nanocellulose will directly affect the properties of the resultant polymer composites. Numerous studies had been performed on the use of nanocellulose, which is hydrophilic in nature, as supporting or reinforcement fillers in polymer system but mainly on hydrophilic polymers such as starch22-24 and poly(vinyl alcohol) (PVOH).25-28 The simplest surface modification method is through the production of nanocellulose from a combination of acid hydrolysis which was commonly used in conventional pulp and paper industry production process. Interestingly, different types of acid will produce different types of nanocellulose through the introduction of side groups on its surface. As depicted in Figure 3, the most common nanocellulose production methods are sulfuric acid process that introduces sulfate ester side groups while acetic acid, hydrochloric acid (HCL), and TEMPO-mediated hypochlorite process introduces acetyl, hydroxyl, and carboxylic acid side groups, respectively.32 Phosphoric and hydrobromic acid were also used for similar purposes but studies on them are limited.29-31 However, self-agglomeration and hydrophilicity due to inherent OH groups present on the surface of nanocellulose are still the limiting factors in its widespread application, which necessitates the discovery of surface hydrophobization and functionalization to expand its field of application. Modifications methods such as acetylation, acylation, silylation, polymer grafting, and fluorescent labelling (which will be discussed in the subsequent sections) were introduced to address the adherent issues as well as introducing additional functionality onto nanocellulose.

Common production methods to yield nanocellulose. Adapted from Ref. 32 with permission of The Royal Society of Chemistry.

Silylation

Silylation corresponds to the process where silyl groups, R3Si are introduced onto the surface of nanocellulose through substitution method. Silanes are considered as effective coupling agents as they have strong affinity for hydroxyl groups even at room temperature. Permanent surface grafting through condensation of SiOH with COH will only occur after a temperature curing process.33

One of the major disadvantage in conventional silylation grafting process is its complicated solvent exchange procedures and dependence on organic solvents. Khanjanzadeh et al.34 thereby developed a simple, solvent-free, and environmental-friendly method of CNC silylation using 3-aminopropyltriethoxysilane (APTES). Initially, APTES was adsorbed onto CNC through hydrogen bonds when it hydrolyzed in water. Then, covalent linkage of the hydrocarbon chain onto the surface of CNC occurred through condensation reaction of the respective silanol and hydroxyl groups. Atomic force microscope imaging depicted that there is no notable changes on the surface morphology of the silylated CNC as compared to the control CNC. Crystallinity of the silylated CNC remained unchanged. On the other hand, it can be deduced that from the thermogravimetric analysis analysis, thermal stability had seen significant improvement after modification.

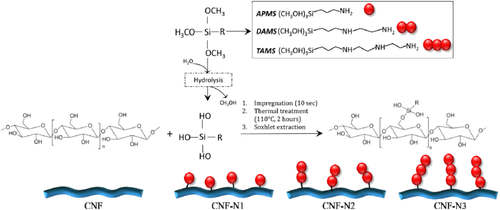

In a recent investigation, effect of silylation from three types of commonly used aminosilane which are 3-aminopropyl trimethoxysilane, 2-aminoethyl 3-aminopropyl trimethoxysilane, and 3-2-(2-aminoethylamino)ethylamino propyl-trimethoxysilane (TAMS) with increasing aminoalkyl chain length, respectively, on CNF was successful demonstrated.35 The mechanism of silylation reaction of the aforementioned aminosilanes onto the surface of CNF is depicted in Figure 4. As a result of aminosilane treatment, CNF was found to be hydrophobic, which was then confirmed by the decrease in surface energy as compared to neat CNF through contact angle measurements. The efficiency of grafting was most prominent with TAMS-treated CNF as the amount of grafting nitrogen molecule strongly affects the grafting efficiency.36 This silylated CNF is suitable to be utilized as a filler material in food packaging products as it shows excellent resistance towards Gram-positive bacteria of Bacillus subtilis and Staphylococcus aureus.

Mechanism of silylation reaction with different types of aminosilane. Reprinted from Ref. 35, Copyright (2017), with permission from Elsevier. [Color figure can be viewed at wileyonlinelibrary.com]

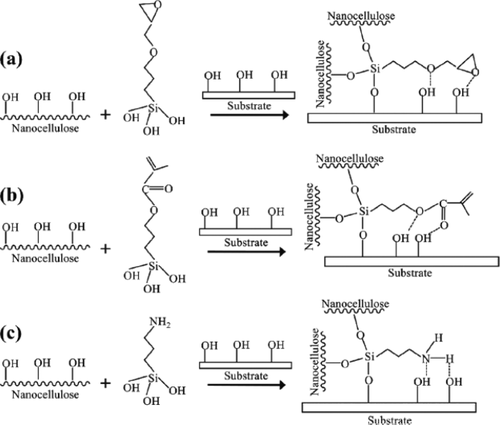

Pacaphol and Aht-ong had recently worked on elucidating the interfacial adhesion of silane-modified CNF film coating onto popular material substrates such as glass and aluminum.37 Figure 5 shows the proposed mechanism of covalent and hydrogen bonding between three different types of silylated CNF and the substrate of interest. The performance of epoxy, methacryloxy, and aminosilane was studied and the CNF modified by aminosilane prevailed in scratch resistance, adhesion, hardness, and Young's modulus and elastic properties. According to the authors, aminosilane performed outstandingly due to the less bulky nature of NH2 side group which subsequently reduced the steric effect and enabled the molecular chains to have an orderly arrangement. Stronger hydrogen bonding that exist between NH2 and OH groups is also one of the contributing factors. From the load-displacement curves data, epoxy silane modified CNF films exhibited the best recovery rate as compared to the other films. In terms of hydrophobicity index, modified CNF film stayed in between glass and aluminum.

Proposed mechanism between substrates and modified CNF by (a) epoxy silane, (b) methacryloxy silane, (c) amino silane. Reprinted from Ref. 37, Copyright (2017), with permission from Elsevier.

