Lessons to be learned in adoption of autonomous equipment for field crops

Editor in charge: Craig Gundersen

Abstract

Autonomous equipment for crop production is on the verge of technical and economic feasibility, but government regulation may slow its adoption. Key regulatory issues include requirements for on-site human supervision, liability for autonomous machine error, and intellectual property in robotic learning. As an example of the impact of regulation on the economic benefits of autonomous crop equipment, analysis from the United Kingdom suggests that requiring 100% on-site human supervision almost wipes out the economic benefits of autonomous crop equipment for small and medium farms and increases the economies-of-scale advantage of larger farms.

Autonomous crop equipment (also known as crop robots) has the potential to resolve the labor shortage in agriculture, increase food security, help address climate change, and reduce the environmental footprint of agriculture (CAAR, 2016; Kessler, 2020; Duckett et al., 2018). Farm labor is scarce almost everywhere and that scarcity has been highlighted particularly in Europe and North America by the COVID-19 pandemic. In industrialized countries, farms use recent immigrants or seasonal migrants for much of the routine work, but pandemic travel restrictions and political backlash is making it more difficult for migrant workers to travel (Charlton & Castillo, 2021; FAO, 2020). One approach to reducing farm labor demand is to remove the human operator from farm equipment, but that change has the side effect of almost eliminating the motivation for using the heavy machinery that dominates commercial farming. Swarms of small robots could do the work of one large machine while simultaneously reducing soil compaction and cutting the risk of machine downtime. The use of autonomous equipment on farms for planting and other field operations could be more timely because small swarm robots could be working when it is too wet for heavy machines, and even if one robot is out for repair, the others could be in operation. In addition, robots could make precision agriculture technically and economically more feasible. Autonomous equipment controlled by artificial intelligence (AI) could manage crop plants individually, applying only the fertilizer and pesticides needed by that plant rather than uniform applications for a whole field, thereby reducing input use. Individual plant management would be facilitated by relatively slow-moving autonomous equipment. When a human driver is involved, speed is essential to make efficient use of that person's time, but that does not allow time for computationally intensive functions like machine vision. Relatively small autonomous equipment can also help agriculture adapt to alternative sources of energy. It can be more easily adapted to electrical power from solar, wind, and other renewable sources than conventional large-scale machines, thereby helping to mitigate climate change effects.

- Summarizing the lessons learned from regulation of autonomous equipment and robots in other sectors of the economy;

- Describing the current status of regulation related to autonomous crop equipment;

- Providing an example from the United Kingdom of how regulation can affect the development of autonomous equipment in crop production.

The article is organized around the three specific objectives. The first section summarizes lessons learned from other economic sectors. The second section describes the current rules under which crop robots are used around the world, and the third section provides an economic assessment based on an example from the United Kingdom of how regulation can affect the use of autonomous crop equipment, farm management, and, ultimately, the size and organization of farms.

LESSONS LEARNED FROM ROBOTS AND AUTONOMOUS EQUIPMENT IN OTHER SECTORS

Because commercial farm experience with autonomous equipment is limited and many autonomous crop technologies are in the prototype or beta test stages protected by non-disclosure agreements, publicly available research on regulation of such equipment is scarce. But use of autonomous equipment in other sectors is growing (e.g., drones, autonomous mining equipment, robotic milking, and driverless cars) and may provide some lessons for regulation of crop production equipment.

To clarify the focus of this comparison, autonomous crop equipment should be distinguished from the machines guided by global positioning systems (GPS) that have become common in commercial agriculture. While advanced GPS guidance systems can be seen as a step toward autonomy, current autosteer technology still requires a human driver. Several words are used to describe farm machines that are mobile and have some autonomy (e.g., robot, autonomous machine, automated equipment). Based on the arguments in Kyriakopoulos and Loizou (2006), for this study, the word “robot” is reserved for machines with substantial AI decision-making capacity, while “autonomous equipment (or machines)” is used when the technology has autonomy of operation with a predetermined path or itinerary. This study focuses on levels 4 and 5 of the widely used driving automation level scale (SAE, 2018). In this study, “automated” is used for stationary machines or mobile equipment with human operators with either mechanical technologies or AI that replaces human workers for one or more tasks other than driving (e.g., a vegetable grading, sorting, and packaging unit towed behind a tractor operated by a human driver). It should be noted that under this definition, the popular terms “milking robot” and “industrial robot” are largely honorific because those machines are not mobile and often have minimal decision-making capacity. Because most of the crop equipment coming on the agricultural market in the next few years will have limited decision-making capacity, this study will focus on “autonomous equipment or machines,” but many of the same regulatory issues will apply to robots with greater decision-making capacity.

