Carbon fibers derived from wet-spinning of equi-component lignin/polyacrylonitrile blends

ABSTRACT

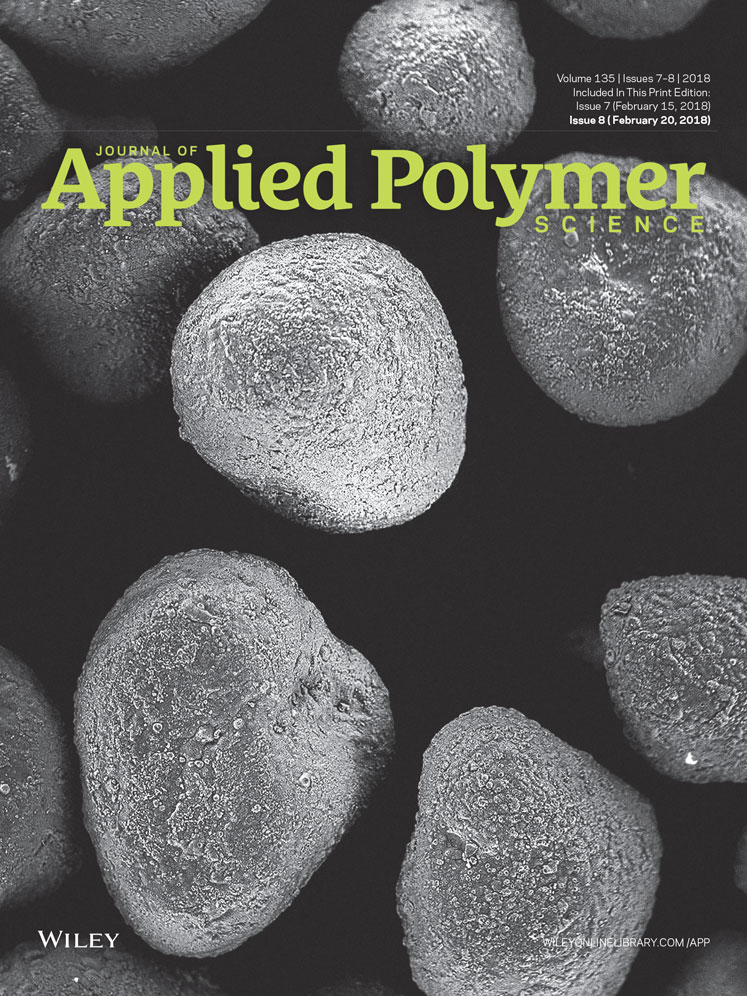

Equi-component blends of polyacrylonitrile (PAN) and lignin, i.e., with a lignin content as large as 50 wt %, were successfully used as precursors to produce carbon fibers. Rheological measurements demonstrated that increasing lignin content in spinning solution reduced shear viscosity and normal stress, indicating a decrease of viscoelastic behavior. This was confirmed by Fourier transform infrared results that show no discernable chemical reaction or crosslinking between PAN and lignin in the solution. However, the resulting carbon fibers display a large ID/IG ratio (by Raman spectroscopy) indicating a larger disordered as compared to that from pure PAN. The macro-voids in the lignin/PAN blend fibers typically generated during wet-spinning were eliminated by adding lignin in the coagulant bath to counter-balance the out-diffusion of lignin. Carbon fibers resulting from lignin/PAN blends with 50 wt % lignin content displayed a tensile strength and modulus of 1.2 ± 0.1 and 130 ± 3 GPa, respectively, establishing that the equi-component wet-spun L/P-based carbon fibers possessed tensile strength and modulus higher than 1 and 100 GPa. © 2017 Wiley Periodicals, Inc. J. Appl. Polym. Sci. 2018, 135, 45903.