Acetylation

The introduction of an acetyl group COCH3 onto the surface of nanocellulose is called acetylation. Acetic anhydride is the most commonly used reagent to functionalize cellulose, mainly with the aim of surface hydrophobization,38 but different objectives such as dispersive/re-dispersive behavior improvement39-42 and properties enhancement42 were reported as well. In the presence of acetic acid, acetylation can be done via two different routes, homogeneous and heterogeneous, in the presence of sulfuric acid as its reaction catalyst. Commercially, heterogeneous route is used to produce cellulose esters but homogeneous acetylation route possess more advantages in terms of reproducibility, excellent end product recovery as dissolution of product during the course of reaction is very minimal and better control over the degree of substitution (DS).43 The ability to alter the DS of cellulose just by varying the ratio of acetic anhydride and acetic acid is important to diversify the application of acetylated cellulose in various fields. Acetylated cellulose with higher DS were reported to be more hydrophobic, thermally resistive and provide great filler–matrix interactions with hydrophobic matrices, which then contributed to the improvement in composite's mechanical properties.41, 44, 45

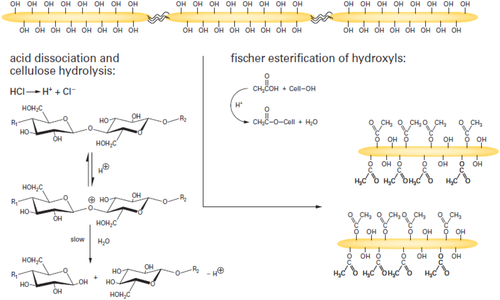

Surface functionalization by acetylation which requires complicated and tedious routes of treatment was simplified by a novel “one pot reaction” method by Braun and Dorgan46 which relies on a single step of reaction. The authors were able to simultaneously hydrolyze cellulose and introduce acetyl functional groups through a combination of HCL and acetic acid with Fischer esterification process. The scheme of reaction is shown in Figure 6. This reaction successfully esterified half of the hydroxyl groups present on the cellulose nanowhiskers (CNW). The resultant CNW was able to disperse well in chemical solvents as opposed to water. Similar work was performed by Yan et al.47 but through a mixture of polyphosphoric acid and phosphoric acid. The resultant acetylated CNC was introduced as a reinforcement filler in poly(lactic acid) (PLA) with excellent results with an improvement of 117% when compared to the neat PLA. The captivating fact is that this “one pot reaction” method opens up the flexibility to control the length of the grafted material with combinations of different types of organic acid used. In another case, CNF with 1% filler content in PLA can lead to a significant decrease on oxygen and water vapor transmission rate which is important in food packaging application.48 Another group of researchers were able to utilize a non-swelling, environmentally friendly “green” solvent, namely 1-butyl-3-methylimidazolium hexafluorophosphate [bmim][PF6], which is a hydrophobic ionic liquid to facilitate grafting performance of acetic, butyric, iso-butyric, and hexanoic anhydride.49 The advantages of this method lies on the nature of ionic liquid as it can be recovered and reused for the next cycle of grafting. The morphology of acetylated CNF was also found to be more porous and was able to maintain its nanoscale dimension.

Reaction mechanism which illustrates the simultaneous occurrence of cellulose hydrolysis and esterification of hydroxyl groups using a mixture of acetic and hydrochloric acid. Reprinted with permission from Ref. 46. Copyright (2009) American Chemical Society. [Color figure can be viewed at wileyonlinelibrary.com]

Acylation/Alkanoylation

The introduction of an acyl group to a chemical structure is known as alkanoylation or acylation. Acyl chlorides, a commonly used as an acylation agent of cellulose was deemed unsatisfactory due to its detrimental effect on the properties of the resulting cellulose product as strong acid such as HCL was required in the process.50 Therefore, alkenyl succinic anhydride which is better and extensively used sizing agent in pulp and paper industries was used to induce acylation in cellulose whiskers from the mantle of sea animal Halocynthia roretzi.51 After modification, the cellulose whiskers showed good dispersivity in low to polarity solvents such as dimethyl sulfoxide, alcohols, dicholormethane, chloroform, and 1,4-dioxane and can be improved through addition of heat. The cellulose whisker was able to retain its cellulose type I crystallinity even after modification. Recently, CNC was acylated with the trifluoroacetic anhydride and various fatty acids to eradicate the influence of humidity on cellulose-derived nanopapers.52 The introduction of stearic acid in particular had also improved the thermal stability of the cellulose nanopaper. Besides, water uptake of the nanopaper decreased with incremental DS due to the increasing hydrophobic layers on the surface of the nanopaper. From the results, it can be seen that utilizing a milder reaction reagent to induce acylation while at the same time preserving the inherent properties of the nanocellulose is possible.

Polymer Grafting

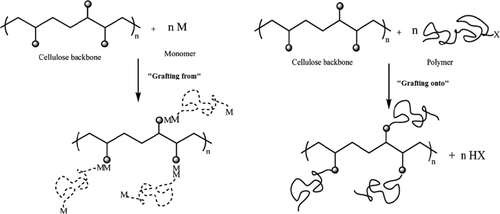

Polymer grafting involves reaction between a long “compatibilizing” tail with the reactive functional groups present on the surface of the nanocellulose. The main purpose of this method is to improve on the apolar character of nanocellulose. Polymer grafting can be divided into two approaches, particularly “grafting from” and “grafting onto” and its schematic representation are illustrated in Figure 7. The “grafting from” approach requires both monomer and initiator to instigate monomer polymerization on the surface of nanocellulose. Advantages such as low steric hindrance and viscosity enables high grafting density but the difficulty in determining the final molecular weight of the polymer is known to be the drawback of this approach.53 The “grafting onto” approach, on the other hand, relies on coupling agent and a known polymer to bind that polymer onto the surface of the nanocellulose. For this case, the molecular weight of the polymer can be determined beforehand but the downside of this approach is the higher viscosity of the processed material and its ability to only achieve a lower grafting density than “grafting from” approach due to packed chains on the surface.53 “Grafting from” approach was reported to be the more popular method than “grafting onto”.54

Schematic illustration of polymer grafting approaches. Adapted from Ref. 54 with permission of The Royal Society of Chemistry.

1 Grafting from

There are two general mechanisms involved in this approach which is the ring opening polymerization (ROP) and radical polymerization (RP). In ROP, the present hydroxyl groups on the surface of nanocellulose acts as the initiator while the amount of monomer used to initiate the groups influences the degree of polymerization of the polymer chain.55 Tin(II) ethylhexanoate (Sn(Oct)2), a common low toxicity catalyst, acted as an initiator in polycaprolactone (PCL) on TEMPO-oxidized CNF through ROP reaction.56 Successful grafting had led towards significant improvement in terms of hydrophobicity and thermal stability, only at the expense of a minor drop in CNF crystallinity due to inadequate coverage of PCL chains grafted onto the surface of TEMPO-oxidized CNF. Additionally, segmented polyurethane matrix with the grafted TEMPO-oxidized CNF as a filler possessed better mechanical properties when compared to ungrafted TEMPO-oxidized CNF, owing to the enhanced interfacial adhesion and dispersive behavior in hydrophobic matrices.