This comparison to other sectors is relevant and urgent because autonomous crop equipment is on the verge of technical and economic feasibility. The Hands Free Hectare (HFH) at Harper Adams University in the United Kingdom showed that wheat and barley could be produced by autonomous equipment and that the cost of retrofitting conventional equipment for autonomy was less than previously estimated (Lowenberg-DeBoer et al., 2021). Anecdotal evidence indicates that autonomous crop equipment is being trialed around the world. Data indicate that about 150 mechanical weeding robots are currently being used in France on sugar beet and vegetable farms (Lachia et al., 2019). In North America, retrofit kits are being sold to convert a conventional tractor and grain cart for co-robotic use in conjunction with a combine operated by a human driver (smart-ag.com). Because of labor constraints, robotic harvesting of fruits and vegetables is high on the research and technology development agenda, but there are many engineering challenges around autonomous horticultural harvesting that may delay widespread adoption (Duckett et al., 2018). Autonomous equipment is being commercialized first for wheat, barley, and other grain crops because they were mechanized decades ago and the technology to make that equipment autonomous is now available.

Lessons learned from regulation of drones

Drones (also called “unmanned aerial vehicles” as UAVs) are in many ways flying robots, so their regulation may provide lessons for regulation of ground-based crop equipment. Agricultural drone applications include remote sensing of farmland for variable rate seeding, fertilization, and crop protection, deterring birds, identification of wildlife, and spraying pesticides in locations difficult to reach. Some, like vineyard spray drones, replace helicopter sprayers, while others such as wildlife identification are complementary applications.

Key regulatory questions are spatial restrictions and requirements of humans to be able to intervene in drone operations. Heavier drones that carry sprayers, for example, generally face stricter rules. Very light drones are typically exempt from much regulation. However, attached cameras can be subject to data and privacy protection rules. Flight space for drones is typically restricted in terms of height, distance to airfields, heliports and air traffic control areas, horizontal and vertical distance to crowds of people or public spaces, and distance to nature protection areas. This limits the use of agricultural drones, particularly in densely populated areas.

Authorization for specific uses of heavier drones and operations close to airfields, in airspace control areas, and so on, are often possible but costly and only for a certain period of time. There is a general “see-and-avoid principle” for operators. Specific regulations, for example, according to the “extended visual line of sight” for sparsely populated areas, can allow a drone pilot to cover greater ranges. Exemptions from sight rules may be authorized, including flying with video glasses, when another person watches in sight and can intervene. However, high demand for authorizations results in administrative delays, for example, of at least 3 months in Switzerland (BAZL, 2020a). Moreover, in Switzerland, agricultural drones used for spraying first need an authorization for spraying, comparable to other sprayers, before the usual authorization of drone use can proceed (BAZL, 2020b). Other European countries have now adopted similar procedures. Drone regulations may have lessons for autonomous crop equipment, particularly for on-site human supervision rules. Patterns of agricultural drone adoption seem to be related to regulation. Drone use beyond data collection for pesticide spraying and other input application has grown most quickly in those countries, like China and Brazil, that have flexible human supervision and aerial pesticide application rules, and very slowly in countries like the United Kingdom where line of sight is required for drones and aerial application is very limited.