The first thermoformable bionanocomposite of PCL-grafted CNC was successfully produced with the help of microwave irradiation.57 The bionanocomposites exhibit hydrophobic character after grafting due to the shielding effect of PCL chain to greatly reduce the amount of active OH groups on the surface of the CNC. Injection molded PCL grafted CNC bionanocomposite performed better in the tensile strength and Young's modulus department than its compression molded counterpart. In another investigation, a l-Lactide monomer with Sn(Oct)2 as its catalyst was successfully grafted on CNC.58 It was found that the CNC to l-Lactide ratio strongly affect the efficiency of grafting and consequential optical, mechanical and thermal properties of the nanocomposite.

Grafting approach through RP involves two steps; (1) initiator immobilization and (2) reaction between a monomer of interest with the initiator immobilized material to start the polymerization process. Recent work demonstrated a novel hybrid poly[poly(ethylene glycol) methylacrylate] copolymer grafted CNC with switchable thermoresponsive behavior synthesized through SI-ATRP polymerization.59 Interestingly, the grafted CNC showed improved dispersivity in assorted solvents such as dioxane, tetrahydrofuran, dimethylformamide (DMF), ethanol, and water while retaining the natural rod-like structures the ungrafted CNC. Lower critical solution temperature (LCST) can be adjusted between 34 and 66 °C by different comonomers feed ratio to vary the dispersive behavior of the grafted CNC. This engaging feature can overt possibilities in “smart” material applications.

The ability of the modified CNC was studied in terms of 1,2,4-trichlorobenzene absorption from water in view of elucidating its potential as an organic pollutant removal. Interestingly, it can absorb up to half of its total weight, far surpassing the amount of absorption by unmodified CNC. CNC with dissimilar charge density was used to study the effect of electrostatic interactions on surface-initiated ATRP in an aqueous media.60 From the overall findings, it can be summarized that the degree of anionic surface present in the CNC played a major role in determining the initiator efficiency. This, however, comes at the expense of high polydispersity due to inefficient deactivation. Another similar grafting method was done by Yin et al.61 but with styrene. Modified CNC was found to be more thermally stable than unmodified CNC. The modified CNC was then used to reinforce polymethylmethacrylate which the elongation at break and breaking strength of the nanocomposite showed favorable results without affecting the transparency.

2 Grafting onto

TEMPO-oxidized CNC from cotton linters was grafted with thermosensitive commercial statistical copolymers of ethylene oxide and propylene oxide, or also known as Jeffamine, through peptide coupling method.62 The solubility of the grafted CNC is highly dependent on the LCST of Jeffamine, where the CNC became more hydrophobic above LCST. Grafting density was considerably high enough to reduce steric effect of the CNCs. A multifunctional modified CNC with two side groups, isocyanate and urethane was developed by Girouard et al.63 to increase its compatibility with various solvents and polymer matrices. In addition, improvement of around 35 °C were reported on the modified CNC onset thermal degradation compared to unmodified CNC. As a filler material, the primary isocyanate group present on the surface of the modified CNC had facilitated the formation of covalent bond with polyurethane elastomer, followed by a remarkable increase in tensile properties for the composite with 5 wt % of modified CNC. Surprisingly, the flexibility of the composites is not affected although the addition of the modified CNC did incur stiffness onto the polyurethane matrix.

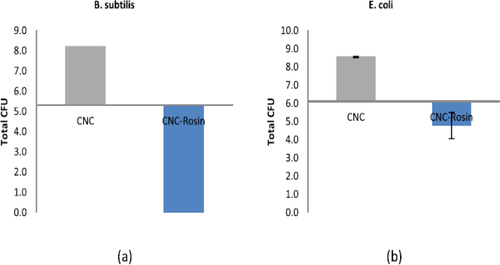

In a recent published work, a group of researchers found that surface grafting of rosin, a product from pine resin which can be cheaply obtained and abundantly available onto CNC was viable.64 A solvent-free procedure, SolReact, adapted from Espino-Pérez and coworkers65 was employed and rosin was successfully grafted on CNC after 10 h of mechanical stirring under a temperature of 130 °C. The grafted CNC showed antimicrobial properties, leaning towards better performance against Gram-negative bacteria as shown in Figure 8. Higher contact angle was observed on the grafted CNC as compared to the original CNC.

Antimicrobial behavior of grafted and un-grafted CNC on (a) Gram-positive bacteria, (b) Gram-negative bacteria. Reprinted from Ref. 64, Copyright (2016), with permission from Elsevier. [Color figure can be viewed at wileyonlinelibrary.com]

Fluorescent Labeling/Tagging

Most of the objective of surface functionalization of nanocellulose is targeted towards inducing hydrophobicity to expand its application. Limited studies have been done to further explore additional functionalization routes that can lead to new pragmatic application of this material. Fluorescent labeling, a process of binding a reactive derivative of fluorophores on a target molecule, has opened doors for nanocellulose towards application in the field of nanomedicine and pharmaceutical drugs.66 Fluorescent-labeled CNC of by fluorescein isothiocyanate and rhodamine B isothiocyanate are safe and was proven that there is no indication of cytotoxicity when cells were penetrated.67 Surface charge which is adjusted by pH can be tuned to improve cell permeation.

Next, CNF was successfully modified with selective fluorescent labeling using two different fluorescent probes, namely fluorescein diacetate 5-maleimide and 7-mercapto-4-methylcoumarin through Diels–Alder cycloaddition and thiol-Michael click chemistry reaction.68 According to the authors, this multicolor-labelled CNF is important in biological application such as multimodality molecular imaging. Next, CNC capable of ratiometric pH-sensing was produced through two different methods of functionalization; a simple one-pot procedure and a thiol-ene click reaction.69 The latter reaction was proven to be better as it was able to increase the number of fluorophores that are available for grafting with lesser amount of dyes used. G6 PAMAM dendrimer-grafted cellulose nanocrystal (CNC-PAMAM) was successfully prepared by Chen et al.70 CNC was extracted with TEMPO-mediated oxidation method to yield COOH functional groups to allow grafting via amide bonding with PAMAM. The pH-responsive behavior was confirmed through favorable results in transmittance, isothermal titration calorimetry, zeta potential, and fluorescence spectroscopy. Dispersion of CNC-PAMAM was found to be stable in between the range of pH 4–10. CNC-PAMAM also demonstrated strong blue fluorescence which can be attributed to the formation of aggregates.

Application of Nanocellulose in Emerging Bioinspired Applications

The search for engineered bionanomaterials that possess intriguing characteristics is proliferating as years goes by. Nanocellulose in its original state or modified state had shown distinctive properties which allows its application in various fields. The following sections will highlight recent publications on the promising applications of nanocellulose in burgeoning applications such as sensor technology, environmental remediation, papermaking, and automotive.

Sensor Technology

Sensors are in no doubt becoming progressively important in our life. Ranging from electronics to healthcare, this blooming technology had recently set sight for bio-based materials such as nanocellulose which is strong, versatile and possess a high surface area that meets all the desired requirements for sensor fabrication. Although there are numerous types of sensors present in the market, only three common types of sensors that had shown proliferated growth in research and development will be discussed in the later sections.