Even when they are heavier, agricultural drones are considered less risky compared to other drones, because they operate close to farmland surfaces and not necessarily close to crowds and critical airspace (BAZL, n.d.). To avoid administrative hurdles and authorization delays for operators, the European Union plans to introduce legislation that requires them only to send in a declaration with “beyond visual line of sight” for rural areas as a standard scenario, although only for drones up to 25 kg (EASA, 2019). In the United States, a North Dakota network of business, research, and government is pooling investment and infrastructure for larger agricultural drones. Their regulatory plan includes “beyond-visual-line-of-sight” operations and requirements for filing flight plans (AP, 2019; Business Facilities, 2019). These developments indicate that regulation specific to agricultural drones is emerging which can facilitate legal and safe applications. However, it can entail additional administrative costs and human resources to fulfill oversight requirements. In practice, regulation for heavier drones needed for applying physical farming inputs is an ongoing challenge.

Comparison to autonomous mining equipment

Since 2008, autonomous trucks have been used in open-pit mines. The iron mines in the Pilbara region of Western Australia have the longest experience with autonomous mining trucks, and the Australian mining industry has developed a “Code of Practice” which has been officially accepted by the Western Australia (Department of Mines and Petroleum, 2015). The Code of Practice is not law, but it is a guide to achieving the occupational safety and health requirements mandated under Western Australia legislation. In Australia, Codes of Practice can be admitted in court proceedings as evidence of what is known about risk and management methods.

The Western Australia Code of Practice focuses on (1) management of autonomous trucks, loaders, and other mobile equipment at mine sites and (2) identification of the risks created by new or existing mobile autonomous mining systems. The Code summarizes the requirements for information, instruction, training, and supervision to ensure the safe operation of the mobile autonomous mining system, outlines the requirements for hazard control, and covers emergency procedures. In particular the Code recommends minimizing interaction of autonomous equipment with personnel and non-autonomous equipment. It also outlines requirements for manual control of the autonomous equipment in an emergency, but it does not require on-site human supervision. The Global Mining Guidelines Group (GMG) issued a similar set of recommendations (2019). GPA is using the Western Australia autonomous mining code of practice as a model for its effort to develop a similar document for autonomous agricultural equipment (GPA, 2019).

In many ways, autonomous trucks in open-pit mines operate in an environment similar to that of farm equipment and thus may provide lessons that can be applied in agriculture. The trucks operate on private property largely following a predetermined path (e.g., taking ore or coal from the mine to initial processing). They are subject to uncertainty from weather and other natural phenomena. For open-pit mining, those natural phenomena include landslides and falling rocks. However, a mine is a much more controlled environment than a field. Mine owners typically control access to mines very carefully, and this control is supported by legislation, mainly for safety reasons. While laws about public access to farmland differ from country to country, in many parts of the world it would not be unusual for a farmer to encounter unanticipated humans or animals in the field. Autonomous farm equipment needs the capacity to deal with those unexpected encounters. Autonomous mining equipment is often supervised remotely with one human for several autonomous vehicles in a swarm concept, rather than requiring a human operator on-site for each vehicle.

Regulation of self-driving automobiles and trucks

Another point of reference for autonomous farm equipment is the regulation of self-driving vehicles on public roads. The first level-5 autonomous vehicle was tested in an urban setting in 2007. Driverless vehicle services are now being tested with customers around the world (Bayern, 2020). For example, a “rider only” self-driving taxi service is being offered to select customers in Phoenix, Arizona, United States. Driverless shuttles carry travelers between railway stations in Paris, France, and at the airport in Manchester, United Kingdom. A self-driving delivery vehicle without a steering wheel or pedals for manual operation has been granted an exemption by the US Department of Transportation (Hawkins, 2020a). The initial use of that delivery vehicle is for grocery and food deliveries. Autonomous semi-trailer trucks are being tested on public roads in several US states (Wiggers, 2020). Autonomous cars are expected to be on the market for individual consumers sometime this decade (Fagnant Daniel & Kockelman, 2015; Juan et al., 2019).

The potential for self-driving cars has attracted the attention of regulators around the world, but there is no consensus about the best way to regulate this technology (Bayern, 2020; Dentons, 2020; Hawkins, 2020b). The key issues are (1) conditions for testing autonomous vehicles on public roads, (2) liability if something goes wrong, and (3) data privacy and security. One of the regulatory questions is whether vehicles can be manufactured without a steering wheel, brake and gas pedals, rear view mirrors, and other items required for safe manual operation. Vehicles without manual operation technology might be cheaper to manufacture, lower weight (and hence more fuel efficient), and more flexible in design, but would be harder to control or unusable in case of problems with the autonomous systems. In many countries, regulation of autonomous vehicles is occurring at multiple levels: municipal, state or province, and national. Countries seeking to be technology leaders and capture some of the business growth that is expected to come with autonomous vehicles are trying to standardize regulation at the national level. Kaplan et al. (2019) predict that regulatory concerns from consumer safety advocates and the traditional automotive industry will delay the widespread commercialization of autonomous vehicles.

Some have argued that while self-driving cars have captured public imagination, the early applications of autonomous vehicles may be agricultural because farm fields are a simpler operating environment for autonomous vehicles than public roads (see, for example, House of Lords, 2017). Any other vehicles in an agricultural field probably belong to the same owner, and technology is available to coordinate them. Farm equipment typically moves slowly, and obstacle detection technology (e.g., LIDAR or laser-based detectors) would allow them to stop when encountering unanticipated humans or animals. Consequently, the regulatory status of autonomous agricultural equipment might be worked out more quickly than that of self-driving on-road vehicles.

Lessons from introduction of automated milking systems

A useful precedent for the use of autonomous equipment in arable farming is the relatively widespread use of automated milking systems (AMS) in the dairy industry. AMS are popularly known as “milking robots.” They allow cows to be milked without direct human involvement. The adoption rates of AMS vary with around 30% of dairy farms in Iceland and Sweden and more than 20% in countries such as Belgium and the Netherlands. Adoption has been lower in other major dairy countries, such as Canada and the United Kingdom (7%), the United States (3%), and Australia and New Zealand (less than 1%) (Eastwood & Renwick, 2020). Farmers' motivations for investing in AMS were economic (reduced labor demand, increased milk yield), social (reduced physical strain, more time to do other things), and beyond (e.g., some farmers perceived an animal welfare improvement from precision data collection) (Vik et al., 2019).

Regardless of the relative efficacy of AMS versus conventional systems, the experience of changing farm workflows and structures after implementation provides a precedent for identifying some of the implications of autonomous systems in arable farming. However, there are few examples of legislation or regulation that has been explicitly put in place to deal with AMS. The International Standards Organization (ISO) has a standard for AMS (ISO 20966: 2007). It is focused on the design of AMS systems and milk hygiene, not animal welfare or human health and safety. Many industrialized countries have milk hygiene and animal comfort and safety recommendations in their dairy industry codes of practice. When AMS were being introduced in the early 1990s, there was some concern about worker health and safety (Lundqvist, 1992), but almost 30 years of experience suggest that AMS do not raise additional health and safety concerns beyond those already incorporated into industrial robotics regulation. Consequently, for worker health and safety, AMS are largely treated the same as stationary industrial robots. The fact that AMS could be handled under existing industrial robot rules has facilitated adoption of the technology. In contrast, the rules for autonomous crop equipment are in the process of being developed and interpreted. The uncertainty is constraining the development and adoption of autonomous crop technology.

CURRENT SITUATION OF REGULATION OF AUTONOMOUS MACHINES IN AGRICULTURE

“ISO18497:2018—Agricultural machinery and tractors—Safety of highly automated agricultural machines—Principles for design” apply to agricultural robots and autonomous equipment. This worldwide standard is focused on design of the equipment, not on its use. Issues addressed in ISO18497 include obstacle detection, the acoustic or visual alarm if a person or animal is detected, and maximum operating speed. At this early stage of crop robot commercialization, regulation seems to be focused on worker health and safety. No country was identified as having specific insurance, liability, intellectual property, or data protection rules related to autonomous crop equipment or crop robots. Some examples of worker health and safety standards include the following.