1 Humidity Sensing

Water, which can exist in a liquid or vapor form, is one of the essential substances that exist on Earth especially to living organisms. The control and determination of the amount of water in its vapor form, or better known as humidity, are prerequisite for different environments and conditions, especially in production and processing industry. Recently, the reliance on humidity sensors are proliferating especially in areas of pharmaceutical, healthcare, agriculture, electronics, weather forecasting, and textile industry.71 For example, the level of moisture present in factory or office needs to be regulated as it will directly affect the health of the workers. The same goes to hospitals where there will be moisture-sensitive patients and contamination issues due to the fluctuation in the indoor air humidity. These issues also can be attributed to the dependence on the old and traditional hygrometers such as the hair tension hygrometers, psychrometers, and manual hygrometers as opposed to newer, much reliable smart electrical humidity sensor. In general, humidity sensors can be classified into two common categories, which is resistive72, 73 humidity sensors, and capacitive72, 74, 75 humidity sensors. Resistive humidity sensors operates on current holding capacity through water adsorption principle while the latter measures electrical impedance by water absorption.

The fabrication of humidity sensors heavily rely on the accurate sensitivity index, fast response with minimal hysteresis, and good recovery rate.71 Most importantly, the sensors developed must be able to withstand high temperature, flexible, lightweight, and can be produced at a minimal cost. Recently, cellulose, a cheap and environmentally friendly source of biopolymer with excellent mechanical properties, was mainly utilized as the host matrix to produce these sensors due to its intriguing properties.72-77 The limitation of cellulose is its ability to conduct electrical current, where modifications or blending with conductive polymer substrate is required. On the other hand, cellulose also plays an important role in the uniform dispersion of carbon based materials such as graphene, reduced graphene oxide, and carbon nanotubes (CNT).78, 79 This is evident when films of PVOH, CNF, and reduced graphene oxide was found to show better conductivity and lower hysteresis to humidity than the films without CNF.71 Mahadeva and coworkers80 had demonstrated an excellent capacitive humidity sensor which consists of a type of conductive polymer, namely polypyrrole coated on a cellulose matrix. The product showed favorable response on higher humidity and temperature. Similar type of sensor which made up of a matrix of CNC isolated from cotton linter and graphene oxide composite was fabricated. At the highest filler loading of 10%, the cheaper and flexible composites were able to show admirable response time when tallied with commercial hygrometers.81

Optical humidity sensor film of methylene blue and hydroxypropyl cellulose (HPC) was developed through spin coating which utilizes the principle of color change to determine the relative humidity of the environment.82 From the experimental results, color changes only occur above 60% relative humidity which in turn narrows its application in areas that have relatively low humidity. However, this film is suitable for food packaging as the indicator used is not carcinogenic and does not consist of heavy metals.83 Therefore, packaging of products that are sensitive to humid environment (>70% relative humidity) such as table salt, garlic, and onions was recommended.

2 Mechanoresponsive Sensing

Mechanoresponsive sensors are sensors that responsive towards mechanical simulation such as pressure, touch, strain, and stress. Strain, pressure and tactile sensors are some examples of mechanoresponsive sensors and they are widely used in infrastructure, automotive, motion detection, wearable electronics, and health monitoring industry. Currently, researchers had shifted their direction towards production of these sensors with the utilization of eco-friendly materials such as nanocellulose which can address and improve on the existing discrepancies of the sensors. In addition, nanocellulose also possess a large electrical dipole moment and piezoelectric properties which is an added benefit as well.84-86 For example, the capability of strain sensors are classified according to their mechanical strength, processability, and stretchability properties. A strong and stretchable graphene nanopaper that was developed by Yan et al.87 took advantage of the inherent mechanical properties of CNC and the results obtained were fascinating when compared to films made purely from graphene. The authors are able to produce a 100% stretchable graphene nanopaper, whereby there are very limited graphene-based strain sensors that can reach above 50% aside from graphene foam strain sensor which is expensive to produce.88, 89 In another case, CNW were able to lower down the electric conductivity percolation threshold when introduced as template into carbon black/natural rubber composite.78 This addition of CNW broaden the scope of application of the composite especially as a strain sensing material. Later, the authors improved on the properties of the composites by fabricating a three dimensional hierarchical conductive composite through a latex assembly technique, where it can achieve an admirable reproducibility rate at a 20% strain amplitude.90

Interest on tactile, pressure, and haptic/kinesthetic sensors which depend on cutaneous sensing had also proliferated in recent years, specifically in mobile devices and smartphones industry.91-94 Actuating behavior was successfully demonstrated on two spin-coated cellulose acetate film bonded together with an air gap.95 From the results, it can also be observed that the actuator can perform in a range of frequencies to generate a haptic feeling. Damping factor was deemed extremely crucial, where reduction of damping factor can significantly improve on the actuator's performance. Low density nanocellulose/few-walled CNT aerogel for pressure sensing was produced by Wang et al.96 where nanocellulose played an important role in the reproducibility of the resistance under compression. Tactile sensor that rely on the synergistic relationship of through isocynate grafting of cellulose nanocrystal with graphene was done, where cellulose nanocrystal film was sandwiched in between two graphene oxide layers to increase the surface area of interaction and facilitate the electron jump between the layers, thereby reducing their resistance.97 These recent findings can pave the way for nanocellulose to fulfill the momentous need for lightweight mechanoresponsive sensors and its ever increasing market impact. To give an example, the benefits of nanocellulose can be exploited by Apple Inc., Cupertino, California, which holds one of the largest market shares in the smartphones industry to develop on their recent innovative “3D Touch” feature which relies on pressure sensors and haptic feedback technology and has been introduced on the latest smartphone product release such as the Iphone 6s and Iphone 7.98

3 Gas Sensing

The need for indoor and outdoor gas monitoring has proliferated in recent years, especially in robotics,99, 100 gas production factories,101-103 air quality monitoring,104, 105 and environmental protection.106, 107 Gas sensors can be classified into numerous types depending on their method of detection such as electrical, acoustic, optic, calorimetric, and chromatographic response.108 The performance can be evaluated through two key indicators which are sensitivity and selectivity. Some other indicators include repeatability, response time, and its energy to cost ratio. Metal oxides, which contain semiconducting properties, were commonly used due to its lower cost of production and its admirable sensitivity. Metal oxides can be classified into two large groups; transition such as Fe2O3, NiO, Cr2O3, and non-transition such as ZnO, SnO2, Al2O3.109-111 These metal oxide-based sensors only works best in high temperatures environment, therefore consuming more energy and cost to operate. Conducting polymers, most notably polypyrrole (PPy),112-115 polyaniline (PANI),116, 117 and polythiophene (PTh)112, 118, 119 were introduced to address this issue as they are able to perform their task at ambient temperatures. Doping process through protonation and redox reaction was performed to improve on the conductivity of the polymers.120 However, in comparison to metal oxides, organic conducting polymers lacks in thermal stability and response time which hampers its use in demanding applications. The versatility in modification of cellulose, especially in its nanoscale form, was taken advantage by Pang et al.121 where regenerated CNFs were introduced into a PANI/TiO2 composite to increase the surface contact area of TiO2 with the ammonia gas. The composite, which targeted towards ammonia gas sensing, showed good repeatability and gas selectivity when exposed to foreign volatile gases such as acetone, methanol, and ethanol at room temperature.