California, United States

No US federal laws currently prohibit the use of, restrict, or provide guidelines for operating autonomous equipment in crop production, but California has set guidelines through the Occupational Safety and Health Administration (OSHA, California Code of Regulations, Title 8, Section 3441(b)) which mandates that all self-propelled agricultural equipment “have an operator stationed at the vehicular controls.” Furthermore, “this regulation does not prohibit the operator occupying or being stationed at a location on the vehicle other than the normal driving position or cab.” In other words, if autonomous equipment is operating in California production agriculture, an operator must be in control, with such control possibly being exercised remotely under stringent circumstances (Raven, 2001). Those requirements for remote operation include the following: (1) the operator must be watching the tractor and workers in the vicinity at all times; (2) the equipment controls must be easily accessible; and (3) the equipment must not be traveling more than 2 mph. The autonomous farming scenario in which the human supervisor is located remotely, occupied with other tasks and alerted to problems by a mobile phone message, would not be possible under a strict interpretation of the California law.

From a cost perspective, a remote operator watching the equipment at all times would probably be at least as costly as an operator on the equipment and would require substantially more technology. Even more cost prohibitive is the restriction that the equipment must not travel more than 2 mph. This speed restriction would make autonomous machinery uncompetitive with conventional farm machinery in most mechanized agriculture (Shockley et al., Forthcoming). Farm equipment manufacturers have tried unsuccessfully to change this California rule, but they have obtained “conditional approval” for autonomous agricultural equipment operating without human workers in the vicinity, mainly for pesticide application (Pankonin, 2019). The argument for autonomy in that case is that autonomous equipment reduces human exposure to pesticides.

It should be noted that the California law was intended for an earlier stage of agricultural technology without GNSS guidance and with human workers in close proximity to the equipment. The law was mainly intended to improve worker safety when furrow-guided harvesting equipment was used (Raven, 2001). In most cases, humans worked ahead of or beside the equipment, doing the actual harvesting and placing the vegetables on a conveyor belt for initial sorting. This is very different from the robot farming scenario with multiple GNSS-guided robots in a field planting, weeding, or harvesting without assistance from human workers. In spite of the changes in technology and farming practices, there is concern that the California law might be a model for regulating autonomous machines that operate without human workers in the vicinity (Janzen, 2017).

EU machine directive

All EU countries are governed by EU Machinery Directive 2006/42/EC concerning the type-approval of agricultural or forestry machinery (EC, 2010). Furthermore, EU Regulation 167/2013 updates rules on the type approval of agricultural vehicles in several areas, including fast tractors (more than 40 kmph), higher road safety, operator safety, and environmental standards (see Department of Transport UK (2017) and NFU (2020)). There are different national as well as EU rules for operating tractors in the field and on public roads. However, tractors have to comply with certain safety standards and deal with the risk of operating them. Special equipment mounted on the tractor and agricultural vehicles should also follow the standards and regulation cited above.

EU rules are then translated into national legislation of the EU member states. According to the European Agricultural Machinery Industry Association, CEMA (2020), the EU is currently drafting a proposal for a revision of the Machinery Directives with a focus on AI and its risks when used in the agricultural sector. One of the aspects of the EU Machine Directive that needs to be clarified is what is meant by a “driver in control” (Hostens, 2019). In many EU countries, that is currently interpreted to mean an on-site human supervisor, but it could be a remote operator or supervisor who monitors the robot occasionally while occupied by other tasks. The proposed machinery regulation (European Commission, 2021) allows remote control equipment, but does not provide for completely autonomous or driverless equipment.

In Germany, the current standard DIN EN ISO 18497:2019-08 summarizes safety specifications on agricultural machinery and tractors including safety specifications of highly automated agricultural machines and principles of safety. This standard includes requirements for obstacle detection, acoustic or visual alarm if an unexpected person or animal is detected, maximum speed, restricted starting of the machine (e.g., only by an operator on-site), and shut down of the machine if communications with the operator are lost. The EU Machinery Directive does not have speed limits, but the autonomous industrial vehicle rules (ISO 3691-4), which are an alternative set of standards used by some agriculture equipment manufacturers, have a speed limit of 800 m/h (ISO, 2020).