Lately, the pairing of CNT with nanocellulose looked promising to be utilized as an upcoming sensing material due to their lightweight, low energy consumption, high sensitivity, and corrosion resistance properties. A flexible conductive paper made up of multiwalled carbon nanotubes (MWCNT) and CNC isolated from banana stem that is able to detect methanol was fabricated, where higher MWCNT content showed better sensor response.75 However, the sensor displayed an unfavorable recovery time which can be associated to the polar characteristics of the composite and its affinity towards OH groups which lead to a slower desorption of methanol. Similar type of materials were used by another group of researchers but through a much simpler dip coating method with promising detection of volatile solvent vapor such as methanol, ethanol, and acetone.122 Yun and Kim123 found that alignment treatment of MWCNT with the chains of cellulose at 80% strain rate had exceptionally improved the mechanical properties of the composite.

The nanocomposite also displayed excellent selectivity as it can differentiate between methanol, ethanol, 1-propanol, and 1-butanol. From the overall findings, it has proven that the advantages of nanocellulose are exhaustive and the complement of nanocellulose with conductive polymers in development of gas sensor looks promising. In addition, the intriguing properties of nanocellulose such as its low volume to weight ratio and compatibility with emerging materials in gas sensing will lead the way towards creating small, robust, and portable battery-driven gas sensors in future.

Nanoremediation for Environmental Protection

In the current state of environmental health, we are facing with an alarming degree of water pollution. Increasing water pollution in particular had resulted in clean water shortage, where conventional wastewater treatment methods such as precipitation, flocculation, membrane filtration, and ion exchange are not sufficient enough to handle the treatment of wastewater. Herein, adsorption technique, which depends on the adhesion of molecules or atoms from a liquid or solid onto a particular surface was recently employed as a cheap and energy saving solution in wastewater treatment.124 Activated carbon was the most commonly used adsorbent due to its excellent adsorbance capacity. However, researchers had then moved towards utilizing an environmentally friendly and bio-based alternative which is nanocellulose. Functionalized nanocellulose in itself or as a composite are able to effectively adsorb metal ions, pharmaceutical drug wastes such as antibiotics and textile dyes as shown in Table 2.

| Pollutants | Functionalized nanocellulose/nanocellulose composite | Source of nanocellulose | Adsorbate | Adsorption experimental conditions | Desorption experimental conditions | References |

|---|---|---|---|---|---|---|

| Heavy metal contaminants | Enzymatic phosphorylated nanocellulose | Kraft pulp | Ag2+, Cu2+, Fe3+ | pH 3–9, 1–8 h | — | Liu et al.133 |

| Magnetic carboxylated cellulose nanocrystals | Commercial microcrystalline cellulose | Pb2+ | pH 2–6 | 0.1 mol/L HCL | Lu et al.134 | |

| Poly (methacylic acid-co-maleic acid) grafted nanofibrillated cellulose | Bleached eucalyptus pulp | Na2+, Pb2+, Cd2+, Zn2+, Ni2+ | 3 h | — | Maatar and Boufi135 | |

| Sulfonated nanocellulose | Bleached wheat straw pulp | Pb2+ | pH 5.0, 20 h | — | Suopajärvi et al.132 | |

| Carboxylated cellulose nanofibrils-filled magnetic chitosan hydrogel beads | Commercial microcrystalline cellulose | Pb2+ | 25 °C, pH 2–5.5, 12 h | 0.01 M HNO3, 12 h | Zhou et al.136 | |

| Multi-carboxyl-functionalized nanocellulose/nanobentonite composite | Cotton whiskers | U4+ | 30 °C, 4 h | 2 h, HCL | Anirudhan et al.137 | |

| Nanocellulose/nanobentonite composite | Cotton | Co2+ | 30 °C, 3 h | 2 h, HCL | Anirudhan et al.138 | |

| Mercaptobenzamide-modified itaconic acid-grafted-magnetite nanocellulose composite | Commercial microcrystalline cellulose | Hg2+ | 30 °C, 4 h | 1 h, 30 °C, HCL, HNO3, NaCl, NaNO3, CH3COONa | Anirudhan and Shainy139 | |

| Pharmaceutical waste | TEMPO-oxidized mesoporous crystalline nanocellulose | Cladophora | Aspirin | 125 and 400 mg aspirin in 1:2 ratio with cellulose for 21, 42, 62 days | — | Carlsson et al.140 |

| Polymer-grafted-magnetite nanocellulose composite | Saw dust | Immunoglobin (IgG) | pH 3–5, 6–9, 10—40 °C in phosphate buffer, 5–240 min | 3 h, 30 °C, 0.01 M CH3COOH, KOH, H2C2O4, Na2CO3, and Na2SO4 | Anirudhan and Rejeena141 | |

| Nanocrystalline cellulose | Green seaweed | Tetracycline hydrochloride | pH 5.0, 15–45 °C | Milli Q water, hexane, acetone, 5% HNO3, and 5% NaOH | Rathod et al.142 | |

| Nano-zinc oxide incorporated graphene oxide/nanocellulose composite | Commercial microcrystalline cellulose | Ciprofloxacin hydrochloride | 3 h | — | Anirudhan and Deepa143 | |

| Commercial dyes | Core–shell structured magnetic nanocellulose | Commercial microcrystalline cellulose | Congo red dye | 0.1–40 mg/L, 1 min | — | Beyki et al.144 |

| Amino-functionalized nanocrystalline cellulose | Bleached aspen kraft pulp | Acid red GR | 100 mg/L, 5 min | — | Ma et al.127 | |

| Amino-functionalized nanocrystalline cellulose | Bleached aspen kraft pulp | Reactive light yellow K-4G | 100 mg/L, 5 min | — | Jin et al.127 | |

| Surface quaternized cellulose nanofibrils | Softwood sulfite pulp | Congo red | 2.5 mg/mL, 1 min | — | Pei et al.145 | |

| Surface quaternized cellulose nanofibrils | Softwood sulfite pulp | Acid green 25 | 2.5 mg/mL, 1 min | — | Pei et al.145 |