Because of the UK departure from the EU, the future of UK agricultural robot regulation is unknown. In many cases, the existing EU rules will probably be incorporated into British law, but there is an opportunity for flexibility. In anticipation of that flexibility, a group of researchers and industry leaders met at Harper Adams University in 2019 to begin the process of formulating a code of practice that would be shared with government (HAU, 2019).

Australian initiative

Under the California rules and the EU Machinery Directive, crop robots and autonomous farm equipment are governed by legislation and regulation adapted from an earlier stage of technology. The Australian grains industry is following a different path. In Australia, there are few laws directly governing the use of autonomous machines and robots on private farm land (GPA, 2019). The majority of these laws relate to risks under common law, state environmental regulations, and federal and state workplace health and safety regulations (GPA, 2019). To address concerns about future regulation of autonomous agricultural equipment, and to realize the potential productivity benefits of those machines, GPA and the Tractor and Machinery Manufacturers Association are supporting development of a Code of Practice for Agricultural Field Machine Autonomy (GPA, 2019). The Society of Precision Agriculture Australia and manufacturers such as John Deere, CNH Industrial, AGCO, and Kubota are actively participating in the development of the code of practice. The hope is that the code will then be adopted by the state governments and eventually by the national government as basis for regulating crop robots and autonomous farm equipment. The code can also help provide the necessary industry confidence to commercialize the technology and the social license to integrate such technology into farming systems (Rainbow, 2019).

To develop the code for agriculture field machine autonomy, the group plans to take a approach similar to the development of the existing code of practice for the use of autonomous machines in the Western Australian mining industry (DMP, 2015). Under Australian law, an endorsed code of practice is admissible in court proceedings and defines obligations for work health and safety. The code being developed will focus on the control of autonomous agricultural field machines used in broadacre arable agriculture (excluding UAVs) and identify the unique risk profiles (including both political and community confidence risks) of existing or new mobile autonomous agricultural machines. The code will be extended to include the training, maintenance, operation, and incidence-reporting requirements for using autonomous agricultural field machines, and how it links to other existing regulations such as pesticide/chemical use.

Around the world, crop robot regulation varies from none in most countries to quite restrictive in the US state of California and in the EU. The most common restrictions imposed are requirements for on-site human supervision and operating speed limit. Those human supervision requirements are focused on the ability of a human operator to intervene immediately if something goes wrong (e.g., the robot fails to follow the predetermined field path or does not stop for an unexpected human, animal, or obstacle). Because human supervision requirements are prominent parts of existing crop robot regulation, the UK example explores the economic implications of such regulation.

A UK EXAMPLE OF IMPACT OF AUTONOMOUS CROP EQUIPMENT REGULATION

The main hypothesis of this study was tested using the HFH linear programming (HFH-LP) model of an arable farm in the English West Midlands (Lowenberg-DeBoer et al., 2021). This model was developed to scale up data from the HFH experience to test the economic implications of swarm robotics for UK arable farming. The HFH-LP model was based on a well-tested and particularly flexible system for modeling farming operations known as the Purdue Crop/Livestock Linear Program (PC/LP) (Dobbins et al., 1990; Dobbins et al., 1992; Dobbins et al., 1994; Preckel et al., 1992). This model accommodates both crop and livestock production, taking into account the use of crop outputs as feedstuffs. Crop modeling allows for sole crops, multi-year crop rotations, and multiple cropping (the raising of more than one crop on the same piece of land within the same year). Categories of resources can be distinguished, including owned and hired labor, plots of land with different soil types, and different types of livestock facilities. An updated version of the PC/LP system has been developed in the General Algebraic Modeling System (GAMS, 2019) modeling language. The HFH-LP model is a modified version of the PC/LP model using the GAMS software. In many ways, the HFH-LP is similar to the Audsley (1981) UK farm LP, but takes advantage of more recent software. Additional information on the model is available in Lowenberg-DeBoer et al. (2021).