There are several nanocellulose functionalization methods such as carboxylation, amination, succinylation, and sulfonation employed to improve the adsorbance efficiency on targeted pollutants. Carboxylated nanocellulose through TEMPO oxidation treatment greatly improves density of COO– functional side groups, where the presence of these carboxylate side groups improved the adsorbance efficiency of copper(II) ions.125 Higher carboxylate contents showed better copper(II) ions adsorbance due to its improved specific surface area of available binding groups. Uranyl (UO2+) ions also showed improved adsorbance characteristics towards carboxylated CNFs.126 Amination of nanocelllulose, which involves introduction of

side groups onto the surface of nanocellulose, positively impacted the adsorbance of anionic dyes such as acid red GR, congo red 4BS, and reactive light yellow K-4G.127 Acidic condition worked best as compared to alkaline condition due to protonation effect provided by an acidic environment towards the interaction between the dyes and the adsorbent. Recent work by the same authors which utilized a lower molecular weight polyvinylamine to introduce amine groups shown better adsorbance to the greater content of amine groups that can be functionalized onto the nanocellulose surface.128

side groups onto the surface of nanocellulose, positively impacted the adsorbance of anionic dyes such as acid red GR, congo red 4BS, and reactive light yellow K-4G.127 Acidic condition worked best as compared to alkaline condition due to protonation effect provided by an acidic environment towards the interaction between the dyes and the adsorbent. Recent work by the same authors which utilized a lower molecular weight polyvinylamine to introduce amine groups shown better adsorbance to the greater content of amine groups that can be functionalized onto the nanocellulose surface.128

Besides dyes, ethylenediamine-treated CNC displayed imperial difference in adsorbance of heavy metal ions such as chromium(IV) ions, where pure CNC only able to adsorb 5.98% whereas its aminated form is able to adsorb up to 98% in aqueous acidic conditions.129 On the other hand, succinylation, which involves reaction between the anhydride groups with hydroxyl groups of nanocellulose, had shown increasing interest in recent years especially as a heavy metal ion removal agent. Singh et al.130 demonstrated that succinated CNC can adsorb up to 95% of chromium(III) ions as compared to pure CNC with only 42% maximum adsorption percentage. On the other hand, Yu et al.131 came up with a sodic succinated CNC with improved adsorption efficiency of Pb2+ and Cd2+ metal ion due to the added ion exchange mechanism. Sulfonation of wheat nanocellulose through a green method of periodate oxidation portrayed another interesting functionalization of nanocellulose to adsorb Pb metal ion.132

Papermaking

In recent years, the dependence on paper-based products especially in packaging had led towards increased interest in improving the quality and properties of conventional papers such as their mechanical strength, writability, and recyclability through the introduction of a renewable and environmentally friendly additive, nanocellulose. This extensive interest can be attributed towards the fascinating properties of nanocellulose such as biodegradability, high aspect ratios, semi-crystalline nature, excellent intrinsic strength, and modification-friendly.146-148 In order to enhance the competitiveness in the papermaking industry, researchers have been turning into utilizing these “green” nanodimensional additives to confer additional properties to the current state of traditional papers. Improvement in terms of water and oxygen barrier properties as well as mechanical properties can be done via inclusion of nanocellulose as an additive or as a coating material. Further evidence will be discussed in detail in the later sections.

1 As Value-Added Additive

Brodin et al.146 demonstrated that the inclusion of CNF as a reinforcement agent into sulfonated and carboxymethylated cellulose pulps increased the density of the resulting paper, which then improves the tensile strength of paper. Light scattering and air barrier properties also improved as a result of CNF addition. However, the papers appeared to be more brittle due to the increase in crystallinity of the composite. Partially acetylated CNF was found to improve on the burst strength index, tensile strength index, and water barrier properties of acetylated pine pulp.39 Similar trend in mechanical properties was shown in another chemically treated all cellulose composite from eucalyptus pulp.149 In another scenario, paper strength improvement through a much traditional method of mechanical beating to tailor the surface properties of the fibers was compared with the addition of CNF to a non-beaten softwood sulfite fiber.150 The latter prevailed in the density, dry and wet tensile strength as well as toughness energy absorption properties. This proves that the energy intensive method of mechanical beating can be replaced by another better, energy-saving method of utilizing nanocellulose as a value-added additive.

A smooth, high optical transmittance, and writable hybrid nanopaper was designed by Fang et al.151 through the combination of unbeaten wood fibers and CNF. Conductive CNT, in the presence of sodium dodecylbenzenesulfonate as surfactant were added to further diversify its application towards optoelectronics. Shape deformity is an issue particularly in electronic application, where the addition of CNF was able to form a stable network structure that can resist deformation better than a standalone nanopaper. To evaluate the performance of the CNT-coated hybrid nanopaper, the authors demonstrated a fully functional touch screen in a bright environment with minimal glaring effect. Another interesting approach was shown in a CNF with graphite (GNP) nanoplatelets paper composite that target towards heat management application such as thermal pads.152 The strong, thermally conductive paper with 75% GNP showed a remarkable tensile strength of up to 40.12 MPa was recommended for aircraft applications that requires high thermal conductivity. As for thermal dissipater in electronic application, the composite with a higher CNF content and lower electrical conductivity was proven better than the well-favored silicone rubber.

In order to save cost and reduce the dependence of raw materials from the forest, recovery of deinked fibers from used paper products such as newspapers and other printed materials is eminent. However, drawbacks such as defects in fibers due to loss in molecular weight of the material and the presence of impurities restrict the quality of the resultant products after numerous cycles of recovery. As an alternative to the industrialized mechanical beating used to recover the fiber's original properties, CNF was added to deinked fiber suspension to improve on their properties such as such as stiffness and tensile strength while retaining indistinguishable and water retention and freeness.153 Furthermore, the deinked fibers will only suffer from minor structural damage as compared to the conventional recovery method.

2 As Nano-Coating Agent

The exploration of CNF as a nano-coating agent only started in recent times, where coating thickness and formulation plays a vital role in the resultant properties of the coated paper. Several methods such as bar coating, spray coating, size press coating, and roll coating were used and these methods allow the variation in coating density and efficiency.147 For example, bar coating, which is the most common method used, was found to provide higher coating density of microfibrillated cellulose (MFC) than size press coating.154

High aspect ratio nanoscale cellulose such as MFC, while maintaining its length in a microfibril scale was first utilized by Syverud and Stenius as a coating material on a base paper with a “wet in wet” technique.155 Interestingly, the strength of MFC films was found to be comparable to cellophane tapes while the mechanical strength of MFC-coated base paper increases dramatically at <10% MFC content. In addition, oxygen permeability rate reduced dramatically on MFC coated base paper which favors oxygen sensitive applications such as food packaging. Another compelling research that coats a base paper with MFC and shellac through a bar-coating technique shown similar improvements in tensile strength.156 Nonetheless, the researchers also highlighted the importance of the synergy between MFC and shellac in further improving the water permeability and air permeance properties of the nano-coated paper.

A novel study was done by Aulin et al.157 which demonstrated the oil barrier properties of MFC-coated films with two types of oil, turpentine, and castor oil with viscosity of 0.002 and 0.5 Pa s, respectively. The correlation of air permeability and penetration time was shown where the decrease in air permeability (as a result of coating density) had resulted in a higher oil resistance. This greaseproof paper are more resistant towards castor oil due to its more viscous nature than turpentine.

The importance of coating layers were revealed when varying CNF coating layers were introduced on bleached bagasse soda pulp.158 Increase in coating layer positively promoted the tensile strength and stiffness of the coated paper due to the increase in weight and thickness of the paper. On the contrary, roughness of the coated paper reduced with increasing CNF coating layers. It was suggested that by lowering the concentration of CNF, it will result in a much more equal coverage of CNF on the paper's surface and more coating layers can be introduced to further improve on the existing properties. In another case, a mix coat formulation of oxidized cellulose nanocrystals (OXCNC) and HPC on bagasse paper showed a noticeable increase in tensile strength and modulus of up to 85 and 201%, respectively.159 Unfortunately, the addition of OXCNC/HPC layer did not improve on the water vapor permeability rate of the bagasse paper.

Automotive Application

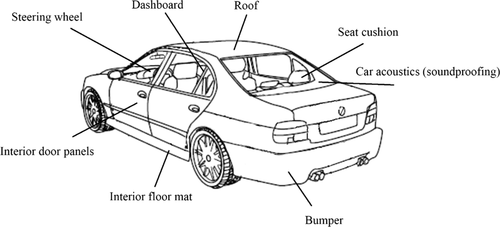

The swing towards sustainable solutions in the automotive industry is an approach towards saving the environment as well as the cost of production. Since “Going Green” is the current notion in automotive industry, numerous attempts have been made by leading car manufacturers to find ways to incorporate natural fibers as a whole or as a composite material into automotive components such as bumper, steering wheel, dashboard, seat cushion, soundproofing system, and interior door panels as illustrated in Figure 9. As shown in Figure 10, BMW 7 series model won the Innovation Award from the Society of Plastics Engineers in the year 2010 for capability of utilizing a whopping 70% natural fibers in its door panel, reducing weight, cost, and carbon footprint.160 Ford, on the other hand, utilized wheat straw as reinforcement agent for its Flex crossover vehicle's inner lid and storage bin due to its improved dimensional stability and lightweight properties.160 High fuel consumption, life cycle energy requirement, and carbon dioxide emission is the key issue to be addressed in this industry which coincidentally can be solved through utilization of environmentally friendly and abundantly available plant fibers in nature. For automotive interior application such as door panels, a lower density product of polypropylene (PP) reinforced coconut coir fibers had shown promising mechanical results to replace conventional PP/glass fiber composites.161 Similarly, weight reduction of 20% was achieved when flax/sisal fiber mat embedded epoxy resin was introduced in the door panels of Mercedes-Benz E-class. In a recent bio-based composite for automotive life cycle study conducted by Boland and coworkers,162 glass fiber PP composite substitution with cellulose fiber PP composite had resulted in a life cycle energy savings of 6.5–7.4% and reduced greenhouse gas emission of up to 16.4%.

Possible applications of nanocellulose in interior and exterior automobile parts.

Lower door panel of the BMW 7 Series sedan. Reprinted from Ref. 161, Copyright (2010), with permission from Elsevier [Color figure can be viewed at wileyonlinelibrary.com].

Such findings had led to the progress in utilizing environmentally friendly materials in their nanodimensional form which will be lighter and can further facilitate the improvement in terms of mechanical properties. Nanocellulose, in particular, which is lightweight and possess high mechanical strength is one of the promising material most of the researchers are looking for. Martoïa et al.163 demonstrated that different types of production and concentration of CNF can affect the properties of the resultant CNF foam. From their findings, an alternating freezing procedure under the influence of mechanical stirring was able to produce CNF foams of bimodal cell structures with improved mechanical properties. This finding can be applied to improve on interior automotive parts such as seating cushion, steering column fillers, knee bolsters, and foam pads. In a recent published work, CNC was added in a glass fiber (GF)/epoxy sheet molding compound (SMC) composite to reduce the overall weight of the composite without compromising the original mechanical properties. From the tensile and flexural results obtained, it can be concluded that the addition of just a minor amount of CNC in a lower GF content (25%) composites was able to perform similarly as the composite with 35 wt % GF content, thereby reducing its overall total weight by 7.5%.164 This finding can affect the high volume production of conventional SMC composite just by incorporating CNC into its composite.

However, concerns on the dispersibility of nanocellulose after drying and compatibility with hydrophobic polymeric matrices limits its widespread use in automotive applications. Besides, the low thermal stability of nanocellulose which makes it susceptible towards structural deformation can adversely affect its potential performance. Therefore, Peng et al.165 introduced low processing temperature water compounding technique to compound wet CNC onto polyamide 6 (PA6), which is a high performance thermoplastic polymer commonly used in automotive to address the aforementioned issues. Solid and foamed composites were produced and the addition of CNC had improved on the tensile properties of the composite. In addition, CNC also acted as a nucleating agent where it increased the cell density by a huge margin while at the same time reducing the cell size, preventing cell rupture due to the reduced surface area. Encouraging results obtained from this technique will lead to the endless possibilities of nanocellulose utilization with other commonly used thermoplastic polymers such as polyethylene and polyurethane to further improve on their mechanical properties.