Because commercial farm experience with autonomous equipment is limited and many autonomous crop technologies are in the prototype or beta test stages protected by non-disclosure agreements, publicly available economic analysis is scarce. Lowenberg-DeBoer et al. (2020) found 18 published studies of the economics of crop autonomous equipment and robotics, all of which find that the current technology is potentially profitable for producers in certain circumstances. Most of those studies use partial budgeting to examine the potential profitability of automation of a single crop operation (e.g., weeding, harvesting). The most systematic analyses are for grains and oilseeds because those technologies present fewer engineering challenges and are closer to commercialization. Shockley et al. (2019) employed farm linear programming to analyze the economics of autonomous equipment for maize and soybean production in Kentucky, United States, based on experience with prototypes. Because autonomous equipment for grain production is not yet on the market and the cost of this equipment is unknown, they reported their key results in terms of the break-even price of computerized controls that would convert conventional tractors to autonomous machines. Their analysis suggested that relatively small autonomous equipment would have economic advantages for a wide range of farm sizes, but especially for small farms. With the availability of data from HFH and using linear programming to model a UK arable farm, Lowenberg-DeBoer et al. (2021) went beyond Shockley et al. (2019) to show that the economic benefits of autonomous technology potentially go beyond labor-saving. Autonomous crop machines would allow medium-size farms to approach minimum per-unit production cost levels that would be competitive with imported grain. Internationally competitive costs of production would mean reduced need for government subsidies and greater independence for farmers. The ability of small “swarm” robots to achieve minimum production costs even on small, irregularly shaped fields would reduce pressure on UK farmers to remove hedges, clear woods, and enlarge fields (Lowenberg-DeBoer et al., 2021).

Impact of human supervision requirements

- 10% of field time—this was the baseline used in the original HFH economics paper.

- 50% of machine time in the field—this was based on an assumption used in the De Witte (2019) study of economics of crop autonomous equipment in Germany. It assumes that the human supervisor must be in the field continuously in case something goes wrong, but does not focus on the robot(s) all the time. For example, the supervisor might be otherwise occupied the rest of the time (e.g., marketing output or purchasing inputs, in a vehicle at the edge of the field working on a computer). It is assumed that if there is more than one robot in the field, the requirement is still only 50% of one human supervisor's attention needed. To simplify the model, it assumed that all the robots on the farm were always in the field at the same time (i.e., if the farm had three autonomous combines, they would be in the field simultaneously, being supervised by one human with 50% of their attention). The human supervisor might be the farm operator or an hourly employee.

- 100% of machine time in the field—This is analogous to the line-of-sight rule for drone use in the United Kingdom or the California OSHA driverless equipment rules. As in the 50% time scenario, it is assumed that if there is more than one robot in the field, the requirement is still only that one human supervisor's attention is needed. The modeling assumed that all the robots on the farm were always in the field at the same time.