Current State of the Industry and the Commercialization Progress of Nanocellulose

As discussed in previous sections, the exceptional characteristics of nanocellulose has enabled its utilization in numerous emerging bioinspired applications. In addition, the valuable inherent traits of nanocellulose have epitomized the foundation of its use as a value-added inclusionary material which sufficiently convinced major companies and industries to venture into the next level of research and development, namely commercialization. As presented in Table 3, it can be seen that majority of the commercial nanocellulose producers are from the Canada, Sweden, United States of America (USA), and Japan. In 2014, a consortium of 100 Japanese-based companies was established which involve major paper producers and manufacturers such as Nippon Paper Industries and Oji Holdings Corp., Toyota Auto Body Co., Mitsubishi Motors Corp., Mitsui Chemicals Inc. and other intriguing companies as well. Such establishment signified the momentous move towards nanocellulose commercialization in the coming years.

| Commercial nanocellulose producers | Year 2015 | Year 2016 | Year 2017 | |

|---|---|---|---|---|

| CNC production capacity (kg per day) | CelluForce, Canada | 1000 | 1000 | 1000 |

| American Process | 500 | 500 | 500 | |

| Melodea, Sweden | Pilot | 100 | 100 | |

| Alberta Innovates, Canada | 20 | 20 | 20 | |

| US Forest Products Lab | 10 | 10 | 10 | |

| Blue Goose Biorefineries, Canada | 10 | 10 | 10 | |

| FPInnovations, Canada | 3 | 2 | 2 | |

| CNF production capacity (kg per day) | Paperlogic | 2000 | 2000 | 2000 |

| University of Maine | 1000 | 1000 | 1000 | |

| American Process | 500 | 500 | 500 | |

| Nippon Paper, Japan | 150 | 150 | 150 | |

| Oji Paper, Japan | 100 | 150 | 150 | |

| Innventia, Sweden | 100 | 100 | 100 | |

| Empa | — | 15 | 15 | |

| UPM, Finland | Pre-commercial | Pre-commercial | Pre-commercial | |

| Dai-ichi Kyogo, Japan | — | Pilot | Pilot | |

| FPInnovations, Canada | Pilot | Pilot | Pilot | |

| Seiko PMC, Japan | — | Pilot | Pilot | |

| SAPPI, the Netherlands | Pilot | Pilot | Pilot | |

| U of Kyoto, RISH | — | Pilot | Pilot | |

| VTT, Finland | Pilot | Pilot | Pilot | |

| Daicel, Japan | Lab | Lab | Lab | |

| Luleå University of Technology, Sweden | Lab | Lab | Lab | |

| US Forest Products Laboratory | Lab | Lab | Lab | |

Commercial nanocellulose products, on the other hand, mushroomed as of late 2015 with innovative products such as adult diapers that is made up of deodorant sheets that exploit the advantages presented by functionalized CNF through TEMPO oxidation method. The surface of TEMPO-oxidized CNF possess high affinity towards high concentrations of metallic nanoparticles, where Nippon Paper Crecia Co. Ltd. had took advantage on this particular attribute and successfully manufactured CNF sheets with huge amount of metal ions that will give rise to antibacterial properties and deodorant. The deodorizing capability was reported to be at least three times as effectual as conventional products in the market.166 Additionally, Mitsubishi Pencil Co. Ltd. and DKS Co. Ltd. had successfully commercialized a gel state CNF, namely “Rheocrysta” that is capable to alter the thickness and viscosity of gel ink commonly used in ballpoint pens. This favors the introduction of a variety of ballpoint pens to suit the different situations and conditions of use.167 Stora Enso, a company based in Finland, supported Elopak with their ‘New Natura Concept’ packages that made use of the lightweight MFC to reduce the weight of traditional packaging materials without sacrificing their stiffness and internal strength. It has been disclosed that more than 100 million packages have been successfully produced as of the year 2016.168 Skincare products also reach out towards the wonder of nanocellulose where one of Innovatech Engineering project, DeLeón Cosmetics came up with a state-of-the-art nanocellulose face masque with anti-aging properties.169 In April 2017, Oji Holdings Corporation announced the commercialization of “AUROVISCO”, a CNF thickener made up of phosphorylated CNF. It has been reported that “AUROVISCO” was made entirely from natural materials; for example phosphoric acid which is widely used in cosmetics.170 Celluforce, the world leader in the commercial production of CNC, ventured into the realms of oil and gas industry when the company partnered with Schlumberger Technology Corp., supplier of a plethora of services to the oil and gas sector. Suspensions extracted out from the ground are often broken down and may contain valuable resources. To address this issue, CNC can be added to improve on the cohesiveness of the suspensions, even under adverse conditions. In addition, the ability of CNC to reduce the volume of pressure and water required to perform extraction opens up the possibilities of extracting resources in areas that are unfavorable at the moment.171

CONCLUSIONS

The advancement of science and green technology has been strictly directed towards the utilization of renewable, toxic-free, and environmentally sound raw materials. Nanocellulose, a sustainable biomaterial which is available in abundance, opens up the endless possibilities of novel applications at various fields due to their innate nature of captivating physical attributes and chemical functionalities. The dire search for “green” materials that is cost effective and environmentally friendly over the past decade had its limitations due to the inherent hydrophilicity and wet-dry-wet dispersivity. This prospect had inspired researchers to expand the application of nanocellulose through innovative chemistry functionalization of nanocellulose. The present review strive to provide a concise analogy of riveting surface functionalization of nanocellulose and the importance of nanocellulose as the “part and parcel” material for the current emerging applications. Such review is timely and of utmost relevance, given the current trend and impetus being targeted towards developing new bio-based nanostructured building blocks to further improve novel biomaterials with modified properties. It should be important to keep note that if nanocellulose is to be industrially produced, a significant obstacle had to be addressed first which is the cost of production. In this particular review, it can be seen that there have been evident success at laboratory scale. Therefore, ensuing research focus on the cost reduction in nanocellulose production, followed by the simplicity of the surface modification process should be the main priorities as this notion will further stipulate the expeditious growth of this “wonder” material for future commercialization.

Biographies

Chin Kwok Mern received his B.S. in Biosystems Engineering from Universiti Malaysia Perlis in 2014. He is currently a Ph.D. student in Sam Sung Ting's research group at Universiti Malaysia Perlis. His research mainly focuses on nanocellulose synthesis and characterization, microbial degradation studies on biodegradable polymer and polymer nanocomposites synthesis and characterization. {FIG Author Photo Chin}

Sam Sung Ting is currently a Senior Lecturer in Universiti Malaysia Perlis. He received his Ph.D. in polymer engineering from Universiti Sains Malaysia in the year 2012. His research specializes on biopolymer, microbial degradation of polymer, and polymer coagulant. He has published more than 70 international research papers, reviews, and books and is currently a member in Institute of Materials Malaysia and Plastic and Rubber Institute of Malaysia. {FIG Author Photo Ting}

Ong Hui Lin is the Associate Professor at Universiti Malaysia Perlis. She received her Ph.D. in Advanced Materials from Universiti Sains Malaysia in 2010. Her research specializes on polymer nanocomposites and she has received more than 15 awards and published more than 20 journal papers. {FIG Author Photo Lin}

Mohd Firdaus Bin Omar is a Senior Lecturer in Materials Engineering at Universiti Malaysia Perlis. He received his Ph.D. in Universiti Sains Malaysia. His research mainly focuses on dynamic behaviors of polymer and composites. {FIG Author Photo Omar}