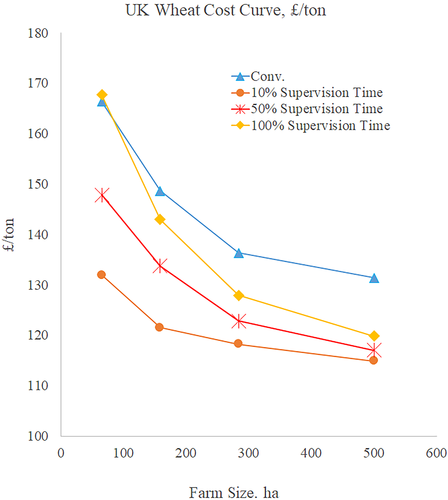

The results are summarized in wheat average cost curves in Figure 1. Wheat production cost was selected as the focus because of the HFH experience with wheat production using autonomous equipment and because wheat production costs are well documented worldwide facilitating international comparison. The range of farm sizes analyzed was chosen as typical of UK agriculture (Lowenberg-DeBoer et al., 2021). The smallest farm size modeled was 66 ha, which is the average farm size for the West Midlands of the United Kingdom. The 159 ha farm size is the average size of grain farms in the United Kingdom, and the 284 ha farm is the average size of larger grain farms over 100 ha. The 500 ha farm is an arbitrarily larger farm size. The cost curves show that increasing human supervision time accentuates the economies of scale for larger farms, compared to either the 10% field time autonomous equipment scenario or the conventional scenario. The 100% supervision time cost curve has a much steeper slope than either the 10% supervision time cost curve or the conventional cost curve. For the smallest farm, the 100% supervision scenario has higher production costs than the conventional equipment cost curve, and for the 500 ha farm it is about £11/ton lower. The implication of higher human supervision time for farm size is that the economic pressure for “bigger is better” is accentuated by requiring increased human supervision. If the cost curve were extended out to even larger farm sizes (beyond 500 ha), that impact would be even greater. The benefits of autonomous equipment on larger scale farms, like those in the United States, Canada, Australia, Brazil, and Argentina, remain to be determined with the alternative hypothesis being that for larger scale farms smart equipment that works with a human operator would be more beneficial.

Securing areas of operation

Another crop robot regulatory alternative would be for fencing to prevent unintended robot–human interaction. This would be analogous to the “cages” around industrial robots to prevent human workers from accidently coming into contact with them. In addition to interfering with wildlife movements, this kind of fencing could substantially increase the investment required for using robots or autonomous equipment. The investment would vary by the type of fencing and field size, shape, and layout. For example, if regulators decided that “deer fencing” with 1.9-m-tall wire mesh and posts every 5 m would be appropriate, and if the average field size were 4 ha (i.e., about 10 acres), the expected fencing cost would be about £11/m or £9070 for a 4-ha field using the mid-point of the range of deer fencing cost estimates from the Agricultural Budgeting and Costing Book (2019). This assumes a professionally installed fence with one gate per field costing £270 per gate. On the smallest farm in the HFH-LP analysis (66 ha total), this would be a total fencing investment of about £136,050, more than tripling the total farm investment for crop production with autonomous equipment. This increased investment and the associated maintenance would make use of crop robots and autonomous equipment economically uncompetitive. The fencing cost would be less if fields were larger, if some fields were contiguous and could be fenced together, or if a fencing type of lower cost could be used.

Further research

Use of crop robots and autonomous equipment is hypothesized to have benefits beyond labor-saving. For example, use of small swarm robots might reduce soil compaction compared to use of large conventional equipment (Lowenberg-DeBoer et al., 2021). That yield improvement might offset some of the cost of human supervision required by regulators. The reduced soil compaction hypothesis has not yet been tested in the field, but if it produced a 10% yield improvement compared to conventional equipment, then the autonomous equipment cost curves in Figure 1 would be pushed down. For example, in the 100% time human on-site supervision scenario with a 10% yield improvement, the cost of wheat production on the 66-ha farm would be £152/ton and on the 500-ha farm £109/ton, which is still substantially below the cost of production compared with conventional equipment at that farm size. This would make wheat production with autonomous equipment competitive at the farm sizes considered in the HFH-LP analysis, but it would not change the slope of the autonomous equipment cost curve. Consequently, even with reduced soil compaction from swarms of small autonomous machines, the human supervision requirement would result in greater economies of scale in crop production and an economic motivation for creating larger farms.

CONCLUSIONS

This paper reviewed the current status of regulation for crop robots and autonomous machines, noted the regulatory environment in terms of regulation of other autonomous equipment (e.g., milking, driverless cars, mining automation), and provided an example of the impact on cost of wheat production in the United Kingdom when various levels of human supervision of autonomous equipment is required. While clear rules on the use of autonomous machines in agriculture could provide more certainty for providers and farmers—and in that way encourage adoption—some rules could substantially change how autonomous equipment is used, and consequently affect the social and economic implications of their adoption. This analysis supports the hypothesis that regulation can have a major impact on the type of autonomous crop equipment that is commercialized and on the pattern of adoption. Compared to the baseline analysis of 10% time on-call human supervision, 100% time on-site human supervision substantially reduces the competitive advantage of autonomous equipment especially for smaller farms. A human supervision requirement creates an economic incentive for large farms where one human can supervise many robots.